Академический Документы

Профессиональный Документы

Культура Документы

Welding Procedure Specification Sample

Загружено:

ezdi20Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding Procedure Specification Sample

Загружено:

ezdi20Авторское право:

Доступные форматы

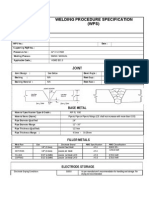

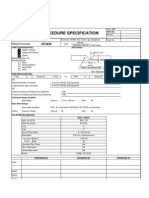

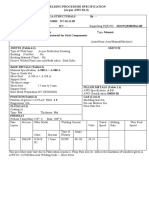

Welding Procedure Specification (WPS)

Code: AWS D1.1 Company Name: www.WPSAmerica.com Address: info@WPSAmerica.com, 1 (877) 977-9353 Identification #:

GMAW-DEMO

Sheet 1 of 2

Is WPS Prequalified?

Yes

Welding Process:

GMAW

Process Type:

Semi-Automatic

Position:

Flat

Supporting PQR No.(s):

Prequalified

Base Metal Part I (Material Spec., type or grade):

Group I and II of Table 3.1-AWS D1.1

Base Metal Part II (Material Spec., type or grade):

Group I and II of Table 3.1-AWS D1.1

Thickness*/Pipe Diameter:

Groove or Fillet Range: T>=6 mm (1/4 in.) * If Prequalified, qualified range as shown in Sketch

Filler Metals: AWS Classification*/AWS Specification:

E70C-6M H4 A5.18 * Electrode-Flux Class. (SAW)

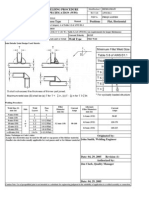

Joint Details/Sketch:

Joint Design Used (Design information for Prequalified WPS as shown in Sketch):

Root Opening G: mm (in) 0 Root Face RF: >=3 mm (1/8 in.) Groove Angle: 60 Radius (J-U): n/a

Weld Type:

Partial Joint Penetration Groove Weld

Joint Type:

Butt Joint Corner Joint

Backing Option:

Welded without backing

Backing Material:

n/a

Back Gouging Method:

n/a

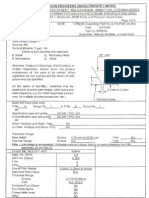

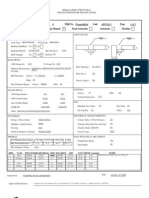

Identification #: GMAW-DEMO

Sheet 2 of 2

Electrical Characteristics: Current Type/Polarity: Transfer Mode (GMAW): Tungsten Electrode (GTAW):

Type: N/A Size: n/a

Shielding:

DCEP Spray Gas Composition (Flux for SAW): Ar + 5 to 15% CO2 Gas Flow Rate: 40 to 50 CFH Gas Cup Size: 5/8 in.

Welding Procedure

Weld Pass Layer(s) No. 1 1 to 2 2 to n Filler Metal Diameter mm(in) 1 GMAW E70C-6M H4 1.4 mm (0.052) 2 to 3 GMAW E70C-6M H4 1.4 mm (0.052) 3 to n GMAW E70C-6M H4 1.4 mm (0.052) Filler Metal Process Classification Current Wire Feed Current Travel Volts Type& Speed Amps Speed (in/min) Polarity (in/min) 200-250 200-250 270-300 DCEP DCEP DCEP 200-250 200-250 270-320 25-27 25-27 26-28 10-14 10-14 12-18 Remarks or Heat Input Root Pass Fill Pass Weld Size >= 10 mm (3/8 in.)

Technique:

Stringer or Weave Bead: Stringer Bead Initial/ Interpass Cleaning: Wire Brush, Grind Number of Electrodes: Single Electrode Spacing: Longitudinal: n/a Lateral: n/a Angle: n/a Contact Tube to Work Distance: 1 to1-1/8 in. Peening: n/a

Heat Treatment:

Preheat Temp., Min C (F): 0 to 10 (C)-Table 3.2 of AWS D1.1 Postweld Heat Treatment: Temp. C (F): n/a Interpass Temp., Min/ Max C (F): 0 to 10 (C)-Table 3.2 of AWS D1.1 Time: n/a

Additional Notes:

The end of contact tube recommended to be recessed in the cup nozzle at least 6 mm (1/4 in.)

Manufacturer/ Contractor Welding Engineer:

Authorized by:

Name: Weld Guy Title: Welding Engineer Date: 12/12/2005

Name: John Smith Title: QA Manager Date: 12/12/2005

Вам также может понравиться

- Smaw Fillet Aws d1.1Документ1 страницаSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Welding Procedure Specification Pipe - 6GДокумент3 страницыWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- Welding Procedure Specification For 24'' PipeДокумент2 страницыWelding Procedure Specification For 24'' Pipeenels77100% (1)

- Welding Procedure SpecificationДокумент21 страницаWelding Procedure Specificationboypardede100% (7)

- PQR FormatДокумент2 страницыPQR Formatravi0009880% (5)

- Welding Procedure Specification - TemplateДокумент2 страницыWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- How To Write A Welding Procedure SpecificationДокумент14 страницHow To Write A Welding Procedure Specificationnizam1372100% (2)

- AWS D1.1 - Example PQR & WPS DocumentsДокумент4 страницыAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Qualification of Welding Procedure Specification FCДокумент14 страницQualification of Welding Procedure Specification FCmister pogi100% (4)

- Wps PQR Aws d11 FormДокумент2 страницыWps PQR Aws d11 Formflakosisas100% (1)

- Welding ProcedureДокумент11 страницWelding ProcedureGFDSGSRTGTRH100% (1)

- Welding Procedure PreparationДокумент122 страницыWelding Procedure Preparationthe_badass1234100% (21)

- WPS PQR WPQ PeiplДокумент16 страницWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Fabrication ProcedureДокумент3 страницыFabrication ProcedureAjay G GopalОценок пока нет

- 6GR WPS PQRДокумент15 страниц6GR WPS PQRKiukStaks100% (6)

- WPSДокумент3 страницыWPSKhurram Burjees100% (1)

- Welding Procedure SpecificationДокумент101 страницаWelding Procedure SpecificationOsman Gone Rana63% (8)

- Sample Welding Procedure Specification (WPS) FormДокумент1 страницаSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- WPS GTAW Stainless SteelДокумент2 страницыWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS For Structure Mild Steel Fillet Weld PDFДокумент2 страницыWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniОценок пока нет

- Guide To Writing A Welding Procedure Specification - December 2015Документ23 страницыGuide To Writing A Welding Procedure Specification - December 2015arnoldbatista55100% (2)

- Fabrication Engineer Job Duties and ResponsibilitiesДокумент2 страницыFabrication Engineer Job Duties and ResponsibilitiesRAKHEE RICHHARIA100% (1)

- ASME 9 - CalculatorДокумент2 страницыASME 9 - CalculatorEmel Besir100% (1)

- Wps For Aluminium WeldingДокумент8 страницWps For Aluminium Weldingvishal bailur50% (2)

- WPS GmawДокумент2 страницыWPS Gmawasikur100% (6)

- Welder Quality ManualДокумент36 страницWelder Quality ManualJonОценок пока нет

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- WPS & PQRДокумент46 страницWPS & PQRJohn Candidate CIns88% (8)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesДокумент9 страницASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajОценок пока нет

- Back Gouging ProcedureДокумент8 страницBack Gouging Proceduremahi1437100% (1)

- WPS E6013+e7018Документ2 страницыWPS E6013+e7018Anvesh Vaddi100% (1)

- WPS PQRДокумент23 страницыWPS PQRHashim Khan88% (8)

- Generalized Guidelines For Structural Steel Welding InspectionДокумент19 страницGeneralized Guidelines For Structural Steel Welding InspectionHariPrasath100% (1)

- A 36 WPSДокумент2 страницыA 36 WPSNaqqash Sajid100% (1)

- WPS (AsmeДокумент8 страницWPS (AsmeMohammad Elhedaby100% (6)

- Welding Procedure Specification Sample - New EditionДокумент2 страницыWelding Procedure Specification Sample - New EditiondanteОценок пока нет

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Документ4 страницыPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluОценок пока нет

- Procedure Qualification SpecificationДокумент4 страницыProcedure Qualification Specificationriyas.hvacworkОценок пока нет

- WPS - D1.1Документ1 страницаWPS - D1.1Nam_HitechОценок пока нет

- WPS - Merd-01Документ3 страницыWPS - Merd-01Phuong NguyenОценок пока нет

- Manual Structural WeldingДокумент12 страницManual Structural WeldingwalitedisonОценок пока нет

- P 91 - Welding WPSДокумент2 страницыP 91 - Welding WPSSuhailshah123475% (4)

- Welding Procedure Specification PresentasiДокумент3 страницыWelding Procedure Specification PresentasiHASIM HASIMОценок пока нет

- Welding Procedure Specification - Kel 3Документ4 страницыWelding Procedure Specification - Kel 3Helmi KusumaОценок пока нет

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Документ2 страницыWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyОценок пока нет

- WPS P91Документ6 страницWPS P91JoseAlbertoNeyraОценок пока нет

- P91 WPSДокумент6 страницP91 WPSPepe SagitarioОценок пока нет

- P91 Profile WpsДокумент6 страницP91 Profile WpsManzar KhanОценок пока нет

- WPS - 018Документ12 страницWPS - 018MAT-LIONОценок пока нет

- Welding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) SketchДокумент1 страницаWelding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) Sketchoomoom0% (1)

- WPS - 017Документ12 страницWPS - 017MAT-LIONОценок пока нет

- APSM WPS 008R Rev. 0Документ3 страницыAPSM WPS 008R Rev. 0Amir NorОценок пока нет

- WPSДокумент2 страницыWPSJuli Agus50% (2)

- WPS GTAW Stainless SteelДокумент4 страницыWPS GTAW Stainless SteelAnand NarayananОценок пока нет

- PQR-WPS-WPQR XXX Rev 0Документ6 страницPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS PQR A36.20Документ5 страницWPS PQR A36.20gchaves504100% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Manual of Sensorless Brushless Motor Speed Controller: Pentium SeriesДокумент4 страницыManual of Sensorless Brushless Motor Speed Controller: Pentium Seriesfosavo5839Оценок пока нет

- ETR Series: A Full Spectrum of Products To Solve Your Application NeedsДокумент106 страницETR Series: A Full Spectrum of Products To Solve Your Application Needs周小安Оценок пока нет

- 5 Contracting Activity and Technical Staff RequirementsДокумент2 страницы5 Contracting Activity and Technical Staff RequirementsDaniyar KussainovОценок пока нет

- Chillers VoltasДокумент4 страницыChillers Voltasanil shuklaОценок пока нет

- The 10 Most Famousfilipino Artists and Their MasterworksДокумент3 страницыThe 10 Most Famousfilipino Artists and Their MasterworksGina MagtibayОценок пока нет

- Valdez, Shenny RoseДокумент3 страницыValdez, Shenny Roseyeng botzОценок пока нет

- Terminals of Ecm: E3 E4 E5 E6Документ2 страницыTerminals of Ecm: E3 E4 E5 E6jeremih alhegn100% (1)

- Synthesis Essay Coming To Grips With GenesisДокумент11 страницSynthesis Essay Coming To Grips With Genesisapi-259381516Оценок пока нет

- Investigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseДокумент5 страницInvestigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseEditor IJTSRDОценок пока нет

- Chapter 7 - Stress - TransformationsДокумент21 страницаChapter 7 - Stress - TransformationsroselleОценок пока нет

- Stopping by Woods On A Snowy EveningДокумент9 страницStopping by Woods On A Snowy EveningJulia Garces100% (2)

- AppearancesДокумент4 страницыAppearancesReme TrujilloОценок пока нет

- Asteroids Prospective EnergyДокумент710 страницAsteroids Prospective EnergySlavica Otovic100% (1)

- Indoor Air Quality Standard Procedures - 2014 RevДокумент12 страницIndoor Air Quality Standard Procedures - 2014 RevFioriAmeliaHathawayОценок пока нет

- Iodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04Документ12 страницIodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04stevgonОценок пока нет

- The Manufacture and Uses of Expanded Clay Aggregate: Thursday 15 November 2012 SCI HQ, LondonДокумент36 страницThe Manufacture and Uses of Expanded Clay Aggregate: Thursday 15 November 2012 SCI HQ, LondonVibhuti JainОценок пока нет

- Quartile1 PDFДокумент2 страницыQuartile1 PDFHanifah Edres DalumaОценок пока нет

- Kami Export - Subject Complements-1 PDFДокумент3 страницыKami Export - Subject Complements-1 PDFkcv kfdsaОценок пока нет

- EXCEL For Pump DesignДокумент2 страницыEXCEL For Pump Designkad-7Оценок пока нет

- Maritime Management SystemsДокумент105 страницMaritime Management SystemsAndika AntakaОценок пока нет

- Notes Transfer of Thermal EnergyДокумент12 страницNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- 2nd APJ Abdul Kalam Essay Writing CompetitionДокумент2 страницы2nd APJ Abdul Kalam Essay Writing CompetitionANURAG SINGHОценок пока нет

- Statics: Vector Mechanics For EngineersДокумент39 страницStatics: Vector Mechanics For EngineersVijay KumarОценок пока нет

- Las Tech Drafting 3Q WKДокумент13 страницLas Tech Drafting 3Q WKClemenda TuscanoОценок пока нет

- Etoricoxib - Martindale 39thДокумент2 страницыEtoricoxib - Martindale 39thCachimbo PrintОценок пока нет

- Hypothesis Testing - IДокумент36 страницHypothesis Testing - Isai revanthОценок пока нет

- Metaphysics of LucretiusДокумент6 страницMetaphysics of LucretiusChristopher BennettОценок пока нет

- Reynold A. Nicholson - The Mystics of IslamДокумент65 страницReynold A. Nicholson - The Mystics of IslamLuminon SamanОценок пока нет

- Sample Appellant BriefДокумент6 страницSample Appellant BriefKaye Pascual89% (9)

- Coffee Quality Manual by Abra Rand Nig Use IДокумент25 страницCoffee Quality Manual by Abra Rand Nig Use IIpungОценок пока нет