Академический Документы

Профессиональный Документы

Культура Документы

JSA - Shut Down and Tie in Work

Загружено:

Nurul HidayahИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JSA - Shut Down and Tie in Work

Загружено:

Nurul HidayahАвторское право:

Доступные форматы

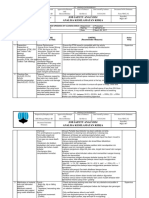

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

Company/ Contractor Department/ Discipline Location/ Area/ Elevation Job Description Company ABC Piping & Mechanical - Shut Down & Tie-In N/A Shut down and tie in work for process line and utility line.

JSA No. Rev No. Job Number/ Project Name Prepared By, Reviewed By, Approved By,

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC

No. 1. 2.

Sequence Of Basic Job Steps Understand job sequence Construction material/ equipment mobilization 1.1 2.1 2.2 2.3

Hazard Identification Hazard Effects Misunderstand of job sequence Non compliance on safety requirement Vehicle/equipment failure Personnel injury

Determining Control Measures 1.1.1 Supervisors have to brief on JSA before work. 2.1.1 All vehicle/ equipments to be used must be inspected and approved vehicle/ equipment will be pasted with a sticker of approval. 2.2.1 Obtain Vehicle Entry Permit/Certicate. 2.2.2 Provide fire extinguisher and spark arrestor for vehicles. 2.3.1 The driver must have the valid driving license and vehicle should meet JPJ requirement 2.3.2 Follow road signage and speed limit. 2.3.3 Ensure vehicles have reverse alarm. 2.3.4 Use the approved route by client. 2.3.5 To check condition of soil/access route for heavy traffic movement. 2.4.1 Ensure crane with PMA and Crane Operator possess valid licence and registered as DOSH competence. 2.4.2 Signal man to direct movement of vehicle. 2.4.3 Workers shall never stand under a suspended and always stand clear of load 2.4.4 Workers shall recheck all the lifting equipment before used. 2.4.5 Operators and drivers should inspect their crane /vehicle/equipment before starting work for the day in order ensure in good confition. 2.4.6 To barricade the working area and put necessary signage to warn others. 2.4.7 Signalman shall used two way communication when visual signal is not possible. 2.5.1 Obtain Road Obstruction Certificate from client. 3.1.1 Obtain LOTO (lock Out Tag Out) Certificate / Permit from client.

Additional Actions

Mechanical operated machine may produce Fire spark and have oil leakage. Accident may occurs due to mishandling of Personnel injury vehicle/ traffic issues.

2.4

Loading and unloading accident may occur Personnel injury during operations.

2.5 3. Isolation of piping system for the shutdown and tie-in work. 3.1

Obstruction of access road Wrongly isolate valve

Personnel injury Plant/ system upset

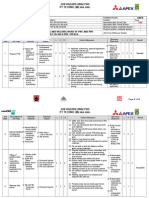

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

Company/ Contractor Company ABC

JSA No. Rev No. Job Number/ Project Name Prepared By,

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

No. Sequence Of Basic Job Steps Hazard

JSA No. Rev No. Job Number/ Project Name Hazard Identification

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC Determining Control Measures 3.1.2 Project team (together with client person in charge) to chain lock and tag the valve with LOTO on the isolation valve to ensure that the valve will not accidentally opened. 3.1.3 Ensure that the valve tagging in placed. 3.1.4 Valve isolation shall be done with client person in charge presence. Additional Actions

Effect

3.2

People accidentally open the valve

Personnel injury

3.2.1 Project team (together with client person in charge) to chain lock and tag the valve with LOTO on the isolation valve to ensure that the valve will not accidentally opened. 4.1.1 To break the flange slowly and check the flange with gas detector to confirm pipe is free from any flammable/ toxic gas. 4.2.1 Ensure that the blinding tagging number in placed as per blinding diagram. 4.2.2 Blinding work shall be done with client person in charge presence. 4.2.3 Supervisor(person in charge) shall be reconfirm diagram before proceeding with next activities. 4.2.4 LOTO procedure shall be strictly followed to ensure the correct method is used. 5.1.1 Load does not exceed the capacity of the lifting equipment 5.1.2 Signal man to direct movement of vehicle. 5.1.3 Workers shall never stand under a suspended and always stand clear of load 5.1.4 Workers shall recheck all the lifting equipment before used. 5.1.5 Operators and drivers should inspect their crane /vehicle/equipment before starting work for the day in order ensure in good confition. 5.1.6 To barricade the working area and put necessary signage to warn others. 5.1.7 Signalman shall used two way communication when visual signal is not possible. 5.1.8 Padding shall be provided on sharp edge to prevent lifting slings from damage 5.1.9 Sling of the correct length and capacity for the job must be used 5.1.10 Rigging the load is carried out by a competent person

Installation of blinding as per blinding diagram

4.1

Hydrocarbon/ others toxic or flammable gas Personnel injury in piping system Wrongly blind on existing line Personnel injury

4.2

Pipe spool/ valve/ pipeline lifting and laying into tie -in location.

5.1

Loading and unloading accident may occur Personnel injury during operations.

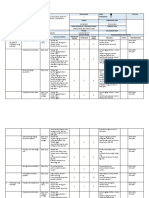

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

No. Sequence Of Basic Job Steps 5.2 Crane topple Hazard

JSA No. Rev No. Job Number/ Project Name Hazard Identification

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC Determining Control Measures Additional Actions

Effect Personnel injury/ property damage

3.1.2 Project team (together with client person in 5.2.1 Ensure that the load and boom is lowered when the cranes left unattended. 5.2.2 Lifting work shall only commence after confirming that the crane is set up satisfactory 5.2.3 Outrigger shall be resting on flat and firm ground with steel plate and wooden plank. 5.2.4 To barricade the working area and put necessary signage to warn others. 5.2.5 Signalman shall used two way communication when visual signal is not possible. 5.2.6 Crane and trailer parking location shall be approved by client prior to start any lifting work 5.3.1 Obtain Road Obstruction Certificate from client. 6.1.1 To standby fire extinguisher (ABC Type 9.0 kg) 6.1.2 To ensure sufficient fire blanket provided to cover the hotwork area & below hotwork area. 6.1.3 To cover and protect any near by cable, pipe or instrument with fire blanket. 6.1.4 To remove any combustible material from directly coming into contact with the spark. 6.1.5 Ensure flash back arrestor are fitted to oxygen and acetylene gas regulators. 6.1.6 To ensure the oxygen and acetylene cylinders are mounted to cylinder trolley with chain or in cylinder cradle. 6.1.7 All gas hoses, fittings and gauges shall be check in good condition and no leak before start work. 6.1.8 Provide standby water hose with stop valve (If required) 6.1.9 Welder must wear face shield and leather glove for protection during the works progress

5.3 6 Field welding for tie-in work 6.1

Obstruction of access road Welding spark

Personnel injury Fire, face and eye injury

6.2

Welding machine / generator may produce Fire spark

6.2.1 To stand - by fire watch & fire extinguisher near to engine driven equipment 6.2.2 Engine driven equipment shall be fitted with spark arrestor. 6.2.3 Engine shall be checked daily to ensure is in good condition and without leakage 6.2.4 Engine shall be stopped while fill-in-diesel. 6.2.5 Welding set used shall properly grounded. 6.3.1 Regular check the extension cable to ensure

6.3

Electrocution

Personnel injury/fatal

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

No. Sequence Of Basic Job Steps Hazard

JSA No. Rev No. Job Number/ Project Name Hazard Identification

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC Determining Control Measures 3.1.2 Project team (together with client person in in good condition. 6.3.2 To ensure extension cables are not to lay across on wet ground or stagnant water. 6.3.3 All electrical tools are to be inspected before 6.3.4 All hotwork to be stop when heavy rain. Additional Actions

Effect

6.4

Workers fall from height

Personnel injury

6.5

Falling object

Personnel injury, property damage

6.4.1 Workers shall wear full body harness with double lanyard and hook to fixed structures while working at height. 6.4.2 No work on structure/slippery condition before grating installation. 6.4.3 Supervisor has to closely supervise all the elevated works. 6.4.4 Provide lifeline if there is no anchorage point to hook lanyard.(Steel cable) 6.4.5 Workers are allowed to use scaffolding platform displayed Green Tag only. 6.5.1 Proper barricade and signage below working area to prevent unauthorized entry. 6.5.2 Handling loose materials by throwing from height are strictly prohibited 6.5.3 Use container to store tools and consumable and transfer by using rope. 6.5.4 Safety net shall be installed under the surface or structure on which employees are working. 6.5.5 Obtain Certificate for The Removal & Reinstallation of Gratings, Handrails, Stair Treads & Other Pieces of Equipment when required to open grating, handrails and other steel structure member. 7.1.1 Ensure that the blinding tagging number in place as per blinding diagram. Supervisor person in charge to reconfirm on the de-blinding point as per diagram before blind removal. 7.2.1 JIT team to check and confirm specification gasket and flange surface cleanesess before flange reinstatement. 7.2.2 Proper torquw and sequence of bolt tightening as per procedure. 7.2.3 To carry out Joint Integrity Test during the re-instatement work.

Deblinding work and Joint Integrity Test (JIT) for flange joint.

7.1

Wrongly remove blinding point

Personnel injury

7.2

Line leaking due not proper tightening work Personnel injury at flange joint.

COMPANY ABC Sdn Bhd Job Safety Analysis (JSA) Worksheet

No. 8 Sequence Of Basic Job Steps Re- Isolate valve for the shutdown tie-in work 8.1

JSA No. Rev No. Job Number/ Project Name Hazard Identification

JSA-Mechanical-011- Shut Down & Tie-In 0 Date 22nd July.2010 Page

Project ABC Determining Control Measures 3.1.2 Project teamthe valve tagging number in placed 8.1.1 Ensure that (together with client person in as per blinding diagram. 8.1.2 Supervisor person in charge to reconfirm on the valve location as per valve isolation diagram. 8.1.3 Valve re-isolation shall be done with client person in charge presence. 8.2.1 Ensure that the line already de-blinding, JIT has been carry out and valve chain lock has been removed before handover to client person in charge for tagged out (LOTO). Additional Actions

Hazard Wrongly reopening valve isolation

Effect Personnel injury

8.2

People accidentally closed the valve

Personnel injury

Вам также может понравиться

- JSA Shut Down and Tie in Work PDFДокумент6 страницJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementДокумент13 страницJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisДокумент15 страницSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshОценок пока нет

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisДокумент16 страницSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityДокумент5 страниц1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliОценок пока нет

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingДокумент4 страницыJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Jha New - PWHTДокумент6 страницJha New - PWHTSalam AlkataluniОценок пока нет

- HydroTest JHAДокумент14 страницHydroTest JHAorganicspolybond100% (2)

- Jsa For TIE INS in Accommodation BlockДокумент4 страницыJsa For TIE INS in Accommodation BlockAliОценок пока нет

- Jsa Nitrogen PurgingДокумент2 страницыJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- JSA For Washing and Air BlowingДокумент3 страницыJSA For Washing and Air BlowingMohammed MinhajОценок пока нет

- JSA For Piping-Hydro TestДокумент10 страницJSA For Piping-Hydro TestMuthu AlaguRajОценок пока нет

- Jsa For Civil Confined Space EntryДокумент11 страницJsa For Civil Confined Space EntryKhuda BukshОценок пока нет

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentДокумент5 страницJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiОценок пока нет

- Injury & Illness Prevention Program: Job Safety Analysis FormДокумент2 страницыInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanОценок пока нет

- Refueling JSA 4 08 2019 Rev.03 Near WaterДокумент9 страницRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariОценок пока нет

- 4..pipe Spool Air Blowing & Cleaning JSA 04Документ2 страницы4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- Risk Assessment - Pipe Fit Up - Hot WorkДокумент7 страницRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberОценок пока нет

- Hydro Test JSAДокумент2 страницыHydro Test JSAEruse Okejero88% (17)

- Job Safety Analysis: Required References Jsa ReviewДокумент4 страницыJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- Grounding System Jsa 2008Документ4 страницыGrounding System Jsa 2008Aldrin100% (5)

- JSA - Dismantling CM ShedДокумент4 страницыJSA - Dismantling CM ShedvivekaramanaОценок пока нет

- QP Cutting JSAДокумент6 страницQP Cutting JSAMohammed MujahidОценок пока нет

- JSA Template 2017-05-31 Cable Tray InstallationДокумент19 страницJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezОценок пока нет

- JSA Welding Confined SpaceДокумент2 страницыJSA Welding Confined Spacegkmlal100% (4)

- JSA For Hydro Test Activites (Generic)Документ4 страницыJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JHA For Tie-In at PCR14-02Документ7 страницJHA For Tie-In at PCR14-02Francis Enriquez TanОценок пока нет

- Jsa For Complete Erection of Tank-001Документ52 страницыJsa For Complete Erection of Tank-001Ashutosh80% (10)

- Aboveground Piping Installation Works 2016Документ7 страницAboveground Piping Installation Works 2016Aldrin75% (4)

- Jsa For WeldingДокумент2 страницыJsa For WeldingMohamed Samir50% (2)

- JSA Hot TapingДокумент3 страницыJSA Hot TapingHeris Sitompul0% (1)

- Jsa Welding Cutting and Grinding at Closing AreaДокумент7 страницJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- 013 JSA For Earthwork at Receiving BasinДокумент4 страницы013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- Jsa n2 Purging PDF FreeДокумент1 страницаJsa n2 Purging PDF FreeSKH CultureОценок пока нет

- JsaДокумент39 страницJsajithin shankar100% (3)

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsДокумент7 страницJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- JSA Install Pipe Support and CagingДокумент5 страницJSA Install Pipe Support and CagingYosua Situmorang100% (1)

- JSA For PiggingДокумент3 страницыJSA For PiggingMohammed Minhaj86% (7)

- JSA Hydrant Pipe LineДокумент7 страницJSA Hydrant Pipe Lineakshay pradeepОценок пока нет

- JSA For Welding GrindingДокумент7 страницJSA For Welding GrindingBabar78% (9)

- Jsa Lifting ProcedureДокумент9 страницJsa Lifting ProcedureMark Irwen GrebialdeОценок пока нет

- Jsa For HydrotestДокумент10 страницJsa For HydrotestAnonymous CcGYhZb080% (5)

- Tanks Confined Space JSAДокумент5 страницTanks Confined Space JSAkosoko100% (1)

- Work Permit Request For HydrotestingДокумент3 страницыWork Permit Request For HydrotestingZeyad Rezk50% (2)

- Jsa Welding and Sleeve InstallationДокумент5 страницJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- JSA - Chemical CleaningДокумент4 страницыJSA - Chemical CleaningkrshhОценок пока нет

- R1937-JSA-005 Job Safety Analysis For Riser InstallationДокумент3 страницыR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalОценок пока нет

- JSA of Drill Machine UseДокумент1 страницаJSA of Drill Machine UseSumair Khalid100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationДокумент6 страницJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jsa For Radiography WorkДокумент2 страницыJsa For Radiography WorkVipul ShankarОценок пока нет

- Jsa For Pipe Fabrication ErrectionДокумент5 страницJsa For Pipe Fabrication Errectionjithin shankarОценок пока нет

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Документ6 страницJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganОценок пока нет

- HIRADC Installation PipeДокумент4 страницыHIRADC Installation PipeamizanОценок пока нет

- JSA Hydro TestingДокумент1 страницаJSA Hydro TestingZeyad RezkОценок пока нет

- Quality Assurance Management: Quality Control Inspection Safety ProceduresДокумент5 страницQuality Assurance Management: Quality Control Inspection Safety ProceduresclintonОценок пока нет

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereДокумент5 страницCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurОценок пока нет

- MOS-09-Generator Set Installation-Rev-0 (05, Jan)Документ42 страницыMOS-09-Generator Set Installation-Rev-0 (05, Jan)Muhammad IrfanОценок пока нет

- Erection Steel Structure ProcedureДокумент15 страницErection Steel Structure ProcedureOussama Sissaoui100% (1)

- Rigging View Modular Overland ConveyorДокумент84 страницыRigging View Modular Overland Conveyorrtyuibnm100% (2)

- Hacking Work & Patch BackДокумент4 страницыHacking Work & Patch BackJamruz JamilОценок пока нет

- Resume LittletonДокумент1 страницаResume Littletonapi-309466005Оценок пока нет

- LEARNING ACTIVITY SHEET in Oral CommДокумент4 страницыLEARNING ACTIVITY SHEET in Oral CommTinTin100% (1)

- Reforms of Parvez MusharifДокумент8 страницReforms of Parvez MusharifTalha AslamОценок пока нет

- DesignДокумент402 страницыDesignEduard BoleaОценок пока нет

- Compal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentДокумент56 страницCompal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentSuhpreetОценок пока нет

- Learning Activity No.2Документ1 страницаLearning Activity No.2Miki AntonОценок пока нет

- Automatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriДокумент9 страницAutomatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriRegistro PersonalОценок пока нет

- PS410Документ2 страницыPS410Kelly AnggoroОценок пока нет

- თინათინ ზურაბიშვილი, თვისებრივი მეთოდებიДокумент111 страницთინათინ ზურაბიშვილი, თვისებრივი მეთოდებიNino LomaiaОценок пока нет

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Документ2 страницыRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonОценок пока нет

- Manual CAT 345C LДокумент20 страницManual CAT 345C LRicardo SotoОценок пока нет

- Ageing World ReportДокумент4 страницыAgeing World Reporttheresia anggitaОценок пока нет

- AA1 Adventure Anthology One r14Документ85 страницAA1 Adventure Anthology One r14dachda100% (1)

- D4462045416 PDFДокумент3 страницыD4462045416 PDFSamir MazafranОценок пока нет

- Math Cad 15Документ3 страницыMath Cad 15Kim ChanthanОценок пока нет

- Safe Motherhood Ao2016-0035 Quality Antenatal Care PDFДокумент9 страницSafe Motherhood Ao2016-0035 Quality Antenatal Care PDFGa B B OrlonganОценок пока нет

- Device InfoДокумент3 страницыDevice InfoGrig TeoОценок пока нет

- STRESS HealthДокумент40 страницSTRESS HealthHajra KhanОценок пока нет

- Questionnaire OriginalДокумент6 страницQuestionnaire OriginalJAGATHESANОценок пока нет

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFДокумент9 страницPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaОценок пока нет

- Marshall Mix Design (Nptel - ceTEI - L26 (1) )Документ7 страницMarshall Mix Design (Nptel - ceTEI - L26 (1) )andrewcwng0% (1)

- Calculating Staff Strength:: Find Latest Hospitality Resources atДокумент8 страницCalculating Staff Strength:: Find Latest Hospitality Resources atPriyanjali SainiОценок пока нет

- Maharishi Language of Gravity - SoS 27Документ3 страницыMaharishi Language of Gravity - SoS 27Prof. MadhavanОценок пока нет

- Ashfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)Документ36 страницAshfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)surajnayak77Оценок пока нет

- Stamp 07 eДокумент6 страницStamp 07 eDumitru TuiОценок пока нет

- CompTIAN10 004Документ169 страницCompTIAN10 004Ian RegoОценок пока нет

- 1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADДокумент15 страниц1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADDaniel MartinsОценок пока нет

- Unit 12 BriefДокумент7 страницUnit 12 Briefapi-477397447Оценок пока нет

- Ibridge Product Spec SheetДокумент2 страницыIbridge Product Spec SheetanupamОценок пока нет

- Norman K. Denzin - The Cinematic Society - The Voyeur's Gaze (1995) PDFДокумент584 страницыNorman K. Denzin - The Cinematic Society - The Voyeur's Gaze (1995) PDFjuan guerra0% (1)