Академический Документы

Профессиональный Документы

Культура Документы

The New SW 76 Submachine Gun (Small Arms Review)

Загружено:

antermvАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The New SW 76 Submachine Gun (Small Arms Review)

Загружено:

antermvАвторское право:

Доступные форматы

Visit us on line at: www.smallarmsreview.

com

The SW 76 shown with its

stock in the extended position.

Nearly twenty complete working guns, but the receivers many of the new applications for

years have passed had to meet a minimum stage of construc- the receiver tubes were approved,

since former Presi- tion as set forth by the BATF. At midnight there were restrictions placed on

dent Ronald Reagan May 18th it was all over. modifications allowed to the re-

signed the infamous The firearm-collecting world is always ceiver tube itself. To date, the BATF has

McClure-Volkmer full of unexpected surprises; often parts or approved the Sten tubes to be made into

Act into law. Al- part sets that are unavailable for years sud- Sterling’s, Lanchesters and most recently

though this piece of denly show up in the warehouses of surplus clones of the Smith & Wesson Model 76.

legislation had a few dealers. One example is the parts and part Yes, the Model 76.

pro-gun clauses, a sets for military issue Thompson subma- The original 9mm Smith & Wesson

last minute amend- chine guns. These parts that were once in a Model 76 submachine gun was first manu-

ment was added that seemingly inexhaustible abundance were factured in 1968 with production ending in

banned all future gone and the prices of the few remaining 1974. 6,000 production guns were built

manufacture of ma- parts were increasing daily. Then, recently, during that period. There were other ear-

chine guns for pri- hundreds of mint to like new M1, M1A1 lier clones of the S&W 76 made. One was

vate ownership. The and M1928 Thompson part sets were found. the MK Arms Company model called the

law took effect on Who would have ever thought this would MK 760 and another was the Global Arms/

May 19, 1986. ever occur - sixty year old Thompsons in Southern Tool’s M76A1. Production of

This piece of leg- new condition! these weapons were just starting up as the

islation forever fixed Every now and then a small quantity of machine gun ban was being enacted, limit-

the number of trans- new, unused registered receiver tubes would ing production of these submachine guns.

ferable machine emerge. Most of the remaining tubes were Lack of magazines was always a prob-

guns in the system. originally produced to be assembled into lem with the Model 76, with originals be-

Since that day prices Sten submachine guns, but then just a few ing scarce and proportionately expensive.

have steadily in- years ago most of the Sten part sets disap- Then, seemingly out of nowhere, the easily

creased as the supply peared, shelving the plans to assemble the adaptable Suomi M31 magazines appeared

of transferable guns tubes into working guns. at bargain basement prices. Not only were

has steadily de- More recently, Class 2 manufactures got the magazines cheap, most of them were in

creased. Today the creative and have submitted plans to the brand new condition. The magazines could

cost of a transferable BATF Technology Branch to use the re- be altered in seconds with a Dremel Tool to

machine gun can ex- maining registered receiver tubes for assem- fit in the Smith Model 76 by simply remov-

ceed the cost of a bly into guns other then the Sten. Although ing a few thousands of metal from the front

new well-equipped

automobile.

Many Class 2

manufactures were

well aware of the

impending restric-

tions a few weeks

prior to the enact-

ment of the ban.

Most of the manu-

facturers worked Jim Burgess’ SW 76, a

night and day to copy of the Smith &

make and register as Wesson Model 76. The

many machine gun example shown here

receivers as pos- has the standard gray

sible. It was not nec- Parkerized finish.

essary to assemble

26 The Small Arms Review • Vol. 9 No. 5 • February 2006

Visit us on line at: www.smallarmsreview.com

guide plate. Accordingly, with the maga-

zine problem solved, the asking prices for

the Model 76 began to increase.

The newest submachine gun on the mar-

ket is the product of Ohio Class 2 manufac-

turer, and no stranger to the Class 3 world,

Jim Burgess. Jim was a once a retail dealer

for John Stemple’s original line of subma-

chine guns, and also manufactured suppres-

sors for them.

Jim’s new creation has been designated

as the SW 76 (without the “&”). The SW

76 guns are manufactured from virgin tubes

that were originally registered by John

Stemple in 1986. Jim has enough parts and Above: Bottom view of the SW 76 barrel retaining catch. The original Smith

receiver tubes to assemble 100 guns. Jim & Wesson design was a straight bar. The redesigned curved catch is much

said that he personally test fires each gun easier to depress and hold.

that he builds to insure proper functioning

before shipping it off to the customer. All

of the parts of the SW 76 will interchange

with an original Smith & Wesson M76 ex-

cept for the bolt. The bolt is not interchange-

able due to the reorientation of the extrac-

tor and the Stemple receiver tubes have an

inside diameter that is slightly larger than

that of an original S&W M76, requiring two

sleeves that act as bearing surfaces to be

placed on the bolt to take up the extra space

inside the receiver.

A big question is; where in the world would

you find the part sets from the Smith &

Wesson Model 76? Original spare parts for

Above: Side view of an original Smith & Wesson Model 76 bolt (top) and a

the gun just don’t exist. The answer; from

bolt from the SW 76. Note the raised bearing surfaces on the lower bolt, and

semiautomatic copies of the Model ’76.

the different extractor positions.

During 2001 the Tactical Weapons Com-

pany of Arizona was engaged to manufac-

ture the parts and receivers for a weapon

that would be marketed as the Omega 760

carbine, a semiautomatic-only copy of the

Smith & Wesson Model 76. Initial sales of

the Omega 760 were brisk but quickly

dropped off. The disappointing sales of the

Omega ultimately drove the decision to

cease production and the decision left a

number of parts that were never assembled

into guns. Jim was able to purchase 100 of

the surplus Omega 760 kits and convinced

Special Weapons to produce the full auto

bolts and the other parts he needed. The

company agreed, and the 9mm SW M76

was born. Special Weapons still have a lim-

Left: Front view of the bolts clearly

shows the different extractor loca-

tions. An original Smith & Wesson

bolt is on the right, the SW 76 bolt

on the left. The repositioning of the

extractor increases its service life,

and provides a more positive extrac-

tion of spent cases.

The Small Arms Review • Vol. 9 No. 5 • February 2006 27

Visit us on line at: www.smallarmsreview.com

ited number of new Omega 760 semiauto-

matic carbines as well as part sets available

for purchase.

One of the weakest areas of the original

Smith & Wesson Model 76 design was its

extractor, which will often fail after several

thousand rounds. One substantial improve-

ment that was implemented into the design

of the SW 76 is the relocation of the extrac- Left side view of

tor from the original 12 o’clock position to the SW 76. This

a 2 o’clock position on the bolt. Relocat- weapon has the op-

ing the extractor substantially reduces lat- tional black powder

eral stress on the extractor effectively ex- coat finish.

tending its service life. The extractor was

also beefed-up for additional durability. The

trigger, magazine catch and sear are easily

serviced on SW 76, pivoting on removable Magazine markings. Note that the SW 76 logo that lacks

pins that are secured with E-clips. While the “&” between the letters.

the sear on the original M76 is easily re-

movable, the trigger and magazine catch are

semi-permanently riveted in place.

The SW 76 uses the same magazines as

the original Model 76 and, like the origi-

nal, the plentiful Suomi magazine will fit

and function in the gun with some minor

fitting. The new SW 76 comes with instruc-

tions on altering the Suomi magazines.

Jim also has designed a suppressor spe-

cifically for his new SW 76. The powder

coated suppressor uses standard 9mm am-

munition and is designed to reduce its ve-

locity to subsonic speeds. The suppressor

will also fit and function on the Smith &

Wesson M76, the MK Arms MK760 and

the Southern Tool M76A1 guns. As mentioned earlier, the availability of free to dealers that send in a copy of their

I was able to get a first hand look and an these guns is limited to 100 pieces , and this SOT. Dealer prices for the SW 76 and sup-

opportunity to test fire the SW 76 at a re- is probably one of the last opportunit ies for pressors are available upon request.

cent shoot in Ohio. The SW 76 is indeed a buyers to purchase a brand new design and For more information, visit Jim’s website

dead ringer for the original M76. Jim newly manufactured machine gun. Jim has at; wwww.jmbdistribution.com. Email;

brought along several of his SW 76 subma- a CD available that has close-up views of jburges@insight.rr.com

chine guns to the shoot and all worked per- the SW 76 submachine gun, plus live-fire

fectly. He also brought along his new sup- demonstrations both with and without Jim’s JMB Distribution

pressor. It, too, was quite impressive and new suppressor. The CD even includes 4291 Valley Quail S.

quiet even when firing standard super-sonic complete assembly and disassembly proce- Westerville, Ohio 43081

9mm ammunition. dures. The cost of the CD is $10.00 and is

28 The Small Arms Review • Vol. 9 No. 5 • February 2006

Вам также может понравиться

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsОт EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsРейтинг: 5 из 5 звезд5/5 (3)

- Sten Building BookletДокумент22 страницыSten Building Bookletpamrick100% (1)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.От EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Рейтинг: 5 из 5 звезд5/5 (1)

- Sterling mk4 SMG PDFДокумент24 страницыSterling mk4 SMG PDFDejan BuckicОценок пока нет

- Nangant Pistol HistoryДокумент67 страницNangant Pistol Historygorlan100% (1)

- Weaponeer Forums - STEN MK II BuildДокумент221 страницаWeaponeer Forums - STEN MK II Buildcrbspoa93% (15)

- Firearms - SMG and MG Reciever BlueprintsДокумент40 страницFirearms - SMG and MG Reciever Blueprintsbrowar44485% (53)

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRОт EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRОценок пока нет

- Blueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsДокумент8 страницBlueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsNorm80% (10)

- Barrel Fitting by Harold HoffmanДокумент114 страницBarrel Fitting by Harold HoffmanNorm100% (7)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunОт EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunОценок пока нет

- UZI SMG ReceiverДокумент7 страницUZI SMG Receiverbrowar444100% (7)

- UZI Bolt InfoДокумент6 страницUZI Bolt InfoNester Tovar100% (12)

- Post 4 23085 M6 Scout InfoДокумент32 страницыPost 4 23085 M6 Scout InfoMike Nichlos100% (2)

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunОт EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunРейтинг: 5 из 5 звезд5/5 (2)

- Puma M1887 Lever Shotgun ManualДокумент24 страницыPuma M1887 Lever Shotgun Manualesporadico123100% (1)

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2Документ18 страницTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2browar444Оценок пока нет

- MP44 BlueprintsДокумент90 страницMP44 BlueprintsNorm100% (8)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОт EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОценок пока нет

- Sten Blueprints Parts Mk2 AДокумент22 страницыSten Blueprints Parts Mk2 Aapi-374043498% (43)

- Practical Guide to the Operational Use of the UZI Submachine GunОт EverandPractical Guide to the Operational Use of the UZI Submachine GunОценок пока нет

- Overall Length 6Документ6 страницOverall Length 6angelines12350% (2)

- Building a Home Defense Remington 870 ShotgunОт EverandBuilding a Home Defense Remington 870 ShotgunРейтинг: 3.5 из 5 звезд3.5/5 (5)

- Bolt Action 3Документ10 страницBolt Action 3browar444100% (2)

- The 10mm Automatic - by Chuck HawksДокумент2 страницыThe 10mm Automatic - by Chuck Hawksblowmeasshole1911Оценок пока нет

- Antique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsОт EverandAntique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Sten Sten Trigger Assembly, Select: From Wikipedia, The Free EncyclopediaДокумент14 страницSten Sten Trigger Assembly, Select: From Wikipedia, The Free EncyclopediaJohn H. Wood100% (1)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsОт EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsОценок пока нет

- The English Sten Sub Machine Gun ExplainedДокумент11 страницThe English Sten Sub Machine Gun Explainedknockelflies100% (3)

- A History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityОт EverandA History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityРейтинг: 4 из 5 звезд4/5 (1)

- Firearms - Blueprint - Sten MK III Sub Machine Gun Receiver BondДокумент1 страницаFirearms - Blueprint - Sten MK III Sub Machine Gun Receiver Bondanjan971% (14)

- The Handloader's Manual of Cartridge ConversionsОт EverandThe Handloader's Manual of Cartridge ConversionsРейтинг: 5 из 5 звезд5/5 (1)

- Browning Round Slide PistolДокумент9 страницBrowning Round Slide PistolHarrie Nak100% (2)

- Gunsmithing the AR-15, Vol. 3: The Bench ManualОт EverandGunsmithing the AR-15, Vol. 3: The Bench ManualРейтинг: 2.5 из 5 звезд2.5/5 (4)

- FN ReceiverДокумент1 страницаFN ReceiverNester Tovar100% (2)

- Practical Guide to the Operational Use of the HK69A1 Grenade LauncherОт EverandPractical Guide to the Operational Use of the HK69A1 Grenade LauncherОценок пока нет

- Sten mk2 Complete Machine InstructionsДокумент24 страницыSten mk2 Complete Machine Instructionsmic2996% (83)

- Proclamation: The Act of Declaration of Philippine IndependenceДокумент8 страницProclamation: The Act of Declaration of Philippine IndependencemaryaniОценок пока нет

- Guardian Field Guide With House RulesДокумент10 страницGuardian Field Guide With House RulesBenguin Oliver MasonОценок пока нет

- Mechanical Principles (1st CH)Документ8 страницMechanical Principles (1st CH)sanchitapanda0401Оценок пока нет

- Practical Guide to the Operational Use of the M79 Grenade LauncherОт EverandPractical Guide to the Operational Use of the M79 Grenade LauncherОценок пока нет

- DSKH Ngan Hang Techcombank Vay 330Документ17 страницDSKH Ngan Hang Techcombank Vay 330giauvinhomesОценок пока нет

- Da Curated Archive 2021-02-23Документ14 страницDa Curated Archive 2021-02-23Bruce Williams100% (2)

- ROTC REVIEWER Military Chuchu OnlyДокумент5 страницROTC REVIEWER Military Chuchu OnlyErille Julianne (Rielianne)Оценок пока нет

- Handloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesОт EverandHandloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesОценок пока нет

- Petition Urging Governors To Protect Medical Cannabis AccessДокумент70 страницPetition Urging Governors To Protect Medical Cannabis AccessMPPОценок пока нет

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopОт EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopРейтинг: 5 из 5 звезд5/5 (3)

- Samples of Book ReviewДокумент16 страницSamples of Book ReviewAmben Victoria100% (1)

- Ken RoscoeДокумент5 страницKen RoscoeOwaisОценок пока нет

- The Essential M1 Garand: A Practical and Historical Guide for Shooters and CollectorsОт EverandThe Essential M1 Garand: A Practical and Historical Guide for Shooters and CollectorsОценок пока нет

- BeastДокумент4 страницыBeastMagikОценок пока нет

- Reaction Paper in General LunaДокумент2 страницыReaction Paper in General LunaDesiree VenturaОценок пока нет

- Practical Guide to the Operational Use of the TT-33 Tokarev PistolОт EverandPractical Guide to the Operational Use of the TT-33 Tokarev PistolРейтинг: 5 из 5 звезд5/5 (2)

- Cavite Mutiny 1872.pinakafinalДокумент27 страницCavite Mutiny 1872.pinakafinalPEÑAS, CHARY ANN C.80% (5)

- Midterm Report Period of Active RevolutionДокумент19 страницMidterm Report Period of Active Revolutionkmangelica oritОценок пока нет

- Hatcher's Notebook: A Standard Reference for Shooters, Gunsmiths, Ballisticians, Historians, Hunters and CollectorsОт EverandHatcher's Notebook: A Standard Reference for Shooters, Gunsmiths, Ballisticians, Historians, Hunters and CollectorsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Custname Citizent Id BirthДокумент3 129 страницCustname Citizent Id BirthBlack Sheep (BlackSheep 黑羊)Оценок пока нет

- First Cry of RebellionДокумент3 страницыFirst Cry of RebellionLorjie Bargaso BationОценок пока нет

- Deadzone RulebookДокумент84 страницыDeadzone RulebookTrixyblueeyesОценок пока нет

- 101 Questions About RIzalДокумент7 страниц101 Questions About RIzalAmira Fatmah Quilapio83% (24)

- 圖解雞尾酒技法 1Документ25 страниц圖解雞尾酒技法 1Ceci LauОценок пока нет

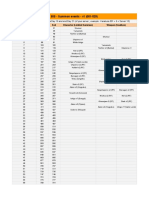

- BIS - Summon Events - v1 (001-525) : Event Begin End Character (Limited Summon) Weapon (Soulbox)Документ3 страницыBIS - Summon Events - v1 (001-525) : Event Begin End Character (Limited Summon) Weapon (Soulbox)Zidan Alma DiwaОценок пока нет

- Sihinayakda Obe Adare - Pavithra SamarasekaraДокумент130 страницSihinayakda Obe Adare - Pavithra Samarasekaraandrew smith0% (1)

- Je Sais Qui Je Suis de Yacouba Isaac Zida PDFДокумент330 страницJe Sais Qui Je Suis de Yacouba Isaac Zida PDFLogan MossОценок пока нет

- WW 3Документ12 страницWW 3ayesha ziaОценок пока нет

- CNDD Joint Readiness Reporting SystemДокумент9 страницCNDD Joint Readiness Reporting SystemJomille Ferraren CernaОценок пока нет

- "Poppy" Pete Buttigieg's Military Records 22-PagesДокумент22 страницы"Poppy" Pete Buttigieg's Military Records 22-PagesHarry the Greek100% (6)

- Battlemech Manual: Full ErrataДокумент17 страницBattlemech Manual: Full ErrataManlio CipulloОценок пока нет

- Brodie - Atom Bomb As Policy MakerДокумент18 страницBrodie - Atom Bomb As Policy MakerradetzkyОценок пока нет

- AIAA - German Marine & Transport of World War IIДокумент100 страницAIAA - German Marine & Transport of World War IIavatar152000Оценок пока нет

- Nosaka Sanzo, El Comunista EstimableДокумент7 страницNosaka Sanzo, El Comunista EstimableEnn MarloweОценок пока нет

- Indrakshi StotramДокумент4 страницыIndrakshi Stotramhamsasoham100% (2)

- ??????? ???? 4 ??????? ??????????? ?? ??????????Документ85 страниц??????? ???? 4 ??????? ??????????? ?? ??????????MAslah Kader BoonОценок пока нет

- SuppressorsОт EverandSuppressorsEditors of RECOIL MagazineОценок пока нет

- Concealed Carry Class: The ABCs of Self-Defense Tools and TacticsОт EverandConcealed Carry Class: The ABCs of Self-Defense Tools and TacticsОценок пока нет

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 5 из 5 звезд5/5 (1)

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 4.5 из 5 звезд4.5/5 (285)

- Prepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideОт EverandPrepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)От EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Рейтинг: 3.5 из 5 звезд3.5/5 (2)

- The Scrambler's Dozen: The 12 shots every Golfer Needs to Shoot Like the ProsОт EverandThe Scrambler's Dozen: The 12 shots every Golfer Needs to Shoot Like the ProsРейтинг: 5 из 5 звезд5/5 (1)