Академический Документы

Профессиональный Документы

Культура Документы

Caesar Ii: Technical Reference Manual

Загружено:

Biyaz KalamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Caesar Ii: Technical Reference Manual

Загружено:

Biyaz KalamАвторское право:

Доступные форматы

CAESAR II

Technical

Reference

Manual

CAESAR II, VERSION 4.20

(LAST REVISED 1/2000)

CAESAR II Technical Reference Manual i

Table of Contents

Table of Contents

Introduction T1-1

Overview T1-2

Program Support / User Assistance T1-2

COADE Technical Support T1-3

Configuration and Environment T2-1

Generation of the CAESAR II Configuration File T2-2

Computation Control T2-3

Use Pressure Stiffening T2-3

Missing Mass ZPA T2-3

Bend Axial Shape T2-3

Rod Tolerance (degrees) T2-4

Rod Increment (degrees) T2-4

Alpha Tolerance T2-4

Friction Stiffness T2-4

Friction Normal Force Variation T2-4

Friction Angle Variation T2-5

Friction Slide Multiplier T2-5

WRC-107 Version T2-5

WRC-107 Interpolation Method T2-5

Incore Numerical Check T2-5

Decomposition Singularity Tolerance T2-5

Minimum Wall Mill Tolerance (%) T2-6

Ignore Spring hanger Stiffness T2-6

Hanger Default Restraint Stiffness T2-6

Default Translational Restraint Stiffness T2-6

Default Rotational Restraint Stiffness T2-6

SIFs and Stresses T2-7

Default Code T2-7

Occasional Load Factor T2-7

B31.3 Sustained Case SIF Factor T2-8

Yield Stress Criterion T2-8

Allow Users SIF at Bend T2-9

CAESAR II Technical Reference Manual ii

Table of Contents

Use WRC329 T2-9

Use Schneider T2-10

All Cases Corroded T2-10

Base Hoop Stress On ( ID/OD/Mean/Lams ) T2-10

Use PD/4t T2-10

Add F/A in Stresses T2-11

Add Torsion in SL Stress T2-11

Reduced Intersection T2-11

B31.1(Pre 1980) T2-11

B31.1(Post 1980) T2-11

WRC329 T2-11

ASME Sect. III T2-12

Schneider T2-12

Class 1 Branch Flexibility T2-12

B31.1 Reduced Z Fix T2-12

No RFT/WLT in Reduced Fitting SIFs T2-12

Geometry Directives T2-13

Connect Geometry Through Cnodes T2-13

Auto Node Number Increment T2-13

Minimum Allowed Bend Angle T2-14

Maximum Allowed Bend Angle T2-14

Bend Length Attachment Percent T2-14

Minimum Angle to Adjacent Bend T2-14

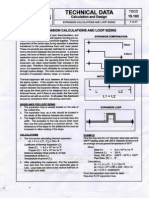

Loop Closure Tolerance T2-14

Horizontal Thermal Bowing Tolerance T2-15

Plot Colors T2-16

Pipes T2-16

Nodes T2-16

Rigids/Bends T2-16

Hangers/Nozzles T2-16

Structure T2-16

Background T2-17

Axes T2-17

Labels T2-17

Highlights T2-17

Displaced Shape T2-17

Stress Level 1 T2-17

Stress Level 2 T2-17

CAESAR II Technical Reference Manual iii

Table of Contents

Stress Level 3 T2-17

Stress Level 4 T2-17

Stress Level 5 T2-17

Stress < Level 1 T2-17

Stress > Level 1 T2-17

Stress > Level 2 T2-17

Stress > Level 3 T2-18

Stress > Level 4 T2-18

Stress > Level 5 T2-18

FRP Pipe Properties T2-19

Use FRP SIF T2-19

Use FRP Flexibilities T2-19

FRP Property Data File T2-20

BS 7159 Pressure Stiffening T2-20

FRP Laminate Type T2-20

FRP Pipe Density T2-21

FRP Alpha (e-06) T2-21

FRP Modulus of Elasticity T2-21

Ratio Shear Mod:Emod T2-21

Axial Strain:Hoop Stress (Ea/Eh*Vh/a) T2-21

Database Definitions T2-22

Structural Database T2-22

Piping Size Specification (ANSI/JIS/DIN/BS) T2-22

Valves and Flanges T2-23

Expansion Joints T2-23

Units File Name T2-23

System Directory Name T2-23

Default Spring Hanger Table T2-23

Enable Data Export to ODBC-Compliant Databases T2-24

Append Reruns to Existing Data T2-24

ODBC Compliant Database Name T2-24

Miscellaneous T2-25

Output Table of Contents T2-25

Output Reports by Load Case T2-25

Displacement Reports Sorted by Nodes T2-25

Time History Animation T2-26

Dynamic Example Input Text T2-26

CAESAR II Technical Reference Manual iv

Table of Contents

Memory Allocated T2-26

User ID T2-26

Disable "File Open" Graphic Thumbnail T2-27

Set/Change Password T2-28

Access Protected Data T2-28

Change Password T2-28

Remove Password T2-28

Units File Operations T2-29

Make Units File T2-29

Review Existing Units File T2-29

Create a New Units File T2-30

Existing File to Start From T2-31

New Units File Name T2-31

View/Edit File T2-31

Convert Input to New Units T2-32

Name of the Input File to Convert T2-32

Name of the Units File to Use T2-32

Name of the Converted File T2-33

Material Database T2-34

Material - Add T2-34

Material - Delete T2-34

Material - Edit T2-34

Number T2-35

Name T2-35

Applicable Piping Code T2-36

Eff, Cf, z T2-36

Density T2-36

Minimum Temperature Curve (A-D) T2-37

FAC T2-37

Cold Elastic Modulus T2-37

Poissons Ratio T2-37

E Mod / Axial T2-37

(Ea/Eh)(Vh/a) T2-37

Shear Modulus T2-38

Temperature T2-38

Exp. Coeff. T2-38

Allowable Stress T2-38

Elastic Modulus T2-38

Yield Stress T2-38

F1, Rr

g T2-38

CAESAR II Technical Reference Manual v

Table of Contents

F2, Rm

g T2-39

F3, Rm

min T2-39

Piping Screen Reference T3-1

Piping Spreadsheet Data T3-2

Help Screens and Units T3-3

From T3-3

To T3-3

DX T3-3

DY T3-3

DZ T3-3

Element Offsets T3-5

Pipe Section Data T3-6

Diameter T3-6

Wt/Sch T3-6

+Mill Tol % T3-7

-Mill Tol % T3-7

Seam-Welded T3-7

Corrosion T3-7

Insul Thk T3-7

Temperatures T3-8

Pressures T3-9

Piping Materials T3-9

Material Name T3-9

Material Properties T3-10

Fiberglass Reinforced Plastic (FRP) T3-10

Densities T3-11

Pipe Density T3-11

Insulation Density T3-11

Fluid Density T3-11

Auxiliary Fields - Component Information T3-12

Bends T3-12

Radius T3-12

Type T3-12

Angle T3-13

Node T3-13

Miter Points T3-13

Fitting Thickness T3-14

Seam-Welded T3-14

Rigid Elements T3-15

Expansion Joints T3-16

Zero Length Expansion Joints T3-16

CAESAR II Technical Reference Manual vi

Table of Contents

Finite Length Expansion Joints T3-16

Effective ID T3-16

SIFs & TEEs T3-17

Input Items Optionally Effecting SIF Calculations T3-18

User-Defined SIFS Anywhere in the Piping System T3-20

Stress Intensification Factors (Details) T3-20

Auxiliary Fields - Boundary Conditions T3-24

Restraints T3-24

Node T3-25

CNode T3-25

Type T3-25

Anchor T3-25

X , Y, or Z T3-25

RX, RY, or RZ T3-26

Guide T3-26

LIM T3-26

XSNB, YSNB, ZSNB T3-26

X2, Y2, Z2 T3-26

XSPR, YSPR, ZSPR T3-26

X (cosx, cosy, cosz) or X (vecx, vecy, vecz) T3-26

RX (cosx, cosy, cosz) or RX (vecx, vecy, vecz) T3-26

XROD, YROD, ZROD T3-26

XROD (COSX, COSY, COSZ) or XROD (VECX, VECY, VECZ) T3-26

Stif T3-27

Gap T3-27

Mu T3-27

Hangers T3-28

Hanger Table T3-28

Hanger/Can Available Space T3-31

Allowable Load Variation (%) T3-32

Rigid Support Displacement Criteria T3-32

Maximum Allowed Travel Limit T3-33

No. Hangers at Location T3-33

Allow Short Range Springs T3-33

Operating Load T3-34

Multiple Load Case Design T3-34

Example Problem of a Multiple Load-Case Spring-Hanger Design T3-35

Free Anchor/Restraint at Node T3-36

Free Code T3-37

Predefined Hanger Data T3-37

Spring Rate and Cold Load T3-38

Re-setting Loads on Existing Spring Hangers T3-38

Nozzle Flexibility - WRC 297 T3-39

CAESAR II Technical Reference Manual vii

Table of Contents

Nozzle Node Number T3-41

Vessel Node Number T3-42

Nozzle Diameter T3-42

Nozzle Wall Thickness T3-42

Vessel Diameter T3-42

Vessel Wall Thickness T3-42

Vessel Reinforcing Pad Thickness T3-42

Distance to Stiffener or Head T3-42

Distance to Opposite Side Stiffener or Head T3-42

Vessel centerline direction vector X, Y, Z T3-42

Vessel Temperature (Optional) T3-43

Vessel Material No. (Optional) T3-43

API 650 NOZZLES T3-44

Nozzle Node Number T3-44

Tank Node Number T3-45

Nozzle Diameter T3-45

Nozzle Wall Thickness T3-45

API-650 Tank Diameter T3-45

API-650 Tank Wall Thickness T3-45

API-650 Reinforcing 1 or 2 T3-45

API-650 Nozzle Height T3-45

API-650 Fluid Height T3-45

API-650 Specific Gravity T3-45

API-650 Tank Coefficient of Thermal Expansion T3-45

API-650 Delta T T3-46

API-650 Tank Modulus of Elasticity T3-46

BS 5500 Nozzles T3-46

Nozzle Node Number T3-47

Vessel Node Number T3-47

Vessel Type Cylinder (0) or Sphere (1) T3-47

Nozzle Diameter T3-47

Vessel Diameter T3-47

Vessel Wall Thickness T3-47

Vessel Reinforcing Pad Thickness T3-47

Distance to Stiffener or Head T3-48

Distance to Opposite-Side Stiffener or Head T3-48

Vessel Centerline Direction Cosines T3-48

Vessel Temperature T3-48

Vessel Material Number T3-48

Displacements T3-49

Auxiliary Fields - Imposed Loads T3-50

Forces and Moments T3-50

Uniform Loads T3-51

CAESAR II Technical Reference Manual viii

Table of Contents

Wind/Wave Loads T3-52

Wind Shape Factor T3-53

Drag Coefficient, Cd T3-53

Added Mass Coefficient, Ca T3-53

Lift Coefficient, Cl T3-53

Marine Growth T3-54

Auxiliary Fields - Piping Code Data T3-55

Allowable Stresses T3-55

Codes T3-56

SC T3-56

SH T3-58

Fn T3-59

Eff T3-59

Sy T3-61

Fac T3-62

Pvar T3-64

Material Fatigue Curves T3-65

Available Commands T3-67

Break Command T3-67

Valve/Flange Database T3-68

Expansion Joint Modeler T3-72

Expansion Joint Modeler Notes T3-76

Expansion Joint Design Notes T3-77

Torsional Spring Rates T3-77

Bellows Application Notes T3-78

Movement Capability T3-78

Spring Forces T3-78

Available Space T3-78

Available Expansion Joint End-Types T3-78

Welded T3-78

Slipon T3-78

WN T3-78

Plate T3-78

Pressure Rating T3-78

Expansion Joint Styles T3-79

Untied T3-79

Tied T3-79

Hinged T3-79

Gimbal T3-80

U-UNIV T3-80

T-UNIV T3-80

Materials T3-80

CAESAR II Technical Reference Manual ix

Table of Contents

Liners T3-81

Covers T3-81

Title Page T3-81

Hanger Data T3-82

No. of Hanger-Design Operating Load Cases T3-83

Calculate Actual Cold Loads T3-83

Allow Short Range Springs T3-83

Allowable Load Variation (%) T3-83

Rigid Support Displacement Criteria T3-84

Maximum Allowed Travel Limit T3-84

Hanger Table T3-84

Multiple Load Case Design Options T3-85

Special Execution Parameters T3-86

Print Forces on Rigids and Expansion Joints T3-86

Print Alphas and Pipe Properties T3-87

Activate Bourdon Effects T3-87

Branch Error and Coordinate Prompts T3-87

Thermal Bowing Delta Temperature T3-88

Liberal Stress Allowable T3-88

Uniform Load in Gs T3-89

Stress Stiffening Due to Pressure T3-89

Ambient Temperature T3-89

FRP Coefficient of Thermal Expansion (x 1,000,000 ) T3-90

FRP Ratio of Shear Modulus/Emod Axial T3-90

FRP Laminate Type T3-90

Bandwidth Optimizer Options T3-90

Combining Independent Piping Systems T3-91

Large Job Includes T3-92

Including Structural Models T3-93

List/Edit Facility T3-94

Block Operations T3-95

Rotate T3-96

Delete T3-96

Duplicate T3-96

Nodes T3-97

Printing an Input Listing T3-98

Input Plotting T3-100

Model Rotation, Panning, and Zooming T3-100

SHFT Option Disabled T3-100

SHFT Option Disabled T3-101

SHFT Option Enabled T3-101

Zooming T3-101

Reset Plot T3-101

CAESAR II Technical Reference Manual x

Table of Contents

Views T3-102

Volume Plotting T3-102

Displaying Element Information T3-102

Expansion Joints and Rigids T3-102

Restraints T3-102

Anchors T3-102

Hangers T3-102

Nozzles T3-102

Bends, Tees T3-103

Forces, Moments, Displacements T3-103

Thicknesses, Diameter, Length, Material Number T3-103

Node Numbers T3-103

Range T3-103

Highlight T3-103

Structural Steel Modeler T4-1

Overview T4-2

General Properties T4-3

Add T4-3

Insert T4-3

Replace T4-3

Delete T4-3

UNITS Specification - UNIT T4-4

Material Identification - MATID T4-5

MATID T4-5

YM T4-5

POIS T4-5

G T4-6

YS T4-6

DENS T4-6

ALPHA T4-6

Section Identification - SECID T4-7

Section ID T4-7

SECID T4-7

Name T4-7

User-Defined T4-8

Area T4-8

Strong T4-8

Weak T4-8

CAESAR II Technical Reference Manual xi

Table of Contents

Polar T4-8

BOXH T4-8

BOXW T4-8

Setting Defaults - DEFAULT T4-10

Setting Nodes in Space - NODE, NFILL, NGEN T4-11

NODE T4-11

NFILL T4-12

NGEN T4-13

n1 T4-13

TO T4-13

BY T4-14

LAST T4-14

NODEINC T4-14

DX,DY,DZ T4-14

Example T4-14

Building Elements - ELEM, EFILL, EGEN, EDIM T4-15

ELEM T4-15

EFILL T4-16

n1 T4-16

TO T4-16

INC T4-16

INCTO T4-17

LAST T4-17

SECID T4-17

MATID T4-17

INCSECID T4-17

INCMATID T4-17

Example T4-17

EGEN T4-18

n1 T4-18

TO T4-18

INC T4-19

INCTO T4-19

LAST T4-19

GENINC T4-19

GENINCTO T4-19

GENLAST T4-19

SECID T4-19

MATID T4-19

INCSECID T4-19

INCMATID T4-19

Example T4-19

CAESAR II Technical Reference Manual xii

Table of Contents

EDIM T4-21

Resetting Element Strong Axis - ANGLE, ORIENT T4-23

ANGLE T4-23

n1 T4-24

ORIENT T4-24

n1 T4-24

TO T4-24

INC T4-24

INCTO T4-24

LAST T4-24

ANGLE T4-25

Examples T4-25

End Connection Information T4-26

Free End Connections - FREE T4-26

n1 T4-26

TO T4-27

INC T4-27

INCTO T4-27

LAST T4-27

Standard Structural Element Connections - BEAMS, BRACES, COLUMNS T4-

28

BEAMS T4-28

Example T4-29

BRACES T4-30

Example T4-31

COLUMNS T4-32

Example T4-33

Defining Global Restraints - FIX T4-34

Examples T4-34

Loads T4-36

Point Loads - LOAD T4-36

Examples T4-36

Uniform Loads - UNIF T4-37

n1 T4-37

TO T4-37

INC T4-38

INCTO T4-38

LAST T4-38

UX,UY,UZ T4-38

Examples T4-38

Gravity Loads - GLOADS T4-39

CAESAR II Technical Reference Manual xiii

Table of Contents

Wind Loads - WIND T4-40

n1 T4-40

TO T4-40

INC T4-40

INCTO T4-41

LAST T4-41

SHAPE T4-41

Examples T4-41

Utilities T4-42

Input Presentation - PLOT, LIST, STAT T4-42

PLOT T4-42

LIST T4-43

Data Processing - STAT T4-45

Structural Databases T4-46

AISC 1977 Database T4-47

AISC 1989 Database T4-51

German 1991 Database T4-57

Australian 1990 Database T4-59

South African 1992 Database T4-60

Korean 1990 Database T4-62

UK 1993 Database T4-63

Controlling the Dynamic Solution T5-1

Dynamic Analysis Input T5-2

Dynamic Analysis Overview T5-3

Random T5-3

Harmonic T5-4

Impulse T5-6

Harmonic Analysis T5-8

Input Excitation Frequencies T5-8

Starting Frequency T5-8

Ending Frequency T5-8

Increment T5-8

Load Cycles T5-10

Harmonic Forces and Displacements T5-11

Force T5-11

Direction T5-11

Phase T5-12

Start Node T5-12

CAESAR II Technical Reference Manual xiv

Table of Contents

Stop Node T5-12

Increment T5-12

Harmonic Displacements T5-14

Displacement T5-14

Direction T5-14

Phase T5-14

Start Node T5-15

Harmonic Displacements at Compressor Flange T5-15

Stop Node T5-15

Response Spectra / Time History Load Profiles T5-17

Time History Definitions T5-17

Name T5-17

Range Type T5-18

Ordinate Type T5-18

Range Interpolation T5-18

Ordinate Interpolation T5-19

EXAMPLE T5-20

Response Spectrum / Time History Profile Data Point Input T5-22

Range T5-22

Ordinate T5-22

Force Response Spectrum Definitions T5-23

Force Spectrum Name T5-23

Maximum Table Frequency T5-23

Number of Points in the Table T5-23

Create Table T5-24

Time T5-24

Force T5-24

Building Spectrum / Time History Load Cases T5-25

Spectrum /Time history Profile T5-25

Factor T5-25

Direction T5-25

Force Set # T5-26

Start Node T5-26

Directives T5-27

Combining Static and Dynamic Results T5-33

Load Case T5-33

Factor T5-33

<Directive Data> T5-34

Spectrum/Time History Force Sets T5-38

Force T5-38

Direction T5-38

Node T5-38

CAESAR II Technical Reference Manual xv

Table of Contents

Force Set # T5-39

Modifying the Dynamic Model T5-43

Mass T5-43

Direction T5-43

Start Node T5-43

Stop Node T5-44

Increment T5-44

Adding Snubbers T5-45

Node T5-45

CNode T5-46

Dynamic Control Parameters T5-47

Analysis Type (Harmonic/Spectrum/Modes/Time-History) T5-49

Harmonic Analysis T5-49

Spectrum Analysis T5-53

Time History T5-57

Static Load Case for Nonlinear Restraint Status T5-61

Stiffness Factor for Friction (0.0-Not Used) T5-62

Max. No. of Eigenvalues Calculated (0-Not used) T5-62

Frequency Cutoff (HZ) T5-65

Closely Spaced Mode Criteria/Time History Time Step (ms) T5-67

Load Duration (Time History or DSRSS Method) (Sec.) T5-67

Damping (Time History or DSRSS) (Ratio of Critical) T5-68

ZPA (Reg. Guide 1.60/UBCGs)/# Time History Output Cases T5-68

Re-use Last Eigensolution T5-71

Spatial or Modal Combination First T5-71

Spatial Combination Method (SRSS/ABS) T5-72

Modal Combination Method (GROUP/10%/DSRSS/ABS/SRSS) T5-72

Grouping Method T5-73

Ten Percent Method T5-73

Double Sum Method (DSRSS) T5-74

Absolute Method T5-75

Square Root of the Sum of the Squares (SRSS) T5-75

Include Pseudostatic (Anchor Movement) Components (Y/N) T5-76

Include Missing Mass Components (Y/N) T5-76

Pseudostatic (Anchor Movement) Comb. Method (SRSS/ABS) T5-76

Missing Mass Combination Method (SRSS/ABS) T5-77

Directional Combination Method (SRSS/ABS) T5-77

Sturm Sequence Check on Computed Eigenvalues (Y/N) T5-77

Advanced Parameters T5-79

Estimated Number of Significant Figures in Eigenvalues T5-79

CAESAR II Technical Reference Manual xvi

Table of Contents

Jacobi Sweep Tolerance T5-79

Decomposition Singularity Tolerance T5-79

Subspace Size (0-Not Used) T5-79

No. to Converge before Shift Allowed (0-Not Used) T5-80

No. of Iterations Per Shift (0-Pgm computed) T5-80

Percent of Iterations Per Shift Before Orthogonalization T5-81

Force Orthogonalization After Convergence (Y/N) T5-81

Use Out-Of-Core Eigensolver (Y/N) T5-81

Frequency Array Spaces T5-81

Pulsation Loads T5-82

Relief Valve Thrust Load Analysis T5-85

Relief Load Synthesis for Gases Greater Than 15 psig T5-85

Line Temperature T5-86

Line Pressure T5-86

ID of Relief Valve Orifice T5-86

ID of Relief Valve Piping T5-86

ID of Vent Stack Piping T5-86

Length of the Vent Stack T5-86

Ratio of Gas-Specific Heats (k) Gas Constant (R) (ft.lbf./lbm./deg.R) T5-87

Does the Vent Pipe Have an Umbrella Fitting (Y/N) T5-87

Should CAESAR II Size the Vent Stack (Y/N) T5-88

Computed Mass Flowrate (Vent Gas) T5-89

Thrust at Valve Pipe/Vent Pipe Interface T5-89

Thrust at the Vent Pipe Exit T5-90

Transient Pressure Rise on Valve Opening T5-90

Transient Pressure Rise on Valve Closing T5-90

Thermodynamic Entropy Limit T5-91

Subsonic Vent Exit Limit T5-91

Valve Orifice Gas Conditions T5-91

Vent Pipe Exit Gas Conditions T5-91

Subsonic Velocity Gas Conditions T5-91

Relief Load Synthesis for Liquids T5-91

Relief Valve or Rupture Disk T5-92

Supply Overpressure T5-92

ID Relief Orifice or Rupture Disk Opening T5-92

ID Relief Exit Piping T5-92

ID Manifold Piping T5-92

ID Supply Header T5-92

Fluid Density T5-93

Length of Relief Exit Piping T5-93

Length of Manifold Piping T5-93

Fluid Bulk Modulus T5-93

CAESAR II Technical Reference Manual xvii

Table of Contents

Supply Header Pipe Wall Thickness T5-93

Output From the Liquid Relief Load Synthesizer T5-93

Computed Mass Flowrate T5-93

Thrust at the End of the Exit Piping T5-93

Thrust at the End of the Manifold Piping T5-94

Transient Pressure Rise on Valve Opening T5-94

Transient Pressure Rise on Valve Closing T5-94

Orifice Flow Conditions T5-94

Exit Pipe End Flow Conditions T5-94

Manifold Pipe End Flow Conditions T5-94

Technical Discussions T6-1

Rigid Element Application T6-2

Rigid Material Weight T6-2

Rigid Fluid Weight T6-2

Rigid Insulation Weight T6-2

Cold Spring T6-4

Expansion Joints T6-8

Hanger Sizing Algorithm T6-10

Spring Design Requirements T6-10

Restrained Weight Case T6-10

Operating Case T6-10

Installed Load Case T6-11

Setting Up the Spring Load Cases T6-11

Constant Effort Support T6-12

Class 1 Branch Flexibilities T6-13

Modeling Friction Effects T6-16

Nonlinear Code Compliance T6-18

Sustained Stresses and Nonlinear Restraints T6-19

Static Seismic Loads T6-22

Wind Loads T6-25

Elevation T6-27

Hydrodynamic (Wave and Current) Loading T6-28

Ocean Wave Particulars T6-29

Applicable Wave Theory Determination T6-30

Pseudo-Static Hydrodynamic Loading T6-31

AIRY Wave Theory Implementation T6-32

Table of Contents

xviii CAESAR II Technical Reference Manual

STOKES Wave Theory Implementation T6-32

Stream Function Wave Theory Implementation T6-33

Ocean Currents T6-33

Technical Notes on CAESAR II Hydrodynamic Loading T6-33

Input: Specifying Hydrodynamic Parameters in CAESAR II T6-37

Current Data T6-37

Wave Data T6-38

Seawater Data T6-39

Piping Element Data T6-39

References T6-40

Evaluating Vessel Stresses T6-41

ASME Section VIII Division 2 - Elastic Analysis of Nozzle T6-41

Procedure to Perform Elastic Analyses of Nozzles T6-43

Description of Alternate Simplified ASME Sect. VIII Div. 2 Nozzle Analysis T6-44

Simplified ASME Sect. VIII Div. 2 Elastic Nozzle Analysis T6-45

Inclusion of Missing Mass Correction T6-46

References T6-49

Fatigue Analysis Using CAESAR II T6-50

Fatigue Basics T6-50

Fatigue Analysis of Piping Systems T6-51

Static Analysis Fatigue Example T6-52

Fatigue Capabilities in Dynamic Analysis T6-61

Creating the .FAT Files T6-63

Calculation of Fatigue Stresses T6-64

Pipe Stress Analysis of FRP Piping T6-66

Underlying Theory T6-66

Micro-Level Analysis T6-66

Mini-Level Analysis T6-71

Macro-Level Analysis T6-72

Implementation of Macro-Level Analysis for Piping Systems T6-74

FRP Analysis Using CAESAR II T6-81

Practical Applications T6-81

Conclusion T6-88

References T6-88

Code Compliance Considerations T6-90

General Notes for All Codes T6-90

Code-Specific Notes T6-94

B31.1 T6-94

B31.3 T6-95

CAESAR II Technical Reference Manual xix

Table of Contents

B31.4 T6-96

B31.4 Chapter IX T6-97

B31.8 T6-98

B31.8 Chapter VIII T6-99

ASME III Subsections NC and ND T6-100

CANADIAN Z662 T6-102

NAVY 505 T6-104

BS806 T6-104

Swedish Method 1 and 2 T6-108

B31.1 (1967) T6-109

Stoomwezen T6-110

RCC-M Subsection C and D T6-110

CODETI T6-111

Norwegian (TBK 5-6) T6-112

FDBR T6-113

BS 7159 T6-113

UKOOA T6-115

Det Norske Veritas (DNV) T6-116

Miscellaneous Processors T7-1

Accounting T7-2

Accounting File Structure T7-7

Batch Stream Processing T7-8

CAESAR II Fatal Error Processing T7-10

Interfaces T8-1

Overview of CAESAR II Interfaces T8-2

CAD Interfaces T8-4

CADWorx/PIPE Link T8-4

DXF AutoCAD Interface T8-4

CADPIPE Interface T8-5

CADPIPE Example Transfer T8-8

General Notes T8-12

Error Code Definitions T8-13

CADPIPE LOG File Discussion T8-13

Section 1Entity Information T8-14

Section 2Segment Information T8-14

Section 3Final CAESAR II Data T8-17

Checking the CADPIPE/CAESAR II Data Transfer T8-17

ComputerVision Interface T8-20

Table of Contents

xx CAESAR II Technical Reference Manual

ComputerVision Interface Prompts T8-20

ComputerVision Neutral File T8-20

CAESAR II Log File T8-21

Checking the ComputerVision/CAESAR II Data Transfer T8-21

Intergraph Interface T8-23

File Name T8-24

Browse T8-24

Minimum Anchor Node T8-24

Maximum Anchor Node T8-24

Starting Node Number T8-24

Node Number Increment T8-24

Filter Out Elements whose Diameter is Less Than T8-24

Remove HA Elements T8-24

Force Consistent Bend Materials T8-25

Include Additional Bend Nodes T8-25

Enable Advanced Element Sort T8-25

Model Tees as 3 Elements T8-25

Model Rotation T8-25

Weight Units T8-25

Insulation Units T8-25

Example Transfer T8-29

Intergraph Data After Element Sort T8-39

Intergraph Data After TEE/Cross Modifications T8-40

Intergraph Data After Valve Modifications T8-41

Intergraph Data After Bend Modifications T8-46

PRO-ISO Interface (Standard) T8-53

PRO-ISO Example Transfer T8-56

Checking the PRO-ISO/CAESAR II Data Transfer T8-58

CATIA/CCPlant Interface T8-59

PCF Interface T8-61

File Name T8-61

Browse T8-61

Starting Node Number T8-61

Node Number Increment T8-62

Condense Tees T8-62

Condense Elbows T8-62

Condense Connected Rigids T8-62

Assume Standard Schedule T8-62

Model Rotation T8-62

Generic Neutral Files T8-63

CAESAR II Neutral File Interface T8-63

Version and Job Title Information T8-63

Control Information T8-64

CAESAR II Technical Reference Manual xxi

Table of Contents

Basic Element Data T8-64

Auxiliary Element Data T8-66

Miscellaneous Data Group #1 T8-73

Units Conversion Data T8-77

Nodal Coordinate Data T8-79

Data Matrix Interface T8-80

Computational Interfaces T8-81

LIQT Interface T8-81

How to Use the CAESAR II / LIQT Interface T8-81

Technical Discussion of LIQT Interface T8-81

Example1 T8-82

Example 2 T8-84

PIPENET Interface T8-86

How to Use The CAESAR II / PIPENET Interface T8-86

Technical Discussion of PIPENET Interface T8-87

File/Set Lists T9-1

CAESAR II File Guide T9-2

CAESAR II Operational (Job) Data Files T9-12

Update History T10-1

CAESAR II Initial Capabilities (12/84) T10-2

CAESAR II Version 1.1S Features (2/86) T10-3

CAESAR II Version 2.0A Features (10/86) T10-4

CAESAR II Version 2.1C Features (6/87) T10-5

CAESAR II Version 2.2B Features (9/88) T10-6

CAESAR II Version 3.0 Features (4/90) T10-7

CAESAR II Version 3.1 Features (11/90) T10-8

Graphics Updates T10-8

Rotating Equipment Report Updates T10-8

WRC 107 Updates T10-8

Miscellaneous Modifications T10-8

CAESAR II Version 3.15 Features (9/91) T10-9

Flange Leakage and Stress Calculations T10-9

WRC 297 Local Stress Calculations T10-9

Stress Intensification Factor Scratchpad T10-9

Miscellaneous T10-9

Table of Contents

xxii CAESAR II Technical Reference Manual

CAESAR II Version 3.16 Features (12/91) T10-10

CAESAR II Version 3.17 Features (3/92) T10-11

CAESAR II Version 3.18 Features (9/92) T10-12

Codes and Databases T10-12

Interfaces Added T10-12

Miscellaneous Changes T10-12

CAESAR II Version 3.19 Features (3/93) T10-14

CAESAR II Version 3.20 Features (10/93) T10-16

CAESAR II Version 3.21 Changes & Enhancements (7/94) T10-18

CAESAR II Version 3.22 Changes & Enhancements (4/95) T10-20

CAESAR II Version 3.23 Changes (3/96) T10-22

CAESAR II Version 3.24 Changes & Enhancements (3/97) T10-23

CAESAR II Version 4.00 Changes and Enhancements (1/98) T10-26

CAESAR II Version 4.10 Changes and Enhancements (1/99) T10-27

Creating the .FAT Files T-AA-1

Calculation of Fatigue Stresses T-AB-1

Chapter 1:

Introduction

Contents

Overview- - - - - - - - - - - - - - - 2

Program Support]

User Assistance - - - - - - - - 2

COADE Technical Support

Contact Information - - - - - 3

This chapter provides the organi-

zation of this manual and impor-

tant information regarding user

assistance.

Overview CAESAR II - Technical Reference Manual

1-2 Introduction

Overview

This CAESAR II Technical Reference Guide is the reference manual for CAESAR II. It

presents the theory behind CAESAR II operations, and explains why certain tasks are

performed. Users are urged to review the background material contained in this manual,

especially when applying CAESAR II to unfamiliar types of analysis.

Chapter 2 of this manual discusses the configuration of CAESAR II and the resulting

environment. This includes language support and program customization. In addition to

the COADE supplied routines, several third-party diagnostic packages are also mentioned.

Chapter 3 is the Piping Input Reference. It contains images of program generated screens,

and explains each input cell, menu option, and toolbar button. Also discussed in detail is

the Plot Screen, which displays the input model graphically.

Chapter 4 examines the Structural Steel Modeler and describes all commands, toolbar but-

tons, menu items, and input fields.

Chapter 5 discusses Dynamic Input and Control Parameters: each input cell, toolbar but-

ton, and menu item is examined. The purpose and effects of the various Dynamic Control

Parameters are detailed.

Chapter 6 contains theoretical overviews of various technical methods used in CAESAR

II. Both common and advanced modeling techniques are covered.

Chapter 7 provides information regarding a few miscellaneous auxiliary processors.

Chapter 8 details interfaces between CAESAR II and other programs.

Chapter 9 presents a list of files associated with CAESAR II.

Chapter 10 lists the CAESAR II update history.

Program Support / User Assistance

COADEs staff understands that CAESAR II is not only a complex analysis tool but also,

at times, an elaborate processone that may not be obvious to the casual user. While our

documentation is intended to address the questions raised regarding piping analysis, sys-

tem modeling, and results interpretation, not all the answers can be quickly found in these

volumes. However, many common errors are discussed in Chapter 10 of this volume and

the user can often save time by looking up the particular error here first.

COADE understands the engineers need to produce efficient, economical, and expedi-

tious designs. To that end, COADE has a staff of helpful professionals ready to address

any CAESAR II and piping issues raised by all users. CAESAR II support is available by

telephone, e-mail, facsimile, the internet, bulletin board service, and by mail; literally hun-

dreds of support calls are answered every week. COADE provides this service at no addi-

tional charge to the user. It is expected, however, that questions focus on the current

version of the program.

Formal training in CAESAR II and pipe stress analysis is also available from COADE.

For many years now, COADE has scheduled regular training classes in Houston and pro-

vided in-house and open attendance training around the world. These courses focus on the

expertise available at COADE modeling, analysis, and design.

CAESAR II - Technical Reference Manual COADE Technical Support

Introduction 1-3

COADE Technical Support

Phone: 281-890-4566 E-mail: techsupport@coade.com

Fax: 281-890-3301 WEB: www.coade.com

BBS: 281-890-7286

COADE Technical Support CAESAR II - Technical Reference Manual

1-4 Introduction

Chapter 2:

Configuration and

Environment

Contents

Generation of the CAESAR II

Configuration File - - - - - - - 2

Computation Control - - - - - - - 3

SIFs and Stresses - - - - - - - - - 7

Geometry Directives - - - - - - - 13

Plot Colors - - - - - - - - - - - - - - 16

FRP Pipe Properties- - - - - - - - 19

Database Definitions - - - - - - - 22

Miscellaneous- - - - - - - - - - - - 25

Set]Change Password - - - - - - 2S

Units File Operations - - - - - - - 29

Convert Input to New Units - - 32

Material Database- - - - - - - - - 34

This chapter discusses the configu-

ration options that are available.

Generation of the CAESAR II Configuration File CAESAR II - Technical Reference Manual

2-2 Configuration and Environment

Generation of the CAESAR II Configuration File

Each time the CAESAR II program is started, the configuration file caesar.cfg is read

from the current data directory. If this file is not found in the current data directory, the

installation directory is searched for the configuration file. If the configuration file cannot

be found, a fatal error will be generated and CAESAR II will terminate (see Chapter 10,

Troubleshooting, for more on fatal errors).

The configuration or setup file contains directives that dictate how CAESAR II will oper-

ate on a particular computer and how it will perform a particular analysis. The caesar.cfg

file is generated by choosing Tools - Configure/Setup (or the Configure Button from the

Toolbar) from the CAESAR II Main Menu.

Note The user must click on the Exit w/Save button on the bottom of the Configure/

Setup window in order to create a new configuration file or to save changes to the

existing configuration file. The configuration program produces the Window

shown in the figure below. Use the tabs to change configuration spreadsheets,

which are described below.

Important CAESAR.CFG may vary from machine to machine and many setup

directives modify the analysis. Do not expect the same input file to

produce identical results between machines unless the setup files are

identical. It is advised that a copy of the setup file be archived with

input and output data so that identical reruns can be made. The units

file, if modified by the user, would also need to be identical if the

same results are to be produced.

The following is a list of CAESAR II setup file options. They are listed by group as they

appear when chosen from the tabs on the Configure Window.

CAESAR II - Technical Reference Manual Computation Control

Configuration and Environment 2-3

Computation Control

Computational Control Configuration Settings

Use Pressure Stiffening

This directive is a flag that causes CAESAR II to include pressure-stiffening effects in

those codes that do not explicitly require its use. In these cases pressure-stiffening effects

will apply to all bends, elbows, and both miter types.

Missing Mass ZPA

The default for this option is Extracted, which means that CAESAR II will use the spec-

trum value at the last extracted mode. Changing this value to SPECTRUM instructs

CAESAR II to use the last spectrum value as the ZPA for the missing mass computations.

Bend Axial Shape

For bends 45 degrees or smaller, a major contributor to deformation can be the axial dis-

placement of the short-arched pipe. With the axial shape function off this displacement

mode is ignored and the bend will be stiffer.

Computation Control CAESAR II - Technical Reference Manual

2-4 Configuration and Environment

Rod Tolerance (degrees)

The angular plus-or-minus permitted convergence error. Unless the change from iteration

n to iteration n+1 is less this value the rod will NOT be converged. The default of

CAESAR II is 1.0 degree. For systems subject to large horizontal displacements, values

of 5.0 degrees for convergence tolerances have been used successfully.

Rod Increment (degrees)

The maximum amount of angular change that any one support can experience between

iterations. For difficult-to-converge problems, values of 0.1 have proven effective here.

When small values are used, however, the user should be prepared for a large number of

iterations. The total number of iterations can be estimated from:

Est. No. Iterations = 1.5(x)/(r)/(Rod Increment)

where:

x - maximum horizontal displacement at any one rod.

r - rod length at that support

Alpha Tolerance

The breakpoint at which CAESAR II decides that the entry in the Temp fields on the input

spreadsheet is a thermal expansion coefficient or a temperature. The default is 0.05. This

means that any entry in the Temp fields whose absolute magnitude is less than 0.05 is

taken to be a thermal expansion coefficient in terms of inches per inch (dimensionless).

Use of this field provides some interesting modeling tools. If Alpha Tolerance of 1.1 is set,

then an entry in the Temp 2 field of -1 causes the element defined by this expansion coeffi-

cient to shrink to zero length. This alternate method of specifying cold spring is quite use-

ful in jobs having hanger design with cold spring (see chapter 8 for more details regarding

Cold Spring).

Friction Stiffness

Friction restraint stiffness. The default is 1E6 lb/in. This value is used when a friction

restraint is non-sliding. In the non-sliding state, stiffnesses are inserted in the two

directions perpendicular to the restraints line of action and opposing any sliding motion.

This is the first parameter that should be adjusted to help a slowly converging problem

where friction is suspected. Lower stiffness values permit more non-sliding movement,

but given the indeterminate nature of the friction problem in general, this error is not con-

sidered crucial.

Friction Normal Force Variation

This tolerance (default of 0.15, or 15 percent) is the amount of variation in the normal

force that is permitted before an adjustment will be made in the sliding friction force. This

value normally should not be adjusted.

CAESAR II - Technical Reference Manual Computation Control

Configuration and Environment 2-5

Friction Angle Variation

Friction sliding angle variation. The default is 15 degrees. This parameter had more sig-

nificance in versions prior to 2.1. This parameter is currently only used in the first iteration

when a restraint goes from the not-sliding to sliding state. All subsequent iterations com-

pensate for the angle variation automatically.

Friction Slide Multiplier

This is an internal friction sliding force multiplier and should never be adjusted by the user

unless so directed by a member of the COADE / CAESAR II support staff.

WRC-107 Version

This directive sets the Version of the WRC-107 bulletin used in the computations. Valid

options are

August 1965

March 1979

March 1979 with the 1B1-1 and 2B-1 off axis curves (default)

WRC-107 Interpolation Method

The curves in WRC Bulletin 107 cover essentially all applications of nozzles in vessels or

piping; however, should any of the interpolation parameters i.e., U, Beta etc. fall outside

the limits of the available curves then some extension of the WRC method must be used.

The default is to use the last value in the particular WRC table. Alternatively, the user may

control this extensions methodology interactively. This causes the program to prompt the

user for curve values when necessary.

Incore Numerical Check

Enables the incore solution module to test the stability of the solution for the current

model and loadings. This option, if enabled, adds the solution of an extra load case to the

job stream.

Decomposition Singularity Tolerance

The default value is 1.0e+10. CAESAR II checks the ratio of off-diagonal coefficients to

the on-diagonal coefficient in the row. If this ratio is greater than the decomposition singu-

larity tolerance, then a numerical error may occur. This problem does not have to be asso-

ciated with a system singularity. This condition can exist when very small, and/or long

pipes are connected to very short, and/or large pipes. The out-of-core solution will, how-

ever, stop with a singularity message. This solution abort will prevent any possibility of an

errant solution. These solutions have several general characteristics:

When machine precision errors of this type occur they are very local in nature, affect-

ing only a single element or very small part of the model, and are readily noticeable

upon inspection.

The 1E10 limit can be increased to 1E11 or 1E12 and still provide a reasonable check

on solution accuracy. Any solution computed after this limit has been increased should

Computation Control CAESAR II - Technical Reference Manual

2-6 Configuration and Environment

always be checked closely for reasonableness. At 1E11 or 1E12 the number of sig-

nificant figures in the local solution has been reduced to two or three.

The 1E10 limit can be increased to 1E20 or 1E30 to get the job to run, but the user

should remember that the possibility for a locally errant solution exists when stiffness

ratios are allowed to get this high. Solutions should be carefully checked.

Minimum Wall Mill Tolerance (%)

This directive is used to specify the default percentage of wall thickness allowed for mill

and other mechanical tolerances.

Note For most piping codes, this value is only used during the "minimum wall thick-

ness" computation. Mill tolerance is usually not considered in the flexibility anal-

ysis.

By default this value is 12.5, corresponding to a 12.5% tolerance. To eliminate mill toler-

ance consideration, this directive should be set to 0.0.

Ignore Spring hanger Stiffness

If this option is enabled, it will cause CAESAR II to ignore the stiffness of spring hangers

in the analysis. This option is consistent with hand computation methods of spring hanger

design, which ignored the effects of the springs.

Important COADE recommends that this value never be changed.

Hanger Default Restraint Stiffness

Where hangers are adjacent to other supports or are themselves very close (for example

where there are two hangers on either side of a trunnion support), the CAESAR II hanger

design algorithm may generate poorly distributed hot hanger loads in the vicinity of the

close hangers. Using a more flexible support for computing the hanger restrained weight

loads often allows the design algorithm to more effectively distribute the systems weight.

A typical entry is 50,000; the default value is 1.0e+12.

Default Translational Restraint Stiffness

This directive defines the value used for non-specified translational restraint stiffnesses.

By default this value is assumed to be 1.0e+12 lb./in.

Default Rotational Restraint Stiffness

This directive defines the value used for non-specified rotational restraint stiffnesses. By

default this value is assumed to be 1.0E12 in.-lb./deg.

CAESAR II - Technical Reference Manual SIFs and Stresses

Configuration and Environment 2-7

SIFs and Stresses

SIFs and Stresses Configuration Settings

Default Code

The piping code the user designs to most often should go here. This code will be used as

the default if no code is specified in the problem input. The default piping code is B31.3,

the chemical plant and petroleum refinery code. Valid entries are B31.3, B31.1, B31.4,

B31.4 Chapter IX, B31.5, B31.8, B31.8 Chapter VIII, ASME-NC(Class 2), ASME-

ND(Class 3), NAVY505, Z662, BS806, SWEDISH1, SWEDISH2, B31.1-1967, STOOM-

WEZEN, RCCM-C, RCCM-D, CODETI, Norwegian, FDBR, BS-7159, UKOOA,

IGE TD-12, and DNV.

Occasional Load Factor

The default value of 0.0 tells CAESAR II to use the value that the active piping code rec-

ommends. B31.1 states that the calculated stress may exceed the maximum allowable

stress from Appendix A, (Sh), by 15% if the event duration occurs less than 10% of any 24

hour operating period, and by 20% if the event duration occurs less than 1% of any 24

hour operating period. The default for B31.1 applications is 15%. If 20% is more suitable

for the system being analyzed then this directive can be used to enter the 20%.

SIFs and Stresses CAESAR II - Technical Reference Manual

2-8 Configuration and Environment

B31.3 states, The sum of the longitudinal stresses due to pressure, weight, and other sus-

tained loadings (S1) and of the stresses produced by occasional loads such as wind or

earthquake may be as much as 1.33 times the allowable stress given in Appendix A. Where

the allowable stress value exceeds 2/3 of yield strength at temperature, the allowable

stress value must be reduced as specified in Note 3 in 302.3.2. The default for B31.3

applications is 33%. If this is too high for the material and temperature specified then a

smaller occasional load factor can be input.

B31.3 Sustained Case SIF Factor

B31.3 Code Interpretation 1-34 dated February 23, 1981 File: 1470-1 states that for sus-

tained and occasional loads an SIF of 0.75i, but not less than 1.0 may be used. This setup

directive allows the user to enter his/her own coefficient. The default is 1.0. To comply

with this interpretation the user would enter 0.75. B31.3 Code Interpretation 6-03 dated

December 14, 1987 permitted users to ignore the stress intensification for sustained and

occasional loads.To comply with this interpretation, the user would enter 0.0.

Yield Stress Criterion

The 132 column stress report produced by CAESAR II contains a value representative of

the maximum stress state through the cross section, computed per the indicated yield crite-

ria theory.

CAESAR II can compute this maximum stress (note, this is not a Code stress) according

to either the Von Mises theory or the Maximum Shear Theory. The selected stress is com-

puted at four points along the axis normal to the plane of bending (outside top, inside top,

inside bottom, outside bottom), and the maximum value is printed in the stress report. The

equations used for each of these yield criteria are listed below:

3D Maximum Shear Stress Intensity (Default)

SI = Maximum of:

S1OT - S3OT

S1OB - S3OB

Max(S1IT,RPS) - Min(S3IT,RPS)

Max(S1IB,RPS) - Min(S3IB,RPS)

Von Mises Stress (Octahedral)

OCT = Maximum of:

(S3OB

2

+S1OB

2

+(S3OB-S1OB)

2

)

1/2

/ 3.0

((S3IB-RPS)

2

+(S3IB-S1IB)

2

+(RPS-S1IB)

2

)

1/2

/ 3.0

(S3OT

2

+S1OT

2

+(S1OT-S3OT)

2

)

1/2

/ 3.0

((S3IT-RPS)

2

+(S3IT-S1IT)

2

+(RPS-S1IB)

2

)

1/2

/ 3.0

Where:

S1OT=Maximum Principal Stress, Outside Top

= (SLOT+HPSO)/2.0+(((SLOT-HPSO)/2.0)

2

+TSO

2

)

1/2

S3OT=Minimum Principal Stress, Outside Top

=(SLOT+HPSO)/2.0- (((SLOT-HPSO)/2.0)

2

+TSO

2

)

1/2

CAESAR II - Technical Reference Manual SIFs and Stresses

Configuration and Environment 2-9

S1IT=Maximum Principal Stress, Inside Top

=(SLIT+HPSI)/2.0+(((SLIT-HPSI)/2.0)

2

+TSI

2

)

1/2

S3IT=Minimum Principal Stress, Inside Top

=(SLIT+HPSI)/2.0- (((SLIT-HPSI)/2.0)

2

+TSI

2

)

1/2

S1OB=Maximum Principal Stress, Outside Top

=(SLOB+HPSO)/2.0+ (((SLOB-HPSO)/2.0)

2

+TSO

2

)

1/2

S3OB=Minimum Principal Stress, Outside Bottom

=(SLOB+HPSO)/2.0- (((SLOB-HPSO)/2.0)

2

+TSO

2

)

1/2

S1IB=Maximum Principal Stress, Inside Bottom

=(SLIB+HPSI)/2.0+ (((SLIB-HPSI)/2.0)

2

+TSI

2

)

1/2

S3IB=Minimum Principal Stress, Inside Bottom

=(SLIB+HPSI)/2.0- (((SLIB-HPSI)/2.0)

2

+TSI

2

)

1/2

RPS=Radial Pressure Stress, Inside

HPSI=Hoop Pressure Stress (Inside, from Lames Equation)

HPSO=Hoop Pressure Stress (Outside, from Lames Equation)

SLOT=Longitudinal Stress, Outside Top

SLIT=Longitudinal Stress, Inside Top

SLOB=Longitudinal Stress, Outside Bottom

SLIB=Longitudinal Stress, Inside Bottom

TSI=Torsional Stress, Inside

TSO=Torsional Stress, Outside

Allow Users SIF at Bend

This feature was added for those users that wished to change the stress intensification fac-

tor for bends. Previously this was not permitted, and the code defined SIF was always

used. If the turns this directive on, he may override the codes calculated SIF for bends.

The user entered SIF acts over the entire bend curvature and must be specified at the TO

end of the bend element. The default is off.

Use WRC329

This directive, when turned on activates the WRC329 guidelines for all intersections, (not

just for reduced intersections). The recommendations made by Rodabaugh in section 5.0

of WRC329 will be followed exactly in making the stress calculations for intersections.

Every attempt has been made to improve the stress calculations for all codes, not just the

four discussed in Rodabaughs paper. Users not employing either B31.1, B31.3 or the

ASME NC or ND codes, and who wish to use WRC329 are encouraged to contact

COADE for additional information. Throughout this document WRC330 and WRC329

are used synonymously (330 was the draft version of 329). When finally published, the

official WRC designation was 329.

SIFs and Stresses CAESAR II - Technical Reference Manual

2-10 Configuration and Environment

Use Schneider

Activates the Schneider reduced intersection assumptions. It was because of observations

by Schneider that much of the work on WRC 329 was started. Schneider pointed out that

the code SIFs could be in error when the d/D ratio at the intersection was less than 1.0 and

greater than 0.5. In this d/D range the SIFs could be in error by as much as a factor of 2.0.

Using the Schneider option in CAESAR II results in a multiplication of the out of plane

branch stress intensification by a number between 1 and 2 when the d/D ratio for the inter-

section is between 0.5 and 1.0. For B31.1 and other codes that do not differentiate between

in and out-of-plane SIFs the multiplication will be used for the single stress intensification

given.

All Cases Corroded

A recent version of the B31.3 piping code mentioned reducing the section modulus for

sustained or occasional stress calculations by the reduction in wall thickness due to corro-

sion. Several users have interpreted this to mean that the reduced section modulus should

be used for all stress calculations, including expansion. This directive allows those users to

apply this conservative interpretation of the code. Turning on All Cases Corroded causes

CAESAR II to use the corroded section modulus for the calculation of all stress types.

This method is recommended as conservative, and probably more realistic as corrosion

can significantly affect fatigue life, i.e., expansion. Leaving this directive off causes

CAESAR II to strictly follow the piping code recommendations, i.e. depending on the

active piping code, some load cases will consider corrosion and some will not.

Base Hoop Stress On ( ID/OD/Mean/Lams )

This directive is used to indicate how the value of hoop stress should be calculated. The

default is to use the ID of the pipe. Most piping codes consider the effects of pressure in

the longitudinal component of the CODE stress. Usually, the value of the hoop stress has

no bearing on the CODE stress, so changing this directive does not affect the acceptability

of the piping system.

If desired, the user may change the way CAESAR II computes the hoop stress value. This

directive has the following options:

IDhoop stress is computed according to Pd/2t where d is the internal diameter of

the pipe.

ODhoop stress is computed according to Pd/2t where d is the outer diameter of

the pipe.

Meanhoop stress is computed according to Pd/2t where d is the average or mean

diameter of the pipe.

Lamshoop stress is computed according to Lams equation, = P ( Ri

2

+ Ri

2

* Ro

2

/ R

2

) / ( Ro

2

- Ri

2

) and varies through the wall as a function of R.

Use PD/4t

Turning this directive on causes CAESAR II to use the simplified form of the longitudi-

nal stress term when computing sustained stresses. Some codes permit this simplified

form when the pipe wall thickness is thin. This option is used most often when users are

comparing CAESAR II results to those from an older pipe stress program. The more com-

prehensive calculation, i.e. the Default, is recommended.

CAESAR II - Technical Reference Manual SIFs and Stresses

Configuration and Environment 2-11

Add F/A in Stresses

Determines whether or not the axial stress term is included in the code stress computation.

Setting this directive to Default causes CAESAR II to use whatever the currently active

piping code recommends. Only the B31.3-type piping codes (i.e. codes where the sus-

tained stress equation is not explicitly given) have the F/A stresses included in the sus-

tained and occasional stress equations. The B31.1-type codes do not include the F/A

stresses because the equations given explicitly in the code do not include it. The F/A

stresses discussed here are not due to longitudinal pressure. These are the F/A stresses due

to structural loads in the piping system itself.

Add Torsion in SL Stress

Some piping codes include torsion in the sustained and occasional stresses by explicitly

including it in the stress equation (i.e. B31.1), and some dont include torsion in the sus-

tained and occasional stresses by implicitly calling for longitudinal stresses only (i.e.

B31.3). Setting the Add Torsion in SL Stress directive to Yes forces CAESAR II to

include the torsion term in those codes that dont include it already by default. Setting this

directive to Default causes CAESAR II to use whatever the currently active piping code

implies. In a sustained stress analysis of a very hot piping system subject to creep, it is rec-

ommended that the user include torsion in the sustained stress calculation via this parame-

ter in the setup file.

Reduced Intersection

Available options are B31.1(Pre 1980), B31.1(Post 1980), WRC329, ASME SEC III, and

Schneider:

B31.1(Pre 1980)

Allows the B31.1 code user to have the pre-1980 code rules used for reduced intersection.

These rules did-not define a separate branch SIF for the reduced branch end. The branch

stress intensification factor will be the same as the header stress intensification factor

regardless of the branch-to-header diameter ratio.

B31.1(Post 1980)

Allows the B31.1 code user to employ the post-1980 code rules for reduced intersections.

The reduced intersection SIF equations in B31.1 from 1980 through 1989 generated

unnecessarily high SIFs because of a mistake made in the implementation. (This is as per

WRC329.) For this reason many users opted for the Pre 1980 B31.1 SIF calculation dis-

cussed above. CAESAR II corrects this mistake by the automatic activation of the flag:

B31.1 Reduced Z Fix = On. Users can vary the status of this flag in the CAESAR II setup

file to generate any interpretation of B31.1 desired. The default for a new job is for

B31.1(Post 1980) and for the B31.1 Reduced Z Fix = On.

The No RFT/WLT in Reduced Fitting SIFs flag also affects the SIF calculations at reduced

intersections and is also available in this release.

WRC329

Allows the user to use the recommendations of WRC329 for reduced intersections. A

reduced intersection is any intersection where the d/D ratio is less than 0.975. The

SIFs and Stresses CAESAR II - Technical Reference Manual

2-12 Configuration and Environment

WRC329 recommendations result in more conservative stress calculations in some

instances and less conservative stress calculations in others. In all cases the WRC329 val-

ues should be more accurate, and more truly in-line with the respective codes intent.

ASME Sect. III

Allows the user to use the 1985 ASME Section III NC and ND rules for reduced intersec-

tions.

Schneider

Activates the Schneider reduced intersection stress intensification factor multiplication.

Has the same effect as the Use Schneider option.

Class 1 Branch Flexibility

Activates the Class 1 flexibility calculations. The appearance of this parameter in the setup

file will completely change the modeling of intersections in the analysis. For intersections

not satisfying the reduced branch rules that d/D<= 0.5 and that D/T <= 100, the branch

will start at the surface of the header pipe. A perfectly rigid junction between the center-

line of the header and surface will be formed automatically by CAESAR II using the ele-

ment offset calculations. SIFs act at the surface point for the branch. When the reduced

branch rules are satisfied, the local flexibility of the header is also inserted at this surface

point. Intersections not satisfying the reduced intersection rules will be stiffer and carry

more load, while intersections satisfying the reduced intersection rules will be more flexi-

ble and will carry less load. All changes to the model are completely transparent to the

user. In systems where the intersection flexibility is a major component of the overall sys-

tem stiffness, the user is urged to run the analysis both with and without the Class 1

Branch Flexibility active to determine the effect this modeling on the analysis. There is

more technical discussion in the section entitled: CLASS 1 BRANCH FLEXIBILITY.

B31.1 Reduced Z Fix

This directive is used in conjunction with B31.1, and makes the correction to the reduced

branch stress calculation that existed in the 1980 through 1989 versions of B31.1. This

error was corrected in the 1989 version of B31.1, and the B31.1 Reduced Z Fix is on by

default in CAESAR II.

No RFT/WLT in Reduced Fitting SIFs

There has been considerable concern involving the SIFs for reduced fittings. Part of the

discussion centers around just what should be considered a reduced fitting. The

CAESAR II default is to assume that welding tees and reinforced fabricated tees are cov-

ered by the reduced fitting expressions, even though the reduced fitting expressions do not

explicitly cover these intersection types. Users wishing to leave welding tees and rein-

forced tees out of this definition should turn this directive on.

CAESAR II - Technical Reference Manual Geometry Directives

Configuration and Environment 2-13

Geometry Directives

Geometry Directives Configuration Settings

Connect Geometry Through Cnodes

Restraints, flexible nozzles, and spring hangers may be defined with connecting nodes. By

default CAESAR II ignores the position of the restraint node and the connecting node.

They may be at the same point or they may be hundreds of feet apart. This directive allows

the user to insist that each restraint, nozzle, or hanger exists at the same point in space as

its connecting node. In many cases, activation of this option will cause plot-wise discon-

nected parts of the system to be re-connected and to appear as -expected in both input

and output plots.

Auto Node Number Increment

This directive sets the value for the Automatic Node Numbering routine. Any non-zero,

positive value in this data cell is used to automatically assume the TO NODE value on

the piping input spreadsheets. The new (TO) node number is determined as:

To Node = From Node + Auto Node Number Increment.

If this value is set to 0.0, automatic node numbering is disabled.

Geometry Directives CAESAR II - Technical Reference Manual

2-14 Configuration and Environment

Minimum Allowed Bend Angle

Very small angle, short radius bends can cause numerical problems during solution. When

the user has a reasonable radius and a small angle there are usually no problems however.

If the small angle bend is grossly small compared to the surrounding elements then the

bend should probably not be used and a different modeling approach employed. This

directive allows the user to reset the minimum angle CAESAR II will accept for a bend

angle. The default is 5.0 degrees.

Maximum Allowed Bend Angle

Very large angle, short radius bends can cause numerical problems during solution. When

the user has a reasonable radius and a large angle there are usually no problems. If the

large angle bend plots compared reasonably well to the surrounding elements then the

bend can probably be used without difficulty. Well-proportioned bends up to 135 degrees

have been tested without a problem. This directive allows the user to reset the maximum

angle CAESAR II will accept for a bend. The default is 95 degrees.

Bend Length Attachment Percent

Whenever the element leaving the tangent intersection of a bend is within (n)% of the

bend radius on either side of the weldline, CAESAR II inserts an element from the bend

weldline to the TO node of the element leaving the bend. The inserted element has a

length equal to exactly (n)% of the bend radius. The user may adjust this percentage to

reduce the error due to the inserted element, however, the length tolerance for elements

leaving the bend will also be reduced. (To get more accurate the user must include less

slop in the system dimensions around bends). The default attachment is 1.0 percent.

Minimum Angle to Adjacent Bend

Nodes on a bend curvature that are too close together can cause numerical problems dur-

ing solution. Where the radius of the bend is large, such as in a cross country pipeline, it is

not uncommon to find nodes on a bend curvature closer than 5 degrees. In these situations

the user may employ this directive to change the CAESAR II error checking tolerance for

the closeness of points on the bend curvature. The default is 5.0 degrees.

Loop Closure Tolerance

The loop closure tolerance used by CAESAR II for error checking can be set interactively

by the user for each job analyzed, or the user can enter the desired loop closure tolerance

via this directive and override without distraction the program default value of 1.0 in. See

the following section for a discussion of the CAESAR II units file.

CAESAR II - Technical Reference Manual Geometry Directives

Configuration and Environment 2-15

Horizontal Thermal Bowing Tolerance

This directive enables the user to specify the maximum slope of a straight pipe element for

which thermal bowing effects will be considered. Thermal bowing is usually associated

with fluid carrying horizontal pipes in which the fluid does not fill the cross section. In

these cases, there is a temperature differential across the cross section. This directive

allows the user to define the interpretation of horizontal. By default, the program uses a

value of 0.0001 as the horizontal threshold value. If a pipe elements pitch is less than this

tolerance, the element is considered to be horizontal, and thermal bowing loads can be

applied to it. An elements pitch is computed from:

PITCH = | DY | / ( DX

2

+ DY

2

+ DZ

2

)

1/2

Plot Colors CAESAR II - Technical Reference Manual

2-16 Configuration and Environment

Plot Colors

Plot Colors Configuration Settings

Pipes

Enter the color for the center-line and volume plots of pipe elements. (Excludes valves,

other rigids and expansion joints).

Nodes

Enter the color for the node numbers.

Rigids/Bends

Enter the color for the rigid elements and for the bend highlighting in the input plot.

Hangers/Nozzles

Enter the color for hanger and nozzle symbols that are displayed on the input plot.

Structure

Enter the color that structural elements should be plotted in.

CAESAR II - Technical Reference Manual Plot Colors

Configuration and Environment 2-17

Should contrast with Pipes.

Background

Enter the color for the plot background. The user should be careful setting this parameter

because all other colors need to be coordinated with the background color.

Axes

Enter the color of the plot axes that appear in the bottom left corner of the screen.

Labels

Enter the color for the geometry labels exclusive of the node numbers. Examples are:

Diameter, Thickness, Length, plot labeling.

Highlights

Enter the color for the input level plot hilite. Should contrast with the color entered for

Pipes.

Displaced Shape

Enter the color for the displaced shape overlay. Should contrast with Pipes.

Stress Level 1

Enter the stress value that defines the lower limit cutoff.

Stress Level 2

Enter the stress value that defines the second lowest stress color-plot limit.

Stress Level 3

Enter the stress value that defines the third lowest stress color-plot limit.

Stress Level 4

Enter the stress value that defines the fourth lowest stress color plot limit.

Stress Level 5

Enter the stress value that defines the upper limit cutoff.

Stress < Level 1

Enter the color for that portion of the pipe that has a stress lower than Stress Level 1.

Stress > Level 1

Enter the color for that portion of the pipe that has a stress greater than Stress Level 1 and

less than Stress Level 2.

Stress > Level 2

Enter the color for that portion of the pipe that has a stress greater than Stress Level 2 and

less than Stress Level 3

Plot Colors CAESAR II - Technical Reference Manual

2-18 Configuration and Environment

Stress > Level 3

Enter the color for that portion of the pipe that has a stress greater than Stress Level 3 and

less than Stress Level 4.

Stress > Level 4

Enter the color for that portion of the pipe that has a stress greater that Stress Level 4 and

less than Stress Level 5.

Stress > Level 5

Enter the color for the portion of the pipe element that has a stress greater than Stress

Level 5. The color of an element from one end to the other varies as the stress varies.

CAESAR II - Technical Reference Manual FRP Pipe Properties

Configuration and Environment 2-19

FRP Pipe Properties

FRP Properties Configuration Settings

Use FRP SIF

By default, when FRP pipe is selected (Material #20), CAESAR II sets the fitting SIF to

2.3. Some users have requested that the standard code SIF be used, others have

requested the ability to specify this value manually.

By turning off this directive, the standard code SIF equations will be applied to all FRP

fittings. This also allows manual specification of these values by the user.

If the BS 7159 or UKOOA Codes are in effect, code SIFs will always be used, regardless

of the setting of this directive.

Use FRP Flexibilities

By default, when FRP pipe is selected (Material #20), CAESAR II sets the fitting flexibil-

ity factor to 1.0. Some users have requested that the standard code flexibility factor be

used.

By turning this directive off, the standard code flexibility factor equations will be

applied to all FRP fittings.

FRP Pipe Properties CAESAR II - Technical Reference Manual

2-20 Configuration and Environment

If the BS 7159 or UKOOA Codes are in effect, code flexibility factors will always be

used, regardless of the setting of this directive.

FRP Property Data File

Standard FRP material properties may be read in from files. The user may select the avail-

able files. Once selected, the program will give the user the option of reading in from that

file.

Users may create FRP material files as text files with the .frp extension; these files should

be stored in the CAESAR\SYSTEM sub-directory. The format of the files must adhere to

the following format:

Sample FRP Data File

Note The data lines must follow exactly the order shown above. The four data lines

defining the UKOOA envelope are intended for future use and may be omitted.

BS 7159 Pressure Stiffening

The BS 7159 code explicitly requires that the effect of pressure stiffening on the bend SIFs

be calculated using the Design Strain (this is based upon the assumption that the FRP pip-

ing is fully pressurized to its design limit). This is CAESAR IIs default method.

When the piping is pressurized to a value much lower than its design pressure, it may be

more accurate to calculate pressure stiffening based on the Actual Pressure stress, rather

than its design strain. Note that this alternative method is a deviation from the explicit

instructions of the BS 7159 code.

FRP Laminate Type

The default Laminate Type (as defined in the BS 7159 code) of the fiberglass reinforced

plastic pipe used should be entered. The valid types are

Chopped strand mat (CSM) and woven roving (WR) construction with internal and exter-

nal surface tissue reinforced layer.

CAESAR II - Technical Reference Manual FRP Pipe Properties

Configuration and Environment 2-21

Chopped strand mat (CSM) and multi-filament roving construction with internal and

external surface tissue reinforced layer.

All chopped strand mat (CSM) construction with internal and external surface tissue

reinforced layer.

This entry is used in order to calculate the flexibility and stress intensity factors of bends;

therefore this default entry may be overridden using the Type field on the bend auxiliary

spreadsheets.

FRP Pipe Density

Weight of the pipe material on a per unit volume basis. This field is used to set the default

weight density of FRP materials in the piping input module.

FRP Alpha (e-06)

In this field, the thermal expansion coefficient for the fiberglass reinforced plastic pipe

used (multiplied by 1,000,000) should be entered. For example, if the value is: 8.5E-6 in/

in/deg, then the user would enter 8.5 in this field. The exponent (E-6) is implied.

If a single expansion coefficient is too limiting for the users application, the actual ther-

mal expansion may always be calculated at temperature in inches per inch (or mm per

mm) and entered directly into the Temperature field on the pipe spreadsheet.

FRP Modulus of Elasticity

Axial elastic modulus of Fiberglass Reinforced Plastic pipe. This is the default value used

to set the data in the input processor. The user may override this value in the input when

necessary.

Ratio Shear Mod:Emod

In this field, the ratio of the shear modulus to the modulus of elasticity (in the axial direc-

tion) of the fiberglass reinforced plastic pipe used should be entered. For example, if the

material modulus of elasticity (axial) is 3.2E6 psi, and the shear modulus is 8.0E5 psi, the

ratio of these two, 0.25, should be entered here.

Axial Strain:Hoop Stress (Ea/Eh*Vh/a)

The product of the ratio of the axial to the hoop elastic modulus and Poissons ratio which

relates the strain in the axial direction to a stress in the hoop direction.

Ea-Elastic modulus in the axial direction.

Eh-Elastic modulus in the hoop direction.

Vh/a-Poissons ratio relating the strain in the axial direction due to a stress in

the hoop direction.

Database Definitions CAESAR II - Technical Reference Manual

2-22 Configuration and Environment

Database Definitions

Database Definitions Configuration Settings

Structural Database

This directive specifies which database file is to be used to acquire the structural steel

shape labels and cross section properties from. The structural databases provided include

AISC 1977, AISC 1989, German 1991, South African 1991, Korean 1990, Australian

1990, and United Kingdom.

Piping Size Specification (ANSI/JIS/DIN/BS)

By default, CAESAR II uses the ANSI pipe size and schedule tables in the input proces-

sor. Users may optionally select the standard tables of another piping specification using

this directive. The available tables are

American National Standard (ANSI)

Japanese Industrial Standard (JIS)

German Standard (DIN)

CAESAR II - Technical Reference Manual Database Definitions

Configuration and Environment 2-23

Valves and Flanges

This directive enables the user to specify which Valve/Flange database should be refer-

enced by CAESAR II during subsequent input sessions. The databases provided include

the following: a generic database, the Crane database, a database (generic) without

attached flanges, and the CADWorx/Pipe database.

Expansion Joints

This directive enables the user to specify which Expansion Joint database should be refer-

enced by CAESAR II during subsequent input sessions. The databases provided include

Pathway, Senior Flexonics, IWK, and Piping Technology.

Units File Name

This directive allows the user to scroll through the available units files and select one to be

active. Since the CAESAR.CFG file is written to the local data directory, different data

directories can be configured to reference different units files.

Units files are searched for first in the local data directory, and then in the active SYS-

TEM directory. The active units file is used for new job creation and all output genera-

tion.

System Directory Name

This directive enables a user to select which SYSTEM directory is used by

CAESAR II. All of the various system directories contain formatting files, units files, text

files, and other user configurable data files. Some of these formatting files are language

specific or Code specific. Therefore, users may want to switch between system directories

depending on the current job. The directive allows the user to scroll through the available

system directories and select one to be ACTIVE. Since the CAESAR.CFG file is written

to the local data directory, different data directories can be configured to reference differ-

ent system directories.

All system directory names must be of the form: SYSTEM.??? where the .??? is a three

character suffix identifying the directory. Users can create system directories as needed,

following this required naming convention. The CAESAR II distribution diskettes con-