Академический Документы

Профессиональный Документы

Культура Документы

8410 Turbines

Загружено:

guimaraes1941Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

8410 Turbines

Загружено:

guimaraes1941Авторское право:

Доступные форматы

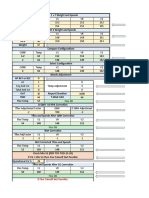

8410 841011 841012 841013 841090

hydraulic turbines, water wheels & regulators, pts Hydraulic Turbines, Water Wheels, of a Power Not Exceeding, 1, 000kw Hydraulic Turbines and Water Wheels, Power 1, 000-10, 000kw Hydraulic Turbines, Water Wheels, of a Power Exceeding 10, 000kw Parts of Hydraulic Turbines and Water Wheels, Including Regulators

Indian standards Guidelines for Selection of Hydraulic Turbine, Preliminary IS 12800 : Dimensioning and Layout of Surface Hydroelectric Power Houses Active Part 3 : 1991 Part 3 : Small, Mini and Micro Hydroelectric Power Houses IS 12837 : Hydraulic Turbines for Medium and Large Power Houses - Guidelines Active 1989 for Selection IS 14197 : Code for model acceptance tests of hydraulic turbines Active 1994

Standards ASME PTC 18-2002, Hydraulic Turbines and Pump - Turbines This Code defines procedures for field performance and acceptance testing of hydraulic turbines and pump-turbines operating with water in either the turbine or pump mode. ASME PTC 29-2005, Speed Governing Systems for Hydraulic Turbine Generators Units The objective of this Code is to provide uniform test methods and procedures to determine the performance and operational characteristics of a hydraulic turbine speed governor. This Code may be used to conduct factory acceptance testing or to evaluate the current characteristics of an installed speed governor. Not all of the possible results that can be determined by application of this Code need be part of every test. Prior to testing, the parties to the test shall agree whether the Code shall be used in whole or in part to satisfy individual test objectives.

IEEE 125-1996, Recommended Practice for Preparation of Equipment Specifications for Speed-Governing of Hydraulic Turbines Intended to Drive Electric Generators Applies to mechanical-hydraulic or electric-hydraulic type governors for all type of hydraulic turbines.

IEEE 810-1994 (R2001), Standard for Hydraulic Turbine and Generator Integrally Forged Shaft Couplings and Shaft Tolerances Applies to the dimensions of integrally forged shaft couplings and to the shaft runout tolerances. Shafts and couplings included in this standard are used for both horizontal and vertical connections between generators and turbines in hydroelectric installations. IEEE C50.12-2005, Standard for Salient-Pole 50 and 60 Hz Synchronous Generators and Generator/Motors for Hydraulic Turbine Applications Rated 5 MVA and Above Contains requirements for all types of 50 and 60 Hz salient-pole synchronous generators and generator/motors rated 5000 kVA and above to be used for hydraulic turbine or hydraulic pump/turbine applications. International Standards IEC 60041 Ed. 3.0 b:1991 "Field acceptance tests to determine the hydraulic performance of hydraulic turbines, storage pumps and pump-turbines" "Specifies methods for any size and type of impulse or reaction turbine, storage pump or pump turbine. Determines whether the contract guarantees have been fulfilled and deals with the rules governing these tests as well as the methods of

computing the results and the content and style of the final report. Replaces IEC 60198 (1966) and IEC 60607 (1978). " IEC 60193 Ed. 2.0 b:1999 "Hydraulic turbines, storage pumps and pump-turbines - Model acceptance tests " IEC 60308 Ed. 2.0 b:2005 Hydraulic turbines - Testing of control systems "Deals with the definition and the characteristics of control systems. It is not limited to the actual controller tasks but also includes other tasks which may be assigned to a control system, such as sequence control tasks, safety and provision for the actuating energy. The following systems are included, speed, power, opening, water level and flow control for all turbine types; electronic, electrical and fluid power devices; safety devices as well as start-up and shutdown devices. " IEC 60545 Ed. 1.0 b:1976 "Guide for commissioning, operation and maintenance of hydraulic turbines" "Establishes suitable procedures for commissioning, operating and maintaining hydraulic turbines and associated equipment. Applies to impulse and reaction turbines of all types, and especially to large turbines directly coupled to electric generators. Also applies to pump-turbines when operating as turbines, and water conduits, gates, valves, drainage pumps, cooling-water equipment, generators, etc., where they cannot be separated from the turbine and its equipment. "

IEC 60609-1 Ed. 1.0 b:2004 "Hydraulic turbines, storage pumps and pump-turbines - Cavitation pitting evaluation Part 1: Evaluation in reaction turbines, storage pumps and pump-turbines" "Provides a basis for the formulation of guarantees applied to cavitation pitting for reaction hydraulic turbines, storage pumps and pump-turbines. It addresses the measurement and evaluation of the amount of cavitation pitting on certain specified machine components for given conditions, which are defined in the contract by output, specific hydraulic energy (E), speed, material, operation, etc. The cavitation-pitting evaluation is based on the loss of material during a given time and under accurately defined operating conditions. All wetted surfaces are considered "

IEC 60609-2 Ed. 1.0 b:1997 "Cavitation pitting evaluation in hydraulic turbines, storage pumps and pumpturbines - Part 2: Evaluation in Pelton turbines " "This standard serves as a basis for the formulation of guarantees on cavitation pitting on Pelton turbine runners. It also provides a basis for the measurement and evaluation of the amount of cavitation pitting on Pelton turbine runners of a given turbine, which is defined in the contract by power, specific hydraulic energy of machine (head), rotational speed, material, operation etc. Guarantees which restrict the extent of caviation pitting and drop erosion on Pelton turbies at the end of an operating period specified in the contract are necessary when the pitting is expected in all or in some operating ranges."

IEC 61362 Ed. 1.0 b:1998 Guide to specification of hydraulic turbine control systems IEC 62237 Ed. 1.0 b:2003 Live working - Insulating hoses with fittings for use with hydraulic tools and equipment Is applicable to mobile insulating hoses with fittings used with hydraulic tools and equipment for live working at nominal voltages exceeding 1 kV r.m.s. at power frequency. Insulating hoses with fittings are used to provide a connection between the hydraulic tool and the pump which are at different potentials. They are not considered as a fixed component of a live working device (e.g. aerial device). They can be connected and disconnected under negligible pressure. They can be directly handled by the user.

IEC/TR 61366-1 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 1: General and annexes" IEC/TR 61366-2 Ed. 1.0 en:1998

"Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 2: Guidelines for technical specifications for Francis turbines"

IEC/TR 61366-3 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering documents Part 3: Guidelines for technical specifications for Pelton turbines" IEC/TR 61366-4 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 4: Guidelines for technical specifications for Kaplan and propeller turbines"

IEC/TR 61366-5 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 5: Guidelines for technical specifications for tubular turbines"

IEC/TR 61366-5 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 5: Guidelines for technical specifications for tubular turbines" IEC/TR 61366-6 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 6: Guidelines for technical specifications for pump-turbines" IEC/TR 61366-7 Ed. 1.0 en:1998 "Hydraulic turbines, storage pumps and pump-turbines - Tendering Documents Part 7: Guidelines for technical specifications for storage pumps"

US federal programmes and mandates for turbines U.S. Department of Energy, National Energy Technology Laboratory "Coal and Power Systems: Turbines" http://www.netl.doe.gov/technologies/coalpower/turbines/index.html This site explores the Turbine Program of the U.S. Department of Energy's (DOE) Office of Fossil Energy (FE). It provides information about NETL's Turbine Program and its goals, current projects and solicitations, and performance targets of on-going projects. U.S. Department of Energy, National Energy Technology Laboratory "Turbine Program: Enabling Near-Zero Emission Coal-Based Power Generation" (June 2005) http://www.netl.doe.gov/technologies/coalpower/turbines/refshelf/brochures/Broc hure%209-19-05.pdf This document delineates todays U.S. Department of Energy (DOE) Turbine Program being implemented by the DOE National Energy Technology Laboratory (NETL). The Turbine Program leverages the knowledge gained in making unprecedented advances in natural gasfueled turbine technology under the highly successful, predecessor Advanced Turbine Systems (ATS) Program. This knowledge will be applied to support DOE efforts to develop and deploy nearzero emission (including carbon dioxide) coal-based energy plants capable of producing both electricity and hydrogen. U.S. Department of Energy, Office of Fossil Energy, "How Gas Turbine Power Plants Work" http://fossil.energy.gov/programs/powersystems/turbines/turbines_howitworks.ht ml A simple cycle gas turbine can achieve energy conversion efficiencies ranging between 20 and 35 percent. With the higher temperatures achieved in the Energy Department's turbine program, future hydrogen and syngas fired gas turbine combined cycle plants are likely to achieve efficiencies of 60 percent or more. When waste heat is captured from these systems for heating or industrial purposes, the overall energy cycle efficiency could approach 80 percent. U.S. Department of Energy, Office of Fossil Energy, "The Turbines of Tomorrow" http://fossil.energy.gov/programs/powersystems/turbines/index.html

The Energy Department's Fossil Energy Program is developing key technologies that will enable advanced turbines to operate cleanly and efficiently when fueled with coal derived synthesis gas and hydrogen fuels. Developing this turbine technology is critical to the creation of near-zero emission power generation technologies. This will assist with the deployment of FutureGen plants that couple production of hydrogen and electricity from coal with sequestration of the carbon dioxide that is produced. Monitoring Requirements for Combustion Turbines (US Environmental Protection Agency) http://www.epa.gov/fedrgstr/EPA-MEETINGS/2001/August/Day-24/m21444.htm

Вам также может понравиться

- Hydraulic Turbine Standards and TestingДокумент4 страницыHydraulic Turbine Standards and Testingraghu_mnОценок пока нет

- Steam TurbinesДокумент5 страницSteam Turbinesavsrao123Оценок пока нет

- 8406 Steam TurbinesДокумент5 страниц8406 Steam Turbinesdavih007Оценок пока нет

- Guide for Selection of Turbine and Governing SystemДокумент96 страницGuide for Selection of Turbine and Governing SystemBehailu FelekeОценок пока нет

- Hydraulic Turbines Od ThaperДокумент90 страницHydraulic Turbines Od ThaperVeronica Naveda Espinoza100% (1)

- List of Useful Hydroelectric Standards Guides and Manuals .Документ3 страницыList of Useful Hydroelectric Standards Guides and Manuals .Raúl Castillo100% (1)

- 3.1 GL For Selection of Turbine and Governing PDFДокумент96 страниц3.1 GL For Selection of Turbine and Governing PDFPablo German TouriñanОценок пока нет

- GBT 7409.3-2008Документ12 страницGBT 7409.3-2008ecsuperalОценок пока нет

- Certification Testing For Small Wind Turbines: D. Corbus, H. Link, S. Butterfield, C. Stork, and C. Newcomb T. SasseenДокумент10 страницCertification Testing For Small Wind Turbines: D. Corbus, H. Link, S. Butterfield, C. Stork, and C. Newcomb T. SasseenAmlan DasОценок пока нет

- Reg Guide 1.9 r3Документ12 страницReg Guide 1.9 r3Kg SubramanianОценок пока нет

- Guidelines for Selection of Turbine and Governing System for Small Hydro ProjectsДокумент91 страницаGuidelines for Selection of Turbine and Governing System for Small Hydro ProjectsManuel Cañadas100% (1)

- Design and Experiments of The Active Magnetic Bearing System For The Htr-10Документ16 страницDesign and Experiments of The Active Magnetic Bearing System For The Htr-10andy131078Оценок пока нет

- 3.1 Turbine and GoverningДокумент90 страниц3.1 Turbine and GoverningYudo Heru PribadiОценок пока нет

- Guidelines For Field Efficiency Tests Including PSP 1687186963Документ32 страницыGuidelines For Field Efficiency Tests Including PSP 1687186963Gaurav KumarОценок пока нет

- Electrical ActuatorДокумент7 страницElectrical Actuatorمحمد علي كريم شكرОценок пока нет

- MEAS D 17 02252R1 4 Split MergeДокумент27 страницMEAS D 17 02252R1 4 Split MergeAditya DoyaleОценок пока нет

- 1 s2.0 0029549393900439 MainДокумент17 страниц1 s2.0 0029549393900439 MainLyes AbbassenОценок пока нет

- Testing real hydro turbines at IIT Roorkee's new hydraulic labДокумент16 страницTesting real hydro turbines at IIT Roorkee's new hydraulic labsainivijayОценок пока нет

- Motor Protection Dynamic InstabilitiesДокумент8 страницMotor Protection Dynamic InstabilitiesmagcanОценок пока нет

- Wind Turbine Dynamic Models for Grid IntegrationДокумент8 страницWind Turbine Dynamic Models for Grid IntegrationAkhilesh PanwarОценок пока нет

- Fluid Power SystemsДокумент142 страницыFluid Power SystemsAbel AregayОценок пока нет

- Modeling of Hydro PlantДокумент57 страницModeling of Hydro Plantshift incharge ikhepОценок пока нет

- Condition Monitoring of Power TransformersДокумент49 страницCondition Monitoring of Power TransformersSanthosh Penugonda0% (1)

- Guide to Developing Hydro Power ProjectsДокумент207 страницGuide to Developing Hydro Power ProjectsShashi TapsiОценок пока нет

- Design Objectives For Spring Mechanism Generator Circuit Breaker With High ReliabilityДокумент6 страницDesign Objectives For Spring Mechanism Generator Circuit Breaker With High ReliabilitysunitharajababuОценок пока нет

- Modelling, Operation and Control of HVDC Connected Oshore Wind FarmsДокумент26 страницModelling, Operation and Control of HVDC Connected Oshore Wind FarmsMohammed Shareef ShaikhОценок пока нет

- Indian Standard 3637Документ10 страницIndian Standard 3637Aman DeepОценок пока нет

- Disclosure To Promote The Right To InformationДокумент79 страницDisclosure To Promote The Right To InformationAmber HudsonОценок пока нет

- Design Criteria Chapre CharkhilДокумент14 страницDesign Criteria Chapre CharkhilAli HassanОценок пока нет

- Nema-Application-guidefor AC Adjustable Speed Drive SystemsДокумент10 страницNema-Application-guidefor AC Adjustable Speed Drive Systemsshadi22Оценок пока нет

- Classification of Electric Propulsion Systems For LNG CarriersДокумент4 страницыClassification of Electric Propulsion Systems For LNG CarriersThomas StОценок пока нет

- Simplified Modeling of Hydraulic Governor-TurbineДокумент5 страницSimplified Modeling of Hydraulic Governor-TurbineShrestha SanjayОценок пока нет

- Resume Murugan ParamasivamДокумент5 страницResume Murugan ParamasivamPower MuruganОценок пока нет

- PLC Controlled Diesel GeneratorДокумент8 страницPLC Controlled Diesel GeneratorPaiman KoplaxОценок пока нет

- Guidelines for selecting small hydro turbinesДокумент90 страницGuidelines for selecting small hydro turbinesAnonymous XBq5J84Оценок пока нет

- Camless Engine Using Electromagnetic Valve Actuator: S.Jagannath Reddy, G.Praveen Kumar and Bollu ShravyaДокумент6 страницCamless Engine Using Electromagnetic Valve Actuator: S.Jagannath Reddy, G.Praveen Kumar and Bollu ShravyaGopiОценок пока нет

- American StandardsДокумент16 страницAmerican Standardsparam.vennelaОценок пока нет

- New Standards For Transformers-Year 2022Документ7 страницNew Standards For Transformers-Year 2022salemg82Оценок пока нет

- Small Scale Hydropower Optimization for Water SupplyДокумент8 страницSmall Scale Hydropower Optimization for Water SupplyRobsonMbiziОценок пока нет

- 11kV Voltage RegulatorДокумент12 страниц11kV Voltage Regulatoroadipphone7031Оценок пока нет

- In Salah Gas Project Engineering Procurement & Construction PhaseДокумент17 страницIn Salah Gas Project Engineering Procurement & Construction PhaseTcl TcllОценок пока нет

- Unit CommДокумент56 страницUnit CommkgurumoorthiОценок пока нет

- Iec 60034, 2004Документ65 страницIec 60034, 2004Horst100% (1)

- Section 1 G: 1 Application 3 DefinitionsДокумент5 страницSection 1 G: 1 Application 3 DefinitionsJon LopezОценок пока нет

- Dynamic Models of Wind Farms For Power System Studies - Status by IEA Wind R&D Annex 21Документ8 страницDynamic Models of Wind Farms For Power System Studies - Status by IEA Wind R&D Annex 21ajitborseОценок пока нет

- Generator and Excitation SystemДокумент43 страницыGenerator and Excitation Systemsandeep11789Оценок пока нет

- 160 MVA Power Transformer RFQДокумент31 страница160 MVA Power Transformer RFQVishnu Kumar VyasОценок пока нет

- Small Wind TurbinesДокумент5 страницSmall Wind TurbinesAmlan DasОценок пока нет

- Hydraulicturbines DrtinaДокумент19 страницHydraulicturbines DrtinanazarasimОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlОт EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlРейтинг: 5 из 5 звезд5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОт EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- UHV Transmission TechnologyОт EverandUHV Transmission TechnologyChina Electric Power Research InstituteОценок пока нет

- Electric Motor Control: DC, AC, and BLDC MotorsОт EverandElectric Motor Control: DC, AC, and BLDC MotorsРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Probability Sampling Guide for Health ResearchДокумент5 страницProbability Sampling Guide for Health ResearchNicole AleriaОценок пока нет

- Preview-9780429675119 A38620781Документ53 страницыPreview-9780429675119 A38620781Milton Alexandre ZiehlsdorffОценок пока нет

- Unit 30 WorkДокумент2 страницыUnit 30 WorkThanh HàОценок пока нет

- Process Strategy PPT at BEC DOMSДокумент68 страницProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- Caso de Estudio 14.1, 14.2 y 14.3Документ6 страницCaso de Estudio 14.1, 14.2 y 14.3Rodolfo G. Espinosa RodriguezОценок пока нет

- Jurnal Metode Pelaksanaan Top Down B.ing PDFДокумент7 страницJurnal Metode Pelaksanaan Top Down B.ing PDFBayu SamiajiОценок пока нет

- Hydrocarbon TechnologyДокумент21 страницаHydrocarbon Technologyghatak2100% (1)

- Gamma Ray Log ShamshadДокумент36 страницGamma Ray Log Shamshadgadi_143100% (6)

- Public Dealing With UrduДокумент5 страницPublic Dealing With UrduTariq Ghayyur86% (7)

- Types of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaДокумент7 страницTypes of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaJimnadominicОценок пока нет

- Field Behaviour of Stiffened Deep Cement Mixing PilesДокумент17 страницField Behaviour of Stiffened Deep Cement Mixing PilesNguyen Quoc KhanhОценок пока нет

- WHLP G9 ESolomon Nov 23-27Документ4 страницыWHLP G9 ESolomon Nov 23-27Ericha SolomonОценок пока нет

- Handout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertДокумент7 страницHandout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertBryan YaranonОценок пока нет

- ACI-439.3R-91 Mechanical Connections of Reinforcing BarsДокумент16 страницACI-439.3R-91 Mechanical Connections of Reinforcing BarsMichi AGОценок пока нет

- Real Time Braille To Speech Using PythonДокумент10 страницReal Time Braille To Speech Using PythonKali LinuxОценок пока нет

- Chapter 3Документ12 страницChapter 3Raymond LeoОценок пока нет

- Friction WedgesДокумент7 страницFriction Wedgespericharla ravivarmaОценок пока нет

- Fc6a Plus (MQTT)Документ44 страницыFc6a Plus (MQTT)black boxОценок пока нет

- Port Ps PDFДокумент2 страницыPort Ps PDFluisОценок пока нет

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisДокумент5 страницPlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraОценок пока нет

- Nordson EFD Ultimus I II Operating ManualДокумент32 страницыNordson EFD Ultimus I II Operating ManualFernando KrauchukОценок пока нет

- Organizational Structure and ProfilesДокумент178 страницOrganizational Structure and ProfilesImran Khan NiaziОценок пока нет

- Fire Risk Assessment FormДокумент16 страницFire Risk Assessment Formmukamat safiiОценок пока нет

- A320 Flex CalculationДокумент10 страницA320 Flex CalculationMansour TaoualiОценок пока нет

- Organizational Change & Development - VIL2021 - 22Документ3 страницыOrganizational Change & Development - VIL2021 - 22Rahul TRIPATHIОценок пока нет

- Telescopic sight basics and reticle typesДокумент18 страницTelescopic sight basics and reticle typesKoala LumpurОценок пока нет

- Muhammad Ajmal: Electrical EngineerДокумент1 страницаMuhammad Ajmal: Electrical EngineerMuhammad AbrarОценок пока нет

- Gabriel Feltran. "The Revolution We Are Living"Документ9 страницGabriel Feltran. "The Revolution We Are Living"Marcos Magalhães Rosa100% (1)

- Ata 47-NGS R25Документ148 страницAta 47-NGS R25NadirОценок пока нет

- Product Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityДокумент1 страницаProduct Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityKABIR CHOPRAОценок пока нет