Академический Документы

Профессиональный Документы

Культура Документы

Turbo Carb

Загружено:

alphatoolsИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Turbo Carb

Загружено:

alphatoolsАвторское право:

Доступные форматы

Solid Carbide High Performance End Mills for machining complex,

contour shapes in tough and hardened mold & die steels.

• Designed for high speed rough improves wear resistance and

and finish milling of mold and toughness

die steels up to 60 Rc • Ti-NAMITE-A (AlTiN) coated

Suggestions for using • Application specific carbide for maximum heat and wear

Turbo-Carb® End Mills l1

resistance

l2 l3

• Helical ball gashing for

• Pressurized air with oil extends d1 d2 improved shearing action

tool life in materials <40 Rc • Extended reach capability

• Use dry air when finish milling or R ± 0.0005 (0.0127mm)

• Rigid construction

roughing materials harder than

40 Rc

• Flood coolant is not

Fractional

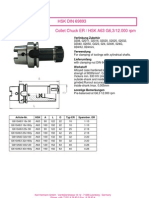

Turbo-Carb® - Series 56B - 2 Flute - Ball End - Extended Reach

recommended Ti-NAMITE-A

Cutting Length Overall Shank (AlTiN)

• The Z-level cutting method and Diameter of Cut Length Diameter Neck EDP

climb milling extend tool life in d 1 l2 l1 d2 l3 No.

roughing applications 1/32 1/32 3 1/4 8º 20’ 1/32 93272

1/16 1/16 3 1/4 7º 40’ 1/16 93273

• Helical interpolation is the 3/32 3/32 3 1/4 6º 50’ 3/32 93274

preferred entry 1/8 1/8 3 1/4 6º 1/8 93275

method. Avoid 3/16 3/16 3 1/4 3º 35’ 3/16 93276 Tolerances (inch)

direct plunging 1/4 1/4 3 1/2 1/4 – 1/4 93277 Diameter d1 d2

5/16 5/16 4 5/16 – 5/16 93278 1/32 – 3/32 +.0000/–.0010 –.0001/–.0003

• Attention to 3/8 3/8 4 3/8 – 3/8 93279 > 3/32 – 1/4 +.0000/–.0012 –.0001/–.0003

programming 1/2 1/2 4 1/2 1/2 – 1/2 93280 > 1/4 – 3/8 +.0000/–.0016 –.0001/–.0003

details, tool holders, 5/8 5/8 5 1/2 5/8 – 5/8 93281 > 3/8 – 3/4 +.0000/–.0020 –.0001/–.0004

TIR, & balance 3/4 3/4 6 1/2 3/4 – 3/4 93282

contribute to

additional tool life

• Speed and feed Metric

Turbo-Carb® - Series 56MB - 2 Flute - Ball End - Extended Reach

recommendations

Cutting Length Overall Shank Ti-NAMITE-A

are based on using Diameter of Cut Length Diameter Neck (AlTiN)

the tool tip

mm

d1 l2

mm

l1

mm

d2

mm

l3

mm

EDP

No.

1 1 76 6 8º 10’ 1 91349

1.5 1.5 76 6 7º 45’ 1.5 91350 Tolerances (mm)

2 2 76 6 7º 10’ 2 91351 Diameter d1 d2

2.5 2.5 76 6 6º 35’ 2.5 91352 1 – 2.5 +0,000/–0,025 –0,0025/–0,0075

3 3 76 6 6º 3 91353 > 2.5 – 6 +0,000/–0,030 –0,0025/–0,0075

4 4 76 6 4º 30’ 4 91354 > 6 – 10 +0,000/–0,040 –0,0025/–0,0075

5 5 89 6 2º 30’ 5 91355 > 10 – 20 +0,000/–0,050 –0,0025/–0,0100

6 6 89 6 – 6 91356

8 8 102 8 – 8 91357

10 10 102 10 – 10 91358

12 12 114 12 – 12 91359

16 16 140 16 – 16 91360

20 20 165 20 – 20 91361

22 SGS HIGH PERFORMANCE

Steels < 40 Rc Steels > 40 - 50 Rc Steels > 50 - 60 Rc

Ad = 10% dia Ad = 5% dia Ad = 4% dia

Diameter Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth

1/32 .0031 76,740 .0006 .0016 90,200 .0005 .0013 61,270 .0004

Roughing - Fractional

1/16 .0063 38,065 .0015 .0031 45,745 .0011 .0025 31,190 .0008

3/32 .0094 25,430 .0020 .0047 30,335 .0015 .0038 20,655 .0011

1/8 .0125 19,100 .0030 .0063 22,700 .0023 .0050 15,595 .0017

3/16 .0188 12,720 .0040 .0094 15,170 .0030 .0075 10,395 .0023

1/4 .0250 9,550 .0050 .0125 11,395 .0038 .0100 7,800 .0029

5/16 .0313 7,635 .0060 .0156 9,120 .0050 .0125 6,240 .0038

3/8 .0375 6,365 .0080 .0188 7,585 .0060 .0150 5,200 .0045

1/2 .0500 4,775 .0100 .0250 5,695 .0075 .0200 3,900 .0057

5/8 .0625 3,820 .0110 .0312 4,560 .0080 .0250 3,120 .0060 FORMULAS – FRACTIONAL

3/4 .0750 3,185 .0120 .0375 3,800 .0085 .0300 2,600 .0063 sfm = rpm x .262 x cutting diameter

rpm = sfm x 3.82 / cutting diameter

P (pitch) = up to 40% of dia

feed (inches / minute) = feed per tooth x number of teeth x rpm

Steels < 40 Rc Steels > 40 - 50 Rc Steels > 50 - 60 Rc

Ad = 3% dia Ad = 2% dia Ad = 1% dia cusp height* = (tool diameter / 2) - √ tool diameter2 – pitch2) / 4

Diameter Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth pitch = √ 4 x (cusp height x tool diameter) – 4 x (cusp height2)

1/32 .0010 116,925 .0007 .0006 144,870 .0006 .0003 125,465 .0005

Finishing - Fractional

1/16 .0019 58,370 .0017 .0013 69,595 .0012 .0006 62,680 .0009

3/32 .0030 38,890 .0022 .0019 46,975 .0017 .0010 39,655 .0012

1/8 .0040 29,185 .0033 .0025 35,470 .0025 .0013 30,125 .0019

3/16 .0060 19,455 .0044 .0038 23,495 .0033 .0019 20,340 .0025

1/4 .0075 14,590 .0055 .0050 17,735 .0042 .0025 15,355 .0032

5/16 .0095 11,675 .0066 .0063 14,135 .0055 .0031 12,335 .0042 * on flat surface

3/8 .0110 9,730 .0088 .0075 11,825 .0066 .0038 10,170 .0050 1 suggested maximum

1/2 .0150 7,295 .0110 .0100 8,870 .0082 .0050 7,680 .0063 2 if recommendation exceeds your

5/8 .0200 5,835 .0120 .0125 7,095 .0090 .0063 6,120 .0067 machine limit use the maximum

3/4 .0230 4,865 .0130 .0150 5,645 .0100 .0075 5,120 .0071 available

P (pitch) = dependent on finish requirement (see formulas)

Steels < 40 Rc Steels > 40 - 50 Rc Steels > 50 - 60 Rc

Ad = 10% dia Ad = 5% dia Ad = 4% dia

Diameter Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth

1 .10 60,640 .015 .05 72,285 .015 .04 49,485 .010

1.5 .15 40,400 .030 .08 48,155 .025 .06 32,965 .020

2 .20 30,335 .045 .10 36,160 .035 .08 24,755 .025

2.5 .25 24,265 .050 .13 28,920 .040 .10 19,800 .030

Roughing - Metric

3 .30 20,215 .075 .15 24,100 .055 .12 16,495 .045

4 .40 15,160 .095 .20 18,070 .065 .16 12,370 .050

5 .50 12,125 .100 .25 14,455 .075 .20 9,895 .060

6 .60 10,110 .125 .30 12,050 .095 .24 8,250 .075

8 .80 7,580 .150 .40 9,035 .125 .32 6,185 .095

10 1.0 6,065 .205 .50 7,230 .150 .40 4,950 .115

12 1.2 5,055 .255 .60 6,025 .190 .48 4,125 .145

16 1.6 3,790 .280 .80 4,520 .200 .64 3,095 .150 FORMULAS – METRIC

20 2.0 3,030 .300 1.0 3,615 .215 .80 2,475 .160 m / min = (3.14 x cutting diameter x rpm) / 1000

P (pitch) = up to 40% of dia rpm = (1000 x m / min) / (3.14 x cutting diameter)

feed (mm / minute) = feed per tooth x number of teeth x rpm

Steels < 40 Rc Steels > 40 - 50 Rc Steels > 50 - 60 Rc

Ad = 3% dia Ad = 2% dia Ad = 1% dia cusp height* = (tool diameter / 2) - √ tool diameter2 – pitch2) / 4

Diameter Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth Axial Depth1 rpm2 Feed / Tooth pitch = √ 4 x (cusp height x tool diameter) – 4 x (cusp height2)

1 .03 92,660 .020 .02 112,555 .020 .010 97,030 .010

1.5 .05 61,730 .045 .03 74,980 .030 .015 64,635 .025

2 .06 46,355 .050 .04 56,305 .040 .020 48,540 .030

2.5 .08 37,075 .055 .05 45,035 .045 .025 38,820 .040

3 .09 30,890 .085 .06 37,520 .065 .030 32,345 .050

Finishing - Metric

4 .12 23,165 .100 .08 28,135 .075 .040 24,255 .060

5 .15 18,530 .110 .10 22,505 .085 .050 19,400 .065

6 .18 15,445 .140 .12 18,760 .105 .060 16,175 .080

8 .24 11,580 .170 .16 14,065 .140 .080 12,125 .105

* on flat surface

10 .30 9,265 .225 .20 11,255 .170 .100 9,700 .130

12 .36 7,720 .280 .24 9,380 .210 .120 8,085 .160 1 suggested maximum

2 if recommendation exceeds your

16 .48 5,790 .305 .32 7,035 .230 .160 6,065 .170

machine limit use the maximum

20 .60 4,635 .320 .40 5,630 .255 .200 4,850 .180

available

P (pitch) = dependent on finish requirement (see formulas)

WWW.SGSTOOL.COM 23

Вам также может понравиться

- 214 MAFord Series 158 WEB Revised 17-04-18Документ12 страниц214 MAFord Series 158 WEB Revised 17-04-18Senad GluhačevićОценок пока нет

- Fresamento SharpДокумент16 страницFresamento SharpklismannengelsОценок пока нет

- Forming Taps: The Right Tool at The Right TimeДокумент9 страницForming Taps: The Right Tool at The Right TimeĐức Nguyễn VănОценок пока нет

- HarveyTool MetricДокумент64 страницыHarveyTool MetricPOLISHING MILL TECHОценок пока нет

- Breathers and Filler BreathersДокумент6 страницBreathers and Filler BreathersKukuh Trisno AjiОценок пока нет

- Merkel - Guides-Guide Strip FBДокумент3 страницыMerkel - Guides-Guide Strip FBÖzgür GürkanОценок пока нет

- U 22 XPWDRFWMДокумент20 страницU 22 XPWDRFWMDavidОценок пока нет

- BimetalicasДокумент8 страницBimetalicasLuis LugoОценок пока нет

- XCD DrillBit BrochureДокумент2 страницыXCD DrillBit BrochureebayksОценок пока нет

- Merkel Guide Strip KF: Design NotesДокумент2 страницыMerkel Guide Strip KF: Design NotesCAT CYLINDERОценок пока нет

- 12-25 15MFD 445X 2Документ1 страница12-25 15MFD 445X 2mohammad teimuriОценок пока нет

- Hoist Chains: For Manual and Motor-Driven HoistsДокумент12 страницHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaОценок пока нет

- Somta Tools User Guide PDFДокумент150 страницSomta Tools User Guide PDFAarón MarxellyОценок пока нет

- Dorian Tool Guide No 4Документ72 страницыDorian Tool Guide No 4Arifin DzulkarnainОценок пока нет

- 12-25 15MFD 447X 2Документ1 страница12-25 15MFD 447X 2mohammad teimuriОценок пока нет

- Pramet 2016.2 - en PDFДокумент26 страницPramet 2016.2 - en PDFManish MoghaОценок пока нет

- AS (One Touch)Документ73 страницыAS (One Touch)Singgih KurniawanОценок пока нет

- Air Vacuum & Blow Gun KitДокумент31 страницаAir Vacuum & Blow Gun KitRolando LoayzaОценок пока нет

- Manual Zenner MTKDДокумент3 страницыManual Zenner MTKDDanОценок пока нет

- 2019 PolyMILL Threadmilling EN PDFДокумент14 страниц2019 PolyMILL Threadmilling EN PDFPalade LucianОценок пока нет

- Merkel Wiper As: Design NotesДокумент1 страницаMerkel Wiper As: Design NotesraulОценок пока нет

- b205g - MS Plus - 201601Документ44 страницыb205g - MS Plus - 201601Alexandre SouzaОценок пока нет

- ISCAR. Turning and Threading ToolsДокумент466 страницISCAR. Turning and Threading ToolsJuan Carlos Encalada100% (2)

- The Finishing Touch: Expect More From A Finishing MillДокумент4 страницыThe Finishing Touch: Expect More From A Finishing MillalphatoolsОценок пока нет

- MBD Annular SectionДокумент4 страницыMBD Annular SectionCompra Venta De Maquinaria IndustrialОценок пока нет

- 175 CacДокумент5 страниц175 CacshjefkeОценок пока нет

- TMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofДокумент2 страницыTMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofFernando TovarОценок пока нет

- Cortador Hidraulico de TuberíaДокумент1 страницаCortador Hidraulico de TuberíaSahara BolivarОценок пока нет

- RS CNC Mechanical Manual Assembly-1Документ117 страницRS CNC Mechanical Manual Assembly-1Pedro MartinhoОценок пока нет

- Bollhoff Kobsert (Press In) Insert Catalog PDFДокумент16 страницBollhoff Kobsert (Press In) Insert Catalog PDFClifford BernardОценок пока нет

- Large Bore High Pressure Hydraulic Cylinders SeriesДокумент18 страницLarge Bore High Pressure Hydraulic Cylinders SeriesHYDRAULICGURUОценок пока нет

- Fraise Uncle Phil DescriptionДокумент4 страницыFraise Uncle Phil DescriptionchevallierludovicОценок пока нет

- Conector - TMC2X Connectors - For - Jacketed - Metal - Clad - Cable PDFДокумент2 страницыConector - TMC2X Connectors - For - Jacketed - Metal - Clad - Cable PDFedwinmenaОценок пока нет

- Conector - TMC2X Connectors - For - Jacketed - Metal - Clad - Cable PDFДокумент2 страницыConector - TMC2X Connectors - For - Jacketed - Metal - Clad - Cable PDFedwinmenaОценок пока нет

- Conector TMC2X Connectors For Jacketed Metal Clad CableДокумент2 страницыConector TMC2X Connectors For Jacketed Metal Clad CableedwinmenaОценок пока нет

- Conector TMC2X Connectors For Jacketed Metal Clad CableДокумент2 страницыConector TMC2X Connectors For Jacketed Metal Clad CableedwinmenaОценок пока нет

- 1792 Brochure LPKF Drilling Milling Routing Tools en PDFДокумент4 страницы1792 Brochure LPKF Drilling Milling Routing Tools en PDFperiodoОценок пока нет

- Solid Carbide End MillДокумент33 страницыSolid Carbide End MillLuis PerezОценок пока нет

- Ebara Stainless Steel Centrifugal PumpДокумент3 страницыEbara Stainless Steel Centrifugal PumpHelda MhptОценок пока нет

- Tenaris ConnДокумент12 страницTenaris ConnDanielОценок пока нет

- Magnum: Rock BitsДокумент1 страницаMagnum: Rock Bitsmohammad teimuriОценок пока нет

- Snap Tite 75sДокумент4 страницыSnap Tite 75sDavid RossОценок пока нет

- 01 Coalescer Elements CombinedДокумент14 страниц01 Coalescer Elements Combinedeino6622Оценок пока нет

- Turbine Blade MachiningДокумент8 страницTurbine Blade MachiningZeeshan HameedОценок пока нет

- Insert Shape ... : R S C T DДокумент11 страницInsert Shape ... : R S C T DskidamdnevnoОценок пока нет

- Dynadet-C3-25ms TDS 2019-04-04 en UKДокумент2 страницыDynadet-C3-25ms TDS 2019-04-04 en UKpepeОценок пока нет

- Critical Equipment Fabrication GuideДокумент103 страницыCritical Equipment Fabrication Guidemayank pandyaОценок пока нет

- Ti NAMITEДокумент2 страницыTi NAMITEalphatoolsОценок пока нет

- Series: Speed Controller With One-Touch FittingДокумент68 страницSeries: Speed Controller With One-Touch FittingTro HoaОценок пока нет

- Chemical Comparison ListДокумент6 страницChemical Comparison ListMuhd Khir RazaniОценок пока нет

- Billet: Direct Cast Billets For Long Steel ProductsДокумент6 страницBillet: Direct Cast Billets For Long Steel ProductsMada TetoОценок пока нет

- Magnum: Rock BitsДокумент1 страницаMagnum: Rock Bitsmohammad teimuriОценок пока нет

- New - Vargus SpotlightДокумент6 страницNew - Vargus SpotlightDedik HandokoОценок пока нет

- Alfa Laval Shutter Valve Product Leaflet PDFДокумент4 страницыAlfa Laval Shutter Valve Product Leaflet PDFJohn Michea CortesОценок пока нет

- LKRK Static Spray Balls Product LeafletДокумент4 страницыLKRK Static Spray Balls Product LeafletalejandroОценок пока нет

- Top Hammer Drill - Productos - Furukawa Rock DrillДокумент1 страницаTop Hammer Drill - Productos - Furukawa Rock DrillMiguel FiallosОценок пока нет

- HC - Range-Overview PDFДокумент4 страницыHC - Range-Overview PDFKique Angeles100% (1)

- Magnum: Rock BitsДокумент1 страницаMagnum: Rock Bitsmohammad teimuriОценок пока нет

- Scheda Tecnica - Cartella SpecialeДокумент1 страницаScheda Tecnica - Cartella Specialemassi.95Оценок пока нет

- DELFERДокумент81 страницаDELFERalphatoolsОценок пока нет

- Z-CARB MD SpeedFeedДокумент1 страницаZ-CARB MD SpeedFeedalphatoolsОценок пока нет

- SAITДокумент166 страницSAITalphatoolsОценок пока нет

- The Finishing Touch: Expect More From A Finishing MillДокумент4 страницыThe Finishing Touch: Expect More From A Finishing MillalphatoolsОценок пока нет

- Z-Carb Original End Mills: Revolutionizes MillingДокумент4 страницыZ-Carb Original End Mills: Revolutionizes MillingalphatoolsОценок пока нет

- Z-Carb JetStream SpeedFeedДокумент2 страницыZ-Carb JetStream SpeedFeedalphatoolsОценок пока нет

- Z-Carb Corner Radius SpeedFeedДокумент2 страницыZ-Carb Corner Radius SpeedFeedalphatoolsОценок пока нет

- Osborn EZ-Flex CatalogueДокумент1 страницаOsborn EZ-Flex CataloguealphatoolsОценок пока нет

- Ti NAMITEДокумент2 страницыTi NAMITEalphatoolsОценок пока нет

- Osborn Novoflex-B CatalogueДокумент1 страницаOsborn Novoflex-B CataloguealphatoolsОценок пока нет

- VDI enДокумент110 страницVDI enalphatoolsОценок пока нет

- HPC Flyer UnzippedДокумент8 страницHPC Flyer UnzippedalphatoolsОценок пока нет

- Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdДокумент4 страницыIce-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdalphatoolsОценок пока нет

- S20x2 Deckel enДокумент9 страницS20x2 Deckel enalphatools100% (1)

- DIN 69871 enДокумент69 страницDIN 69871 enalphatoolsОценок пока нет

- MAS-BT enДокумент62 страницыMAS-BT enalphatoolsОценок пока нет

- HSK DIN 69893 enДокумент29 страницHSK DIN 69893 enalphatoolsОценок пока нет

- Pull Studs enДокумент8 страницPull Studs enLLОценок пока нет

- Threading ToolsДокумент9 страницThreading ToolsalphatoolsОценок пока нет

- DIN 2080 enДокумент45 страницDIN 2080 enalphatoolsОценок пока нет

- Powerbor DrillsДокумент6 страницPowerbor DrillsalphatoolsОценок пока нет

- 199437-Unit 4Документ36 страниц199437-Unit 4Yeswanth rajaОценок пока нет

- (X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Документ9 страниц(X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Bharath KumarОценок пока нет

- Address MappingДокумент26 страницAddress MappingLokesh KumarОценок пока нет

- MSDS - Tuff-Krete HD - Part DДокумент6 страницMSDS - Tuff-Krete HD - Part DAl GuinitaranОценок пока нет

- COOKERY10 Q2W4 10p LATOJA SPTVEДокумент10 страницCOOKERY10 Q2W4 10p LATOJA SPTVECritt GogolinОценок пока нет

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsДокумент2 страницыIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisОценок пока нет

- WEEK6 BAU COOP DM NextGen CRMДокумент29 страницWEEK6 BAU COOP DM NextGen CRMOnur MutluayОценок пока нет

- ICSI-Admit-Card (1) - 230531 - 163936Документ17 страницICSI-Admit-Card (1) - 230531 - 163936SanjayОценок пока нет

- The Electricity Act - 2003Документ84 страницыThe Electricity Act - 2003Anshul PandeyОценок пока нет

- Banjara EmbroideryДокумент34 страницыBanjara EmbroideryKriti Rama ManiОценок пока нет

- Ytrig Tuchchh TVДокумент10 страницYtrig Tuchchh TVYogesh ChhaprooОценок пока нет

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyДокумент58 страницSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiОценок пока нет

- DesalinationДокумент4 страницыDesalinationsivasu1980aОценок пока нет

- Allan ToddДокумент28 страницAllan ToddBilly SorianoОценок пока нет

- TSR KuДокумент16 страницTSR KuAngsaОценок пока нет

- Lending OperationsДокумент54 страницыLending OperationsFaraz Ahmed FarooqiОценок пока нет

- Supergrowth PDFДокумент9 страницSupergrowth PDFXavier Alexen AseronОценок пока нет

- How To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFДокумент35 страницHow To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFCaroline NobreОценок пока нет

- Oracle FND User APIsДокумент4 страницыOracle FND User APIsBick KyyОценок пока нет

- General Diesel Engine Diagnostic Guide PDFДокумент3 страницыGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3Оценок пока нет

- Audit On ERP Implementation UN PWCДокумент28 страницAudit On ERP Implementation UN PWCSamina InkandellaОценок пока нет

- Interruptions - 02.03.2023Документ2 страницыInterruptions - 02.03.2023Jeff JeffОценок пока нет

- Pneumatic Fly Ash Conveying0 PDFДокумент1 страницаPneumatic Fly Ash Conveying0 PDFnjc6151Оценок пока нет

- Level 3 Repair: 8-1. Block DiagramДокумент30 страницLevel 3 Repair: 8-1. Block DiagramPaulo HenriqueОценок пока нет

- Linux For Beginners - Shane BlackДокумент165 страницLinux For Beginners - Shane BlackQuod Antichristus100% (1)

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaДокумент3 страницыArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarОценок пока нет

- Catalogo AWSДокумент46 страницCatalogo AWScesarОценок пока нет

- X-17 Manual Jofra PDFДокумент124 страницыX-17 Manual Jofra PDFBlanca Y. Ramirez CruzОценок пока нет

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementДокумент33 страницыADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- SCDT0315 PDFДокумент80 страницSCDT0315 PDFGCMediaОценок пока нет