Академический Документы

Профессиональный Документы

Культура Документы

ST 9122 Experimental Techniques and Instrumentation

Загружено:

ananthaaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ST 9122 Experimental Techniques and Instrumentation

Загружено:

ananthaaАвторское право:

Доступные форматы

ST 9122 EXPERIMENTAL TECHNIQUES

AND INSTRUMENTATION

FORCES AND STRAIN MEASUREMENT

Choice of Experimental stress analysis methods, Errors in

measurements Strain gauge, principle, types, performance and

uses. Photo elasticity - principle and applications - Hydraulic jacks

and pressure gauges Electronic load cells Proving Rings

Calibration of Testing Machines Long-term monitoring vibrating

wiresensors Fibre optic sensors.

UNIT I

Choice of Experimental stress analysis methods

Stress

This is a measure of the internal resistance in a

material to an externally applied load. For

direct compressive or tensile loading the

stress is designated o and is defined as:

stress =

load W

area A

o

Types of stress

Compressive

stress

Compressive load

Tensile load

Compressive load

Tensile load

Tensile

Stress

Errors in measurements

Some terminology

True value standard or reference of

known value or a theoretical value

Accuracy closeness to the true value

Precision reproducibility or agreement

with each other for multiple trials

PGCC CHM 103 Sinex

Types of Errors

Determinate (or Systematic)

Sometimes called bias due to error in one

direction- high or low

Known cause

Operator

Calibration of glassware, sensor, or instrument

When determined can be corrected

May be of a constant or proportional nature

PGCC CHM 103 Sinex

Types of Errors continued

Indeterminate (or Random)

Cannot be determined (no control over)

Random nature causes both high and low

values which will average out

Multiple trials help to minimize

PGCC CHM 103 Sinex

PGCC CHM 103 Sinex

sampling

preparation

analysis

Representative

sample

homogeneous

vs.

heterogeneous

Loss

Contamination

(unwanted addition)

Measurement

of Analyte

Calibration of

Instrument or

Standard

solutions

How about sampling a

chocolate chip cookie?

How do you assess the total error?

One way to assess total error is to

treat a reference standard as a sample.

The reference standard would be

carried through the entire process to

see how close the results are to the

reference value.

PGCC CHM 103 Sinex

Expressing accuracy and precision

Mean (average)

Percent error

Range

Deviation

Standard deviation

Percent coefficient of variation

precision

accuracy

Strain gauge, principle, types,

performance and uses

What is Strain?

Strain is the amount of deformation of a body due to an applied

force. More specifically, strain (e) is defined as the fractional change

in length.

, c is strain

What is Strain Gauge?

A strain gauge, a device whose electrical resistance varies in

proportion to the amount of strain in the device. The most widely

used gauge is the bonded metallic strain gauge.

How to Select Strain Gauge?

Use Vishay Strain Gauge as Example

1. Grid length (250 = 0.250 inch)

2. Grid pattern and tab geometry (uniaxial, biaxial, three-element rosette, shear pattern)

3. Type of grid alloy and backing (strain gauge series EA, Constantan grid, polyimide backing)

4. Option features: protection, termination (L = pre-attached Leads, E= Encapsulated with

exposed tabs.)

5. Strain gauge resistance (350=350 ohms)

6. Self temperature compensation (STC # = 06 for steel substrate)

Gauge selection

http://www.vishay.com/brands/measurements_group/strain_gages/

mm.htm

Note : The S-T-C number is the approximate thermal expansion coefficient in

ppm/ deg F of

the structural material on which the strain gage will display minimum

thermal output.

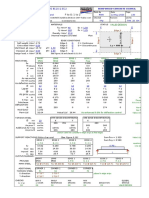

How to Measure from Strain Gauge?

Wheatstone bridge with strain gauge

R3

When Vo is zero, R1*R3=R2*R4

When the strain gauge is strained,

R3=R3+AR

Vo=

o = MC / I

E = Ao / Ac, where

C = t/2, C is the distance to

the neutral axis.

M is the bending moment = PL

I is the moment inertia for a

cross section, I= b(t^3)/2

G = gauge factor,

(AR/R)/(AL/L)

The gauge factor for various

alloys,

A = 2.05, K = 2.1, D = 3.2, P = 2.0

(Vishay strain gauge)

( )( )

1

2 3 1 4

s

R R

V

R R R R

A

+ +

( )( )

2 3 2 4

0

1 3 s

R R R R

V

R R G V

c

+ +

=

How to Install Strain Gauge?

Objective

Have strain gauge to produce the same amount of strain as the substrate.

Procedure

Align the grid direction with the uniaxial

Solder wires to termination which provides stress relief.

Apply adhesive to substrate and attach strain gauge with clamps and rubber pressure pads.

Cure the adhesive at room temperature or elevated temperature.

What happens to our plastic substrate when cure at elevated temperature?

Tape or secure wires to avoid stress from heavy instrument.

Substrate

Wires

Termination

Strain gauge

Adhesive

ECE 480, Prof. A. Mason

Fiber-optic Temperature Sensor

Sensor operation

small prism-shaped sample of single-crystal undoped GaAs attached to

ends of two optical fibers

light energy absorbed by the GaAs crystal depends on temperature

percentage of received vs. transmitted energy is a function of

temperature

Can be made small enough for biological implantation

GaAs semiconductor temperature probe

Вам также может понравиться

- Concrete Technology Mini Project Group:8Документ22 страницыConcrete Technology Mini Project Group:8Mashal Shah JehanОценок пока нет

- 22m High Wall at Durga Temple With PECДокумент5 страниц22m High Wall at Durga Temple With PECGerald TanОценок пока нет

- Bio Gas Final ProjectДокумент75 страницBio Gas Final ProjectMowafk AlsharabyОценок пока нет

- Asconium: Technical NoticeДокумент14 страницAsconium: Technical NoticenanoОценок пока нет

- Post-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Документ6 страницPost-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Educadd AMEERPET HyderabadОценок пока нет

- M45 Grade As Per Is 10262Документ4 страницыM45 Grade As Per Is 10262Ashok RajanavarОценок пока нет

- Final Staircase Report Phase-2editedДокумент69 страницFinal Staircase Report Phase-2editedSuyog DardeОценок пока нет

- Geopolymer Concrete Sem 8 (GPC)Документ21 страницаGeopolymer Concrete Sem 8 (GPC)daahdadaОценок пока нет

- Experimental Investigation On Hybrid Fibre Reinforced Concrete by Partial Replacement of MДокумент33 страницыExperimental Investigation On Hybrid Fibre Reinforced Concrete by Partial Replacement of MAarthiОценок пока нет

- Estimate - Construction of CC Road From Prabhakar Shinde To Vyankati Manthanwar House at Mauja Nagepalli Ta. Aheri Dist. GadchiroliДокумент27 страницEstimate - Construction of CC Road From Prabhakar Shinde To Vyankati Manthanwar House at Mauja Nagepalli Ta. Aheri Dist. Gadchirolidholeatul23Оценок пока нет

- GTU ThesisДокумент53 страницыGTU ThesisMananОценок пока нет

- Summary of Revised Codes For Concrete in 2018Документ4 страницыSummary of Revised Codes For Concrete in 2018Vijayakrishna SingamsettiОценок пока нет

- MINI PROJECT - FINAL BOOK 5-MergedДокумент71 страницаMINI PROJECT - FINAL BOOK 5-MergedKalaiОценок пока нет

- Mix Design For Concrete Grade M 42Документ4 страницыMix Design For Concrete Grade M 42NaveenkumarОценок пока нет

- Analysis of Road ItemДокумент15 страницAnalysis of Road ItemSHAILENDRAОценок пока нет

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeДокумент5 страницSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANAОценок пока нет

- Report of AggregateДокумент10 страницReport of AggregateNisaAris50% (2)

- NCC Report 2015 - Corrected by NCCLJДокумент64 страницыNCC Report 2015 - Corrected by NCCLJPhani Krishna BadipatiОценок пока нет

- Infracem - WK-19Документ1 страницаInfracem - WK-19Sirajul IslamОценок пока нет

- Mix Design PosterДокумент1 страницаMix Design PosterAbhilash KumarОценок пока нет

- Concrete Mix DesignДокумент12 страницConcrete Mix DesignAnand.5Оценок пока нет

- Highway Lab Report (Full) PDFДокумент84 страницыHighway Lab Report (Full) PDFWai KiatОценок пока нет

- Technology Data's For PMGSYДокумент20 страницTechnology Data's For PMGSYmagbool100% (1)

- MIHIR 7th Sem. Civil ProjectДокумент19 страницMIHIR 7th Sem. Civil ProjectKUNAL SHAHОценок пока нет

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Документ4 страницыF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamОценок пока нет

- Sample No. Total Weight (GMS)Документ4 страницыSample No. Total Weight (GMS)Soundar PachiappanОценок пока нет

- Meta Rubberdam Profoma r1Документ23 страницыMeta Rubberdam Profoma r1MR. PRATIK JASWANTEОценок пока нет

- SP-62 2004 CC RoadsДокумент38 страницSP-62 2004 CC Roadsnimm1962Оценок пока нет

- Bar Bending Schedule - RCC Slab NewДокумент10 страницBar Bending Schedule - RCC Slab NewGourav SachdevaОценок пока нет

- 2911 3Документ44 страницы2911 3rambinodОценок пока нет

- Mix Design - Assignement 1 - AP21203Документ3 страницыMix Design - Assignement 1 - AP21203pooja apteОценок пока нет

- Civil Engg Basic Knowledge PDFДокумент3 страницыCivil Engg Basic Knowledge PDFASHUTOSH GUPTA100% (5)

- Calculation of Quantity of Cement Mortar in Brickwork and PlasterДокумент2 страницыCalculation of Quantity of Cement Mortar in Brickwork and PlasterYathish1430% (1)

- Bolt Capacity Is 800 2007Документ1 страницаBolt Capacity Is 800 2007JaineshОценок пока нет

- Department of Civil Engineering List of Indian Road Congress (Irc)Документ7 страницDepartment of Civil Engineering List of Indian Road Congress (Irc)senthilncc100% (1)

- 000.final Project Batch 12Документ57 страниц000.final Project Batch 12Teja bodduОценок пока нет

- LSM and WSMДокумент2 страницыLSM and WSMshakeelwaseemОценок пока нет

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsДокумент19 страницModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- BbsДокумент24 страницыBbsGanesh EshwarОценок пока нет

- Experimental Study On Self Compacting Concrete Final ReportДокумент43 страницыExperimental Study On Self Compacting Concrete Final ReportTaimoor NasserОценок пока нет

- Analysis of Tenement 1Документ84 страницыAnalysis of Tenement 1IyswariyaОценок пока нет

- Cube Test ReportДокумент1 страницаCube Test ReportShubham MareОценок пока нет

- Karan Singh 1801000032 ReportДокумент57 страницKaran Singh 1801000032 ReportshwetaОценок пока нет

- INFLUENCE of Microsilica and Nano Silica in Concrete MixturesДокумент27 страницINFLUENCE of Microsilica and Nano Silica in Concrete MixturesSwathi Sv100% (1)

- Seismic Analysis of Overhead Circular Water TanksДокумент10 страницSeismic Analysis of Overhead Circular Water TanksGiurcanas Andrei0% (1)

- b4 PDFДокумент1 страницаb4 PDFCARL JAMESОценок пока нет

- (California Bearing Ratio Value) : ExperimentДокумент2 страницы(California Bearing Ratio Value) : ExperimentRefisa JiruОценок пока нет

- Drain Design MetricДокумент31 страницаDrain Design MetricEmre MermerОценок пока нет

- Cable Route MarkerДокумент2 страницыCable Route Markersundareee96Оценок пока нет

- Paper For Bearing Capacity PDFДокумент4 страницыPaper For Bearing Capacity PDFernestnsabimana74Оценок пока нет

- Environment and Hydrology Objective QuestionsДокумент5 страницEnvironment and Hydrology Objective QuestionsICE Group of Education BhopalОценок пока нет

- Liquefaction Potential of Cohesionless Soils in South MumbaiДокумент58 страницLiquefaction Potential of Cohesionless Soils in South MumbaiDrGanesh KameОценок пока нет

- Tension Member: 5.1 Types of Tension MembersДокумент6 страницTension Member: 5.1 Types of Tension MembersbaizubirajiОценок пока нет

- Experimental Techniques and InstrumentationДокумент18 страницExperimental Techniques and InstrumentationMaharajan McsОценок пока нет

- SensorsДокумент137 страницSensorsVarsha AcharyaОценок пока нет

- Introduction To Thermocouple and Strain GaugeДокумент18 страницIntroduction To Thermocouple and Strain GaugeMalu MohanОценок пока нет

- Resentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46Документ18 страницResentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46aslamhossainОценок пока нет

- Unit - IIIДокумент215 страницUnit - IIINishigandha Bansode100% (1)

- Strain Measurements: - Module GoalsДокумент14 страницStrain Measurements: - Module GoalspachieduОценок пока нет

- Tirtharaj Pati - Details of Strain Gauge Sensor PDFДокумент13 страницTirtharaj Pati - Details of Strain Gauge Sensor PDFTirtharaj PatiОценок пока нет

- UT 0030 Thickness Measurement Surveys PDFДокумент15 страницUT 0030 Thickness Measurement Surveys PDFAhmed Ben Nouma0% (1)

- Bhalala Dhruv Emmi Exp-4Документ8 страницBhalala Dhruv Emmi Exp-4CLINIXОценок пока нет

- Question Paper:: Eighth Engineenng ANDДокумент2 страницыQuestion Paper:: Eighth Engineenng ANDananthaaОценок пока нет

- Iron and SteelДокумент21 страницаIron and SteelananthaaОценок пока нет

- Karunya University: End Semester ExaminationДокумент2 страницыKarunya University: End Semester ExaminationananthaaОценок пока нет

- 10ei308 Data CommunicationДокумент2 страницы10ei308 Data CommunicationananthaaОценок пока нет

- Digital Instrumentation and Control SystemsДокумент36 страницDigital Instrumentation and Control SystemsDarkmatter DarkmatterrОценок пока нет

- Research Regulations For Ph.D. Programme 2009: Karunya UniversityДокумент11 страницResearch Regulations For Ph.D. Programme 2009: Karunya UniversityananthaaОценок пока нет

- GyroscopeДокумент4 страницыGyroscopeananthaaОценок пока нет

- Concrete Mix Design DOE PDFДокумент15 страницConcrete Mix Design DOE PDFkarthiksamp100% (2)

- НАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFДокумент364 страницыНАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFAnver AkperovОценок пока нет

- SM-204-TechReport 01 2022 AnsichtДокумент4 страницыSM-204-TechReport 01 2022 AnsichtDanny DoanОценок пока нет

- States of Matter Grade 9-ACts-Practice TestДокумент5 страницStates of Matter Grade 9-ACts-Practice TestAref DahabrahОценок пока нет

- A Study of Material Non-Linearity During Deformation Using FEM SofwareДокумент82 страницыA Study of Material Non-Linearity During Deformation Using FEM SofwareRicky GunawanОценок пока нет

- Electrically Heated Catalysts Close-Coupled Catalysts Hydrocarbon Adsorber /trap SystemsДокумент6 страницElectrically Heated Catalysts Close-Coupled Catalysts Hydrocarbon Adsorber /trap SystemsKeval ParmarОценок пока нет

- ROAD DATA 18.11.2016 Uranipuram PDFДокумент99 страницROAD DATA 18.11.2016 Uranipuram PDFHRS REGIONAL LAB TANJAVURОценок пока нет

- Mechanical DesignДокумент34 страницыMechanical DesignNiki LaudaОценок пока нет

- Retrofitting of RC Structure Using FRP Laminate: AbstractДокумент10 страницRetrofitting of RC Structure Using FRP Laminate: AbstractYo Yo AkОценок пока нет

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdДокумент7 страницPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdzvjesosОценок пока нет

- Specific Gravity of Pigments: Standard Test Methods ForДокумент5 страницSpecific Gravity of Pigments: Standard Test Methods ForPyone Ei ZinОценок пока нет

- Unit 1 - Review QuestionsДокумент2 страницыUnit 1 - Review QuestionsshaniceОценок пока нет

- Ampel Bamboo Leaves Silicon Dioxide (SiO2) ExtractionДокумент8 страницAmpel Bamboo Leaves Silicon Dioxide (SiO2) ExtractiondianОценок пока нет

- Summary Guide in Earth ScienceДокумент7 страницSummary Guide in Earth ScienceMeriam WebsterОценок пока нет

- Major Items of Supply Proposed Manufacturers NationalityДокумент1 страницаMajor Items of Supply Proposed Manufacturers NationalityAvinash Lal100% (1)

- Presentation On Utilities & Offsite Iffco, ParadeepДокумент22 страницыPresentation On Utilities & Offsite Iffco, ParadeepSOCRATESОценок пока нет

- Zanussi ZWS 510801Документ20 страницZanussi ZWS 510801LoreelayОценок пока нет

- Aceites IndustrialesДокумент4 страницыAceites IndustrialesVictor ZhicayОценок пока нет

- Cobalt: Definition, Mineralogy and DepositsДокумент19 страницCobalt: Definition, Mineralogy and DepositsJesusSalamancaОценок пока нет

- Norelem Grupa 02000 enДокумент56 страницNorelem Grupa 02000 enBogdan CraciunОценок пока нет

- Method Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFДокумент12 страницMethod Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFFendi Rang TigorОценок пока нет

- FinfetДокумент25 страницFinfetsathyanarainraoОценок пока нет

- Atlas Copco Air Compressor Parts Catalog PDFДокумент881 страницаAtlas Copco Air Compressor Parts Catalog PDFLicínio Dâmaso100% (4)

- 0620 s06 Ms 3Документ5 страниц0620 s06 Ms 3Varun PanickerОценок пока нет

- SDS Carmeuse CaOДокумент6 страницSDS Carmeuse CaOBagas Prasetyawan Adi NugrohoОценок пока нет

- Determination of In-Situ Unit Weight of Soil: Experiment No 2 & 3 Soil Mechanics Laboratory CE PC 594Документ30 страницDetermination of In-Situ Unit Weight of Soil: Experiment No 2 & 3 Soil Mechanics Laboratory CE PC 594SumanHaldar100% (1)

- Concrete NDT SeminarДокумент62 страницыConcrete NDT SeminarlokeshlokОценок пока нет

- 50CДокумент6 страниц50Cjhacademyhyd89% (9)