Академический Документы

Профессиональный Документы

Культура Документы

Honda CT90 Owners Manual

Загружено:

Tatooinesky100%(7)100% нашли этот документ полезным (7 голосов)

27K просмотров34 страницыHonda CT90 Owners Manual

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документHonda CT90 Owners Manual

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

100%(7)100% нашли этот документ полезным (7 голосов)

27K просмотров34 страницыHonda CT90 Owners Manual

Загружено:

TatooineskyHonda CT90 Owners Manual

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 34

SERIAL NUMBER LOCATION,

NOMENCLATURE

(OPERATING INSTRUCTION.

ELECTRICAL CONTROLS,

Inaturents and Inclstor Lights

iin Swe

Neactight Control Switch

Horn Button

Tur Signal Control Switch 2

MECHANICAL CONTROLS

‘Steering Lock.

Front Brake Lever.

Handle Clamp Lever

ear Change Pedal

High Low Speed Range Seloior Lever

CGhok Lover and High Altitude Selector Koad.

FUEL AND OL !

Fuel Valve

Fel Tan

mC O NT ENT Smee |

oll Recommendation.

PRERIDING INSPECTION.

STARTING THE ENGINE

‘Starting 2 Cold Engine

Starting in Extreme Cold weather

Starting 4 Warm Engine

SREAC-IN PROCEDURE

RIDING THE MOTORCYCLE

PARKING

MAINTENANCE

MAINTENANCE SCHEBULE

MAINTENANCE OPERATIONS

Engine Olt Replenishment

Engine Ol Change

oir

Spark Plug

Contst Breaker Point Gap

Ignition Timing

Valve Tappet Cisranice

A Cleaner :

‘Throttle Cable

Throttle Grp Flay

SeeReReeeeERRBERY

Ccarburetoe

Fuel Strains

Cuteh

Brive Chain

Drive Chain Lbicstion

‘ire Inflation Pressure

Front suspension

Front Fark Of

Bstery

Front Wiel Removal

Rear Wheel Removal

Headlight Beam

Stoplight Suited

Headlight Bulb Replacement

TalStoplght Bulb Replacement

Turn Signallight Bulb Replacement

TooU KIT...

SPECIFICATIONS.

WIRING DIAGRAM

eins

saaanceeeen

‘The frame seal number © is stamped on the left of the stering head

pine, and the engine serial number @ i located on the crankcase directly

Shove the step bar attaching point

‘These serial numbers are required when registering the motorcycle. Further,

the frame serial number must be indicated when processing the warranty

{aim and for ordering spare pats

Engine sei Bambee

NOMENCLATURE~

Speedometer

ont bake lever

ete rip

© Headlight control switch

© Rear brake pedal

ick starter pedal

(© Rear brake lever

@ Horn button (below)

Handle lamp lever

© Main switch

@ Gear change pedal

@ Tailstop ight

ii

dal” @) Rear brake pedal Fuel nk

OPERATING INSTRUCTIONS ~

ELECTRICAL CONTROLS

Instruments and Indicator Lights

‘The speedometer is mounted on the headlight caso and the Indicator ights

are incorporated within the speedometer, The funcions are shown ia the

fable on the next page

sped range Indestars

Speedometer

Odometer

Neutral indicator |

light (green)

High beam indi-

ator light (ed)

ear speed

range indeators

Turn signal ind

ator light (amber)

Function

Indicates driving speed

Indcates total accumulated distance

travelled

Light wil be on when the twansmision

isin neutral

Light wil be on when height is on

igh beam ‘refer to page 13)

Indicates proper speed for each shit

| igh will ash ovhen the turn signal

light (option! is operating

‘Main Swit

‘The main switch & located on the

let side ofthe steering head pipe

Functions. of the respective switch

Postiont are shown inthe chat

below.

© "ORE aon

ON pontine dt

Trerrontn[ SSCs «dey Rena

sore” Allelecical ccs ate open; engine does | Key can, be

oe tart removed.

Recalled ening can be

son» stted; headlight and talstop ight ean cannot

ON" ert neual innit Bon when | be vcmowed

Headlight Conteol Switch

‘The headlight control switch @ Is mounted on the eight handle grip switch

housing. The switch can be operated by the thumb without faking, the

hand off the handle

‘The red dot postion @ i for day time riding, The headlight and ta

will not be on. The “L” @ and the "H" @ postion are for riding with

both tights be_on; In which ease, "L" @ is for low beam or dim, used

‘when approaching or following ater vehicles, The "H” @ postion is for

Tigh beam and in this postion the high bear indicator light In the spoed-

meter will be on.

‘The. headlight. wil only come on

wien the main switch i im the on

Potton. (refer to page 12,

5

Low tam on

gn bam pn

S ieedtate ctl onto an

3

Horn Button

“The horn button (Di located on the let handle grip swith housing. While

the horn button is depressed, the horn wl operate.

Turn Signal Control Switeh|

When the turn signal Hght is being used, 1 is operated by the turn signal

control siteh (Tun signal lights are optional part

sng vay MECHANICAL CONTROLS

‘The front brake lever @ is located at the right handle grip switch housing.

‘elie oe Tek ert oo ae Be cea ns

1m

Sern lek (9 Fret brake ever

Handle Clamp Lever

The handle ofthe HONDA CT9O ie designed so that it can be pivoted at

handle bar stom to provide compacinss for tse in transporting the motor:

cycle

Follow the procedure below for preparing the handle.

‘Rake and pull the handle clamp fever @ al the way t0 the fea to une

hoa the Rendle and then pivot the handle Bar counterclockwise 50 20

that ie parlgl fo the (ane centering, Reset the chimp lever to

lock the handle bs.

2. To prepare the motorycle for riding reset the handle bar to the normal

Postion by aligning tha td marke on the center oF the handle Br.

oa)

(Mane camp ever) Index nace

Gear Change Pedal

‘The gear change pedal @ located near the let foot rest i ofthe propressve

shit postive stop type, which means one fll stroke of the gear Caange

pecs hi Sore 'earpoiion. ‘The shitingscwence’ sanged

{shown in the figure

‘Shiting from the neutral postion into 1s (lw) gears pertormed by depres:

‘ing the, forward end of the gear change pedal with the toe, Sting, to

rd Sand th top) gear pataned by progressively depresing the

{orvard end of the pede shitng down tote lower pours perigened

by progressively depresing the rear end’ ofthe pesel

© Gar chang pial ‘Biing wens

Wigh-Low Speed Range Selector Lever

‘The above speed range selector lever) i located at the left crankcase

cover on the bottom side of the postiorque cover. The lever selection

Stand SH are stamped on the positorgue cove.

When additonal power i required for climbing steep grade or riding

with a heavy load, siting the selector lever tothe “L” range will provide

the necessary power

(0 Wlebtow seed range slo ever

Choke Lever and High Altitude Selector Knob

‘The choke lever © and a high altude selector knob @ ts located on the

Tet side ofthe carburetor.

Rating the ‘choke lever will close the choke valve (refer to page 25~27

{or itt use), To eblain maximum petfoemance for riding in high altitude

es Righ attude selector knob is provided to give the proper fuel mix-

lure for the alttude condition, Pall this knob out when traveling at

Ltitade above 6000 fect, low 600 fet, push the Knob in

ID Cink lever

FUEL AND OIL,

Fuel Valve

The fuel valve @ is located at the let side of the carburetor. When the

fuel valve sin the "S poston, fuel can nat flow from the fuel tank to

the carburetor. The fuel valve should be set in this postion when the

motoreycle is parked. Turing the fuel valve to the “ON” positon lows

fuel to flow to the carburetor trom the main fuel supply. Turning the ful

valve to the "RES" poston allows fuel to flow from the reserve. supply

When the main fuel supply is exhausted, the fuel valve should be turned

to the “RES” poston thereby allow

ing you to proceed to the nearest

Screw out the drain valve @ to empty

the fuel contained in the carburetor

when carrying the motoryce,

Fuel Tank

The il tk i octed under the eat The fel tak acy 6

US gal Goliten including 17 US pt Oliten in the reserve supDy

Premium grade ful with an octane rating of 85 oF above must be used

Benak mis ofl with he fue

12 Pa fo ep

(it Recommendation

It is very important to use only premivm qualty lls intended for service

IMS, DO, DMG (API service classification) or is equivalent. SAE 10W-20

Than all weather oll and should be used over the normal range of outside

temperature. Oil should be changed at the prescribed Intervals according

to the MAINTENANCE SCHEDULE” on

page 3 SE] SE] SE

NOTE: Nondetergentandlow aval | caques_feuresTne] ORES

iy. are 5 ot recom

tnended. The use of proper engine tre

Siesod_ oll change intervals are || #9

our ‘best assrance of continued elle

Telabilty and. performance from "

our HONDA engine. Also, the re- |[ #2 ee

mental aaatives || gay

"ind will only ne olfle

costs

a

PRE-RIDING INSPECTION

Prior to starting your motorcycle, it Is advised that you perform 2 general

eet ron at's mater of abl to. make sure that the motoreycl isn

reese riding condition. This nection wil only quite 2 few minutes

Boe tve you mich time and expense in the Long run

aoe ee Sbuing items and it adjustment or servicing i necessary, eefer

fo the appropriate section Inthe manual

+L Engine ol fvel—adé engine oil ft below the lower level mark on

the dipstick (page 32)

7 re eee a mtotine when isnot enough for travel, (page 20

2B ue ev) rear brakes--edjuat free ply Inthe front brake lever and brake

pedal ft incorrect. (page 51,32)

Pret ir pressre.inflat tires IF 1 to0 low: (page 54)

see eieaahat chain tenion when Its t00 sloppy. (page 47

Trotle operation repair i Ie not smooth. (page 43)

sete At and headight-repair when they do not light propery.

(pase 3982.

sere

23

STARTING THE ENGINE

Staring a Cold Engine

Pall the high aitude selector knob out when traveling at altude above

St feet Selow 00 feet, push the knob In

1. Turn the fuel valve to the “ON” postion

2 Insert the key into the main switeh and turn to the on postion, At

this time, abvewve the green neutral inaestor light on the elt side of

the speedometer. The ight will be lighted when the transmission i i

the seul positon

4 Rake the choke lever tothe fll closed poston

4 Twist the thottle grip inward sighty and step on the Kick starter pedal

With a rapid kick stoke perform the kick stating until the engine tart

I'the engine fas to stare after severe! repeated attempts, turn of the

main switch and ower the choke lver tothe full open poston, twist the

Theat’ geip inward. fly and. crank the engine using the tick starter

pedal. this is then followed by turning the main switch to the on

Poaition and folowing the starting procedure outlined in steps 1 through

WPhowever, at thn time use of the choke Is nok necesty

5. After the engine stats, operate. at approximately 30D%pm until the

engine will properly respond to the throtie when the choke is open

Starting in Extreme Cold Weather

Prime the engine before stating by cranking several times with the kick

tarter pedal, The main switeh should be tured of. The choke. should

be fly closed and the throtle opened. Followed by the procedure for

Starting 4 cold engine.

Starting a Warm Engine

‘When the engin is to be restarted while itis sill warm, proceed a8 for

(old engine sarting procedure, however, the use of the choke ts not

necessary,

BREAKIN PROCEDURE,

“The motorcycle should not be exposed to severe or abusive riding conditions.

This precaution wil be rewarded with extadong trouble free life of the

rmotoreyle.

is recommended that fr the fit 600 miles (1000), the motoreyle not

be operted in excess of 0% of the maximum speed in the respective

sean

RIDING THE MOTORCYCLE

1. After the engine has been warmed up, the motorcycle fs ready for siding

2. While the engine is ili, depress the forward end ofthe gear change

pedal to shit nto low (It gear

1. Increase the engine speed by twisting the throttle grip inward.

‘When the motoreycle attains & speed of approximately TO mph, close the

Trot and shift to 2ad gear By depressing the forward end ofthe gear

‘change pedal

5 This tequcnee is repeated to progressively shift to 3rd and sth (top)

eat The shiting pattern ingested on page 1. The maximum allow

ble speed for the respective geas are shown in the following table

moh

(isin sw [ae | a _| ho

low peed range | | a]

ee

6 When decelerating the motorcycle, coordination of the throttle and the

front and rear brakes Is most important.

{y'The smooth gradval application of both the ffont and rear brakes

Together with the required thrttle” coordination wil, under most

Conditions, assure postive speed reduction and stability. As the

Imotoreyle speeds are reduced, I i common” practice to shit the

TTansmision propretsvey into the gear appropriate forthe mtoryee

This assures manimam control through better braking effectiveness

tnd acceleration when necessary

For maximum deceleration and stopping, simultaneously cose the

throttle, disengage the clutch and appiy bot the front and rear brakes,

ts the motoreycle comes to 2 stop disengage the clutch. This mae

reaver requires smooth coordination of the controls and to maintain

Skil should be practiced frequenty

2

27

Independent aplication of either the front or rear brakes is posable,

but if only one brake is applied strongly enough to lock the respective

wheel, braking effectiveness is greatly reduced and control of the

Imotoreyle is if

PARKING

‘When parking the motorcycle, postion the main switch to the off postion

land remove the key. The steering should abo be locked. "Turn the fuel

valve to the "5" postion.

snnemenener MAINTENANCE

MAINTENANCE SCHEDULE

‘The mileage intervals shown Inthe MAINTENANCE SCHEDULE ae intended

tse guide for esablihing regular maintenance and lubrication periods for

your HONDA. Sustained severe or high speed operation under adverse

Conditions may necessate more frequent servicing, To determine specific

fecommendations for conditions under which you use your moteroyce,

‘onslt your authorized HONDA dealer.

Especially when your HONDA C10 has been turned over or involved in

Zeolion, have Your HONDA dealer carefully inspect the major components,

‘pam, suspension and steering pars, for misalignment or damage to

Insure further safe operation,

sere Maint = sere aid Fi ond ea ree

si, Pit Par ir sates

Se apne

oe =o erie =a EE Sree

Stine a Sap iee tt

mel pepe be “apie Lau}

Ht Fs

oes otto =a 8

-check oF adjust — oyoToto sponta wecessary ae =

‘ivy Cain and Srocket—adiot 2° Un peop eek o[olo

} ibrieate or replace o}o}ojo ae = i 1

MAINTENANCE OPERATIONS

Engine Oil Replenishment .

cr cgi fv! spring inspection page 2) and replenish engine

Sasha the lee lower than the Tower level marks Cec the fv

Sith theo lle cap ptt wthost Sewing in

Entine Oil Change

“he engine othe cit facoraflecing the pestrmance andthe sic

Iteet the engine. Tortora

teeommendd on pe 32s be

toed andthe a Siva rnin

Pere the ol

atthe proper level

Should be changed at the MAINTE-

NANCE SCHEDULE a5 shown on

page 20. Perform the engine oll

Change in the following manner

Drain the lf while the engine still

‘warm 36 ths will assure complete

nd rapid draining.

Remove the ail iler cap © from

32

the right crankcase cover.

Place 2 chp pan under the engine to catch the oll, and then remove

the dain plug © with the mm spanner.

Alter the oil tops dralaing trom the crankcase, operate the kick starter

Several times Yo sean any all which maybe left fm the engine

\When the oi has been completely drained, reinstall the dra plug making

sure thatthe packing ored on this plug i good condition.

5. Fil he crankcase through the oll filer epening with approximately 19

US pt @3liten of recommended glade oll (fer to page 22). Make

sure thatthe ol eve between

the upper ® and lower marks

Ifthe level i ow, addi.

NOTE: When operating the motor

‘eyele in unusual dusty condition,

Wis recommended that the

changes be performed at more

frequent intervals than that spe

fied in the MAINTENANCE SCHE-

© Dain be

“The oil fter is of the centrifugal and screen type,

Prindple operation of the centrifugal fiter Isto seperate al the impurities

fand metal tps in the oll by centrifugal force and permitting only the highly

pried il to come in contact withthe moving part ofthe engine.

1 Drain the engine olin accordance with Engine Ol Change on page 32~

a

2 Remove the footrest and kick starter pedal from the engine.

3. Remove the right cankease cover

by unscrewing the screws =

4, Separate the right erankease cover

fake from the right crankcase.

Pol out the seeen fiter © from

the righ crankease and wash it

tnth lean solvent of gasoline

Seren ter

Remove the culch outer cover @ from the clutch outer «by uncom

tng the two screws.

Remove all metal chipe and tt from the center of the clutch outer,

sing 2 clean rag

Resstembly of the component pats performed inthe reverse order of

the procedure above, further, replace the damaged of defective crank-

cise’ gasket with new Roms.

Spark Plog.

INGK D-OHS i used on thi model.

: Servicing ofthe sparkplug ia follows

pet Pls wrench which is provided in the tool ue

aaa? ca Teal hr et

Neb Sk et wah

(grounded) electrode «. Sa as

Er es

Hes bear 5

eran sk gas

borning

Do not use improper heat range

park plugs tor Z

(0 Sorkin emp) Negative eave BY

Contact Breaker Point Gap

4

2

TRomove the point and. dynamo covers

Spee the conta! breaker points @ arith tiger or small screw driver

ee and examine for pitung. I pitted or burned, the pont should be

foplsced and the condenser checked. A gay digcooration normal and

CBS removed yh pon He iling soul be done crtly and

Geb ‘e'rinimom.” Clean the poit contacts after fing with a ean

pice of unrated paper sich ssa busines ardor chemical point cleaner

Rotate the dynam Foor in the_countercockwise erection (se arow)

fe find the potnt where each breaker point gap Is at maximum and

heck using 9 clearance gauge

‘ihe standard gap 8 0020616

in aa~o4mm

When’ adusiment is nocesary,

loosen the contact breaker plate

IGekng screws © and) move the

Gn breaker plate to achieve

CGrret gap. When propel gep-

ods reighien the locking few

6 Contact beater pnts

ets Eres Bite oking serene

Do not perform this operation unl point gaps have been adjusted

". Rotate the dynamo rotor in the. counterclockwise direction and align

the “F mark © to the index mark dh At thie time, the contact breaker

points @ should jut stat to open

2. To adjus, loosen the two base plate locking screws @ and move the

contact breaker baseplate @. Moving the plate in the clockwise diet

tion wil advance the timing

@ 1p Contact lers plate

tnder'mark —Buorpeteneing news” Buse alate

3 Alter performing the ignition timing adjustment, recheck the contact

breaker point gap @ to asure that It had not been changed

The state ignition timing i relatively accurate and will give satsfctory

engine performance, however, the use ef the sabe timing method will

Sssure the most precise timing.

‘When using the stabo timing ight to check the timing, ile the engine

at 10-9.

Perform the adjustment in the same manner as described adove,

Valve Tappet Clearance

Excessive valve tappet clearance will cause tappet ote, and litle or no

Gearance wil cause valve damage and loss of power Therefore, the valve

lappet clearance should be mantsined proper

The valve tappet clearance mutt be checked when the engine i col

1"Remove the dynamo cover and tappet adurting ole caps

2 Rotate the dynamo rotor counterlackwise-untl the: mark @ on the

Gynamo rotor ines up wth the ting index mark © onthe sat.

ST mark Alling wry ok rt

13 Gitar eee

In this postion, the piston may either be on the compresion or the

exhaust stroke

‘he adjustment must be made when the piston is on top of the com-

pression stoke when both the inlet and exhaust valves ate closed. This

Eonation can be determined by shifting the tappes with fingers though

the tappet adjusting holes. i the tapes are fee, itis an indision

that the valves are closed and that the piston is on the compression

stroke. the tappes are tight and the valves are open, rotate the dymamo

fotoe 360° and reign the *T” matk to the timing Index mark, Check

the clearance of both valves by inating the W002i. (405mm) clearance

f1uge provided in the tool Kit between the adjuting screw and the

Wit is necessary to make an adjustment, loosen the adjusting screw lock

rut @ and turn the adjusting screw (so that the valve clearance. will

Ofer a slight resstance when the clearance gauge @ is inierted. After

completing the adjustment, tighten the adjusting screw lock nut while

holding the adjusting screw to prevent from turning, Finally recheck

the clearance again to make sure that the adjustment has not been

disturbed

Air Cleaner

‘When the air eleaner is logged with dust, affects the engine performance

tnd therelore, it should bo cleaned periodical

T'kemove the wing nut © and si cleaner tube setting screw ©, and remove

the air cleaner tobe 4 i

2 Unscres he fing late setting bolt @ and semove the fixing pate ©.

4 Puivout the alr cleaner clement ponge) from the ae cleaner cas

4 Soa the a, eaer ‘loner inetgoe of crag oat By hand and then

Asan teeing ser

1B Ae dame eemone

Throttle Cable

Chock for smooth rotation of the thotle gti {fom the full pen to the

full close postions Check when at ful left and flight steering postions.

Inspect the condition of theote cable from the that. grip down to the

Carburetor. Ifthe cable is kinked, challed or impeopery route, it should

bbe replaced andjor rerouted. Recheck cables for tension or ses at both

{Ul Tet and ful eight stering postions

‘Throttle Grip Play

Stand thle wi play pproxiatly WF ofthe gp routon

When iti found to be excesve,

remove the main pipe cover, and ad

just atthe tote cable adster 2

by sliding back the rubber sleeve @>

‘on the carburetor end of the cable

(2 Torte cable jer

Carburetor

A carburetor which i out of adjustment will adversely affect the perfor

mance of the engine, thereforo, Its Important that the carburetor always

bbe maintained. in perfect adjustment. “Carburetor adjustment should only

bbe made wen the engine Is operating temperature,

1. Set the idling speed to. 1.200rpm with the throtle stop screw

“Turning the screw clockwise direction wil increase engine speed

22, Manipulate the air screw @ to obtain the maximum and stable engine

speed. The standard air screw

Sertng is between 1, to T open

{com full dose positon,

4, Readjit the throtle slop screw

ifitis necentary to rest the sing

speed

NOTE: Malfunction of the engi

high speed can be ca

System therefore, determing the

hose the tube etore

fempting 40 correct the cont

By adjusting screws. 1 Aree

Strainer

‘The fuel strainer is incorporated in the carburetor body. Accumulation

‘of dit inthe srsiner will restrict the flow of the fuel and. cause the ca.

buretor to mallunction, therfore, the fuel strainer should be serviced

periodically

4L Remove the main pipe cover.

2 Turn the fuel valve to."S” postion and remove the strainer cap, remove

the © ring seal @ and the screen filter ©. Wash in solvent o gasoline

and reassemble. Turn fuel valve to “ON” position and check for leas,

cuteh

1L Clutch must be adjusted with the engine shut of Loosen the adjuster

Tock nat

12 Tum the clutch adjuster > dockwise about one tum; do not turn exces-

sively

ext, slowly turn the adjuster counterclockwise and stop when the screw

fa to turn heavy

4 From this point, back off the adjuster in the clockwise direction 12 to

418 ton, and ghten the lock nut

Chock to make sure thatthe clutch eperates properly after adjustment

"The engine should. start easly

With the hick starter without the

teh sipping

2) When changing. gear, the clutch

Slipping. shoule be smooth and

Tight, "especially ‘hen shifting

‘down in gear to the newt gear

a

© Cash ster

1 ode net

Drive chain

‘The condition of the’ dhve chain will have considerable ffect on the

transmision af power from the engine tothe rear wheel. I not propery

maintained, the deve chain can cause. premature wear and_ damage tO

transmision and rear whe bearings and sprockets av well a5 9 ae A

propery adjusted and lubricated ive chain assures safe, smooth and trouble

free operation ofthe vital dive system

41 Place the motoreycle on its main stand

2 Move the chain up and down at the midpoint between the sprockets

{and check the total movement,

‘The standard slack should be 04

~Uain. (10~20mm),

4. To adjust the chain sack, frst

loosen the rear axle nut (> and

sleeve nut @ (eter to page 48:

4. Looten the adjusting nut «> on both the right and left chain adjusters

and turn the aglusing nt.

Turn the adjusting nut clockwise to decrease chain sack,

Align the index mark on both chain adjusters © to the same poston

‘onthe both side scales @ ofthe rear fork

5. Make sure that the rear axle nut, sleeve nut and lock nuts are properly

tightened

6, Readjust the rear brake as necessary to correct for the repositioning of

the eear wheel assembly. (refer to Page 32)

7. Remove the main sind and check the chaln slack while siting on the

machine. Rll ether forward or

Backward for enough tobe cetain

there ino tight spots

‘When the dive chain adjustment

have been performed, recheck for

contect dive chaln sick,

8 fee tas Ie

f¢ Chain Lubrication

Remove the dive chain by removing the etining clip with pliers

Do not bend or twist the lp. When possible Installs new haste nk

Clean the chain thoroughly in a suitable solvent." Rinse In cloan lent

and alow to dy. Inspect the chain for wear {oi sloppines) stifness

and binding at the joints and broken or separated walers If any of

‘these condtions exist the chain should be replaced.

‘Alo inspect sprocket teth for wear. Never install a new chain on bay

‘wor sprockets or install 2 badly worn chain on new sprockets Yous

HONDA dealer can help you determine the condition of there hem

Immerse the chain in 2 pan or vestl containing 4 mature of SAE TOW-

30 engine oil and petroleum jellyratio of TUSqu (1 ite) ll «9 Dor

{20051 petroleum ely and heat to "GO to 250 for approxima

10 minutes,

Remove the pan from the source of heat and carefully agitate immersed

chain with a crew driver, When cool, remove the chain allowing i 0

hangover the: pan and. drain of excess lubricant. Use 2 cloth or 28

to wipe off remaining excess lubricant.

4, Coretiy route drive chain onto the sprockets using the fear sprockets

{6 poston the chain ends while insaling the master nk side plato and

Fetaning cip. Note thatthe closed end of the retaining clip @) must

face the direction of forward wheal rotation,

5. Adjust rear drive chain a8 decribed In steps 1~7 page 47~#8,

Retaining ai

Front Brake

11 Raise the front whee! off the ground by placing a support block under

{hevcane pith front wheel by: hand and taste the amount the

Iront bra iver must be moved before the brake starts take hold

Be lege free ay @ shou be QB Lin ~My a he end of

2. Wadjurtment i necessary, turning the front brake adjusting aut @ in

th Gockwie tirection will docrese the free play.

NOTE: Make sure that the cut-out on the adjusting nut it seated on

the brake arm pin after the fnal adjustment has been made

© Frowt brake lever Free play ‘Front brake adjesting wat

e|

mie 4 The adjustment of the rear brake lever @ can be made independently

‘Rais the reir wheel off the ground by placing the main stand under by the adjuster st the lower end of the brake cable.

the motorcycle, : oe “The nominal fee pay @) is epproximately Bin. mm)

2 Rotate the rear wheel by hand and note dstance the rear brake pedal 5 ithe adjustment fo necessary, looren the ciresar lock mut © and turn

Up travel @ fore the brake holds the eable adjuster @ locke to increase the psy

3 Nomina fe travels Q3—42In. G~30 mm,

i the adjustments necesary, make the adjustment by turning the cear

adjusting nut, Turn clockwise for Tess tree tvel’counterloceviee

Tor greater fro travel

Tire Inflation Pressure

Correct tire inflation pressure wil provide maximum stability, riding comfort

tnd te le

Koop tres propery inflted, and check the inflation pressure before ring

[ Tie inflation pressure

Front 256psi, 1Bkglen?

Rear 2Spsi, 20kg/em"

Feont Suspension

{Check the font fork assembly by locking the front brake and pumping the

fork up and down vigorosy ig

Inspect forthe smoot Cushion action and oll seepage around the cushion

cies

Creal inspect all front suspension fsteners for tighnes, this includes

the atachment points of the fork tobe, brake components and handle br

Front Fork Oil

‘To maintain good riding characteristics and increase fork service life, the

Glin the front fork should be changed periodically

3 Unscrew the front fork drain plug at the bottom of fork cyiinder,

‘rain te ol by pumping the fork while plug is out. Replace the plug

Securely ater dering.

2. Remove the top filler plug @ and fill the front fork cylinder with 46~

‘tbonn, (130~tee) of premivm qualty ol of SAE WW-90 grade

3, Securely tighten the top filer plug after fillog.

Stren fork Se Ps Top lee De

Battery

1 the motoreyele i operated with an insufficient (ow) batery electrolyte

level sulfation and battery plate damage may occur. Inspecting and. mal

taining the electrolyte level isa simple, quick operation, therefore should

be" performed frequenty as indeated in the MAINTENANCE. SCHEDULE

tee opage 3.

‘The 6V-55AH btery is mounted within the frame center

Remove the right side cover and check the electrolyte level

‘The corect clecrolyte level Is

between the upper & and lower

level marks on the battery ate

To correct the elecioyte level,

remove the battery mounting band

tnd remove the battery coll cps

fromthe cells needing evel

correction. For case of cell level

‘correction a mallsyringe or psc

funnel should be wed. Carefully

dd the proper amount of distiled P naters

water to bring theelctroyte level) Upper rl mark

(D lover irl mark

‘ofthe calls etween the lower and upper level masks. For maximum bat

tery performance and ie, ony dtilled water should be added, however,

In.an emergency stuation where electrolyte level found to be low and

dlsited water iz not avaiable, inking water or alow mineral content

‘an be ured. Reina the cll caps

NOTE: Battery removal may be necessary when battery electrolyte

(SPECIFIC GRAVITY) reading is below 1200, indicating. the need of

battery recharging, or when the battery is removed for storage.

4 Battery installtion is performed in the revere order of removal. Pay

paticuar attention tothe batery rabber mounts pads andthe ver! tobe

outing. The vent tube Is not pinched or bent exeasvely, otherwise the

battery may be damaged,

Front Wheel Removal

4. alse the front wheel off the ground by placing a support under the

engine

2. Remove the speedometer cable and front brake cable from the front

brake pene.

3. Remove the front axle nut.

4 Pullout the front axle and the font wheel can be removed from the

frame

Reat Wheel Removal

1. Looe the rer ale nut, sleeve nut, drive chaln adjusting nut and dione

eet the deve chain atthe joint eli.

2, Remove the rear brake adjusting aut and remove the rear brake rod

from the brake arm.

3, Remove the rear Torque arm bolt a the rear brake panel

‘4 Pullout the rear ale and the rear wheel can be removed from the

frame.

NOTE: During reassembly, the drive chain joint should be installed

in the way that the open end will face opposite to the divection of

rotation. (Reler to page 50.

Headlight Beam

The headight must be properly adjusted forsale night diving. This mote

cyte has provisions to sdjust the headlight Inthe vertical and sso horizontal

Sections.

“U"The verial adjustment Is made by the bolts which mount the head

Tighe caze The headlight is normally adjusted Inthe vertical rection £0

thatthe center of the beam inspect the ground a the pont 16S feet

{Gom) in front of the motoreyle i the riding atitude

2, The horizontal adjustment is made with the adjusting screw @ located

‘on the left side of the headlight when facing the matoreycle

‘Taming the serew in wll focus

the beam toward the let side of

the sider

Menage mounting tate

© Adie rer

59

Stoplight Switch Headlight Bulb Replacement

‘The stoplight switch adjustment is made with the stoplight switch @® located LB ea te = ight rim from the headlight case by removing the two

Seon Si sea oe soe i

cane ee ee am aces win | * Regret at pi 0 and ure ok oe 9

2, Turn on the main switch (red dot postion.

4. Adjust ‘the stoplight switch #9 that the stoplight will come on when

the brake pedal is depressed tothe point where the brake jst stats to

luke hold. ifthe stoplight switch ate in switching on the stoplight

crew in @ the switehadjsting

tau and the stoplight comes

fn too early, screw ut the

Sdjsting nt

i

sa

re

2 hajatine met

Tailstoplight Bull Replacement

1 Remove the screws ftaning the tallstopight fons

2 Prete the bulb @ Inward and twit to the lef, and the bulb can be

removed.

4. Replace with a g00d bulb

‘4 When installing the talight fen, do not overtighten the screws, 25 ths

may damage the lens

Turn Signallight Bulb Replacement (optional pas)

The bub replacement is made in the ame manner as forthe tailstopight

bulb in the above paragraph,

© Taleo bate

“TOOL KIT:

‘The toolkit )i¢ mounted in the right side cover located at the frame

Center. Minor adjustment and parts replacement can be performed with

the tools contained in the Kit. "Adjustments or rapais which cannot be

performed withthe tools in the Kit should be referred to your HONDA

‘ester.

12 Mbt ste ever

Listed below arg the items included in the toolkit

“D Woclamm open end spanner

@ 852mm open end spanner

© Sparc plug ereach: For spark log

( 2mm wrench: For rear ane sleeve nut

{© mm wrench: For front and rear axle not

© Wrench handle

© Pls

Tool bog

{ 9mm spanner: For valve tppet lock aut

4 Valve fappet adjust rene

(W No. 3 cross polnt screw diver

1 No. 2 cross point serew driver

(9 No. 2 stew driver

& Screw diver arp: For screw diver

& Clearance gauge? For lappet clearance adjustment

items atached tothe motoreyle ina Separate package

‘D A.can of tovchp paint

© Spare bauery fuse

0

—=

or

© om

oo

o—

—

o—

=eeeeeneernennenee SPECIFICATIOOS

Te

DIMENSIONS [

‘Overall length | 740m. 1800 mm

‘Overall with | asin C ce0mm)

‘Overall height | ax7in cco mm

‘whet base Moin. (120mm)

weicnt

‘Corb weight er)

CAPACITIES

Engine oll A9Uspt. Coster

Fuel tank “GUSgal. (ole)

Fuel reserve tank A7USpL. (OBiter i)

ENGINE {|

Bore and stroke 171797 in. (50315 mm)

__ Compression

Displacement

Horse power

Contact breaker point

Spark plug sap

Valve clearance

‘CHASSIS AND SUSPENSION

Caster

Tel

Tie size, font

Tire siz, rear

POWER TRANSMISSION

Primary reduction

Final reduction

Gear ratio, 15

tna

ard

a

SAB cuin. (9)

705/300 rpm

‘912~0016 in. 03~04 mm)

(0624-0028 In. (06~07 mm)

‘602 in. (005 mm)

or

255i0. 5 mm)

275-0 eR

275-7 PR)

300

an

at

Positorque gear ratio

tow range 167

High vange +1000

FLECTRICAL 7

6v-55AH

[AG generator

Headlight ev-asiasw

Talstopight ev-srew

Meter light ev-isw

Neutral indicator light evisw

igh Beam indicator light 6V=13W

Fre “samp

Вам также может понравиться

- Buck Rogers - Gottlieb ManualДокумент23 страницыBuck Rogers - Gottlieb ManualTatooinesky89% (9)

- Gottlieb (Technical Seminar Workbook)Документ62 страницыGottlieb (Technical Seminar Workbook)Tatooinesky100% (1)

- An Introduction To Bally Flipper GamesДокумент49 страницAn Introduction To Bally Flipper GamesTatooinesky100% (2)

- Bally Future Spa Instruction ManualДокумент38 страницBally Future Spa Instruction ManualTatooineskyОценок пока нет

- Gottlieb Black Hole Instruction ManualДокумент53 страницыGottlieb Black Hole Instruction ManualTatooinesky100% (2)

- Gottlieb Genie Pinball Instruction ManualДокумент22 страницыGottlieb Genie Pinball Instruction ManualTatooinesky100% (1)

- Gottlieb James Bond 007 Instruction ManualДокумент14 страницGottlieb James Bond 007 Instruction ManualTatooinesky100% (1)

- Seepage Through Dams (Casagrande, 1937)Документ23 страницыSeepage Through Dams (Casagrande, 1937)Tatooinesky80% (5)

- Joint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : California Geologists Board's ResponseДокумент2 страницыJoint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : California Geologists Board's ResponseTatooineskyОценок пока нет

- Correlation of The Upper Ellensburg Formation With The Old Scab Mountain Eruptive Center, East-Central Cascade Range, WashingtonДокумент203 страницыCorrelation of The Upper Ellensburg Formation With The Old Scab Mountain Eruptive Center, East-Central Cascade Range, WashingtonTatooinesky100% (1)

- Joint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : OSBGE ResponseДокумент7 страницJoint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : OSBGE ResponseTatooineskyОценок пока нет

- Joint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : Washington Licensing Board's ResponseДокумент2 страницыJoint Task Force On Areas of Practice (JTFAP), Engineering and Geology Practice Guidelines (DRAFT Report) : Washington Licensing Board's ResponseTatooineskyОценок пока нет

- Memorandum of Understanding, Oregon Geology and Engineering BoardsДокумент2 страницыMemorandum of Understanding, Oregon Geology and Engineering BoardsTatooineskyОценок пока нет

- Fish Habitat Rehabilitation ProceduresДокумент313 страницFish Habitat Rehabilitation ProceduresTatooineskyОценок пока нет

- Ocean Shores Managment Plan 2005Документ194 страницыOcean Shores Managment Plan 2005TatooineskyОценок пока нет

- Coastal Sand Dunes of Oregon and WashingtonДокумент198 страницCoastal Sand Dunes of Oregon and WashingtonTatooineskyОценок пока нет

- Rec Erc 74 10Документ61 страницаRec Erc 74 10TatooineskyОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- RoadSense For Riders Your Licence MV2076Документ21 страницаRoadSense For Riders Your Licence MV2076Kimball FiniganОценок пока нет

- Chapter One: What Is Traffic Engineering?Документ8 страницChapter One: What Is Traffic Engineering?Mustafa KhalilОценок пока нет

- Road Safety AwarenessДокумент11 страницRoad Safety AwarenessSajidОценок пока нет

- Light Rail 09-1Документ1 страницаLight Rail 09-1legaleagle99999Оценок пока нет

- Alberta Transportation Safety Act-Aug 15, 2012Документ200 страницAlberta Transportation Safety Act-Aug 15, 2012canadiangrizzer1Оценок пока нет

- Temporary Photo DocumentДокумент1 страницаTemporary Photo DocumentDiane WhittakerОценок пока нет

- CEC 204 AssignmentДокумент11 страницCEC 204 AssignmentOlukayode Emmanuel BoluwajiОценок пока нет

- Level of Service-IITДокумент31 страницаLevel of Service-IITkumarnramОценок пока нет

- Hamburg Project Cited As A National Model of Collaboration National Model of CollaborationДокумент8 страницHamburg Project Cited As A National Model of Collaboration National Model of CollaborationLucas ReigstadОценок пока нет

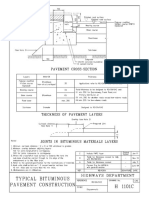

- Typical Cross Sections-6Документ1 страницаTypical Cross Sections-6UMESH SIKARWARОценок пока нет

- Talking About Necessity and Obligation.: Rules PracticeДокумент1 страницаTalking About Necessity and Obligation.: Rules Practiceyenifer guzman100% (1)

- Poor Road ConditionДокумент2 страницыPoor Road ConditionAnshu ShahОценок пока нет

- Aggressive Cross Reference Guide1 PDFДокумент73 страницыAggressive Cross Reference Guide1 PDFayman akrabОценок пока нет

- Guardrail PropertiesДокумент2 страницыGuardrail PropertiesScooby DooОценок пока нет

- Application No.: LLR Fresh AcknowledgementДокумент1 страницаApplication No.: LLR Fresh AcknowledgementChadaram Jagadish JagadishОценок пока нет

- TR Hca PretestДокумент6 страницTR Hca PretestRomeОценок пока нет

- DL - ReportДокумент1 страницаDL - ReportGaurav DhakaОценок пока нет

- MS For Pothole RepairДокумент41 страницаMS For Pothole RepairAdrian FrantescuОценок пока нет

- 15.1. As Built Drawing - KML Route (A3) - MTI Cepu - XL GenengДокумент9 страниц15.1. As Built Drawing - KML Route (A3) - MTI Cepu - XL GenengmamassanjayaОценок пока нет

- Mort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementДокумент42 страницыMort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementAkshay PendurkarОценок пока нет

- Urban Transport Systems and Congestion-A Case Study of PuneДокумент5 страницUrban Transport Systems and Congestion-A Case Study of PuneSwikriti PatnaikОценок пока нет

- To Civil Engineering: RoadsДокумент30 страницTo Civil Engineering: Roadshemant kumarОценок пока нет

- Traffic Flow TheoryPPTДокумент16 страницTraffic Flow TheoryPPTBenj FigueroaОценок пока нет

- AU2288Документ19 страницAU2288Chandler MinhОценок пока нет

- Wearing Coat ThicknessДокумент1 страницаWearing Coat ThicknessanjanaОценок пока нет

- Arkansas Driver License Study Guide: Volume 1 - Edition 7Документ100 страницArkansas Driver License Study Guide: Volume 1 - Edition 7Anonymous hjzrqR5TSWОценок пока нет

- Importance of Geometric DesignДокумент13 страницImportance of Geometric DesignNiteshKrJhaОценок пока нет

- Dear HananДокумент3 страницыDear HananRodiah OsmanОценок пока нет

- Railway Management SystemДокумент2 страницыRailway Management SystemIrfan ZubairОценок пока нет

- Saturday - Gran Fondo PEIДокумент2 страницыSaturday - Gran Fondo PEIAliceCameronRussellОценок пока нет