Академический Документы

Профессиональный Документы

Культура Документы

RTM Underground Pipes

Загружено:

mithileshmaverickИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RTM Underground Pipes

Загружено:

mithileshmaverickАвторское право:

Доступные форматы

Composite Structures 68 (2005) 267283 www.elsevier.

com/locate/compstruct

Development of the trenchless rehabilitation process for underground pipes based on RTM

Woo Seok Chin, Dai Gil Lee

Available online 26 April 2004

Mechanical Design Laboratory with Advanced Materials, Department of Mechanical Engineering, Korea Advanced Institute of Science and Technology, ME3221, Guseong-dong, Yuseong-gu, Daejeon-shi 305-701, South Korea

Abstract In order to overcome the disadvantages of conventional excavation technology for repairing and replacing worn-out underground pipes, various trenchless technologies have been developed and tried. But trenchless technologies so far developed have some drawbacks such as high cost and inconvenience of operation. In this study, a rehabilitation process for underground pipes has been developed using vacuum assisted resin transfer molding (VARTM) with glass ber fabric preform to overcome the disadvantages of present trenchless technologies. For the reliable operation of the developed method, a simple method to apply pressure and vacuum to the reinforcement was devised with a exible mold technology. From the investigation, it has been found that the developed process requires shorter operation time and lower cost with smaller and simpler operating equipments than those of the conventional trenchless technologies. 2004 Elsevier Ltd. All rights reserved.

Keywords: Trenchless; Rehabilitation; Underground; RTM; CIPP; Dielectrometry

1. Introduction Underground pipes, such as sewer and water-supply pipes, gas pipes, shield pipes of communication cables and electric power cables, etc., have been constructed all over the world, and they are gradually increased in proportion to industrialization and increase of income. But these underground pipes have been undergone several problems such as cracks, breakages, or corrosion due to the inappropriate design, careless management, and the aging of pipe materials [1]. Since all of these problems could lead to huge disaster and loss of social fund, such as soil and water pollution, ground subsidence, and explosion due to the gas leakage, the largescale rehabilitation of those damaged underground pipes is very imminent. In order to solve these problems, the excavation technology has been used widely, which replaces the damaged pipe with new one through the

* Corresponding author. Tel.: +82-42-869-3221; fax: +82-42-8695220/5221. E-mail address: dglee@kaist.ac.kr (D.G. Lee). URL: http://scs.kaist.ac.kr.

excavation of the ground. Since such a conventional method has many drawbacks and irrationality induced by the needless excavation of the ground, various trenchless (sometime called excavation free or no-dig) technologies without any excavation of the ground have been developed and tried worldwide. However, these technologies also have many disadvantages such as high processing cost, inconvenience of operation and limited applications [1]. Since RTM has the capability to fabricate large and complex three-dimensional anisotropic ber reinforced composite structures at the designed position with low production cost, it may be plausible to apply RTM to repair large underground pipes [2]. Although there are many researches that are related to the trenchless rehabilitation technologies and RTM [36], the RTM process to repair underground pipes has not been attempted until now. Therefore, in this study, a new trenchless rehabilitation process of underground pipes to overcome such problems of former trenchless technologies and adequate to the situation of high trac road, has been tried and achieved with E-glass ber fabric preform and unsaturated polyester resin by vacuum assisted resin transfer molding (RTM).

0263-8223/$ - see front matter 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.compstruct.2004.03.019

268

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Also several dierent combinations of reinforcing ber preform have been tried through material tests and experiments. In order to remove the micro void and excessive resin within the reinforcing element and enhance the resin wetting eciency, the void removal method using porous breathing tubes has been devised and tested. For the reliable process, the wetting and curing status of instilled resin were on-line monitored using a dielectric sensor and a dielectrometer. After the rehabilitation experiment on a small scale had been performed successfully, actual repairing experiments have been performed at the real concrete conduits. Finally, the eciency of the developed process was evaluated with respect to processing variables, such as process cost and time, which were compared with those of the conventional trenchless technology. Also, the design criteria for the reinforcing element were suggested to assure the sucient reinforcing eect with minimum material cost.

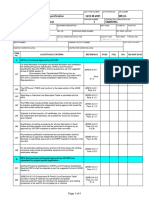

2. Trenchless rehabilitation process using RTM 2.1. Introduction of developed process The rehabilitation process composed of four steps is studied in this paper. Fig. 1 shows the process which is a modication of the general RTM process. The range of internal diameter of the underground pipes for the

application of the developed process is 1501000 mm, and the length of pipe can be up to 50 m. Step 1: After cleaning the interior of target conduits (underground pipes), a wire is placed through conduits by the mobile robot as shown in Fig. 1(a). Then, as shown in Fig. 1(b), the reinforcing element of Fig. 2 is installed at the designated position of conduits by a winding machine. The adhesive of suitable viscosity is pasted on the outer protection skin, which gives lubrication eect during the dragging process as well as adhesion between the reinforcing element and the target conduits. Step 2: After placing the reinforcing element in the conduit, the both ends are closed and sealed as shown in Fig. 1(c) using two specially designed covers. At this time, the covers and the reinforcing element are clamped with a band clamp that is tightly tted into the groove of the cover in the manner as shown in Fig. 3. After sealing both ends of the reinforcing element, the compressed air or nitrogen gas is supplied into the inside cavity through the air inlet of covers to expand the inner protection skin. This makes the outer protection skin and ber preform contact closely to the inner surface of the conduits, and removes wrinkles and twists in the reinforcing element that might occur during the placing operation as shown in Fig. 1(d). Then the pressure in the cavity is removed, which helps the easy resin transfer at the next stage. Step 3: A predetermined amount of unsaturated polyester resin is injected into the ber preform with a

Fig. 1. Repairing processes of underground pipes with RTM: (a) preprocessing; (b) placing of the reinforcing element; (c) attaching of the covers and sealing; (d) removal of wrinkles and twists of the reinforcing element; (e) injection of polyester resin; (f) wetting of resin into the ber preform and removing voids and excessive resin within the preform.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

269

Glass-fiber Preform

Inner Protection Skin

cavity must be maintained. The temperature increase in the cavity using some devices, such as the hot air blower fan equipped with a compressor can decrease the curing time of resin. After the injected resin is completely cured, the covers at both ends of the reinforcing element are removed to complete the entire processes. 2.2. Material selection and tests

Outer Protection Skin

Fig. 2. Conguration of the reinforcing element.

Fig. 3. Clamping method of covers and the positions for pasting adhesive.

RTM machine through the resin inlet of the cover as shown in Fig. 1(e). Due to the low viscosity of the unsaturated polyester resin, it is easy to transfer the resin into the ber preform under low pressure. Step 4: After injecting the resin, the compressed air or nitrogen gas is fed into the cavity again to make the injected resin wet the ber preform uniformly as well as bringing the reinforcing element into close contact with the inner surface of the conduit as shown in Fig. 1(f). The process is performed while a vacuum is applied to the reinforcing element through the air vent of the cover, which helps the resin wetting and removes the micro void and excessive resin within the ber preform. Also the volatiles produced during the cure of polyester are evacuated through the air vent of the cover. When the surplus resin and void within the ber preform are completely removed, the wetting of the ber preform and the resin ow are ceased, followed by resin cure. In order to prevent the resin within the ber preform from owing down due to the gravity, the pressure in the

Since the underground structures are usually exposed to chemically harsh environment and subjected to heavy compressive load, the selection of repairing materials considering reinforcing eects is very important. Also the costs, such as material cost, processing cost, etc., should be considered carefully because large amount of material is required for repairing huge underground structures and the short operation time is important not to induce any trac congestion. Therefore, in this study, the unsaturated polyester resin with low viscosity, which is ve times cheaper than epoxy, was selected and used. The PC670 (Aekyung Chemical, Daejeon, Korea) is orthophthalic type unsaturated polyester resin with a low viscosity before cure (0.2 Pa s), which is transparent and has the possibility of ller addition to reduce cost and strengthen toughness. Table 1 shows the material properties of PC670 used in this study. The reinforcing element for repairing underground pipes is composed of the reinforcing ber preform and two inner and outer protection skins as shown in Fig. 2. These two protection skins protect the glass ber preform from the internal surface of underground conduits and subterranean water or sewage left within the conduit. Also the inner and outer skins encapsulate the ber preform in order to act as the mold during RTM process. The protection lms not only protect the ber preform but also sustain the tensile load up to 80 kN that is induced by the air pressure of inside cavity (the maximum air pressure applied to the conduit of 1000 mm diameter is 0.1 MPa) and the traction force during the process [7]. The material for protection skins should have chemical stability when contacted to unsaturated polyester resin because the styrene monomer used for hardening of polyester, may react with the skin material. In this study, the Pro-Sol lm, a kind of tarpaulin lms

Table 1 Material properties of the cured unsaturated polyester resin (Aekyung PC670) Property Flexural strength (MPa) Flexural stiness (GPa) Tensile strength (MPa) Tensile modulus (GPa) Tensile strain (%) Value 104 3.9 54 4.1 1.5

Curing conditions: MEKPO (of 55% peroxide) 1% + 6% Co-Naph 0.1% Room temperature/24 h + 60 C/5 h.

270

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

(LG Chemical, Seoul, Korea), was used for the protection skins because the Pro-Sol lm had superior tensile properties as well as chemical stability when contacted with the styrene monomer in polyester resin [1,7]. The thickness of Pro-Sol lm used in this study was 0.55 mm with the tensile strength of 100 MPa. Among the three stages of RTM process (preforming, resin wetting, and curing), the resin wetting is the core process of RTM because the product quality is mostly governed by the degree of wetting [8]. The resin wetting during RTM process, which is viscous ow through the porous media, may be expressed by Darcys law as follows. U K rP l 1

of transverse direction of the preform, the stacked mat of [Unidirectional mat 1 ply/continuous strand mat 2 plies/ unidirectional mat 1 ply]Total stacking sequence was employed. Tables 2 and 3 show the measured permeabilities of various ber mats and the tensile strengths of cured glass/polyester composites, respectively. From the test results, the stacked mat with high permeability and moderate tensile strength was selected for preform materials. 2.3. Resin ow and wetting analysis The resin ow during the rehabilitation process was modeled as the circumferential ow in the ber preform as shown in Fig. 4 on the assumption that the radial and longitudinal resin ows were neglected. Since the outside pressure and inside vacuum are applied to the reinforcing element to wet the ber preform with the resin, the net pressure for the resin ow was constant during the whole process. Considering the pressure drop due to gravity, the net pressure, P , in the ber preform may be expressed as follows. P Pair Pvacuum qgh 2 where Pair and Pvacuum represent the air and vacuum pressures, respectively, q is the density of resin, and h is the height dierence of the resin front that can be expressed as follows. h r r cos h r1 cos h 3 Since the resin ows in the r and z directions can be neglected due to the thin ber preform, the velocity uh of the resin front in the h direction is expressed as uh Khh Khh @P rP l l r@h Khh d Pair Pvacuum qgr1 cos h l dl

where, K is the permeability of ber preform, l the viscosity of resin, and DP the pressure gradient. Therefore, the resin wetting time is dependent on the permeability of ber preform. When the viscosity of resin and the available maximum pressure gradient are given, the permeability of ber preform, K, should be maximized to reduce the overall process time. Also the strength of ber preform should be large because the ber preform forms a polymer matrix composite after the rehabilitation process, which should sustain the external load subjected by the ground and trac. In order to select the proper materials for ber preform, permeability and tensile strength of various E-glass ber mats, unidirectional mats (T800-E06; Dong-il Industrial, Seoul, Korea), continuous strand mats (M8600; Keun-yung Industrial, Seoul, Korea), crowfoot satin woven mats (Spec.#224; Hyundai Fiber, Kyoungnam, Korea), chopped strand mats (CM450A; Hankuk Fiber, Kyoungnam, Korea), and roving cloth mats (WR580A; Hankuk Fiber, Kyoungnam, Korea) were experimentally measured [9,10]. To reinforce the strength

Table 2 Measured permeabilities of the various E-glass ber mats Type of mat Unidirectional (T800-E06) Continuous strand (M8600) Stacked mat [UD/CSM/CSM/UD]T Satin woven (Spec.#224) Volume fraction (%) 42.1 47.0 9.1 13.5 25.8 42.4 48.5 54.6 21.2 26.6 18.2 22.4

Kxx (m2 ) 1010 45.5 7.52 17.8 9.96 41.1 0.602 0.368 0.204 25.3 20.3 44.3 17.5

Kyy (m2 ) 1010 39.2 5.32 17.6 9.99 40.0 0.497 0.267 0.151 23.4 19.8 43.3 17.2

Roving cloth (WR580A) Chopped strand mat (CM450A)

UD (T800-E06): unidirectional mat, CSM (M8600): continuous strand mat.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283 Table 3 Tensile properties of the glass/polyester composite materials Type of mat Unidirectional (T800-E06) Continuous strand (M8600) Stacked mat [UD/CSM/CSM/UD]T Satin woven (Spec.#224) Roving cloth (WR580A) Fiber volume fraction (%) 47 10 14.5 29.5 26.6 42.4 28.5 Tensile strength (MPa) 630 55 77.2 340 288 471 259 Youngs modulus (GPa) 33.9 6.87 7.4 18.2 16.6 28.2 13.5

271

UD (T800-E06): unidirectional mat, CSM (M8600): continuous strand mat.

Table 4 Viscosity of the uncured polyester resin (PC670) w.r.t. the environmental temperature Temperature Room temperature (25 C) 10 C 5 C Viscosity (Pa s) 0.25 0.75 1.0

Fig. 4. Model for resin ow in the ber preform used for resin wetting analysis.

where l is the length of the resin front measured along the circumference of conduit and 0 6 h 6 p. Using Eq. (4) and the measured values of permeabilities of various ber mats, the movement of resin front and complete wetting time were calculated with respect to environmental temperature (viscosity of resin), types of ber preform, and diameters of conduits on the assumption that inside vacuum and outside air pressure of 30 kPa were applied to the reinforcing element. Tables 4 and 5 show the measured viscosity of uncured polyester resin (PC670) with respect to the environmental temperature and the permeabilities of ber mats used in the analysis, respectively. Fig. 5 shows the predicted resin wetting time calculated under the

assumptions of constant viscosity of resin at a certain experimental temperature and uniform permeability of ber preform. As shown in Fig. 5, the stacked mat of [Unidirectional mat 1 ply/continuous strand mat 2 plies/unidirectional mat 1 ply]Total stacking sequence was the most appropriate for the shortest processing time because it assured the shortest resin wetting time. In order to verify these analysis results, small-scale rehabilitation experiments were performed in the transparent acryl pipes of inner diameters of 180 and 300 mm using the preforms of stacked mats and satin woven mats, respectively. From the experiments, it was found that the predicted wetting times had an error less than 7% [11]. Since the resin wetting time should be regulated by controlling the process variables, such as temperature and pressure during the actual rehabilitation process, diagrams relating these process variables are required in order to accomplish the repairing process reliably and eectively. Therefore, the resin ow analysis was performed with respect to the environmental temperature and applied net pressure (vacuum + air pressure) for the conduit of specied internal diameter. Fig. 6 shows the predicted resin wetting time of the preform of stacked mats whose

Table 5 Permeabilities of the various E-glass ber mats used in the resin ow analysis Type of mat Unidirectional (T800-E06) Continuous strand (M8600) Stacked mat [UD/CSM/CSM/UD]T Satin woven (Spec.#224) Roving cloth (WR580A) Chopped strand mat (CM450A) Volume fraction (%) 47.0 13.5 25.8 54.6 26.6 22.4 Kxx (m2 ) 1010 7.52 9.96 41.1 0.204 20.3 17.5 Kyy (m2 ) 1010 5.32 9.99 40.0 0.151 19.8 17.2

UD (T800-E06): unidirectional mat, CSM (M8600): continuous strand mat.

272

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

60 50

Wetting Time (min)

180

40 30 20 10 0 0 200

Wetting Time (min)

UD CSM Roving Chopped Stacked

150 120 90 60 30 0

UD CSM Roving Chopped Stacked

(a)

400 600 800 Diameter (mm)

1000

1200

(b)

200

400 600 800 Diameter (mm)

1000

1200

240 200 UD CSM Roving Chopped Stacked

160 140 25 10 0

Wetting Time (min)

160 120 80 40 0 0 200

Wetting Time (min)

120 100 80 60 40 20 0

(c)

400 600 800 Diameter (mm)

1000

1200

(d)

100

300

500 700 Diameter (mm)

900

1100

Fig. 5. Predicted resin wetting time of the rehabilitation process with respect to environmental temperature, types of ber perform, and diameters of conduits: (a) at 25 C; (b) at 10 C; (c) at 5 C; (d) the resin wetting time of the preform of satin woven mat with respect to environmental temperature and diameters of conduits.

ber volume fraction is 25.8% as the temperature and applied pressure are changed. By using these analysis results, diagrams shown in Fig. 6 were prepared to control the process variables. 3. On-line process monitoring with dielectrometry The resin wetting and curing are two major process of RTM because the product quality is dependent on the degree of wetting [8] and its cure process [12]. Therefore, it is necessary to monitor the wetting and curing status of resin continuously during the rehabilitation process in order to yield a satisfactory reinforcing quality in the shortest process time. Since the Pro-Sol lms used in this study are not only opaque but also placed underground, it is dicult to check them with the naked eye. For this reason, dielectrometry and dielectric sensors were employed to on-line monitor the resin ow and cure status in this work, from which the applied pressure and temperature were adjusted. The dielectrometry has been known as a promising technique to in situ monitor the entire cure process of thermosetting resin continuously. When an alternating electric eld is applied to the two electrodes of the dielectric sensor embedded in the

composite material as shown in Fig. 7(a), the dipole and ions within the resin, which is a dielectric material, are aligned following an applied alternating electric eld. At this time, the combination of two electrodes and polymeric resin can be modeled as a parallel equivalent circuit composed of resistance Rm and capacitance Cm as shown in Fig. 7(b). The mobility of dipoles and ions has close relations with the cure state and the viscosity of resin within the composite material as shown in Fig. 7(c), and can be expressed by the dissipation factor D, which represents the ratio of the energy loss by movements of dipoles and ions to the supplied electric energy. The dissipation factor for the equivalent circuit shown in Fig. 7(b) can be obtained as follows [12]. IR Vm IR ZC 1 D 5 I Z x R C IC Vm C R m m where IR IC Vm ZR ZC electric current in resistance (A) electric current in capacitance (A) voltage applied to equivalent circuit (V) equivalent impedance of resistance X equivalent impedance of capacitance X

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

273

200 190

1 100 120 10 0

4.40 4.13 3.87 3.61 3.35 3.08 2.82 2.56 2.30 2.03 1.77 1.51 1.25 0.98 0.72

180 170

Pressure (kPa)

160 150 140 130 120 110

P re 140 ssu re

(kP

160

20 180 200 30

a)

(a)

ra pe em

e tur

e gre (de

C)

100 10 20 30

Time (min)

Temperature (degree C)

200 190

20

15

10

5 100 120 0 10 160 20 180 200 30

18.04 16.96 15.89 14.81 13.73 12.65 11.57 10.50 9.42 8.34 7.26 6.18 5.10 4.03 2.95

180 170

Pressure (kPa)

160 150 140 130 120 110

P re 140 ssu re

(kP

a)

(b)

Te

era mp

e tur

e gre (de

C)

100 10 20 30

Time (min)

Temperature (degree C)

200 190

60

40

20

51.87 48.77 45.66 42.55 39.45 36.34 33.23 30.12 27.02 23.91 20.80 17.70 14.59 11.48 8.38

180 170

Pressure (kPa)

160 150 140 130 120

100 120 10 0 140

Time (min)

P re

ssu re (

kP a

160

20 180 200 30

(c)

ra pe em

de e( tur

e gre

C)

110 100

10

20

30

Temperature (degree C)

Fig. 6. Variation of resin wetting time with respect to environmental temperature and applied net pressure for the specied inner diameter of conduits: (a) diameter of 0.3 m; (b) diameter of 0.6 m; (c) diameter of 1.0 m.

frequency of an applied alternating electric eld (Hz; 1 kHz was used in this study)

The principle of dielectrometry is to monitor the cure state by measuring this dissipation factor [1,12]. Since the value of the dissipation factor changes when the dielectric sensor contacts the resin, it is possible to monitor the resin wetting as well as the cure status by measuring the dissipation factor continuously.

In this work, a 1-channel dielectrometer and an interdigital capacitance (IDC) dielectric sensor were used to monitor the resin wetting and curing during the rehabilitation process. In order to check the availability of the proposed monitoring method, the resin wetting experiments were performed in the transparent acryl pipe of 180 mm diameter (the smallest inner diameter of the conduit in this study) with 1 m length and 5 mm thickness using the reinforcing element in which one

274

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Electrode

IR

AC Electric Field

IC Vm

Rm

Cm

(a)

Polymer Composite

(b)

Cure state

Behavior of Dipoles & Ions

+ Dipoles

Ions

Uncured

Fully oriented

Curing

Partially oriented

Fully cured

Random

(c)

Fig. 7. Principle and measuring method of cure status of composite with dielectric sensor: (a) measuring method; (b) equivalent circuit of dielectric sensor and composite; (c) behavior of dipoles and ions w.r.t. the cure status of composite materials.

dielectric sensor was embedded in the middle upper portion of ber preform as shown in Fig. 8. In order to observe the ow of resin with the naked eye, transparent PVC lm of 1.0 mm thickness was used for the outer protection skin. After manufacturing the reinforcing element in the manner shown in Fig. 2, it was placed in the acryl pipe, and the two covers were attached at the both ends of the reinforcing element. Then the resin wetting experiment was performed fol-

lowing the general rehabilitation process of Fig. 1. From the experiments, it was found that the proposed monitoring method detected well the resin wetting as well as curing as shown in Fig. 9, in which the increase of measured dissipation factors at the initial stage occurred when the dielectric sensor contacted the resin. The resin wetting time measured by the dielectric sensor was about 7.5 min and it took about 3 h to complete the resin curing at 50 C.

Fig. 8. Reinforcing element with a breathing tube and a dielectric sensor whose dimension is 9 mm 250 mm 168 lm.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

275

Dissipation Factor

Curing Completed

0.8

0.6

0.4 0 100 Time (min) 200 300

0.7

Dissipation Factor

Wetting Completed

0.6

0.5

0.4 0 5 10

Time (min)

Fig. 9. Dissipation factor of unsaturated polyester resin during the rehabilitation process measured by the dielectrometer and dielectric sensor.

15

20

4. Rehabilitation experiments with developed process Using the above results and the developed process, several real rehabilitation experiments, whose schematic diagram is shown in Fig. 10, were performed at the concrete pipe (reinforced spun concrete pipe) used for

underground applications. The diameter and length of the three concrete pipes were 300 mm and 10 m, 600 mm and 10 m, 600 mm and 30 m, respectively. After the reinforcing elements were prepared using the stacked mats and Pro-Sol lms in the manner of Fig. 2 considering the dimensions of the target concrete pipes, a porous breathing tube of 8 mm inside diameter was inserted into the upper position of the reinforcing element as shown in Fig. 11 [7]. The breathing tube was connected to the air vent of the reinforcing element to apply a vacuum, which enhanced the eciency of void removal much. For the process monitoring, one dielectric sensor was embedded in the ber preform and connected to the dielectrometer whose sensor line was connected through the breathing tube. Since the length of the pipes is somewhat long, the method for supplying the resin uniformly along the reinforcing element was needed. For this end, two resin injection pipes with small pinholes were installed along the reinforcing element as shown in Fig. 11, which was connected to RTM machines to inject unsaturated polyester resin into the ber preform. By regulating the distance between pinholes, the resin injection amount per unit length was made uniform [7]. Since the breathing tube and the resin injection tube were installed in the reinforcing element in the manner as shown in Fig. 12, they could be easily removed by pulling out one end of them before curing of resin. After installation of the reinforcing element, its both ends were closed using specially designed cover assembly that are composed of a steel ring, a steel disk, and an acryl disk as shown in Fig. 13. Fig. 14 shows the cross sectional view of the reinforcing element after installation. The cover assembly is equipped with the pressure gauge for checking an internal air pressure as well as the

Fig. 10. Schematic diagram of the repairing-reinforcing experiment with glass ber fabric and unsaturated polyester resin using RTM and dielectrometry.

276

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Fig. 11. Conguration of the reinforcing element containing the porous breathing tube and the resin injection pipes with pinholes.

Fig. 12. Pipe removal after the completion of resin wetting.

air inlet for pressurizing the internal cavity. After attaching the cover assembly to the reinforcing element, the multi-joint clamp made of chain-link as shown in Fig. 15 was tightened using the steel ring with inner and outer protection lms by tting into the groove of steel ring. The groove on the circumferential face of the steel ring increased the load transfer capability and sealing eect of the resin, and the transparent acryl disk oered the visibility of inside status. In order to seal the gap between the inner and outer protection skins and the internal cavity of reinforcing element, thermosetting adhesive, DP460 of 3M whose material properties are given in Table 6, was pasted on the interface of two skins, and a circumferential groove of steel ring. The resin reservoir shown in Fig. 10, which was placed between the reinforcing element and a vacuum pump, prevents the expelled resin from going into a vacuum pump directly and separates voids from the resin through breathing tube. Since the amount of the bleeded resin could be measured by the gauge on the resin reservoir, it was possible to predict a ber volume fraction of the cured reinforcing element through a simple calculation. After removing the wrinkles and twists in the reinforcing element by expanding the inner protection lm, a predetermined amount of unsaturated polyester resin (130% of the required amount) was injected into

the ber perform with the RTM machine, which mixed the resin with cure catalyst (MEKPO; methyl-ethyl-ketone-peroxide) at predetermined rate. Then the resin wetting and curing were followed in sequential order to complete the entire rehabilitation process. The RTM machines (high volume H.I.S.e hand-held casting unit; Venus-Gusmer, Washington, USA) were actuated by high pneumatic pressure and their detailed specications are given in Table 7. Test conditions and specications of each experiment are depicted in Table 8. Since the long pipes with large diameters were tested, fairly long times were required to nish the resin wetting. Therefore, a little amount of the cure retardant for slowing down the cure reaction was used in order to obtain the sucient process time considering the gelation time of the unsaturated polyester resin (PC670) listed in Table 9. From the experiments, it was found that large threedimensional composite structures could be constructed inside of the large concrete pipes without any dry region as shown in Fig. 16. Also, it was found that the void removal method through the porous breathing tubes and the resin injection pipes with small pinholes were very eective to expel the micro-void.

5. Comparison of processing cost and time There are about 80 sorts of trenchless technologies so far developed all over the world and largely classied into four kinds: slip-lining, cured-in-place pipes (CIPP) lining, close-t lining, and spirally wound pipes lining [11]. Among them, CIPP has been very successful through the achievements of Insituform (Insituform Technologies, Ltd., Chestereld, United Kingdom) and Paltem/Phoenix, and has attracted many modications and improvement. Since the CIPP products probably take 3540% of the global sewer market, the trenchless rehabilitation method developed in this study was compared with the two conventional CIPP lining processes (one was Paltem/Phoenix lining process and the other was D-Ins lining process) with respect to cost,

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

277

Fig. 13. Photographs of cover for sealing the both ends of the reinforcing element for 600 mm pipe: (a) steel ring, (b) assembly of steel ring and steel disk, (c) assembly of cover (steel ring + steel disk + acryl disk) and multi-joint clamp.

Fig. 14. Cross sectional view of the reinforcing element and concrete pipes after installation.

time, and reinforcing eects. The Paltem/Phoenix lining process is a cured-in-place lining process that was developed by Tokyo Gas (Tokyo Gas Co., Ltd., Tokyo, Japan) and Ashimori Industry (Ashimori Industry Co., Ltd., Osaka, Japan) for lining gas pipes, in which a polyethylene resin coated woven hose is bonded with epoxy resin to the pipe to be repaired in inversed shape by water or air pressure [13]. From the beginning, this

process was named Paltem (pipeline automatic lining system), and then became known as Phoenix in Europe because Osaka Bosui (Osaka Bosui Construction, Co., Osaka, Japan) participated in this development shared it with a French company Le Jointe Interne [13]. The D-Ins lining process (Samil Setec, Seoul, Korea) is a modied Insituform process, in which the polyester fabric felts impregnated with polyester, or vinylester

278

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Fig. 15. Multi-joint clamp: (a) photograph of multi-joint clamp with roller chain links, (b) assembly of cover and clamp, (c) detailed drawing of the multi-joint clamp, (d) roller chain rink and detailed draft of joining part.

Table 6 Material properties of the cured epoxy adhesive (3M DP460) Properties CTE (106 m/m C) Poisson ratio Density (kg/m3 ) Elastic modulus (GPa) Tensile strength (MPa) Tg : glass transition temperature. Value 59.0 (below Tg ) 159.0 (above Tg ) 0.4 1100 2.7 37

Table 7 Specications of the RTM machine (Venus-Gusmer, Inc., Washington, USA) Property Mass injection output Injection capacity Air consumption Catalyst mixing ratio (volume) Catalyst jug Value 2.313.6 kg/min. 0.408 kg/stroke 0.28 m3 /min. 0.53.0% 2 gallon (7.57 l)

resin are used and also installed in the conduit in the inversed shape by water pressure. The mechanical properties of reinforcing element developed in this study (RTM liner) were tested and

compared with that of Paltem-SZ liner and D-Ins liner, and the production cost and processing time were compared only with those of D-Ins process. For the convenience, the reinforcing element of this study was named RTM liner. The tensile properties of the RTM liner were measured with INSTRON 4206 according to ASTM D3039 and their exural properties were measured with the same machine according to ASTM D790. Tables 10 and 11 show the comparison results of mechanical properties and the production cost and processing time, respectively. As listed in Table 10, it has been found that the RTM liner of this study has much superior mechanical properties to those conventional liners for sewer rehabilitation. The comparison results of production cost and processing time in Table 11 were carried out on the assumption that the extra cost was same for both cases and the processes were applied to repair the conduit of 300 mm inner diameter. From the results, it was found that the margin of repairing cost of developed process was about 85 US $, and the margin of repairing time was about 16 h. Comparing with the excavation technology, this newly developed process could cut cost of excavation technology by more than 40%. If the diameter of target conduits is increased, the eect of cost saving will be further enhanced.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283 Table 8 Test conditions of each rehabilitation experiment Descriptions (diameter length) Preform Injected resin (kg) Resin:MEKPO Retardant Environmental temperature (C) Viscosity of resin (Pa s) Inner pressure (kPa) 300 1000 (mm) [UD1/CSM3/UD1] 44 100:1 (volume) No 5 0.81.0 2030 600 1000 (mm) [UD2/CSM4/UD2] 120 100:0.75 No 14 0.40.5 2030 600 3000 (mm) [UD2/CSM4/UD2] 400 100:0.75 15000 ppm 16 0.30.4 2030

279

UD (T800-E06): unidirectional mat, CSM (M8600): continuous strand mat. Table 9 Gelation time of the unsaturated polyester resin (PC670) with respect to the amount of cure catalyst (MEKPO) Temperature (C) 20 25 30 36 MEKPO (methyl-ethyl-ketone-peroxide) 0.6 46 31 18 11.5 0.8 41 25 14.5 9.5 1.0 32 21.5 12 8.5 1.26 28.5 17 10.5 8 Remarks Unit: % Unit: min

Fig. 16. Real rehabilitation experiment using concrete pipes of 600 mm inner diameter: (a) initial setup of the equipments; (b) resin injection (RTM machine#1) and application of vacuum; (c) resin injection (RTM machine#2); (d) photograph of the real construction experiment; (e) photograph of the repaired concrete pipes; (f) inner surface of repaired concrete pipes.

280

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Table 10 Comparison of the mechanical properties between the reinforcing element developed in this study and conventional liners for sewer rehabilitation RTM liner Resin system Felt Tensile strength Flexural strength Flexural modulus

a b

Paltem-SZa Unsaturated polyester Chopped strand glass ber + polyester fabric 60 110 6.0

D-Insb Unsaturated polyester Unwoven polyester fabric 23 53 1.9

Unsaturated polyester E-glass ber 340 420 15.8

Material data from Ashimori Industry, Japan. Material data from Samil Setec, Korea.

Table 11 Comparison of repairing cost with CIPP (cured-in-place pipes) lining process Cost Material Process Extra Total Margin RTM method (US $/m) 38 95 Same a 133 a 85 D-Ins lining process (US $/m) 72 146 Same a 218 a

Material cost: reinforcing element, resin, adhesive, tubes, etc. Extra cost: inspection, cleaning, perforation of junction, etc. Repairing cost of excavation technology: 380 US $/m. 1 US$ 1300 won.

6. Design criteria of the reinforcing element As mentioned previously, the RTM liner of this study has much higher mechanical properties than those of conventional liners, which might be somewhat overdesigned, consequently there is a possibility of further material cost saving. Therefore, it is necessary to develop some design criteria of the RTM liner which can guarantee sucient material properties with minimum cost. On the assumption that the RTM liner is composed of unidirectional mats (T800-E06) and continuous strand mats (M8600) only, the design criteria of RTM liner was suggested in order to reduce the material cost with sucient reinforcing eect. The American Society for Testing Materials (ASTM) has produced the specications drafted by committees of engineers drawn from users and suppliers. These specications are issued provisionally and revised in accordance with the comments of the industry received by ASTM. In 1989 ASTM produced F1216-89 which was subsequently revised in 1991 and 1993. The current issue ASTM F1216-93 covers the design and installation issues and performance of installed liners [13]. Underground pipes are largely classied into two kinds by their application: gravity pipes and pressure pipes, and each of them are divided into partially deteriorated pipes and fully deteriorated pipes according to their damaged condition. ASTM F1216 suggests some design considerations to determine the thickness of CIPP (liner) for repairing underground pipes case-by-case (totally four cases). In this study, the RTM liner for rehabilitating the

fully deteriorated gravity pipes of 300 mm inner diameter was considered and its design criteria were suggested. Since a fully deteriorated pipe is structurally unsound and cannot support soil and outside load, the RTM liner for this case should be designed to support hydraulic, soil and outside loads. ASTM F1216 suggests that the following equation should be used to calculate the minimum thickness of CIPP liner for repairing the fully deteriorated gravity pipes [14]. E 12D=t

3

P 0:00064 SI units

where E is the initial modulus of elasticity (MPa), D is the mean inside diameter of original pipe (mm) and t is the thickness of CIPP liner (mm). Since the RTM liner is basically the combination of the unidirectional mat and continuous strand mat, its total thickness is the summation of the thickness of used mats. However, since the thicknesses of ber mats before resin wetting are dierent from those after curing followed by resin wetting, their eective thicknesses (the thickness that each ber mat occupies within the cured composite made of those mats) after curing should be known to design the liner using Eq. (6). The elastic modulus of the arbitrarily stacked composite made of unidirectional mats and continuous strand mats can be calculated through the rule of mixture (ROM) if their eective thicknesses are known, because the ber volume fractions of each layer can be determined from their eective thicknesses. To obtain the eective thickness of each ber mat, the following procedure was devised.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

281

The most well-known permeability modeling for Newtonian ow through various porous media is the KozenyCarman equation which considers the porous medium as a bundle of capillaries, which was known that this equation could predict the permeability in the ber direction pretty well [15]. Generally, the Kozeny Carman equation is Ki rf2 1 vf r 2 e3 f 2 4Ci vf 4Ci 1 e

3

4.5E-09

Permeability (m2)

3.5E-09

y = 8.9755E-09x - 5.3147E-09

2.5E-09

7

(a)

1.5E-09

x=

5.0E-10 0.6 2.5E-09 0.7 0.8 0.9 1.0 1.1

e3 1+ e

1.2

where Ki is the permeability in the i-direction i x; y; z, rf is the ber radius, Ci is the Kozeny constant to be determined experimentally, vf is the ber volume fraction, and e is the void ratio which is expressed by the following equation. e 1 1 vf 8

Permeability (m2)

y = 1.4203E-11x + 4.9486E-10 1.5E-09

Since the permeability is proportional to the function of void ratio, it was possible to derive the empirical relation between the permeability and void ratio using the permeabilities and the ber volume fractions of unidirectional mats and continuous strand mats listed in Table 2. From the plot of the permeabilities versus x e3 = 1 e shown in Fig. 17, two experimental equations for K (one is for unidirectional mat and the other is for continuous strand mat) were obtained as follows. KUD 8:9755 109 x 5:3147 109 KCST 1:4203 1011 x 4:9486 1010 9

x=

5.0E-10

e3 1+ e

100

(b)

20

40

60

80

Fig. 17. Plot of the permeabilities versus x e3 =1 e: (a) unidirectional mat (T800-E06); (b) continuous strand mat (M8600).

Since the ply weight of each glass ber mat and the density of E-glass ber are known, the ber volume fractions of the unidirectional mat and continuous strand mat with an arbitrary thickness can be calculated. Then the permeabilities of each ber mat at the specied thickness can be determined from Eq. (9). In order to determine the eective thickness of two ber mats, the measured permeability of the stacked mat listed in Table 2 and the concept of equivalent permeability were used. When the permeability for ow in the horizontal direction changes from layer to layer as shown in Fig. 18, which is similar to the ow in the stacked mat, the equivalent permeability of n layers can be formulated as follows [16]. Keq

n 1X K i hi h i1

10

equivalent permeability of the layered preform can be determined from Eq. (10). After transforming the variable x in Eq. (9) into the function of thickness of each mat because the void ratio can be expressed by means of the eective thickness, it can be combined with the Eq. (10). Since the permeability Keq and the total thickness h of stacked mat are known, the eective thickness of unidirectional mat and continuous strand mat can be determined by solving Eqs. (9) and (10) simultaneously. From the calculation, it was found that 1 ply of the unidirectional mat (T800-E06) and the continuous strand mat (M8600) have the eective thickness of 0.868 and 1.132 mm, respectively. In order to determine the thickness of RTM liner using the Eq. (6), its modulus should be known. Since the cured RTM liner is the mixture of unidirectional mats, continuous strand mats and polyester resin, its equivalent modulus can be formulated by employing the rule of mixture (ROM) as following. E vf;UD Ef;UD vf;CST Ef;CST vm Em 11

where, Keq and h are the equivalent permeability and total thickness of n layers and Ki and hi are the permeability and thickness of the individual layers, respectively. It was known that Eq. (10) agrees pretty well to the experimental result irrespective of staking sequence when the total thickness of preform is relatively thin and the through-thickness ow is negligible [6]. If the permeabilities of the individual layer are known, the

where, vf;UD and Ef;UD are the ber volume fraction and modulus of unidirectional mats, respectively, vf;CST and Ef;CST are those of continuous strand mats, respectively, and vm and Em are those of matrix (polyester resin), respectively.

282

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283

Fig. 18. Horizontal resin ow through the porous media composed of n layers with dierent permeabilities.

From the material properties given in Tables 1 and 3, Ef;UD ( 67 GPa) and Ef;CST ( 30 GPa) were obtained through ROM. Since the eective thickness of each mat is known, the equivalent modulus of RTM liner composed of those mats can be determined if the number of each mat is specied. Using Eqs. (6) and (10) and the previous result, other stacking sequences for RTM liner were suggested. When one ply of the unidirectional mat and two plies of the continuous strand mats were selected, vf;UD and vf;CST are 0.107 and 0.116, respectively. This gives the equivalent modulus of 14 GPa and 3 E=12D=t of 0.001341, which is two times larger than the limit value of 0.00064. Another solution is to use three plies of the continuous strand mats. This gives the 3 equivalent modulus of 8.2 GPa and E=12D=t of 0.000997, which is also larger than the limit value. Since the price of unidirectional mat ($2.4/m2 ) is about 1.5 times more expensive than that of continuous strand mat, it is evident that the newly suggested stacking sequences are more cost eective than the original one. Because large amount of ber mats are required to repair huge and long underground conduits, the eect of cost saving will be large. Since the design criteria of RTM liner suggested in this study uses just two materials, such as unidirectional mats and continuous strand mats, it will be possible to extend the range of design parameter (wide variance of materials) by performing the previous design procedure with more diverse materials, which will lead to the further enhanced cost saving.

E-glass ber reinforced composites were used for reinforcing damaged underground pipes and the RTM technology was modied for fabricating large underground composite structures. Also the reinforcing element for repairing the interior of damaged underground pipes has been developed through various material tests and experiments. For the reliable rehabilitation process, the glass ber preform was covered with tarpaulin lms that worked as a exible mold and protection skins and a porous breathing tube was used to remove the volatile and micro void within the reinforcing element. After actual repairing experiments have been performed at the real concrete pipes, the eciency of the developed process was evaluated and compared with those of the conventional trenchless technology. From the comparison of processing cost and processing time, it was found that the developed process was very eective in view of cost and time. Finally, the design criteria of the reinforcing element which assure the sucient reinforcing eect with minimum material cost have been suggested.

Acknowledgements This work was supported nancially by the Korean Government under NRL (National Research Laboratory) projects and, in part, by BK 21 Project. The authors would like to thank to their nancial support.

References 7. Conclusions In this study, a new trenchless rehabilitation process of underground pipes, which not only overcomes the problems of former trenchless technologies, but also is adequate to the situation of high trac road, has been tried with E-glass ber fabric and unsaturated polyester resin by vacuum assisted resin transfer molding (RTM).

[1] Lee DG, Chin WS, Kwon JW, Yoo AK. Repair of underground buried pipes with glass ber composites using RTM. Comp Struct 2002;57(14):6777. [2] Mallick PK. Fiber-reinforced composites. Marcel Dekker; 1988. p. 34. [3] Kang MK, Lee WI. Analysis of resin transfer/compression molding process. Polym Comp 1999;20(2):293304. [4] Toutanji H, Dempsey S. Stress modeling of pipelines strengthened with advanced composites materials. Thin-Walled Struct 2001;39: 15365.

W.S. Chin, D.G. Lee / Composite Structures 68 (2005) 267283 [5] Skordos AA, Kahnanas PI, Partridge IK. A dielectric sensor for measuring ow in resin transfer molding. Measure Sci Technol 2000;11:2531. [6] Diallo ML, Gauvin R, Trochu F. Experimental analysis and simulation of ow through multi-layer ber reinforcements in liquid composite molding. Polym Comp 1998;19(3):24656. [7] Chin WS, Kwon JW, Lee DG. Trenchless repairing of underground pipes using RTM based on the axiomatic design method. J Comp Mater 2003;37(12):110926. [8] Advani SG. Flow and rheology in polymer composites manufacturing. Elsevier; 1994. p. 4668. [9] Adams KL, Russel WB, Rebenfeld L. Radial penetration of a viscous liquid into a planar anisotropic porous medium. Int J Multiphase Flow 1988;14:20315. [10] Standard test method for tensile properties of polymer matrix composite materials. American Society for Testing and Materials D3039/D3039M-95a. 1995.

283

[11] Chin WS, Kwon JW, Lee DG. Trenchless repairing of underground pipes using RTM and dielectrometry. 3rd International Conference on Composites in Infra-Structures, San Francisco, USA, June 2002. [12] Kwon JW, Chin WS, Lee DG. In-situ cure monitoring of adhesively bonded joints by dielectrometry. J Adhes Sci Technol 2003;17(16):211130. [13] Downey DB. Trenchless methods for sewer renovation. In: International Seminar for the Expansion of Sewer Rehabilitation and Trenchless Technologies, vol. 1. 1999. p. 110. [14] Standard practice for rehabilitation of existing pipelines and conduits by the inversion and curing of a resin-impregnated tube. American Society for Testing and Materials F1216-93. 1993. [15] Gutowski TG. Advanced composites manufacturing. John Wiley & Sons; 1997. p. 4168. [16] Das BM. Principles of geotechnical engineering. PWS Publishing Company; 1993. p. 14850.

Вам также может понравиться

- 7.1 Assignment-1-Position-Object After Lesson 7Документ26 страниц7.1 Assignment-1-Position-Object After Lesson 7DiwakerОценок пока нет

- National Education Policy 2020 IndiaДокумент66 страницNational Education Policy 2020 IndiaDisability Rights Alliance100% (1)

- Long Term Unemployment StatisticsДокумент38 страницLong Term Unemployment Statisticsvemuriraja0% (1)

- List of SCOPUS and UGCCARE JournalsДокумент4 страницыList of SCOPUS and UGCCARE JournalsHasdi PutraОценок пока нет

- The Effects of Chemical Treatment On The Structural - VEДокумент14 страницThe Effects of Chemical Treatment On The Structural - VEmithileshmaverickОценок пока нет

- Environmental Resistance and Mechanical Performance of Basalt and Glass FibersДокумент8 страницEnvironmental Resistance and Mechanical Performance of Basalt and Glass FibersmithileshmaverickОценок пока нет

- International Journal of Mechanical Sciences: Guangyong Sun, Shaowei Tong, Dongdong Chen, Zhihui Gong, Qing LiДокумент16 страницInternational Journal of Mechanical Sciences: Guangyong Sun, Shaowei Tong, Dongdong Chen, Zhihui Gong, Qing LimithileshmaverickОценок пока нет

- The Effect of Silane Treatment On The Mechanical 1991Документ14 страницThe Effect of Silane Treatment On The Mechanical 1991mithileshmaverickОценок пока нет

- Tensile Behavior Contrast of Basalt and Glass Fibers After Chemical TreatmentДокумент7 страницTensile Behavior Contrast of Basalt and Glass Fibers After Chemical TreatmentmithileshmaverickОценок пока нет

- Mechanical Properties of 3D Woven Basalt Fiber Composite Materials: Experiment and FEM SimulationДокумент7 страницMechanical Properties of 3D Woven Basalt Fiber Composite Materials: Experiment and FEM SimulationmithileshmaverickОценок пока нет

- Static and Dynamic Analysis of Basalt FiberДокумент9 страницStatic and Dynamic Analysis of Basalt FibermithileshmaverickОценок пока нет

- An Analysis of The Three-Dimensional Resin-Transfer Mold Filling ProcessДокумент15 страницAn Analysis of The Three-Dimensional Resin-Transfer Mold Filling ProcessmithileshmaverickОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Effect of Fouling On Heat Exchanger - ScribdДокумент40 страницEffect of Fouling On Heat Exchanger - Scribdratninp9368Оценок пока нет

- TS 15280Документ1 страницаTS 15280GiveawayОценок пока нет

- Chem - Report 1Документ7 страницChem - Report 1Udaya ZorroОценок пока нет

- Class X Science Pre Board Sample PaperДокумент23 страницыClass X Science Pre Board Sample PaperNasla ShiyasОценок пока нет

- Fuel Gas Conditioning-EmailДокумент2 страницыFuel Gas Conditioning-Emailkelburn50% (2)

- Classes of CompoundsДокумент12 страницClasses of CompoundsReynaldo VirtucioОценок пока нет

- Analysis of SalivaДокумент14 страницAnalysis of Salivajgbalanay8492antОценок пока нет

- Enzymes - Life Sciences Questions and Answers - SanfoundryДокумент8 страницEnzymes - Life Sciences Questions and Answers - SanfoundryHUAWEI HUAWEIОценок пока нет

- GEO424 Lect08 Soil Water Snow PDFДокумент38 страницGEO424 Lect08 Soil Water Snow PDFAires Rafael Rutherford AiresОценок пока нет

- Experiment 1: Determination of Corrosion Rate of Metals: ObjectiveДокумент3 страницыExperiment 1: Determination of Corrosion Rate of Metals: Objective041Mir QazimОценок пока нет

- Difference Between Surface Plasmon Resonance and SPPДокумент3 страницыDifference Between Surface Plasmon Resonance and SPPAparna ViswanathОценок пока нет

- Job-Mix Formula (Sample)Документ18 страницJob-Mix Formula (Sample)Mohammad Ali Salem Mauna25% (4)

- High Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsДокумент6 страницHigh Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsDanZel DanОценок пока нет

- PETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsДокумент18 страницPETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsMiguel Angel GonzalesОценок пока нет

- Brenntag Tofa Data Sheet: BFA 101 - Tall Oil Fatty AcidДокумент1 страницаBrenntag Tofa Data Sheet: BFA 101 - Tall Oil Fatty AcidniteshacharyaОценок пока нет

- Effect of Supplementary Cementitious Materials On Carbonation of Cement PastesДокумент31 страницаEffect of Supplementary Cementitious Materials On Carbonation of Cement PastesNora al-anssariОценок пока нет

- QCR W 2001Документ4 страницыQCR W 2001Madhan KannanОценок пока нет

- Poster Making and Gallery WalkДокумент3 страницыPoster Making and Gallery WalkOdyssey Nicolle Esquejo LuisОценок пока нет

- KROMA Automatic Clinical Chemistry Analyzer 150 T - H - LINEAR CHEMICALS - PDF Catalogs - Technical DocumentationДокумент1 страницаKROMA Automatic Clinical Chemistry Analyzer 150 T - H - LINEAR CHEMICALS - PDF Catalogs - Technical Documentationhenok derejeОценок пока нет

- Comparison Chart: (828 Ratings) (877 Ratings)Документ11 страницComparison Chart: (828 Ratings) (877 Ratings)RoseОценок пока нет

- Evaluation of Predicted Equations For Swelling PotentialДокумент6 страницEvaluation of Predicted Equations For Swelling PotentialGonzalo100% (1)

- Redubar A Register of All Gas RegulationsДокумент64 страницыRedubar A Register of All Gas RegulationsMilos BajicОценок пока нет

- Understanding Oscillatory Behaviour of Gibbsite Precipitation CircuitsДокумент12 страницUnderstanding Oscillatory Behaviour of Gibbsite Precipitation CircuitsPRACHIPRAVA PRADHANОценок пока нет

- Guide To BondingДокумент46 страницGuide To Bondingbotan_mihaiОценок пока нет

- ESD Tape ApplicationsДокумент6 страницESD Tape Applicationslordycarlos8588Оценок пока нет

- Biochemistry Notes - Nucleotide MetabolismДокумент5 страницBiochemistry Notes - Nucleotide MetabolismneedthisforepiОценок пока нет

- Structure of LeavesДокумент7 страницStructure of Leaves门门Оценок пока нет

- McCabe-Thiele Method 1Документ37 страницMcCabe-Thiele Method 1HariKrishnaBushi100% (2)

- PTFE Cap1Документ6 страницPTFE Cap1RajanSharmaОценок пока нет