Академический Документы

Профессиональный Документы

Культура Документы

Ruhaak SWRO Pecatu 04 DesignCalc 80068 01 8 PX Power Model Selector

Загружено:

Ayi JabarutiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ruhaak SWRO Pecatu 04 DesignCalc 80068 01 8 PX Power Model Selector

Загружено:

Ayi JabarutiАвторское право:

Доступные форматы

PX® Energy Recovery Device System Analysis

A B C D E F G H

FLOW US gpm 122 64 58 64 122 55 67 67

3

m /hr 28 14 13 14 28 13 15 15

3

m /day 667 348 319 348 667 300 367 367

PRESSURE psi 37 37 841 810 841 0 818 29

bar 2.5 2.5 58.0 55.9 58.0 0.0 56.4 2.0

QUALITY ppm 35,000 35,000 35,000 37,700 36,502 200 66,203 63,640

PX DEVICE ARRAY INPUT DESCRIPTIONS INPUTS

PX model PX-45S Units Metric or English M or E M

Number of PX units quantity 2 Manual or auto efficiencies m or a a

PX unit flow m3/hr 7.6 Permeate flow m3/day 300

PX lubrication per array m3/hr 0.8 RO recovery rate % 45%

PX lubrication flow % 5.1% RO feed pressure bar 58.0

Dfferential pressure HP side bar 0.5 Membrane differential pressure bar 1.6

Differential pressure LP side bar 0.5 PX LP discharge pressure bar 2.0

PX efficiency % 93.5% Feedwater salinity mg/l 35,000

PX mixing at membrane feed % 4.3% Motor power Hz 50 or 60 50

Operating capacity % 74.7% Currency type $

PX Power Savings kW 25.6 Cost of power $/kWh 0.10

Estimated CO2 Savings tons/year 132 HP pump efficiency % 82%

HP pump motor efficiency % 96%

HIGH PRESSURE PUMP Circulation pump efficiency % 63%

Pump efficiency % 90% Circulation pump motor efficiency % 94%

Motor efficiency % 91% Circulation pump VFD efficiency % 97%

Power consumed kW 25.1 PX device design margin % 5%

CIRCULATION / BOOSTER PUMP PX SYSTEM POWER RESULTS

ERI PX booster pump model 50 Hz HP-8503 Total power consumption kW 27

Number of PX booster pumps quantity 1 Specific power consumption kWh/m3 2.15

Pump efficiency % 56% Specific power consumption kWh/kgal 8.1

Motor efficiency % 89% Power cost saved with PX $/year 22,432

VFD efficiency % 97%

Power consumed kW 1.8 Warnings NONE

Suggestions NONE

SYSTEM FEED PUMP kW 0.0

Notes:

ERI PX device and circulation pump selection is based upon assumptions not stated here. Please refer ERI sales personnel for additional information.

Вам также может понравиться

- 404a 22G1Документ5 страниц404a 22G1ddzoningcomОценок пока нет

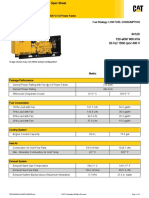

- Diesel Generator Sets: Standby: 60 HZ, 480V & 600VДокумент2 страницыDiesel Generator Sets: Standby: 60 HZ, 480V & 600VAllan SalazarОценок пока нет

- Diesel Generator Sets: Standby & Prime: 60 HZ, 480V & 600VДокумент2 страницыDiesel Generator Sets: Standby & Prime: 60 HZ, 480V & 600VAndres GutierrezОценок пока нет

- Caterpillar C9 D300 GC SubmittalДокумент42 страницыCaterpillar C9 D300 GC SubmittalGerman E.Оценок пока нет

- Prs Qes 80 400-230v 50hz en WuxiДокумент6 страницPrs Qes 80 400-230v 50hz en WuxiDesign BookОценок пока нет

- Diesel Generator Sets: Standby: 60 HZ, 208V, 480V & 600VДокумент2 страницыDiesel Generator Sets: Standby: 60 HZ, 208V, 480V & 600VAllan SalazarОценок пока нет

- CAT C13 400kW SubmittalДокумент42 страницыCAT C13 400kW SubmittalAli AlshazlyОценок пока нет

- 11.1 c18 AbertoДокумент2 страницы11.1 c18 AbertoRafael de Oliveira SouzaОценок пока нет

- 1103A-33TG1 EngineДокумент5 страниц1103A-33TG1 EngineAnamta KhanОценок пока нет

- Fiche Technique QES 390 CDДокумент6 страницFiche Technique QES 390 CDMProd AmmoОценок пока нет

- C18 625 Kva PrimeДокумент3 страницыC18 625 Kva PrimeDedi MaryadiОценок пока нет

- Inmesol Deutz AD-500Документ3 страницыInmesol Deutz AD-500Agus RasidОценок пока нет

- LEHE1722 - C15 400kWДокумент2 страницыLEHE1722 - C15 400kWMatheusОценок пока нет

- 403a 15G1Документ5 страниц403a 15G1mkmkmkmkmkmkmkmkmkmkОценок пока нет

- New Caterpillar CAT C15 GC SubmittalДокумент62 страницыNew Caterpillar CAT C15 GC Submittalعبدالرحمن محمدОценок пока нет

- Image Shown May Not Reflect Actual Configuration: Metric EnglishДокумент3 страницыImage Shown May Not Reflect Actual Configuration: Metric EnglishdinukaeeОценок пока нет

- BP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVAДокумент5 страницBP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVARobet PrasetyoОценок пока нет

- Cummins 330 PDFДокумент3 страницыCummins 330 PDFMarcelo Herrera100% (1)

- Long Run Energy: Main FeaturesДокумент3 страницыLong Run Energy: Main FeaturesNguyen Vu Hoang ThachОценок пока нет

- Deutz BF6M1015 Technical DataДокумент3 страницыDeutz BF6M1015 Technical DataMuhammad rizkiОценок пока нет

- Genset SpecДокумент3 страницыGenset SpecArnold Thamrin van LutteranОценок пока нет

- Image Shown May Not Reflect Actual Configuration: Metric EnglishДокумент3 страницыImage Shown May Not Reflect Actual Configuration: Metric EnglishJessica Tatiana Muñoz OrtizОценок пока нет

- Image Shown May Not Reflect Actual Configuration: Metric EnglishДокумент3 страницыImage Shown May Not Reflect Actual Configuration: Metric EnglishMarcelo FernandezОценок пока нет

- GBW22P 2023 10 08 11 36 46Документ9 страницGBW22P 2023 10 08 11 36 46Marian DumitruОценок пока нет

- De400 CatДокумент2 страницыDe400 CatLena LorenkoОценок пока нет

- Pramac GSW110IДокумент10 страницPramac GSW110IJanko GardaševićОценок пока нет

- 1206a-E70ttag3 PN3184 - 4Документ4 страницы1206a-E70ttag3 PN3184 - 4MohamedJaberKutkutMjkОценок пока нет

- 400 Series: Electro Unit 5.1 KWM at 1800 RPMДокумент5 страниц400 Series: Electro Unit 5.1 KWM at 1800 RPMnabiloo47Оценок пока нет

- GBW22P - 2020-09-25-08-17-20Документ9 страницGBW22P - 2020-09-25-08-17-20Mark Smark SengendoОценок пока нет

- Marine Engine-6170 Series: General SpecificationsДокумент3 страницыMarine Engine-6170 Series: General SpecificationsTrần Hoài VinhОценок пока нет

- 4M06G22-5 BaudouinДокумент4 страницы4M06G22-5 BaudouinJohan von HoldtОценок пока нет

- GSW110P: Main FeaturesДокумент11 страницGSW110P: Main FeaturesDhanushka HerathОценок пока нет

- Datasheet QSC83Документ2 страницыDatasheet QSC83Thành DanhОценок пока нет

- 03-20kva Data Sheet 404a-22g1Документ5 страниц03-20kva Data Sheet 404a-22g1Muse AFОценок пока нет

- Technical Data Sheet 50EPM, 60EPMДокумент1 страницаTechnical Data Sheet 50EPM, 60EPMkwstdbjp5fОценок пока нет

- Deutz 1013Документ3 страницыDeutz 1013Retno Pudji LestariОценок пока нет

- TSS DM1908 04 GS Epg 7155724Документ3 страницыTSS DM1908 04 GS Epg 7155724Wilfrid DutruelОценок пока нет

- Image Shown May Not Reflect Actual Configuration: Metric EnglishДокумент3 страницыImage Shown May Not Reflect Actual Configuration: Metric EnglishPaola NoMás DicenОценок пока нет

- De22e3 MДокумент2 страницыDe22e3 MSami KhanОценок пока нет

- 6 Original Datasheet Proposed ManufaДокумент7 страниц6 Original Datasheet Proposed ManufaJegadeshwaran RОценок пока нет

- 403d 15g EngineДокумент4 страницы403d 15g EngineIqra khanОценок пока нет

- 403d 15g EngineДокумент4 страницы403d 15g EngineIqra khanОценок пока нет

- 3412C 725 Ekw/ 906 kVA/ 60 HZ/ 1800 RPM/ 480 V/ 0.8 Power FactorДокумент3 страницы3412C 725 Ekw/ 906 kVA/ 60 HZ/ 1800 RPM/ 480 V/ 0.8 Power FactorMed ZidiОценок пока нет

- Apg 680Документ7 страницApg 680Magaly PeraltaОценок пока нет

- WUXI PRS QES 60 400-230V 50Hz EN WuxiДокумент6 страницWUXI PRS QES 60 400-230V 50Hz EN WuxiMohammed DjouadjОценок пока нет

- DS207 CPGK PDFДокумент3 страницыDS207 CPGK PDFhonafa- R.O.N.OОценок пока нет

- Model: C250 D2R Fuel Type: Diesel Document No.: Ds207-Cpgk-RevcДокумент3 страницыModel: C250 D2R Fuel Type: Diesel Document No.: Ds207-Cpgk-Revchonafa- R.O.N.OОценок пока нет

- 22 Kva Meer PDFДокумент6 страниц22 Kva Meer PDFDiary CompanyОценок пока нет

- TSS DM8233 01 GS Epg 7335016Документ3 страницыTSS DM8233 01 GS Epg 7335016MikaelОценок пока нет

- GSW250P (Alt. LS) - 2023-03-28-10-38-54Документ9 страницGSW250P (Alt. LS) - 2023-03-28-10-38-54sarahalawa222Оценок пока нет

- GSW45P 2023 06 16 13 11 05Документ9 страницGSW45P 2023 06 16 13 11 05lucy.morrisОценок пока нет

- Generator Set Data Sheet: Fuel ConsumptionДокумент3 страницыGenerator Set Data Sheet: Fuel ConsumptionJohn CardonaОценок пока нет

- 13 02 PI375P - 60Hz-R0Документ2 страницы13 02 PI375P - 60Hz-R0mustafaОценок пока нет

- Electric Vehicle V1.2odsДокумент4 страницыElectric Vehicle V1.2odsLongluuОценок пока нет

- Image Shown May Not Reflect Actual Configuration: Metric EnglishДокумент3 страницыImage Shown May Not Reflect Actual Configuration: Metric EnglishAkilaJosephОценок пока нет

- Open Gensets With Deutz Engine: Engine: Alternator: ECO28-1L/4 Scope of SupplyДокумент3 страницыOpen Gensets With Deutz Engine: Engine: Alternator: ECO28-1L/4 Scope of SupplyAhmed ZeharaОценок пока нет

- TSS DM1909 04 GS Epg 9463839Документ3 страницыTSS DM1909 04 GS Epg 9463839mnezamiОценок пока нет

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsОт EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsРейтинг: 3 из 5 звезд3/5 (5)

- BF# Msds SheetДокумент9 страницBF# Msds SheetAlvaro Rojas AnzolaОценок пока нет

- MERICON™ I, II, III - Caustic Treatments - Merichem - IIДокумент1 страницаMERICON™ I, II, III - Caustic Treatments - Merichem - IIOthman Mat YamanОценок пока нет

- UK Sub6 The Livestock Waste Control Scheme - Soakaway-SystemДокумент5 страницUK Sub6 The Livestock Waste Control Scheme - Soakaway-SystemLuiz AlvesОценок пока нет

- 110 Pacific Steam Laundry vs. LLDAДокумент11 страниц110 Pacific Steam Laundry vs. LLDAcharmssatellОценок пока нет

- PWC Basics of Mining 4 Som Mine Waste ManagementДокумент46 страницPWC Basics of Mining 4 Som Mine Waste Managementakm249Оценок пока нет

- 10-Hydroponics System PDFДокумент28 страниц10-Hydroponics System PDFAgusNurjayaFaizОценок пока нет

- DLP 6 LO2 Safe Disposal of Tools and MaterialsДокумент13 страницDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- Introduction - WWT AzucareraДокумент7 страницIntroduction - WWT AzucareraSadieОценок пока нет

- 1effect of COVID - 19 Pandemic On EnvironmentДокумент23 страницы1effect of COVID - 19 Pandemic On EnvironmentamolОценок пока нет

- Rbs Epoxy Mortar LW HS 2014Документ6 страницRbs Epoxy Mortar LW HS 2014adeoye_okunoyeОценок пока нет

- Unitor Chemical Treatment SummaryДокумент7 страницUnitor Chemical Treatment Summaryamirouche15Оценок пока нет

- Specifications For Conservancy Tanks 35200522532 257Документ2 страницыSpecifications For Conservancy Tanks 35200522532 257ruwanpura100% (1)

- Gómez Et Al. - 2021Документ11 страницGómez Et Al. - 2021Juan Caballero FloresОценок пока нет

- Galvanic SeriesДокумент11 страницGalvanic SeriesblakasОценок пока нет

- Chapter 1 Transport - Plant-3Документ37 страницChapter 1 Transport - Plant-3SaroОценок пока нет

- Floor Plan SymbolsДокумент34 страницыFloor Plan SymbolsMatthew DavidОценок пока нет

- Bowee: Product CatalogДокумент55 страницBowee: Product CatalogHasan AkilОценок пока нет

- Choline Chloride in Clay and Shale Stabilizer-619Документ4 страницыCholine Chloride in Clay and Shale Stabilizer-619Lê Công100% (1)

- The Processes Used in Modern Sewage Treatment PlantsДокумент2 страницыThe Processes Used in Modern Sewage Treatment PlantsPravat SatpathyОценок пока нет

- Discover NC River Basins BookletДокумент16 страницDiscover NC River Basins Bookletapi-290100812Оценок пока нет

- Oil Gator: Natures Way To Bioremediate HydrocarbonsДокумент2 страницыOil Gator: Natures Way To Bioremediate HydrocarbonsOppo XОценок пока нет

- Local Media6250702252742969499Документ23 страницыLocal Media6250702252742969499Nade RouzevОценок пока нет

- Importance of Environmental EngineeringДокумент5 страницImportance of Environmental EngineeringAdhesha Fernando100% (1)

- Suspended Growth Biological Treatment ProcessesДокумент51 страницаSuspended Growth Biological Treatment Processesalvaro.roldan1Оценок пока нет

- Huatan Filtration CatalogДокумент61 страницаHuatan Filtration CatalogmuhammedshihasuОценок пока нет

- Basf - Ape SystemДокумент86 страницBasf - Ape SystemdixmitОценок пока нет

- Exercise Unit 3Документ8 страницExercise Unit 3Hân HoàngОценок пока нет

- Solid and Hazardous WasteДокумент14 страницSolid and Hazardous Wastehazel enguilloОценок пока нет

- Analysis of The Chaliyar IssueДокумент189 страницAnalysis of The Chaliyar Issuekannan.urОценок пока нет

- Project Child Labour ShakespeareДокумент78 страницProject Child Labour ShakespeareSuman KarОценок пока нет