Академический Документы

Профессиональный Документы

Культура Документы

DCN 47 51570605

Загружено:

Shilpa GanganИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DCN 47 51570605

Загружено:

Shilpa GanganАвторское право:

Доступные форматы

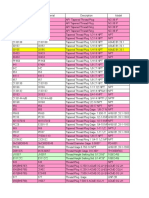

X-OVER DETAILS

JOB No: ADH-40C10-A1.0709226- 021/02

CLIENT: PRVEEN INDUSTRIES PVT.LTD

PART No: 2304 -WG

Work Order No.: RT8001030

REPORT No: DSP-1275

DWG.No: 51551210B-WF REV.0

REF CODES: API 6A / ASME SEC.VIII Div.2

DATA:

MIN. O.D. A in 4.750

MIN. I.D.(uncorroded) B in 3.000

C.A. C.A in 0 1 / 16

0.0625

MIN. I.D.(corroded) B in 3.000

WORKING PRESSURE, INTERNAL Pwi psi 5000

TEST PRESSURE Pt psi 10000

WORKING PRESSURE, EXTERNAL Pwe psi 0

MATERIAL SPEC. AISI 4140, Max 18-22 RC 75K - H2S

YIELD STRENGTH Sy psi 75,000

ULTIMATE TENSILE STRENGTH Su psi 95,000

JOINT EFFICIENCY E 1

RATIO OF OD TO ID Y 1.58333333333333

API 5CT FACTOR F 0.8

THICKNESS, CORRODED t in 0.875

INSIDE RADIUS (CORRODED) R in 1.5

THICKNESS, ACTUAL T in 0.875

MIN. I.D., ACTUAL C in 3

T.F., Temperature Reduction Factor @ 350 DEG. F 1

ALLOWABLE STRESSES:

HOOP STRESS AT W.P Sw psi Sy(2/3) OR Su(1/2) 47500

HOOP STRESS AT T.P. St psi Sy(5/6) OR Su(2/3) 62500

PRIMARY+SECONDARY STRESS Ss psi Su OR Sy(2) 95000

ACTUAL STRESSES:

MAX.PRIMARY STRESS AT W.P Sw psi [(Pw*R/t)+Pw/2]/TF 11071 PASS

MAX.PRIMARY STRESS AT T.P. St psi [(Pt*R/t)+Pt/2]/TF 22143 PASS

MAX.PRIMARY+SECONDARY AT T.P Ss psi [2*Pt*Y^2/(Y^2-1)]/TF 33272 PASS

MAX.ALLOWABLE T.P AS PER API 5CT Pt psi [2*F*St*T/A]*TF 22105 PASS

TENSILE LOADS:

ALLOWABLE TENSILE LOAD

lbs 0

@AMBIENT & 0 PSI

LONGITUDINAL STRESS AT W.P=10000

lbs (2*Pw*R/t)+Pw/2 19643

PSI

SAFETY FACTOR FOS 1

TENSILE LOAD CAPACITY AT 0 PSI lbs Cross.Area*FOS*Sy 798,492 PASS

Cross.Area*FOS*Sy

TENSILE LOAD CAPACITY AT 10000 PSI lbs 778,849

-LONG. STRESS

EXTERNAL PRESSURE/COLLAPSE PRESSURE(Pc) CALCULATION:

D/t RATIO D/t 5.43

MAX. EXTERNAL PRESSURE ALLOWABLE 0

AS PER API 7G APPENDIX-A

SAFETY FACTOR FOR EXTERNAL

PRESSURE

F 0.67

MAX. COLLAPSE PRESSURE Pc psi 2*F*Ym*((D/t)-1)/(D/t)^2 15103 PASS

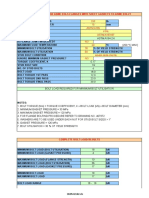

Temperature Ratings (Table 4.2, API 6A) From Table 7.9 Hydrostatic Body Test Pressure, psi

Temperature

Classification Deg. Fahrenheit Deg. Celsius

Working

Pressure Test

Min. Max. Min. Max. Rating Pressure

K -75 180 -60 182 (psi) (psi)

L -50 180 -46 182 2,000 4,000

P -20 180 -29 182 3,000 6,000

R Room Temperature Room Temperature 5,000 10,000

S 0 150 -18 166 10,000 15,000

T 0 180 -18 182 15,000 22,500

U 0 250 -18 121 20,000 30,000

V 35 250 2 121

MATERIAL SPEC. 17/4 PH to NACE MR-01-75 H2S

YIELD STRENGT Sy psi 105,000

ULTIMATE TENS Su psi 120,000

MATERIAL SPEC. 17/4 PH SS (P110)

YIELD STRENGT Sy psi 110,000

ULTIMATE TENS Su psi 120,000

MATERIAL SPEC. AISI 4130, 18-22 HRC NACE MR-01-75 H2S

YIELD STRENGT Sy psi 75,000

ULTIMATE TENS Su psi 90,000

MATERIAL SPEC. AISI 4140, 18-22 HRC NACE MR-01-75 H2S

YIELD STRENGT Sy psi 80,000

ULTIMATE TENS Su psi 95,000

MATERIAL SPEC. AISI 4145, 30-36 HRC STD SERVICE (Q125)

YIELD STRENGT Sy psi 125,000

ULTIMATE TENS Su psi 135,000

MATERIAL SPEC. 13 Cr, 95K to NACE MR-01-75 H2S (C95)

YIELD STRENGT Sy psi 95,000

ULTIMATE TENS Su psi 110,000

MATERIAL SPEC. 9 Cr 1 Mo to NACE MR-01-75 H2S

YIELD STRENGT Sy psi 80,000

ULTIMATE TENS Su psi 95,000

MATERIAL SPEC. ASTM A 182 Gr. F51, NACE MR-01-75 H2S

YIELD STRENGT Sy psi 65,000

ULTIMATE TENS Su psi 90,000

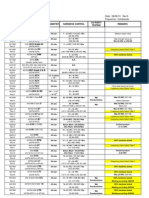

X-over DETAILS

JOB No: IND.M.4.11.0133

CLIENT: PARVEEN INDUSTRIES PVT.LTD

PART No: 51570605-WF

Work Order No.: IND.M.4.11.0133

REPORT No:

DWG.No: 51570605-WF

REF CODES: API 6A / ASME SEC.VIII Div.2/API 5CT

Adapter Flange

TOP 7"-5 STUB ACME Elmar Box Threaded

BOTTOM 7.1/16" -5000 Psi WP

DATA:

MIN. O.D. A in 6.750

MIN. I.D.(uncorroded) B in 4.000

C.A. C.A in 0

MIN. I.D.(corroded) B in 4.000

WORKING PRESSURE, INTERNAL Pwi psi 5000

TEST PRESSURE Pt psi 7500

WORKING PRESSURE, EXTERNAL Pwe psi 0

MATERIAL SPEC. AISI 4140, Max 18-22 RC 75K - H2S

YIELD STRENGTH Sy psi 75,000

ULTIMATE TENSILE STRENGTH Su psi 95,000

JOINT EFFICIENCY E 1

RATIO OF OD TO ID Y 1.6875

API 5CT FACTOR F 0.8

THICKNESS, CORRODED t in 1.375

INSIDE RADIUS (CORRODED) R in 2

THICKNESS, ACTUAL T in 1.375

MIN. I.D., ACTUAL C in 4

T.F., Temperature Reduction Factor @ 350 DEG. F 1

ALLOWABLE STRESSES:

HOOP STRESS AT W.P Sw psi Sy(2/3) OR Su(1/2) 47500

HOOP STRESS AT T.P. St psi Sy(5/6) OR Su(2/3) 62500

PRIMARY+SECONDARY STRESS Ss psi Su OR Sy(2) 95000

ACTUAL STRESSES:

MAX.PRIMARY STRESS AT W.P Sw psi [(Pw*R/t)+Pw/2]/TF 9773 PASS

MAX.PRIMARY STRESS AT T.P. St psi [(Pt*R/t)+Pt/2]/TF 14659 PASS

MAX.PRIMARY+SECONDARY AT T.P Ss psi [2*Pt*Y^2/(Y^2-1)]/TF 23118 PASS

MAX.ALLOWABLE T.P AS PER API 5CT Pt psi [2*F*St*T/A]*TF 24444 PASS

TENSILE LOADS:

ALLOWABLE TENSILE LOAD

lbs 0

@AMBIENT & 0 PSI

LONGITUDINAL STRESS AT W.P=10000

lbs (2*Pw*R/t)+Pw/2 17,045

PSI

SAFETY FACTOR FOS 0.88

TENSILE LOAD CAPACITY AT 0 PSI lbs Cross.Area*FOS*Sy 1,531,633 PASS

Cross.Area*FOS*Sy

TENSILE LOAD CAPACITY AT 10000 PSI lbs 1,514,588

-LONG. STRESS

EXTERNAL PRESSURE/COLLAPSE PRESSURE(Pc) CALCULATION:

D/t RATIO D/t 4.91

MAX. EXTERNAL PRESSURE ALLOWABLE

0

AS PER API 7G APPENDIX-A

SAFETY FACTOR FOR EXTERNAL

PRESSURE

F 0.67

MAX. COLLAPSE PRESSURE Pc psi 2*F*Ym*((D/t)-1)/(D/t)^2 16302 PASS

MATERIAL SPEC. 9 Cr 1 Mo to NACE MR-01-75 H2S

YIELD ST Sy psi 80000

ULTIMATESu psi 95000

MATERIAL SPEC. AISI 4140, 18-22 HRC NACE MR-01-75 H2S

YIELD ST Sy psi 80000

ULTIMATESu psi 95000

Вам также может понравиться

- ASTM Tables ConvertersДокумент314 страницASTM Tables ConvertersVasileios PantouvakisОценок пока нет

- Business Intelligence DashboardДокумент12 страницBusiness Intelligence Dashboardabi habudinОценок пока нет

- A286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableДокумент8 страницA286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableMahesh PanditОценок пока нет

- Hydraulic Seals - Rod SealsДокумент176 страницHydraulic Seals - Rod SealsRoberto HipólitoОценок пока нет

- Specification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness TestingДокумент4 страницыSpecification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness Testingstephen lewellenОценок пока нет

- Trimec: Chemical Compatibility ChartДокумент12 страницTrimec: Chemical Compatibility ChartMandiriОценок пока нет

- SLB Check List-1Документ2 страницыSLB Check List-1Jitendra BhosaleОценок пока нет

- Instructions For Champ III Packers: SectionДокумент18 страницInstructions For Champ III Packers: SectionMohamed ShafieОценок пока нет

- Thread GageДокумент30 страницThread GageRosendo RizoОценок пока нет

- What Are Positive Displacement Mud Motors in Drilling For Oil and GasДокумент10 страницWhat Are Positive Displacement Mud Motors in Drilling For Oil and GasAhmedОценок пока нет

- Hydrotest ProcedureДокумент3 страницыHydrotest ProcedureAprilia dwita sariОценок пока нет

- Galling 2Документ6 страницGalling 2Ricardo MartinsОценок пока нет

- Helical Compressing Spring Calculation PDFДокумент4 страницыHelical Compressing Spring Calculation PDFViktor KovtunОценок пока нет

- h06971 HV Series IcvДокумент3 страницыh06971 HV Series IcvLoganBohannonОценок пока нет

- Training Records TPL5013Документ6 страницTraining Records TPL5013Pradip Tapan Banerjee100% (1)

- Excel Project ManagerДокумент30 страницExcel Project ManagerFika JeОценок пока нет

- Himansu Sekhar Mohapatra: Professional SummaryДокумент5 страницHimansu Sekhar Mohapatra: Professional SummaryHimansu MohapatraОценок пока нет

- API AARsДокумент2 страницыAPI AARsDhaval ChitreОценок пока нет

- Motors PresentationДокумент38 страницMotors PresentationnjileoОценок пока нет

- Acme & Stub Acme LoadДокумент4 страницыAcme & Stub Acme Loadraseen pОценок пока нет

- Quality Docs DEP 17 0803Документ7 страницQuality Docs DEP 17 0803Edwin MPОценок пока нет

- S-069274 - EPDM Connectivity Test Tool InstructionsДокумент2 страницыS-069274 - EPDM Connectivity Test Tool InstructionsKMGanapathiОценок пока нет

- 1.0 Scope:: NDT & Corrosion Control ServicesДокумент1 страница1.0 Scope:: NDT & Corrosion Control Servicesm_armoutiОценок пока нет

- Catalogo New PrecisionDrill ML HB r2 PDFДокумент214 страницCatalogo New PrecisionDrill ML HB r2 PDFDei AdrianzaОценок пока нет

- Drawn by Date RevisionДокумент10 страницDrawn by Date RevisionИван ВасильевОценок пока нет

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEДокумент8 страницHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagОценок пока нет

- Solidworks Workgroup PDM InstallationДокумент7 страницSolidworks Workgroup PDM InstallationmecanicajcОценок пока нет

- h06974 MC Series IcvДокумент2 страницыh06974 MC Series IcvLoganBohannonОценок пока нет

- Motor PresentationДокумент23 страницыMotor PresentationVirgilioОценок пока нет

- Near Bit GammaДокумент2 страницыNear Bit GammaQiang ZhangОценок пока нет

- O Ring Calc4Документ8 страницO Ring Calc4Babu RajamanickamОценок пока нет

- AISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredДокумент6 страницAISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredCristina NicheОценок пока нет

- Torque For B7 L7 Stud BoltsДокумент2 страницыTorque For B7 L7 Stud Boltsrbagri0% (1)

- Almen Strip Holders: Meets SAE J442Документ2 страницыAlmen Strip Holders: Meets SAE J442donhan91Оценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Use of Alloy 718 and 725 in Oil and Gas IndustryДокумент9 страницUse of Alloy 718 and 725 in Oil and Gas IndustryEddyWangОценок пока нет

- 000 Indice APIДокумент6 страниц000 Indice APIJoel Pacheco DiazОценок пока нет

- Oil Field: Main CatalogueДокумент176 страницOil Field: Main CatalogueM. Aguiar100% (1)

- Activity 2Документ16 страницActivity 2Kate Joshua A. MinguitoОценок пока нет

- Solidworks Routing - Piping and TubingДокумент3 страницыSolidworks Routing - Piping and TubingLuis Rodrigo SanchezОценок пока нет

- Survey Course - APS FormatДокумент83 страницыSurvey Course - APS FormatHaffi Díaz López100% (1)

- JPT 2016-10Документ88 страницJPT 2016-10Ali AbukhzamОценок пока нет

- Chapter 2-J Positive Displacement MotorsДокумент23 страницыChapter 2-J Positive Displacement MotorsFor Free Drilling Training CenterОценок пока нет

- Hardness Spec (FMC) Rev 5Документ2 страницыHardness Spec (FMC) Rev 5aezeadОценок пока нет

- SandHug BailerДокумент2 страницыSandHug BailerAhmedMohsenОценок пока нет

- Bolt Torque ASME B16 5 Flanges Sheet Gaskets 02Документ17 страницBolt Torque ASME B16 5 Flanges Sheet Gaskets 02pirataenriqueОценок пока нет

- How To Manually Delete An Enterprise PDM File Vault (Archives and Database) PDFДокумент7 страницHow To Manually Delete An Enterprise PDM File Vault (Archives and Database) PDFrachamreddyrОценок пока нет

- Sop 151-1Документ4 страницыSop 151-1m_armoutiОценок пока нет

- Title: Halliburton Management System FO-GL-HAL-SCQ-703A-3 Area: Function/PSL: Owner: Approved By: Job Revision By: Rev NoДокумент6 страницTitle: Halliburton Management System FO-GL-HAL-SCQ-703A-3 Area: Function/PSL: Owner: Approved By: Job Revision By: Rev NoJuan G Cleves AОценок пока нет

- Dump Bailer - Omega PDFДокумент2 страницыDump Bailer - Omega PDFJeisson E Ruiz DОценок пока нет

- Msheireb General Rig InfoДокумент2 страницыMsheireb General Rig InfoAftandil QarmonОценок пока нет

- APS Rotary PulserДокумент2 страницыAPS Rotary PulserWajid KhattakОценок пока нет

- Instructions For Champ IV Packers: SectionДокумент20 страницInstructions For Champ IV Packers: SectionMohamed ShafieОценок пока нет

- Catalog C v5 PDFДокумент80 страницCatalog C v5 PDFAshokОценок пока нет

- TH Hill Sales PresentationДокумент19 страницTH Hill Sales PresentationzmОценок пока нет

- RTTS Model 2 Circulating Valves: SectionДокумент18 страницRTTS Model 2 Circulating Valves: SectionMohamed ShafieОценок пока нет

- Modulus of Elasticity at DT 'E' (Ksi)Документ8 страницModulus of Elasticity at DT 'E' (Ksi)Debabrata MajiОценок пока нет

- PTT GSP5-MODBUS LIST-Revised - R6Документ19 страницPTT GSP5-MODBUS LIST-Revised - R6JemeraldОценок пока нет

- FABCO Pipe Catalog PDFДокумент24 страницыFABCO Pipe Catalog PDFMohamed AklОценок пока нет

- Ejercicio 246 PSV438 RESUELTOДокумент2 страницыEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaОценок пока нет

- Magnetic CircuitДокумент64 страницыMagnetic CircuitheroОценок пока нет

- Coulomb Failure Criterion: Structural GeologyДокумент5 страницCoulomb Failure Criterion: Structural GeologyVinay PrasadОценок пока нет

- TOP 2-2-800 Center of GravityДокумент11 страницTOP 2-2-800 Center of Gravityalper bmcОценок пока нет

- 06 Momentum 06Документ4 страницы06 Momentum 06dil19860209100% (1)

- Intro To Design of BridgesДокумент9 страницIntro To Design of Bridgesarunkumar.mgsОценок пока нет

- Heat TransgerДокумент56 страницHeat TransgerShusha Shomali67% (3)

- Diffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationДокумент38 страницDiffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationPrateek DwivediОценок пока нет

- Liquid Hydrogen Storage With Active Cooling For Space PDFДокумент11 страницLiquid Hydrogen Storage With Active Cooling For Space PDFAlberto popescuОценок пока нет

- Tesis PDFДокумент120 страницTesis PDFdaniel sernaОценок пока нет

- National Institute of Technology Calicut: Department of Mechanical EngineeringДокумент2 страницыNational Institute of Technology Calicut: Department of Mechanical EngineeringAjaratanОценок пока нет

- Semester 2 Answer 2019 Chung Ling ButterworthДокумент3 страницыSemester 2 Answer 2019 Chung Ling ButterworthKhang Ni 康妮 FooОценок пока нет

- The Route To Measurement TransducersДокумент88 страницThe Route To Measurement TransducersBuiDucVinhОценок пока нет

- Circular Motion & Gravitation MCДокумент15 страницCircular Motion & Gravitation MCWillyОценок пока нет

- 242 Wikarta Kuliah IV Keseimbangan Benda TegarДокумент21 страница242 Wikarta Kuliah IV Keseimbangan Benda TegarEffendi HabibieОценок пока нет

- Mock Test Physics (ICSE CH 1 2 3)Документ4 страницыMock Test Physics (ICSE CH 1 2 3)Ishani MishraОценок пока нет

- Assessment 1 Circular MotionДокумент6 страницAssessment 1 Circular Motionhadia nasirОценок пока нет

- دمج الى 6 م اسفلتДокумент37 страницدمج الى 6 م اسفلتtrjirew3Оценок пока нет

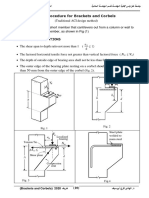

- Brackets and Corbels ACI 318 L # 1Документ7 страницBrackets and Corbels ACI 318 L # 1soran azizОценок пока нет

- 〈912〉 VISCOSITY-ROTATIONAL METHODSДокумент10 страниц〈912〉 VISCOSITY-ROTATIONAL METHODSVieno Gino CruzОценок пока нет

- Design Report: HAWT Graduation ProjectДокумент30 страницDesign Report: HAWT Graduation ProjectMohamed MedhatОценок пока нет

- Lab Report Radius of GyrationДокумент4 страницыLab Report Radius of GyrationShahzaibali AfaqОценок пока нет

- (Lecture - 2 - Updated) Dynamics of Structures Chapter 2 PDFДокумент37 страниц(Lecture - 2 - Updated) Dynamics of Structures Chapter 2 PDFMasood AhmedОценок пока нет

- 6th Semester SyllabusДокумент12 страниц6th Semester SyllabusSaurabh RathoreОценок пока нет

- Learning Science 10: Quarter 2 - Week 1Документ5 страницLearning Science 10: Quarter 2 - Week 1Aliah Jeonelle RamosОценок пока нет

- fl3 Navier Stokes PDFДокумент6 страницfl3 Navier Stokes PDFekoxyz1067Оценок пока нет

- Aerodynamic Modeling & Simulation of HGVДокумент26 страницAerodynamic Modeling & Simulation of HGVManjunath PattarОценок пока нет

- Partial DerivativesДокумент3 страницыPartial DerivativesS M AkashОценок пока нет

- 0508-10 Centrifugal CleanersДокумент13 страниц0508-10 Centrifugal CleanersbgpinuОценок пока нет

- Motion in One DimensionДокумент12 страницMotion in One DimensionShinji50% (2)