Академический Документы

Профессиональный Документы

Культура Документы

BusBar Short Circuit Calculation

Загружено:

bhaskarinvuИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BusBar Short Circuit Calculation

Загружено:

bhaskarinvuАвторское право:

Доступные форматы

01.03.2007 (Rev.

CALCULATIONS IN SUPPORT OF FAULT LEVEL OF 65 kA FOR ONE SECOND

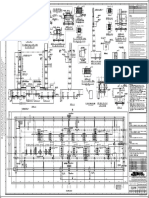

4000 A TP ALUMINIUM BUS DUCT DRAWING NO.G 7643 R0

i) ii) iii) iv) v) vi) vii)

Rating Bus Bars Per Phase Fault Level Enclosure Ambient Temperature Working Temperature Rating Chart

4000 Amps 3 x 200 mm x 12 mm 65 kA for 1 Second In a ventilated room 50OC 85OC INDAL Electrical Grade Aluminium

(1)

THERMAL RATING a) Rating as per Table 2 (INDAL) For 3 x 200 mm x 12 mm Aluminium Bus Bars Derating Factor Temperature Rise of 35OC over an ambient of 50OC. Magnetic Enclosure Proximity Factor Enclosure Factor Paint / Sleeving Factor Combined Derating Factor 0.817 5300 Amps

b)

0.850 1.000 0.920 1.250 0.817 x 0.850 x 1.000 x 0.920 x 1.250 0.799 Say 0.80 0.80 x 5300 4240 Amps

c)

Actual Current Rating of above Bus Bars

Conclusion

Safe as the rating works out to be 4240 Amps as against 4000 Amps required.

.Contd..2

(2)

(2)

SHORT TIME RATING I T Q1 Q2 = A = Short Circuit Current Short Circuit Time Initial Temperature Final Temperature Cross Sectional Area in Sq. inch Ix 14 x 10

4

= = = =

65 kA 1 Second 85 C 200OC

O

A =

Q2 + 258 log 10 Q1 + 258

O

X)

Cross sectional Area in case of initial temperature of 85 C and final temperature of 200OC.

65 x 10 x 14 x 10

4

1

458 log 10 343

= =

1.309 Sq. inch 845 Sq.mm

Conclusion

Area considered is 7200 Sq.mm Hence SAFE

(3)

MECHANICAL STRESS & INSULATOR SPAN

FM I K S FM =

Mechanical Force Developed at the time of Short Circuit. Short Circuit Current. Space Factor For Rectangular Bus Bar. Spacing between the Phases = 190 mm. 16 x I

2

x 10 S

-4

xK N/M

.Contd..3

(3)

The value of K as calculated from the graph given in J&P Hand Book page 212 by taking the ratio (S-a) / (a+b) on comparing it with a/b will be 0.50.

6 -4

Hence FM =

16 x 65 x 70 x 10 x 10 190

x 0.50

= =

19158 N/M 1954.88 Kg Per Meter

Force Developed at a span of 350 mm

= =

1954.88 x 0.350 684.20 Kg.

Since there are two supports one at on top and one at bottom, force per support will be 342.10 Kg. a) Powermat supports (SMC) type 312-K having capacity to withstand force of 2000 kg will be provided meaning thereby that there will be a safety factor of 5.85 times. Distance : The support to support distance of max 350 mm will be maintained. Above calculations / recommendations are OK for a phase to phase gap of 130 mm.

b)

c)

(4)

FINAL DESIGN OFFERED Chamber Size Bus Bars Phase to Phase Gap Support to Support Distance 700 mm (minimum) 3 x 200 mm x 12 mm per phase 130 mm 350 mm

Вам также может понравиться

- Bus Bar Calculation - RequirementДокумент20 страницBus Bar Calculation - Requirementsrigirisetty208100% (2)

- Client: - M/ P C H P - L - ProjectДокумент5 страницClient: - M/ P C H P - L - Projectgirishprabhu19840% (1)

- Bus Bar Sizing Calculation for 3200A Main PanelДокумент9 страницBus Bar Sizing Calculation for 3200A Main PanelsbpathiОценок пока нет

- Earthing CalculationДокумент14 страницEarthing CalculationNatarajan Ramakrishnan100% (18)

- Cable Sizing CalculationДокумент4 страницыCable Sizing CalculationRohan Gurav100% (6)

- 3200A Busduct Busbar Calculation PDFДокумент4 страницы3200A Busduct Busbar Calculation PDFPramod B.Wankhade100% (7)

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelДокумент1 страницаParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarОценок пока нет

- Panel Busbar Sizing Calculations - Thomas and RataДокумент4 страницыPanel Busbar Sizing Calculations - Thomas and Ratakapil100% (12)

- Aluminium Busbar Sizing Software OutputДокумент3 страницыAluminium Busbar Sizing Software Outputkapil100% (4)

- Bus Duct Calculations For 4000A Rated CurrentДокумент4 страницыBus Duct Calculations For 4000A Rated CurrentGnanavel GОценок пока нет

- Transformer Neutral CT SizingДокумент2 страницыTransformer Neutral CT SizingPramod B.Wankhade100% (4)

- Alumimium Bus Bar Calculation 4000AДокумент5 страницAlumimium Bus Bar Calculation 4000ATjsampathkumar Kumar67% (6)

- DSLP CalculationДокумент7 страницDSLP Calculationravi shankar100% (1)

- Tneb Power Engineers HandbookДокумент2 страницыTneb Power Engineers Handbooksalman50% (4)

- Busbar Sizing For 50ka For 1 SecДокумент1 страницаBusbar Sizing For 50ka For 1 SecAnagha Deb100% (6)

- Sizing Calculation of Battery ChargerДокумент15 страницSizing Calculation of Battery ChargerRavi Chandar83% (6)

- Busbar Sizing CalculationДокумент1 страницаBusbar Sizing CalculationJanardhanan Palani100% (3)

- Selection and Sizing of APFC PanelДокумент21 страницаSelection and Sizing of APFC PanelpvpavanОценок пока нет

- 110V Battery SizingДокумент21 страница110V Battery SizingHassenL100% (3)

- Transformer and DG Set SelectionДокумент3 страницыTransformer and DG Set SelectionZIPDASHОценок пока нет

- Fault level calculation using base MVA methodДокумент2 страницыFault level calculation using base MVA methodTreesa Archnana100% (3)

- 11kV or 33kV Cable Sizing CalculationДокумент1 страница11kV or 33kV Cable Sizing Calculationanamulk-183% (18)

- Transformer & DG SizingДокумент10 страницTransformer & DG Sizingvinaynagvanshi5Оценок пока нет

- Calculate Voltage Drop and Select Cable SizeДокумент31 страницаCalculate Voltage Drop and Select Cable SizeCharlotte WilkinsonОценок пока нет

- Cable Impedance CalculationsДокумент4 страницыCable Impedance CalculationsJoseph PoplingerОценок пока нет

- Typical HT & LT Power Cable Sizing CalculationДокумент13 страницTypical HT & LT Power Cable Sizing CalculationSamant SauravОценок пока нет

- SEO-Optimized Lighting Transformer TitleДокумент8 страницSEO-Optimized Lighting Transformer TitleShrikant KajaleОценок пока нет

- Busbar CalculationДокумент8 страницBusbar Calculationd_rosembergОценок пока нет

- 36KV Outdoor Ring Main Unit Technical SpecificationДокумент9 страниц36KV Outdoor Ring Main Unit Technical SpecificationBADRI VENKATESHОценок пока нет

- Acb Selection & CalculationДокумент18 страницAcb Selection & CalculationYogesh DabholeОценок пока нет

- Fault Current Calculations and Relay SettingДокумент118 страницFault Current Calculations and Relay SettingRohan Gurav94% (52)

- CT calculations for 33kV Switchgear for ADWEA contract no G1408Документ31 страницаCT calculations for 33kV Switchgear for ADWEA contract no G1408jm.mankavil6230100% (2)

- MCC Bus Bar Sizing CalculationДокумент12 страницMCC Bus Bar Sizing Calculationerkamlakar223480% (5)

- 33kV Line Loss Estimation - KaradikondaДокумент8 страниц33kV Line Loss Estimation - Karadikondasomdatta chaudhury0% (1)

- 630A MCC BUSBAR SIZING CALCULATIONДокумент42 страницы630A MCC BUSBAR SIZING CALCULATIONAnonymous OKkHA0NzОценок пока нет

- Voltage Drop For 11KV CableДокумент1 страницаVoltage Drop For 11KV CableMohamed Anwar0% (1)

- 11kV CT CalculationДокумент38 страниц11kV CT Calculationjm.mankavil6230100% (9)

- Derating FactorДокумент6 страницDerating FactorSatya BysaniОценок пока нет

- Busbar Sizing CalculationДокумент13 страницBusbar Sizing CalculationPower Solution100% (2)

- SV POWER Lightning Protection Calculation Sheet - T.G BuildingДокумент11 страницSV POWER Lightning Protection Calculation Sheet - T.G BuildingPrabhash Verma100% (2)

- Electrical Engineering: Calculate Size of Bus barДокумент19 страницElectrical Engineering: Calculate Size of Bus barhemant kumar100% (1)

- MV CAPACITOR SIZING CALCULATION FOR KARAIKAL PORT PROJECTДокумент3 страницыMV CAPACITOR SIZING CALCULATION FOR KARAIKAL PORT PROJECTRaja ShannmugamОценок пока нет

- Battery Sizing Calculation KPD 981 Com E4 005 p0Документ16 страницBattery Sizing Calculation KPD 981 Com E4 005 p0drawler0% (1)

- Battery Sizing CalculationДокумент11 страницBattery Sizing Calculationyasser5100% (1)

- ACSR Conductor SizingДокумент13 страницACSR Conductor SizingraghuvarmaОценок пока нет

- S.C Calculations: Short Circuit StudyДокумент17 страницS.C Calculations: Short Circuit StudyAhmedRaafatОценок пока нет

- HT Capacitor Bank CalculationДокумент5 страницHT Capacitor Bank CalculationSankalp MittalОценок пока нет

- BusBar Short Circuit CalculationДокумент3 страницыBusBar Short Circuit CalculationNaman SharmaОценок пока нет

- Below Ground & Above Ground Earthing CalculationДокумент8 страницBelow Ground & Above Ground Earthing CalculationPramod B.Wankhade0% (1)

- Bus Cal - 2500aДокумент11 страницBus Cal - 2500aPCE PROJECTS PVT. LTD.Оценок пока нет

- Electrical Machines-I Question BankДокумент8 страницElectrical Machines-I Question BankPapasani srividyaОценок пока нет

- Calculating cable sizes, fault currents and power factor correctionДокумент12 страницCalculating cable sizes, fault currents and power factor correctionVs PkdОценок пока нет

- Design Cal IndoramaДокумент13 страницDesign Cal IndoramaKUNALJAYОценок пока нет

- Annex B (Informative) Sample Calculations: B.1 Square Grid Without Ground Rods - Example 1Документ7 страницAnnex B (Informative) Sample Calculations: B.1 Square Grid Without Ground Rods - Example 1Jeferson FranciscoОценок пока нет

- Nov2022 Coaching JGBДокумент51 страницаNov2022 Coaching JGBNadzОценок пока нет

- LT & HT Cable SizingДокумент5 страницLT & HT Cable Sizingguptaakhil99Оценок пока нет

- Column Design As Per Is 456 Validation RequestedДокумент14 страницColumn Design As Per Is 456 Validation RequestedM ChoudharyОценок пока нет

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Документ5 страницUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatОценок пока нет

- Cable CalculationДокумент4 страницыCable Calculationmohd hazimОценок пока нет

- 4RX254.0X12.7MM Al Busbar 6300A CapacityДокумент1 страница4RX254.0X12.7MM Al Busbar 6300A CapacityMuthu KumaranОценок пока нет

- Taconite Duty - InprosealsДокумент1 страницаTaconite Duty - InprosealsbhaskarinvuОценок пока нет

- UL Versus UR Rating: Knowing The Difference Could Be VitalДокумент1 страницаUL Versus UR Rating: Knowing The Difference Could Be VitalbhaskarinvuОценок пока нет

- Using External Current Transformers with CR DevicesДокумент1 страницаUsing External Current Transformers with CR DevicesbhaskarinvuОценок пока нет

- Sunlike 8W 20W 30W 50W: Series Wattage Optic Type Color Temperature Mounting Options FinishДокумент10 страницSunlike 8W 20W 30W 50W: Series Wattage Optic Type Color Temperature Mounting Options FinishbhaskarinvuОценок пока нет

- Ground Fault Sensor: CR7310 SeriesДокумент2 страницыGround Fault Sensor: CR7310 SeriesbhaskarinvuОценок пока нет

- An Extremely Durable, Water-Tight, Industrial Luminaire: ApplicationsДокумент3 страницыAn Extremely Durable, Water-Tight, Industrial Luminaire: ApplicationsbhaskarinvuОценок пока нет

- PlexPower Serie Stroomonderbekers Appleton a.T.X.Документ4 страницыPlexPower Serie Stroomonderbekers Appleton a.T.X.bhaskarinvuОценок пока нет

- UL Certifi Ed 65 kAIC Enclosure RatingДокумент2 страницыUL Certifi Ed 65 kAIC Enclosure RatingbhaskarinvuОценок пока нет

- Faq About HRG Technology: Webinar Q&A, July 2020Документ11 страницFaq About HRG Technology: Webinar Q&A, July 2020bhaskarinvuОценок пока нет

- 3 Phase Imbalance Detection Using CR7310 SensorДокумент1 страница3 Phase Imbalance Detection Using CR7310 Sensorr.veenaaОценок пока нет

- TFG - SOLTECH - SATELIS Solar LED Ligths BrochuresДокумент5 страницTFG - SOLTECH - SATELIS Solar LED Ligths BrochuresbhaskarinvuОценок пока нет

- 3 Conduct. TerminalsДокумент1 страница3 Conduct. TerminalsbhaskarinvuОценок пока нет

- Se-Cs30 Series: AccessoriesДокумент4 страницыSe-Cs30 Series: AccessoriesbhaskarinvuОценок пока нет

- Solar-Gs: Key FeaturesДокумент3 страницыSolar-Gs: Key FeaturesbhaskarinvuОценок пока нет

- CT SchneiderДокумент4 страницыCT SchneiderNoli OtebaОценок пока нет

- .438 X .750 (4) SLOTS #10-32 GROUND STUD: No Classified CharacteristicsДокумент1 страница.438 X .750 (4) SLOTS #10-32 GROUND STUD: No Classified CharacteristicsbhaskarinvuОценок пока нет

- What is a medium-voltage distribution transformerДокумент33 страницыWhat is a medium-voltage distribution transformerbhaskarinvuОценок пока нет

- VLF TestingДокумент7 страницVLF TestingbhaskarinvuОценок пока нет

- Understanding The Neher-McGrath Calculation and The Ampacity of ConductorsДокумент7 страницUnderstanding The Neher-McGrath Calculation and The Ampacity of ConductorsbhaskarinvuОценок пока нет

- Adss Spec Annx 2Документ43 страницыAdss Spec Annx 2Alapati Nageswara Rao100% (1)

- Megger-Application Guide For Power Factor Testing of BushingsДокумент8 страницMegger-Application Guide For Power Factor Testing of BushingsMárcio Vieira SilvaОценок пока нет

- Adss Spec Annx 2Документ43 страницыAdss Spec Annx 2Alapati Nageswara Rao100% (1)

- Shield Routing Through Zero Sequence CTДокумент1 страницаShield Routing Through Zero Sequence CTbhaskarinvuОценок пока нет

- ASTMДокумент1 страницаASTMbhaskarinvuОценок пока нет

- Connector Installation Guide REV 02.03.16Документ34 страницыConnector Installation Guide REV 02.03.16bhaskarinvuОценок пока нет

- Test Relaying CTs with ANSI BurdensДокумент1 страницаTest Relaying CTs with ANSI BurdensbhaskarinvuОценок пока нет

- A Case For The Separated Double Tie: Main A Main B Tie N.C. N.CДокумент4 страницыA Case For The Separated Double Tie: Main A Main B Tie N.C. N.CcokicisneОценок пока нет

- UL Bulletin On Electrical Connections PDFДокумент2 страницыUL Bulletin On Electrical Connections PDFbhaskarinvuОценок пока нет

- Efct Series: AccessoriesДокумент4 страницыEfct Series: AccessoriesbhaskarinvuОценок пока нет

- Application For HV Motor Circuit FusesДокумент4 страницыApplication For HV Motor Circuit FusesbhaskarinvuОценок пока нет

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Документ2 страницыKirloskar Brothers Limited: A Kirloskar Group Company Established 1888Mohan CharanchathОценок пока нет

- Electrical Checklist Plan Review ChecklistДокумент13 страницElectrical Checklist Plan Review ChecklistCB100% (1)

- TTT Diagram & Heat TreatmentДокумент65 страницTTT Diagram & Heat TreatmentSudheer ChauhanОценок пока нет

- Marcet Boiler ExperimentДокумент10 страницMarcet Boiler ExperimentErmias AsfawОценок пока нет

- TWPH Rev - 5Документ1 страницаTWPH Rev - 5pravinmishra1245Оценок пока нет

- FE 3300 The Use of Fans in Pneumatic ConveyingДокумент4 страницыFE 3300 The Use of Fans in Pneumatic ConveyingAvery OppegardОценок пока нет

- Ethiopia WarehouseДокумент5 страницEthiopia WarehouseJohn TesfamariamОценок пока нет

- 8-En 5850-A - Stack Valves Cetop 07Документ7 страниц8-En 5850-A - Stack Valves Cetop 07abuzer1981Оценок пока нет

- ME306 Advanced Manufacturing Technology, September 2020Документ2 страницыME306 Advanced Manufacturing Technology, September 2020samnoon muadОценок пока нет

- Boiler IntroductionДокумент17 страницBoiler IntroductionDavid SilalahiОценок пока нет

- Pump Design PresentationДокумент9 страницPump Design PresentationKayode Ijaola100% (1)

- Hygrobar B WaterstopДокумент2 страницыHygrobar B WaterstopMahesh SavandappaОценок пока нет

- 8 - Comparative Study of Piled Raft Foundation PDFДокумент5 страниц8 - Comparative Study of Piled Raft Foundation PDFHaleem Ullah KhanОценок пока нет

- Bolts Torque CalculatorДокумент4 страницыBolts Torque Calculatorcaod1712Оценок пока нет

- Letlok Tube Fitting Catalog 2017Документ94 страницыLetlok Tube Fitting Catalog 2017chipulinoОценок пока нет

- Tata Steel - Advantica Controlled EnvironmentsДокумент20 страницTata Steel - Advantica Controlled EnvironmentsGabriel CamargoОценок пока нет

- Pressure Testing Procedures for Refinery EquipmentДокумент8 страницPressure Testing Procedures for Refinery EquipmentsajiОценок пока нет

- Chapter 3: Design Principles of Embankment DamsДокумент14 страницChapter 3: Design Principles of Embankment DamsRefisa JiruОценок пока нет

- Pipefill PDFДокумент8 страницPipefill PDFAlaa RamadanОценок пока нет

- PlasticДокумент20 страницPlasticspiraldaoОценок пока нет

- Foam Pig Selection GuideДокумент5 страницFoam Pig Selection GuidearunperthОценок пока нет

- A Project Report On Cost Reduction in Melting - A SQC and Six Sigma ApproachДокумент107 страницA Project Report On Cost Reduction in Melting - A SQC and Six Sigma ApproachArun Prince100% (1)

- Standard One-Storey School Building: (2 - Classrooms)Документ16 страницStandard One-Storey School Building: (2 - Classrooms)Prime Agritech EngineeringОценок пока нет

- LamellaДокумент3 страницыLamellaRomeo Padilla IIIОценок пока нет

- BDK ValveДокумент12 страницBDK ValvevinaypОценок пока нет

- Background: The Duct Tape BookДокумент5 страницBackground: The Duct Tape BookCloudine IzonОценок пока нет

- IRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Документ100 страницIRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Saroon Afshan76% (29)

- Carbide Banding - Effect On FatigueДокумент15 страницCarbide Banding - Effect On FatigueSteve Green100% (1)

- Introduction To Piping Material ActivitiesДокумент23 страницыIntroduction To Piping Material ActivitiesAnh Vân TrầnОценок пока нет

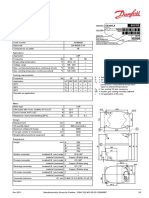

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralДокумент2 страницыGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaОценок пока нет

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessОт EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessРейтинг: 4 из 5 звезд4/5 (6)

- The Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceОт EverandThe Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceРейтинг: 4.5 из 5 звезд4.5/5 (23)

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- Lost in Math: How Beauty Leads Physics AstrayОт EverandLost in Math: How Beauty Leads Physics AstrayРейтинг: 4.5 из 5 звезд4.5/5 (125)

- Summary and Interpretation of Reality TransurfingОт EverandSummary and Interpretation of Reality TransurfingРейтинг: 5 из 5 звезд5/5 (5)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismОт EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismРейтинг: 4 из 5 звезд4/5 (500)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1395)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (241)

- Too Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldОт EverandToo Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterОт EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterРейтинг: 4.5 из 5 звезд4.5/5 (409)

- Strange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsОт EverandStrange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsРейтинг: 4 из 5 звезд4/5 (94)

- The End of Everything: (Astrophysically Speaking)От EverandThe End of Everything: (Astrophysically Speaking)Рейтинг: 4.5 из 5 звезд4.5/5 (155)

- Quantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishОт EverandQuantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Quantum Physics: What Everyone Needs to KnowОт EverandQuantum Physics: What Everyone Needs to KnowРейтинг: 4.5 из 5 звезд4.5/5 (48)

- What is Life?: With Mind and Matter and Autobiographical SketchesОт EverandWhat is Life?: With Mind and Matter and Autobiographical SketchesРейтинг: 4 из 5 звезд4/5 (139)

- Infinite Powers: How Calculus Reveals the Secrets of the UniverseОт EverandInfinite Powers: How Calculus Reveals the Secrets of the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (126)

- In Search of Schrödinger’s Cat: Quantum Physics and RealityОт EverandIn Search of Schrödinger’s Cat: Quantum Physics and RealityРейтинг: 4 из 5 звезд4/5 (380)

- Bedeviled: A Shadow History of Demons in ScienceОт EverandBedeviled: A Shadow History of Demons in ScienceРейтинг: 5 из 5 звезд5/5 (5)

- The Beginning of Infinity: Explanations That Transform the WorldОт EverandThe Beginning of Infinity: Explanations That Transform the WorldРейтинг: 5 из 5 звезд5/5 (60)

- Mastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicОт EverandMastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicРейтинг: 4 из 5 звезд4/5 (91)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОт EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОценок пока нет

- Starry Messenger: Cosmic Perspectives on CivilizationОт EverandStarry Messenger: Cosmic Perspectives on CivilizationРейтинг: 4.5 из 5 звезд4.5/5 (158)

- The Holographic Universe: The Revolutionary Theory of RealityОт EverandThe Holographic Universe: The Revolutionary Theory of RealityРейтинг: 4.5 из 5 звезд4.5/5 (75)