Академический Документы

Профессиональный Документы

Культура Документы

Epoch XT Training Presentation

Загружено:

jpaguirresandИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Epoch XT Training Presentation

Загружено:

jpaguirresandАвторское право:

Доступные форматы

EPOCH XT Training Presentation

Introduction and Basic Operation

?

EPOCH XT

Product Overview

`

EPOCH XT Product Overview

The EPOCH XT is the first in a new

generation of Ultrasonic Flaw

Detectors from Olympus NDT.

Released in August of 2006,

The EPOCH XT has been designed to

set a new standard for flaw detector

performance. The XT instrument

platform is completely new and unique.

The instrument is 100% digital with

highly accurate analog signal

reproduction, and precise digital

filtering.

The EPOCH XT has also been

designed to withstand the harsh

environments that are common in the

NDT field with its rugged design and

IP67 environmental rating.

4

EPOCH XT Key Features

EN12668-1 Compliant The EPOCH XT is the only

Olympus NDT Flaw Detector to meet this specification.

Case sealed to IP67 Instrument case is designed to be

completely sealed against water for use in harsh

environments

Battery Flexibility The EPOCH XT can be used with

Lithium Ion, Nickel Metal Hydride, or Alkaline C-Cell

Batteries

Color Liquid Crystal Display (LCD) Provides good

visibility in a variety of lighting conditions with user

selectable color schemes

USB Host and USB Client Ports

EPOCH XT Key Features Standard Software

The EPOCH XT is offered with several standard software

features that were previously sold as added-cost options:

Standard Dynamic DAC/TVG

Standard Curved Surface Correction

Standard PRF Adjustment from 10Hz to 1000Hz in 10Hz increments.

At release the EPOCH XT

has three software options:

DGS/AVG

AWS D1.1 / D1.5

GageView Pro 3.1

EPOCH XT Key Features Onboard Reporting

The EPOCH XT allows the

operator to develop inspection

reports on the instrument and

directly print them using the

USB Host connection to a

PCL5 USB printer.

Document is .html format

All headers can be customized

in the instruments datalogger.

Each ID in a file is printed on a

separate page.

EPOCH XT Key Features Measurement Flexibility

The EPOCH XT can display up to 5 measurements on the live screen

Gate 1 and Gate 2 are completely independent unless the operator

chooses to have Gate 2 track Gate 1 (Echo-to-Echo mode).

Operator chooses measurements most relevant to his inspection.

Available measurements include: Thickness, Soundpath, Surface Distance,

Depth, Min & Max Depth, Amplitude, Min & Max Amplitude, Amplitude to Curve, dB to

Curve, Flat Bottom Hole Size, Overshoot, AWS D1.1 Rating, and Gate 2 Gate 1

8

EPOCH XT Key Features Corrosion Thickness

Gage Datalogger Files

Many customers use EPOCH flaw detectors for thickness surveys for

various reasons.

The EPOCH XT datalogger has been designed to make thickness

surveys more convenient by offering all of the file types found in the

37DL PLUS Corrosion Thickness Gage.

File Types:

Incremental

Sequential

Seq. with Custom Pt.

2D

2D with Custom Pt.

2D EPRI

3D

Boiler

9

EPOCH XT

Common Applications + Features

Weld Inspection

Standard DAC/TVG

AWS D1.1 / D1.5 Option

Soundpath Leg Grid Mode

Onboard Reporting

Both gates may be used to

take measurements

Forging Inspection

Standard DAC/TVG

TVG Table

Onboard DGS/AVG Option

Keypad adjustable PRF

500+ inch range

475V Tunable Square Wave

Pulser

Composite Insp.

Tunable square wave

pulser with PerfectSquare

Technology

475V max pulse energy

Digital Filters

TVG Table

Corrosion Surveys

37DL+ file types

Large memory capacity

Onboard reporting

File Summary view

Database download to

USB drives.

Casting Inspection

Tunable square wave

pulser with PerfectSquare

Technology

475V max pulse energy

Digital Filters

TVG Table

Boiler Inspection

Superior EMAT

performance

37DL+ file types

Large memory capacity

Onboard reporting

File Summary view

Database download to

USB drives.

Thin Materials

PerfectSquare

technology allows excellent

near surface resolution

Spike Mode available

First Peak Measurement

Mode

50V pulse energy setting

Plastic Inspection

Tunable square wave

pulser with PerfectSquare

Technology

475V max pulse energy

Digital Filters

TVG Table

Capabilities will be further expanded with Phase II development.

19

EPOCH XT

Physical Features

11

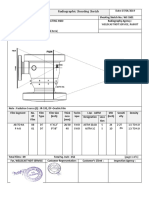

EPOCH XT Dimensions

Weight: 4.7 lbs. (2.1kg)*

Height: 10.9 in. (277mm)

Case Width: 5.5 in. (140mm)

Thickness at hand: 2.0 in. (50mm)

Thickness at screen: 2.5 in. (63mm)

* Weight with Lithium Ion Battery

1?

EPOCH XT Transducer Connections

BNC or Large LEMO transducer posts are available at the

same price.

BNC connectors are designed to be sealed to IP67. Caps are

provided to protect unused connector in wet environments

LEMO connectors do not meet IP67. Will be supplied with a protective

rubber cap, but these still must be protected from water.

Standard size LEMO connectors for IP67 are not available but we are

pursuing other connection possibilities.

It is possible to switch connector types, this must be

performed at an authorized Olympus NDT service center.

1`

EPOCH XT IP67 Environmental Rating

The EPOCH XT is designed to meet the requirements of IP67

This test means that the instrument can be submerged in 3 ft of water for 30

minutes and no liquid will enter the case.

This test has been conducted and passed several times. The instruments

actually float and must be weighted down to conduct the test.

HOWEVER

ONDT does not recommend that operators

submerge their instrument for any reason.

The EPOCH XT is not suitable for use

underwater.

ONDT will not cover internal water damage

under warranty in most cases.

The IP67 rating is intended to provide a

concrete specification that communicates

the environmental durability of the

instrument. Operators must still use their

best judgment before exposing the

instrument to a harsh environment.

14

EPOCH XT Handstrap Design

Bi-directional design for left or

right handed operation

Three mounting locations are

built into the instrument case

Switch hand strap from one side

to the other without any tools

Side mounting points

Fixed bottom mounting point

1

EPOCH XT Integrated D-Rings

The EPOCH XT has four integrated

D-Ring connectors that allow the use

of a chest harness.

The D-Ring mounting locations are

extremely rugged.

Removal of D-Rings will not affect

the instruments seal.

Top D-Rings are mounted at the

pipestand mounts.

Bottom D-Rings are mounted at the

lower corners of the instrument.

1

EPOCH XT Pipestand Design

The EPOCH XT has a completely

new pipestand design.

Compact

Lightweight

Durable

Simple adjustment just pull the

stand to the desired position,

you do not need to pull or push

at the instrument mounting

points.

Easily removable

1

EPOCH XT Battery Door

Quick release fasteners allow

access to the battery compartment

without the use of tools.

Built-in channels hold alkaline C-

Cell batteries in place.

Membrane vent sealed with Gore-

Tex

TM

to keep moisture out while

allowing gases to exit.

18

EPOCH XT USB Connection Door

Sealed door protects USB Host,

USB Client, and AC Adaptor

connections.

Sealed with thumb screws to allow

access without the use of tools.

USB Client used for communication

with a PC (GageView Pro)

USB Host used for direct printing

and for database backup to USB

drives.

19

EPOCH XT Optional Hardware I/O

The sealed 16 pin Lemo connection on the top of the

EPOCH XT is called the Hardware I/O connection.

This connection is an option on all EPOCH XTs.

All instruments will ship with this connection at no

additional charge until October 2006.

This connection is currently used for Alarm Outputs,

Trigger Input, and Sync Out.

Future uses include the instruments encoder interface.

?9

EPOCH XT

Hardware Design

?1

Unique Digital Architecture

The EPOCH XT is the first of a new generation

of instruments from Olympus NDT.

The EPOCH XTs 100% digital architecture is the

first of its kind.

This allows performance and features that have

never been available on portable ultrasonic flaw

detectors.

Three patents have been filed based on the

EPOCH XTs design to protect our significant

advantages over the competition.

??

High Dynamic Range Receiver

The EPOCH XTs receiver design allows class leading performance

Excellent Signal-to-Noise performance

High Dynamic Range (usable gain range)

Over 100dB for all filter settings

Unique EPOCH XT only features:

Full gain adjustment on frozen waveforms.

Amplitude measurement accuracy of 0.25%

Unprecedented TVG performance with 110dB

of dynamic gain in a setup and 100dB/usec

slopes between points. *depends on filter setting

?`

Digital Receiver Filters

Digital Receiver Filters provide many advantages over the analog

filters used in competing equipment and in the EPOCH 4 series.

Advantages include:

Highly accurate filter performance

Elimination of variability due to components

New and/or custom filters can be created

and implemented through software updates.

*This is not going to be a free service. If a

customer is interested we would have to quote

this as an added-cost feature.

?4

First Peak Measurement

The EPOCH XT is has three built in measurement modes:

Highest Peak (Peak) Measurement

Edge (Flank) Measurement

First Peak Measurement

First Peak Measurement measures the first peak in Gate 1 or Gate 2.

This feature is typically used to make accurate thickness

measurements on thin materials.

?

EPOCH XT Keypad Design

?

EPOCH XT KEYPAD (English)

5 Function Keys

Three setup menus

for display settings,

measurements and

general instrument

preferences.

Region within gray line

used for direct alpha-

numeric character entry.

Active whenever

instrument is in EDIT

MODE or when operator

presses [ALPHA/NUM].

Main navigation area

is similar to EPOCH

4 series.

?

EPOCH XT KEYPAD (International)

5 Function Keys

Three setup menus

for display settings,

measurements and

general instrument

preferences.

Region within gray line

used for direct alpha-

numeric character entry.

Active whenever

instrument is in EDIT

MODE or when operator

presses [ALPHA/NUM].

Main navigation area

is similar to EPOCH

4 series.

?8

New Keypad Functions

Direct Entry of Parameter Values:

The EPOCH XT keypad has an integrated alphanumeric section.

This section is primarily used to enter characters in the instruments

datalogger, similar to the EPOCH 4 series.

This section may also be used to directly enter

parameter values for rapid adjustment. This is

easily accomplished by following the steps below:

1. Press the button for the desired parameter.

2. Press the [Alpha/Num] key.

3. Punch in the value on the keypad.

4. Press [Enter].

To set the GAIN to 55dB, you would press:

?9

New Keypad Functions

Coarse and Fine Parameter Adjustment

Parameters in the EPOCH XT have three

adjustment methods available:

Direct Entry

Function Key Presets

Slewing with the Arrow Keys

In order to speed up adjustments with the Arrow keys, the EPOCH XT has a new

feature that allows most parameters to be adjusted in Coarse or Fine increments

with the Arrow keys.

The UP and DOWN Arrow keys are used for COARSE adjustments.

The LEFT and RIGHT Arrow keys are used for FINE adjustments.

In most cases, the coarse and fine steps have been defined for the operator. For

the GAIN adjustment the operator may set his preferences in the INST SETUP

Menu EditPara TAB. The default setting is 6dB for Coarse steps and 0.1dB for

Fine steps.

FINE

COARSE

`9

New Keypad Functions

Delay Function:

The EPOCH XT has a new Delay function, also known as Display Delay.

This function is used to move the time (distance) area that is currently

viewed onscreen without affecting the calibrated zero offset position.

This feature has been available on competing instruments for quite awhile,

but the EPOCHs have only had a ZOOM function available. The EPOCH XT

also retains the ZOOM feature for Gate 1.

DELAY

`1

New Keypad Functions

Meas / Reset Function:

The MEAS/RESET function is similar to the same function in Olympus NDT

Thickness Gages.

This button is used to exit from menus and return to the live A-Scan

measurement screen.

`?

EPOCH XT

User Interface

``

EPOCH XT Software User Interface

The EPOCH XT has a completely new software user interface design.

Some of the highlights of the new design are listed below:

More modern appearance with better organization of parameters.

Split screen and full screen display modes that are familiar to EPOCH

operators

Multiple color schemes to maximize visibility in various lighting conditions

New grid display modes for X and Y axes meet various market needs

5 user customizable measurement locations

New tabbed menu structure similar to MG2 series

`4

EPOCH XT Display (Split Screen)

5 Function Presets

4 Measurement Locations

Dual Gate Icons

Battery Indicator

New Delay Setting

PRF Adjustment

File and ID Names

NOTE: The fourth

(large) measurement

location can be split in

half to display the fourth

and fifth measurement if

activated by the

operator.

`

EPOCH XT Display (Full Screen)

5 Function Presets

4 Measurement Locations

Dual Gate Icons

Battery Indicator

New Delay Setting

Range Display

Leg Indication

File and ID Names

NOTE: The fourth

(large) measurement

location can be split in

half to display the fourth

and fifth measurement if

activated by the

operator.

`

EPOCH XT Color Schemes

The Factory Color Scheme is the default setting for the EPOCH XT.

This color scheme provides excellent indoor visibility. It has been

designed to provide color differentiation between parameter labels,

settings, and units, and also between measurement icons and

the displayed readings.

`

EPOCH XT Color Schemes

The screenshots below show the Outdoor Color Scheme.

The Outdoor Color Scheme is designed to allow good display

visibility in direct sunlight.

`8

EPOCH XT Color Schemes

The ELD Color Scheme is shown in the screenshots below.

The ELD Color Scheme is an alternative to the Factory indoor color

scheme. This scheme has been designed to be similar to the ELD

displays in previous generation equipment with some improvements.

`9

EPOCH XT Grid Modes

The EPOCH XTs grid display modes have been enhanced to meet

global market needs and competitive instrument features.

The X-Axis has three display modes:

Standard: 10 equally spaced grid lines. Same as EP4 series

SoundPath: 5 equally spaced grid lines that show sound path

measurements. Based on Delay and Range settings.

Leg: This mode displays up to 5 grid lines labeled LEG1 to LEG5. These

grid lines correspond with the skip distance for your angle beam setup.

The Y-Axis has two display modes:

100%: Displays amplitude from 0 to 100% screen height just like the EPOCH

4 Series. Amplitude is measured to 110%.

110%: Displays amplitude from 0 to 110% screen height. Allows easy

instrument setup to 100% for linearity or other system checks.

49

EPOCH XT Grid Modes

Standard X-Axis Display Examples:

100% A-Scan 110% A-Scan

41

EPOCH XT Grid Modes

Soundpath X-Axis Display Examples:

100% A-Scan 110% A-Scan

4?

EPOCH XT Grid Modes

Leg X-Axis Display Examples:

100% A-Scan 110% A-Scan

4`

EPOCH XT Setup Menus

The EPOCH XT has three setup menus that are used

to control various instrument functions.

DISPLAY SETUP MEAS SETUP INSTR SETUP

This strategy has been implemented because the

EPOCH 4 series menu has gotten complex and

many levels deep. The three separate menus

organize functions more logically.

This structure also allows us to take advantage of a

tabbed menu structure similar to the MG2 / 35 series

instruments.

44

EPOCH XT Setup Menu Structure

All of the menus in the EPOCH XT have been organized in a similar

manner and the navigation within the menus is standardized.

There are four types of controls that are found within a menu:

TABS

SUB-LEVEL TABS

CONTROL GROUPS

PARAMETERS

Navigation and adjustment is accomplished by using the arrow

keys and the enter key. In some cases the operator may use the

direct entry method to enter parameter values if desired.

NOTE: Full instructions for menu navigation can be found in the instrument operating manual.

4

EPOCH XT Setup Menu Navigation

TABS run across the top of the display when the operator enters one

of the setup menus:

The operator uses the Left and Right Arrow keys to move from one tab

to the next. The active tab is highlighted by the instrument. The

operator presses the [ENTER] key to select and move into a TAB.

4

EPOCH XT Setup Menu Navigation

SUB-LEVEL TABS run vertically on the left side of the display. These

are only present in some of the EPOCH XT TABS.

In the screenshot to the left the operator

has already selected the TAB EditPara by

highlighting it and pressing [ENTER].

The operator is now navigating through a

set of vertical SUB-LEVEL TABS. He must

use the Up and Down Arrow keys to select

a tab (highlight it), and press [ENTER] to

enter the SUB-LEVEL TAB.

Pressing [2

nd

F], [ENTER] will bring the

operator back to the EditPara TAB.

4

EPOCH XT Setup Menu Navigation

CONTROL GROUPS are sets of PARAMETERS that have been

grouped together based on their function. These are located within

TABS or SUB-LEVEL TABS depending on the setup menu. CONTROL

GROUPS are usually surrounded by a box for visual reference.

In the screenshot to the right you

see the Meas TAB in the MEAS

SETUP Menu.

This TAB contains two

CONTROL GROUPS.

CONTROL GROUP 1

CONTROL GROUP 2

48

EPOCH XT Setup Menu Navigation

In this example the operator has used the Left and Right Arrow Keys to select the

Meas TAB. To enter the first CONTROL GROUP he must press [ENTER]. To

enter the second CONTROL GROUP he must press [ENTER] again. Since there is

no third CONTROL GROUP in this TAB, pressing the [ENTER] key again will bring

the operator back to the Meas TAB.

1

st

[ENTER] Press 2

nd

[ENTER] Press 3

rd

[ENTER] Press

49

EPOCH XT Setup Menu Navigation

PARAMETERS are selected (highlighted) using the Up and Down

Arrow keys. They are typically adjusted using the Left and Right

Arrow keys, but in some cases the operator may use direct entry.

In the screenshot to the right the

operator has used the [ENTER] key to

select CONTROL GROUP 2, and the

Up and Down Arrow keys to select the

X Value PARAMETER.

The Value of the X Value

PARAMETER is adjusted using the Left

and Right Arrow keys, or by pressing

[ALPHA/NUM], entering the desired

value, and then pressing [ENTER].

9

EPOCH XT Display Setup Menu

This menu is used to control how the instrument will display

information on the screen. There are two tabs within this menu:

Color TAB:

Controls for instrument color scheme

Brightness control

Shows examples of display appearance for a selected color scheme

A-Scan TAB:

BASELINE BREAK selection

Live A-Scan and Peak Mem/Hold A-Scan filled or hollow

Grid setup for X and Y axes.

1

EPOCH XT Setup Menus

DISPLAY SETUP MENU TABS

?

EPOCH XT Measurement Setup Menu

This menu is used to select the 5 displayed measurements, control

gate measurement modes, and to setup options/features like

DAC/TVG, DGS, AWS, etc. There are three tabs:

Meas TAB:

Select displayed measurements

Select units (in, mm, usec)

Select measurement resolution for thickness and amplitude

Calibration mode Soundpath or Depth

X-Value same as EP4 series X-Correct

CSC setup (now a standard feature)

Select Trigger Mode

`

EPOCH XT Setup Menus

Gates TAB:

Activate Gate 2 Tracking. This forces Gate 2 to track the position of a

measurement in Gate 1 similar to Echo-to-Echo in an EPOCH 4.

GATE 1 Measurement Mode (PEAK, EDGE, FIRST PEAK)

GATE 2 Measurement Mode (PEAK, EDGE, FIRST PEAK)

GATE 1 Polarity (DEFAULT, POS, NEG)

GATE 2 Polarity (DEFAULT, POS, NEG)

Options TAB

DAC/TVG

DGS/AVG

AWS

More to come

4

EPOCH XT Setup Menus

MEAS SETUP MENU TABS

EPOCH XT Setup Menus

MEAS SETUP MENU TABS

EPOCH XT Instrument Setup Menu

INSTR SETUP This menu is used to select preferences, regional

settings, control Editable Parameters, and check instrument status.

General TAB:

Pulser Mode (Square or Spike)

Filter Group (Standard or other custom groups)

Language

Key Beep

Alarm Beep

All Lock

Cal Lock

Locale for Radix and Date Pattern

Temperature Calibration mode (Auto or Manual)

Date and Time settings

EPOCH XT Instrument Setup Menu

INSTR SETUP This menu is used to select preferences, regional

settings, control Editable Parameters, and check instrument status.

EditPara TAB:

Editable Parameters similar to EP4 series

Status TAB:

Instrument information

Splash Screen TAB

Setup company info for startup screen

8

EPOCH XT Setup Menus

INSTR SETUP MENU TABS

9

EPOCH XT Setup Menus

INSTR SETUP MENU TABS

9

EPOCH XT

Software Options

1

EPOCH XT DAC/TVG

The EPOCH XT DAC/TVG feature is standard in all instruments. This

feature is similar to the Advanced DAC/TVG option in the EPOCH 4

series instruments with improvements.

DAC/TVG Operation Modes:

ASME

ASME III

CUSTOM

JIS

20-80%

TVG Table

?

EPOCH XT DAC/TVG Activation

DAC/TVG is setup and activated in the MEAS SETUP menu under the

Options TAB as shown in the screenshot below:

Once the desired DAC/TVG

mode has been selected the

operator presses the

[MEAS/RESET] key.

The operator will be returned to

the live screen and the EPOCH

is ready to acquire DAC/TVG

points.

`

EPOCH XT DAC/TVG Setup

The DAC/TVG Setup Procedure is the same for ASME, ASME III,

Custom and JIS DAC modes.

DAC/TVG Setup Steps:

1. Position Gate 1 over the first echo.

2. Press [F5] (Auto 80%)

3. Press [F1] to capture the point

4. Position Gate 1 over the next echo

5. Repeat steps 2-4 until all points are

captured.

6. Press [F4] (DONE) to complete the

setup.

Other Functions:

DELETE Deletes the last captured

point.

ERASE Erases the entire DAC/TVG

setup.

4

EPOCH XT DAC/TVG Operation

Once the DAC/TVG points have been captured the operator is ready to

use the instruments DAC/TVG setup. The curves are fully dynamic

with Range, Delay, Gain, and Zoom. The F-Key Functions are:

F1 = DAC/TVG View Switches between

the DAC and TVG views of the setup.

F2 = DAC/TVG Gain Allows the operator

to move the DAC/TVG curves and

the echoes vertically to achieve

accurate and code-compliant defect

sizing.

F3 = Gain Step This parameter sets the

adjustment step for DAC/TVG Gain.

F5 = Next DAC/TVG Rotates through

the available DAC/TVG curves.

Measurements are taken based on

the currently selected curve (double

thickness on screen).

Special DAC/TVG Modes - Custom

The Custom DAC/TVG feature allows the operator to setup up to three

warning curves (plus the main curve) from +10dB to -24dB from the

main curve. The operator must choose the number of curves in the

activation procedure. After that, the setup is the same as ASME DAC.

Special DAC/TVG Modes 20-80%

20-80% DAC uses a combination of DAC and TVG to keep the DAC

curve between 20% and 80% screen height. The only difference in the

setup procedure is that the operator does not use the Auto-80%

feature before each point is captured.

Special DAC/TVG Modes TVG Table

The TVG Table in the EPOCH XT is an advanced feature that is used to

create fully customized TVG setups. These setups are not linked to

any DAC setup. Typical uses include:

Building custom TVGs for immersion inspection

Building TVGs for large forging inspections using DGS/AVG diagrams

for the transducer that will be used

Suppress Interface and Backwall echoes to achieve better near and far

surface resolution.

Eliminating near surface noise in materials like composites while using

high gain in the far field to see clearly see the backwall and far surface

defects.

8

Special DAC/TVG Modes TVG Table

In the example below the TVG Table is being used for three purposes:

Equalize defect echo heights throughout the test piece

Suppress the interface echo when the sound enters the test piece. This

allows near surface defects to be detected.

Suppress the backwall echo so it can be monitored on-screen and to

allow detection of far surface defects.

9

Special DAC/TVG Modes TVG Table

Near Surface Defect Far Surface Defect

TVG Table Specifications are by far best in class:

Dynamic Gain Adjustment 110dB (competitors offer 40dB)

Slope Up to 100dB/usec* (competitors offer 12dB/usec to 40dB/usec)

Number of Points 50 (competitors offer 10 to 20 points)

*Depends on Filter Setting

9

EPOCH XT DGS/AVG

The EPOCH XT offers DGS/AVG as an added-cost option. The

functionality of the option is very similar to the onboard DGS/AVG

option in the EPOCH 4 series. All recent updates in the EPOCH 4

series have been carried over into the EPOCH XT.

Registration Level is adjustable on the

live screen.

Delta Vt (Transfer Correction) is

adjustable on the live screen.

X-Value is adjustable in DGS/AVG setup.

1

DGS/AVG Activation

The DGS/AVG option is activated in the MEAS SETUP menu under the

Options TAB. The Activation steps are listed below:

1. Turn DGS/AVG ON

2. Select Probe Type

a. Library Straight Beam

b. Library Angle Beam

c. Library Dual

d. Custom Straight Beam

e. Custom Angle Beam

3. Select Probe

4. Select Reference Reflector

5. Enter Transfer Correction

6. Enter Registration Level

7. Enter Warning Level

8. Enter Attenuation Corrections

9. Enter X-Value for AB Probes

?

DGS/AVG

After all of the DGS parameters have been setup, the operator presses

[MEAS/RESET] to return to the live screen. He must capture the echo

from his reference reflector and the instrument will draw the DGS/AVG

curves on the display.

Press F1 to capture reference echo. Size defects with DGS/AVG Curve

`

EPOCH XT AWS D1.1 / D1.5

The EPOCH XT AWS D1.1 / D1.5 Software Option is

intended to assist operators performing weld inspections

according to AWS D1.1 / D1.5 regulations.

4

EPOCH XT AWS D1.1 / D1.5

While performing the inspection, the EPOCH provides the operator

with the calculated D value (A-B-C=D) used to evaluate welds.

A (Indication Level): Automatically calculated in the EPOCH 4 for any

indication echo less than 100% Full Screen Height.

B (Reference Level): User entered at instrument calibration.

C (Attenuation Factor): Automatically calculated based on the EPOCH

Soundpath Calculator.

The EPOCH saves all data for A, B, C, and D for later review and

inspection report generation.

AWS Activation

The AWS D1.1 / D1.5 Option is activated in the MEAS SETUP Menu

under the Options TAB.

AWS Activation

After AWS D1.1 / D1.5 is turned ON, the operator must capture a

reference echo. This is shown in the screenshots below:

AWS Measurement

Once the reference echo has been captured the EPOCH XT will

automatically provide a D rating for a non-saturated gated reflector.

This is shown below:

The instrument will store all setup parameters, measurements, the

A-Scan, as well as the values for A, B, C, and D from the AWS

formula.

8

EPOCH XT

Calibration

9

Straight Beam Calibration

Materials:

CABLE

BCM-74-6

COUPLANT

B-2

TRANSDUCER

A109S-SM

TEST BLOCK

2214E

89

Straight Beam Calibration

Parameters Reset

Parameters Reset will revert to the factory default settings.

PRESS:

In the RESETS section,

Select PARAMETERS:

Press to Exit this SETUP when completed

To Reset

To Confirm

81

Straight Beam Calibration

Place a Drop of Couplant on the .200 and .500 Steps and

set the transducer on the .200 (THIN STANDARD) step.

INSTRUMENT PARAMETERS SETUP

10 dB of Gain =

.2320 in/uS Velocity =

8?

Straight Beam Calibration

INSTRUMENT PARAMETERS SETUP

5 Mhz Transducer =

1.5 8.5 Filter =

1 Range =

8`

Straight Beam Calibration

CAPTURE AND CALIBRATE

Gate 1 Start

= .200

Gate 1 Width

= .200

Echo Height = 80%

84

Straight Beam Calibration

CAPTURE AND CALIBRATE

Calibrate to .200 Step

Enter .2

8

Straight Beam Calibration

Move the transducer to the .500 step (THICK STANDARD)

CAPTURE AND CALIBRATE

Gate 1 Start = .500

Echo Height = 80%

8

Straight Beam Calibration

CAPTURE AND CALIBRATE

Calibrate to .500 Step

Enter .5

8

Straight Beam Calibration

Straight Beam Calibration is complete.

Capturing Echoes with the gate will give you readings in

the top right. Editing the placement of these readings can

be done in the MEAS SETUP Menu.

88

Angle Beam Calibration

Materials:

CABLE

BCB-74-6

COUPLANT

B-2

TRANSDUCER + WEDGE

A431S-SM

ABWS-6-45

TEST BLOCK

TB7541-1

89

Angle Beam Calibration

4 Steps for an Angle Beam Calibration

1. Locate the Beam Index Point (BIP) of the Probe.

2. Verify the Refracted Angle

3. Calibrate for Distance (Using the Auto-Cal Feature)

4. Calibrate for Sensitivity

99

Angle Beam Calibration

Parameters Reset

Parameters Reset will revert to the factory default settings.

PRESS:

In the RESETS section,

Select PARAMETERS:

Press to Exit this SETUP when completed

To Reset

To Confirm

91

Angle Beam Calibration

INITIAL SETUP

50 dB of Gain =

.1280 in/us Velocity =

45 Deg Angle =

2.25Mhz Transducer =

10 Range =

.5 4.0 Mhz Filter =

2.27 Mhz

9?

Angle Beam Calibration

Locate the Beam Index Point:

1. Align the wedge with the zero mark on the IIW Type I Block

2. Move the transducer forward and backward until the echo amplitude from the 4 arc

is peaked (The Peak Memory can be used for this by pressing: )

3. After the signal has been peaked,

mark on the wedge directly over the

zero mark on the IIW. This is the

Beam Index Point.

1/4 Locate Beam Index Point

9`

Angle Beam Calibration

Verify the Refracted Angle

1. Position the transducer over the appropriate angle mark on the IIW Block (In this

case it is the 45 deg located on the bottom side of the IIW).

2. Mover the transducer forward and backward to peak up echo from the large

circular hole in the block. Peak Memory aids in this process by pressing .

2/4 Verify Refracted Angle

94

Verify the Refracted Angle

Angle Beam Calibration

After the signal is peaked, hold the transducer stationary. Verify that the Beam

Index Point mark on the wedge is equal to the degrees called out on the IIW

Block.

This is the REFRACTED ANGLE for the transducer and wedge.

If the Beta Value differs from the one initially entered, enter a new angle by

pressing and fine tuning the angle using keys.

2/4 Verify Refracted Angle

9

1. Couple the transducer to the IIW Block so that the

Beam Index Point is directly over the 0 deg mark.

Angle Beam Calibration

4

1

2. Adjust Gain so

that 2 waveforms

are observed

(the 4 and 9).

3/4 Calibrating for Distance

9

Angle Beam Calibration

Peak the 4 echo using

Press to capture the

echo and press Auto-8

With the Gate on the 4 echo,

press then

Enter

Then to continue

Note: The Peak Mem must be turned off before pressing the CAL key

3/4 Calibrating for Distance

9

Angle Beam Calibration

Move the Gate to the 9

echo and bring it to 80%

Auto-80 Feature

Press then

Enter the distance of 9 by

followed by

3/4 Calibrating for Distance

98

On the underside of the IIW

Block, peak the 0.060 hole

GATE button, bring the peak

of this echo to 80%

Press then

This sets the Ref Gain

Angle Beam Calibration

0.060 side

drilled hole

4/4 Calibrating for Sensitivity

99

The Reference Gain has

been set.

To adjust Scanning dB:

In 6.0 dB Increments

Angle Beam Calibration

4/4 Calibrating for Sensitivity

In 0.1 dB Increments

199

EPOCH XT

Datalogger

191

EPOCH XT Datalogger

The EPOCH XT has an advanced datalogger designed for typical flaw

detection use and also for corrosion thickness gauging surveys.

The datalogger is located in a menu similar to the three setup menus

discussed previously.

The datalogger allows the operator to setup several file types

Incremental

Sequential

Seq. with Custom Pt.

2D

Up to 10,000 IDs may be saved. Every ID contains: Operator selected

measurements, A-Scan, Instrument Setup, Software Option Setup,

Alarm Conditions, Display Flags/Markers, and Peak Mem / Peak Hold

conditions.

2D with Custom Pt.

2D EPRI

3D

Boiler

19?

EPOCH XT Datalogger

The operator has the ability to enter additional information for each file

created:

Description

Inspector ID

Location Note

Onboard Reports with customized

headers may be created.

Instrument Parameter and Database

resets may be performed

19`

EPOCH XT Datalogger Menu

PRESS:

194

EPOCH XT Datalogger Menu

19

EPOCH XT File Open TAB

The File Open TAB displays a list of all of the files in the EPOCH

XTs datalogger.

The operator uses the Up and Down Arrow Keys to highlight the

desired file.

For the highlighted file the instrument will display:

Filename

File Type

Date and Time Created

Description

Inspector ID

Location Note

There are two levels of Function

key presets in this TAB.

Level 1

Level 2

19

EPOCH XT File Open TAB

File Open Tab Function Key Descriptions

OPEN This will open the selected file and return the operator to the

live screen. This does NOT recall any instrument setup parameters.

This function only makes the opened file the current save-to location.

CONTENTS This function allows the operator to view the individual

stored IDs within a file. You will see all stored measurements, the A-

Scan, Setup Parameters, etc.

SUMMARY This function allows the operator to view the saved

measurements for each stored ID within the file.

CANCEL Returns the operator to the live A-Scan display.

19

EPOCH XT File Open TAB

File Open Tab Function Key Descriptions continued

RENAME Allows the operator to rename the file in a popup box as

shown in the screenshot below:

CLEAR Clears data stored within the selected file.

DELETE Deletes the selected file and all data.

198

EPOCH XT File CONTENTS

When the operator view the contents of a file he will see a scrollable

window as shown in the screenshots below:

The operator uses the up and down arrow

keys to view the entire ID.

The top of the window shows the A-Scan and

instrument measurements.

The bottom of the window shows the

instrument setup parameters and any

additional measurements. In this case you

see AWS D1.1 related measurements

displayed at the bottom of the ID window.

The operator uses the Left and Right Arrow

keys to move from one ID to the next within

the file.

199

EPOCH XT File CONTENTS

When the operator view the contents of a file he will see a scrollable

window as shown in the screenshots below:

File CONTENTS Function Key Descriptions:

FIRST Jumps to the first ID in the file.

LAST Jumps to the last ID in the file.

RECALL Recalls the selected ID and returns to the

live screen. The instrument setup will be frozen on recall.

The operator must press [MEAS/RESET] to begin

inspecting.

CLEAR Clears the data in the selected ID

FIND Allows the operator to type in the name of an ID

and jump directly to it.

119

EPOCH XT File SUMMARY

When the operator view the contents of a file he will see a scrollable

window as shown in the screenshot below:

This window shows a list of all of

the IDs within the file, the

measurement units (in, mm, or

usec), and the measurements that

the operator has chosen to store.

Up to 5 measurements can be

stored and viewed for each ID#.

ID# File Name Measurements Unit

111

EPOCH XT Create TAB

The EPOCH XT Create TAB allows the operator to setup and create

new files that will be placed in the list located under the Open TAB.

The Create tab is made up of several CONTROL GROUPS. These will

change based on the file type that is being created. In general, the file

creation procedure is:

1. Select the file type

2. Name the file

3. Setup an ID prefix if desired

4. Build the ID list

5. Select ID increment method

6. Enter description if desired

7. Enter inspector ID if desired

8. Enter location note if desired

9. Press F1 to CREATE the file

11?

EPOCH XT Page Setup TAB

The PageSetup TAB is used to generate onboard reports in the

EPOCH XT. This TAB provides the operator with up to 8 Labels and

Headers that will appear at the top of a printed report. These reports

may be printed directly from the instrument to a PCL5 compatible USB

printer.

The operator also uses this tab

to setup the onboard printer

driver for laser jet or bubble jet,

draft mode or high quality, and

color or black and white.

11`

EPOCH XT Sample Report

114

EPOCH XT Resets Tab

The Resets TAB is used to reset the instrument to the condition it was

in when it shipped from the factory.

Master / Database Resets all parameters and clears the instruments

datalogger. This will also shut down the instrument.

Parameters Loads the factory default setup parameters and returns

the operator to the live A-Scan display.

Editable Parameters Reloads factory

values for all function key presets.

11

EPOCH XT

Accessories

11

EPOCH XT Accessories

Batteries When placing an order you will be able to specify NiMH or

Lithium Ion battery. The instrument

and its external charger can charge

both battery types.

C-Cells All EPOCH XTs have the

ability to use Alkaline C-Cell

batteries. Every instrument will ship

with a foam block to help hold C-Cell

batteries in place before the battery

door is closed.

11

EPOCH XT Accessories

External Charger The EPOCH XT

has an external smart battery

charger available as an option. This

battery charger has the ability to

calibrate these batteries periodically

greatly extending their useful life.

Sun Shade The sun shade casts a

shadow on the EPXT display. Outdoor

conditions might require this

accessory for better visibility. The sun

shade grips onto the XXX with or

without the Rubber Boot.

118

EPOCH XT Accessories

Hardware I/O This option should be ordered when the instrument is

ordered because an upgrade requires the instrument to be sent to a

service center.

Hardware I/O cable We are designing a 16 pin LEMO cable to match

the instruments I/O port. The cable will not have a connection on the

non-instrument end. This cable will be supplied with an output diagram

for integration.

Rubber Boot The rubber boot

features an removable plastic window

that protects the instruments

permanently bonded display window.

119

EPOCH XT Accessories

Chest Harness The EPOCH 4 chest harness is available for use with

the EPOCH XT. Since D-Rings are case mounted the Rubber Boot is

not required for chest harness use.

Transport Case The EPOCH XT Transport case is being designed to

allow more storage of transducers, extra batteries, cables, couplant, etc.

1?9

Questions??

Вам также может понравиться

- Panametrics Olympus Epoch XT DatasheetДокумент8 страницPanametrics Olympus Epoch XT Datasheetcorey_resslerОценок пока нет

- UTChapter5 CalibrationДокумент82 страницыUTChapter5 CalibrationAzhar GulzarОценок пока нет

- Procedure For UtДокумент12 страницProcedure For UtMohammad SyeduzzamanОценок пока нет

- 4#600 Body RSSДокумент1 страница4#600 Body RSSRavi patelОценок пока нет

- Practical Eddy Current Testing: - General ProcedureДокумент7 страницPractical Eddy Current Testing: - General Procedurekhizer mohamedОценок пока нет

- Reviewed UT Procedure 10-12-2016Документ18 страницReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- Rp-20-Ut-011-Tcr-Saudi CementДокумент1 страницаRp-20-Ut-011-Tcr-Saudi CementRonel John Rodriguez CustodioОценок пока нет

- Calibration Methods and Reference Standards in Ultrasonic TestingДокумент4 страницыCalibration Methods and Reference Standards in Ultrasonic TestingKevin HuangОценок пока нет

- Positive Material Identification (Pmi)Документ2 страницыPositive Material Identification (Pmi)MurugadossRajendranОценок пока нет

- IRIS SetupДокумент32 страницыIRIS SetupAqib AliОценок пока нет

- Phased Array and TOFD ProbesДокумент17 страницPhased Array and TOFD ProbesNDTInstructorОценок пока нет

- Annexure-1 Scan PlanДокумент6 страницAnnexure-1 Scan Planநந்த குமார் சம்பத் நாகராஜன்Оценок пока нет

- API 510 Corr. Rate & Rem Life Cal.Документ1 страницаAPI 510 Corr. Rate & Rem Life Cal.Ejaz Ahmed RanaОценок пока нет

- Ultrasonic Testing Report For PipingДокумент54 страницыUltrasonic Testing Report For Pipingeldobie3Оценок пока нет

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Документ18 страницCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Tĩnh Hồ TrungОценок пока нет

- NDT in Canada 2017 Olivier LavoieДокумент20 страницNDT in Canada 2017 Olivier LavoieChandrashekhar ThiramdasuОценок пока нет

- Astm Reference Block For MetalДокумент10 страницAstm Reference Block For MetalrupamОценок пока нет

- Eddy Current Standard Depth and F90 Calculator: FrequencyДокумент3 страницыEddy Current Standard Depth and F90 Calculator: Frequencyemre sahinОценок пока нет

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFДокумент11 страницInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Оценок пока нет

- Methodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesДокумент1 страницаMethodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesEphraim John Tangelon AquinoОценок пока нет

- ISO 17025 NDT Lab Accreditation CertificateДокумент3 страницыISO 17025 NDT Lab Accreditation Certificatekiki270977Оценок пока нет

- Ultrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar JhaДокумент55 страницUltrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar Jhajhaamit4100% (2)

- Ct02 Ect Extended AsmeДокумент1 страницаCt02 Ect Extended AsmeVasyaОценок пока нет

- Radiography Exposure Time CalculatorДокумент7 страницRadiography Exposure Time CalculatorngmthongОценок пока нет

- Si EvertДокумент4 страницыSi EvertLaxmikant TiwariОценок пока нет

- PA Probe Catalog en 201308Документ24 страницыPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaОценок пока нет

- SLOFEC TankScanningДокумент7 страницSLOFEC TankScanningツ ツОценок пока нет

- BeamTool Scan Plan SummaryДокумент2 страницыBeamTool Scan Plan Summarywilfran villegasОценок пока нет

- Thickness Measurement LocationДокумент77 страницThickness Measurement LocationWahyudi Kurniawan100% (2)

- Requirements For Non-Destructive Examination Methods Eddy CurrentДокумент21 страницаRequirements For Non-Destructive Examination Methods Eddy Currentzemog001Оценок пока нет

- BLOQUEДокумент1 страницаBLOQUEAlvaro Alexis Mendoza PradaОценок пока нет

- Positive Material IdentificationДокумент2 страницыPositive Material IdentificationGovindKrishnanОценок пока нет

- Evaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeДокумент3 страницыEvaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeWoodrow FoxОценок пока нет

- 2018 Doppler CatalogДокумент24 страницы2018 Doppler CatalogRene ParedeschaconОценок пока нет

- Mini-Wheel Encoder: Standard InclusionsДокумент2 страницыMini-Wheel Encoder: Standard InclusionsGhaithОценок пока нет

- Introduction of Ultrasonic TestingДокумент70 страницIntroduction of Ultrasonic TestingMAXX ENGINEERS100% (1)

- Guide Wave Ultrasonic Pipe Test ProcedureДокумент10 страницGuide Wave Ultrasonic Pipe Test ProcedurejeswinОценок пока нет

- Beamtool Scan Plan: Inspection LayoutДокумент4 страницыBeamtool Scan Plan: Inspection LayoutMohan RajОценок пока нет

- Procedure For ULTRASONIC THICKNESSДокумент4 страницыProcedure For ULTRASONIC THICKNESSKarrar TalibОценок пока нет

- SED - AUT Brochure Advanced NDTДокумент23 страницыSED - AUT Brochure Advanced NDTannmj17Оценок пока нет

- Dye Penetrant ProcedureДокумент8 страницDye Penetrant ProcedureTouil HoussemОценок пока нет

- Beamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsДокумент3 страницыBeamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்Оценок пока нет

- Linearity of Equipment GainДокумент4 страницыLinearity of Equipment GainReezman MalkeОценок пока нет

- Testing Session TOFD EECI - EurosonicДокумент47 страницTesting Session TOFD EECI - EurosonicRupam BaruahОценок пока нет

- Omniscan Setup - Basic SetupДокумент29 страницOmniscan Setup - Basic SetupcarlosОценок пока нет

- Calibration of The Testing SystemДокумент7 страницCalibration of The Testing SystemAsad KhanОценок пока нет

- EX - 12.7MM - PLATE 01 PAUT Report TrainingДокумент4 страницыEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarОценок пока нет

- Supplier Document Cover Page: Greater Enfield Subsea EPCIДокумент29 страницSupplier Document Cover Page: Greater Enfield Subsea EPCIKarthikeyan GanesanОценок пока нет

- Epoch - LT Thickness Guage ManualДокумент2 страницыEpoch - LT Thickness Guage ManualNouman BashirОценок пока нет

- Olympus Epoch XTДокумент8 страницOlympus Epoch XTTimothy FieldsОценок пока нет

- EPOCH 600 Training PresentationДокумент140 страницEPOCH 600 Training Presentationcfa_21350% (2)

- Ultrasonic Air Leak Systems UA Ultraprobe 15000 BrochureДокумент4 страницыUltrasonic Air Leak Systems UA Ultraprobe 15000 BrochureFirmanJohannesMaruliTuaSimanullangОценок пока нет

- EPOCH600 EN 201409 WebДокумент8 страницEPOCH600 EN 201409 WebSani TipareОценок пока нет

- Bench Products Catalog 2010Документ12 страницBench Products Catalog 2010Phong NguyenОценок пока нет

- EPOCH 600 Training Presentation 3-2014Документ193 страницыEPOCH 600 Training Presentation 3-2014Raul MedinaОценок пока нет

- Up-9000 ManualДокумент33 страницыUp-9000 ManualSunday PeterОценок пока нет

- Honeywell Gas Detector Impact Pro (In English)Документ4 страницыHoneywell Gas Detector Impact Pro (In English)Dang Minh HuongОценок пока нет

- EPOCH 600 Training Presentation 3-2014Документ193 страницыEPOCH 600 Training Presentation 3-2014Jhon R CPОценок пока нет

- Vijeo Designer TutorialДокумент88 страницVijeo Designer TutorialBo Cu Bin100% (1)

- DELTA User Interface Guide - 103202 - R2.5.15Документ90 страницDELTA User Interface Guide - 103202 - R2.5.15Dennis ChaiОценок пока нет

- User Manual Guide Samsung Galaxy Tab 3.8.0Документ200 страницUser Manual Guide Samsung Galaxy Tab 3.8.0assaudОценок пока нет

- Template Editor: Tekla Structures 11.0 Basic Training April 21, 2005Документ39 страницTemplate Editor: Tekla Structures 11.0 Basic Training April 21, 2005AnaviОценок пока нет

- CADWorx Plant User GuideДокумент559 страницCADWorx Plant User GuideMee WinОценок пока нет

- ARMD 5.8 User ManualДокумент83 страницыARMD 5.8 User ManualIvan YurkoОценок пока нет

- MA - 1VCD601602 - SWICOM Operational (EN) DДокумент28 страницMA - 1VCD601602 - SWICOM Operational (EN) DtuanvuttОценок пока нет

- Install Classroom Presentation Tool USBДокумент2 страницыInstall Classroom Presentation Tool USBFrancisco QuintanillaОценок пока нет

- Develop basic Android appДокумент21 страницаDevelop basic Android apped tuОценок пока нет

- Data Domain Health CheckДокумент6 страницData Domain Health ChecksreekanthdamaОценок пока нет

- Torchlight ManualДокумент57 страницTorchlight Manualkoffamof100% (3)

- PIPEPHASE98 Getting Started GuideДокумент129 страницPIPEPHASE98 Getting Started GuidewillОценок пока нет

- KPP 015 ManualДокумент17 страницKPP 015 ManualPedro Ramirez RomeroОценок пока нет

- Analysis of Emoji and Emoticon Usage in Blackberry and WhatsApp CommunicationДокумент7 страницAnalysis of Emoji and Emoticon Usage in Blackberry and WhatsApp CommunicationTaghreed Abdul salamОценок пока нет

- GLS 612 Lab 1Документ4 страницыGLS 612 Lab 1gladysОценок пока нет

- Snap PatentДокумент21 страницаSnap PatentCharles GrossОценок пока нет

- Sound Pack Installation Instructions ENG 210602Документ14 страницSound Pack Installation Instructions ENG 210602Anton PoluboyarinovОценок пока нет

- Aspen FLARENET Getting StartedДокумент62 страницыAspen FLARENET Getting StartedAde Nurisman100% (7)

- CM2 Combined 2013Документ120 страницCM2 Combined 2013Ansh JainОценок пока нет

- Voyage Planner Installation and Operation Instructions 81339-3-EnДокумент32 страницыVoyage Planner Installation and Operation Instructions 81339-3-EnIonutz Ionutz100% (1)

- Onboarding Guide To The Microsoft Azure Enterprise Portal (Direct Enrollment)Документ53 страницыOnboarding Guide To The Microsoft Azure Enterprise Portal (Direct Enrollment)Ahmad FleifelОценок пока нет

- Caita Powercopy, CatalogДокумент161 страницаCaita Powercopy, Catalogmmk_worldОценок пока нет

- NFPA 780 Simplified Risk CalculatorДокумент21 страницаNFPA 780 Simplified Risk Calculatorsammy muisyoОценок пока нет

- Max17201gevkit Max17211xevkitДокумент24 страницыMax17201gevkit Max17211xevkitmar_barudjОценок пока нет

- NVIDIA Control Panel and System Monitor With ESA User GuideДокумент47 страницNVIDIA Control Panel and System Monitor With ESA User GuideYifan Greenbank LingОценок пока нет

- VUMA Manual PDFДокумент143 страницыVUMA Manual PDFDiland Andres Lázaro BernalОценок пока нет

- Operator's Manual: Programming Coin MechanismsДокумент40 страницOperator's Manual: Programming Coin Mechanismsrjurado5149100% (1)

- Tipstricks Petrel Studio 2012Документ18 страницTipstricks Petrel Studio 2012th1nkОценок пока нет

- Commercial Studies 7101 Sow Year 9 For SPN 21 Express Track - 2 YearsДокумент41 страницаCommercial Studies 7101 Sow Year 9 For SPN 21 Express Track - 2 YearsYenny TigaОценок пока нет

- wILCOM 2006 User Manual PDFДокумент1 177 страницwILCOM 2006 User Manual PDFdesign kanga50% (2)