Академический Документы

Профессиональный Документы

Культура Документы

08G Horn Systems

Загружено:

Dane WallaceИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

08G Horn Systems

Загружено:

Dane WallaceАвторское право:

Доступные форматы

ZG

HORN SYSTEMS

8G - 1

HORN SYSTEMS

CONTENTS

page GENERAL INFORMATION INTRODUCTION . . . . . . . . . . . DESCRIPTION AND OPERATION BODY CONTROL MODULE . . . HORN RELAY . . . . . . . . . . . . . HORN SWITCH . . . . . . . . . . . . HORN . . . . . . . . . . . . . . . . . . . DIAGNOSIS AND TESTING HORN RELAY . . . . . . . . . . . . . HORN SWITCH . . . . . . . . . . . HORN . . . . . . . . . . . . . . . . . . REMOVAL AND INSTALLATION HORN RELAY . . . . . . . . . . . . HORN SWITCH . . . . . . . . . . . HORN . . . . . . . . . . . . . . . . . . page .............. 3 .............. 3 .............. 3 .............. 4 .............. 4

............. 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1 1 1

............. 2 The horn relay is located in the Power Distribution Center (PDC), in the engine compartment. Refer to the PDC label for relay identification and location. If a problem is encountered with a continuously sounding horn, it can usually be quickly resolved by removing the horn relay from the PDC until further diagnosis is completed. The horn relay cannot be repaired and, if faulty or damaged, it must be replaced.

GENERAL INFORMATION INTRODUCTION

Following are general descriptions of the major components in the factory-installed horn systems. Refer to 8W-41 - Horns/Cigar Lighter in Group 8W Wiring Diagrams for complete circuit descriptions and diagrams. NOTE: This group covers both Left-Hand Drive (LHD) and Right-Hand Drive (RHD) versions of this model. Whenever required and feasible, the RHD versions of affected vehicle components have been constructed as mirror-image of the LHD versions. While most of the illustrations used in this group represent only the LHD version, the diagnostic and service procedures outlined can generally be applied to either version. Exceptions to this rule have been clearly identified as LHD or RHD, if a special illustration or procedure is required.

HORN SWITCH

A center-blow, resistive membrane type horn switch is installed on the back side of the driver side airbag module trim cover in the center of the steering wheel. When the center area of the airbag trim cover is depressed, the horn switch completes a circuit to ground for the coil side of the horn relay. The steering wheel and steering column must be properly grounded for the horn switch to function. The horn switch is only serviced as a part of the airbag module trim cover. If the horn switch should fail, or if the airbag is deployed, the airbag module trim cover and horn switch unit must be replaced.

DESCRIPTION AND OPERATION HORN RELAY

The horn relay is a International Standards Organization (ISO) micro-relay. The terminal designations and functions are the same as a conventional ISO relay. However, the micro-relay terminal orientation (or footprint) is different, current capacity is lower, and the relay case dimensions are smaller than those of the conventional ISO relay. The horn relay is a electromechanical device that switches battery current to the horn when the horn switch grounds the relay coil. See the Diagnosis and Testing section of this group for more information on the operation of the horn relay.

HORN

The standard, dual-note, electromagnetic diaphragm-type horns are secured next to each other on a bracket beneath the right radiator closure extension panel and forward of the right front inner wheelhouse. The two horns are connected in parallel and are grounded through their wire harness connector and circuit to an eyelet bolted to the right inner fender shield near the Power Distribution Center (PDC), and receive battery feed through the closed contacts of the horn relay. The horns cannot be repaired or adjusted and, if faulty or damaged, they must be replaced.

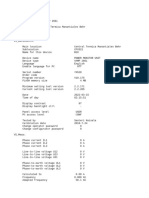

NUMBER

TERMINAL FEED COMMON LEGEND IDENTIFICATION COIL GROUND COIL BATTERY NORMALLY OPEN NORMALLY CLOSED

8G - 2

HORN SYSTEMS

ZG

DESCRIPTION AND OPERATION (Continued)

BODY CONTROL MODULE

A Body Control Module (BCM) is used on this model to control and integrate many of the electronic functions and features included on the vehicle. The BCM contains a central processing unit and interfaces with other modules in the vehicle on the Chrysler Collision Detection (CCD) data bus network. The CCD data bus network allows the sharing of sensor information. This helps to reduce wire harness complexity, reduce internal controller hardware, and reduce component sensor current loads. At the same time, this system provides increased reliability, enhanced diagnostics, and allows the addition of many new feature capabilities. The horn system is one of the outputs of the BCM. The BCM is programmed to energize or de-energize the horn relay in response to certain inputs from the Vehicle Theft Security System (VTSS) and the Remote Keyless Entry (RKE) system. Refer to Group 8P - Power Lock Systems for more information on the RKE system. Refer to Group 8Q - Vehicle Theft/Security Systems for more information on the VTSS. The BCM is mounted under the driver side outboard end of the instrument panel, behind the instrument panel support armature and below the outboard switch pod. Refer to Group 8E - Instrument Panel Systems for the removal and installation procedures. For diagnosis of the BCM or the CCD data bus, refer to the proper Body Diagnostic Procedures manual. The BCM can only be serviced by an authorized electronic repair station. Refer to the latest Warranty Policies and Procedures manual for a current listing of authorized electronic repair stations.

the PDC label for horn relay identification and location. Remove the horn relay from the PDC as described in this group to perform the following tests: (1) A relay in the de-energized position should have continuity between terminals 87A and 30, and no continuity between terminals 87 and 30. If OK, go to Step 2. If not OK, replace the faulty relay. (2) Resistance between terminals 85 and 86 (electromagnet) should be 75 5 ohms. If OK, go to Step 3. If not OK, replace the faulty relay. (3) Connect a battery to terminals 85 and 86. There should now be continuity between terminals 30 and 87, and no continuity between terminals 87A and 30. If OK, see the Relay Circuit Test in this group. If not OK, replace the faulty relay.

Horn Relay

RELAY CIRCUIT TEST (1) The relay common feed terminal cavity (30) is connected to battery voltage and should be hot at all times. If OK, go to Step 2. If not OK, repair the open circuit to the PDC fuse as required. (2) The relay normally closed terminal (87A) is connected to terminal 30 in the de-energized position, but is not used for this application. Go to Step 3. (3) The relay normally open terminal (87) is connected to the common feed terminal (30) in the energized position. This terminal supplies battery voltage to the horn(s). There should be continuity between the cavity for relay terminal 87 and the horn relay output circuit cavity of each horn wire harness connector at all times. If OK, go to Step 4. If not OK, repair the open circuit to the horn(s) as required. (4) The coil battery terminal (86) is connected to the electromagnet in the relay. It is connected to battery voltage and should be hot at all times. Check for battery voltage at the cavity for relay terminal 86. If OK, go to Step 5. If not OK, repair the open circuit to the PDC fuse as required.

DIAGNOSIS AND TESTING HORN RELAY

For circuit descriptions and diagrams, refer to 8W-41 - Horns/Cigar Lighter in Group 8W - Wiring Diagrams. WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY STEERING WHEEL, STEERING COLUMN, OR INSTRUMENT PANEL COMPONENT DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

RELAY TEST The horn relay is located in the Power Distribution Center (PDC) in the engine compartment. Refer to

POWER DISTRIBUTION CENTER NEGATIVE CABLE

ZG

DIAGNOSIS AND TESTING (Continued)

(5) The coil ground terminal (85) is connected to the electromagnet in the relay. It is grounded through the horn switch when the horn switch is depressed. It can also be grounded by the Body Control Module (BCM) in response to inputs from the Vehicle Theft Security System (VTSS) or the Remote Keyless Entry (RKE) system. Check for continuity to ground at the cavity for relay terminal 85. There should be continuity with the horn switch depressed, and no continuity with the horn switch released. If not OK, see the diagnosis for the Horn Switch in this group.

HORN SYSTEMS

8G - 3

(5) Depress the center of the airbag module cover and check for continuity between the horn switch feed wire and the horn switch ground wire on the airbag module. There should now be continuity. If not OK, replace the faulty horn switch.

HORN

For circuit descriptions and diagrams, refer to 8W-41 - Horns/Cigar Lighter in Group 8W - Wiring Diagrams. (1) Unplug the horn wire harness connector. Measure the resistance between the ground circuit cavity of the horn wire harness connector and a good ground. There should be no measurable resistance. If OK, go to Step 2. If not OK, repair the circuit to ground as required. (2) With the horn wire harness connector still unplugged, depress the horn switch. There should be battery voltage at the horn relay output circuit cavity of the horn wire harness connector. If OK, replace the faulty horn. If not OK, repair the open circuit to the horn relay as required.

HORN SWITCH

For circuit descriptions and diagrams, refer to 8W-41 - Horns/Cigar Lighter in Group 8W - Wiring Diagrams. WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY STEERING WHEEL, STEERING COLUMN, OR INSTRUMENT PANEL COMPONENT DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect and isolate the battery negative cable. Remove the lower steering column cover/knee blocker. Check for continuity between the metal steering column jacket and a good ground. There should be continuity. If OK, go to Step 2. If not OK, refer to Group 19 - Steering and check for proper installation of the steering column ground clip. (2) Remove the driver side airbag module as described in Group 8M - Passive Restraint Systems. Unplug the horn switch wire harness connectors from the airbag module. Unplug the Body Control Module (BCM) wire harness connector B (white). Unplug the horn relay from the Power Distribution Center (PDC). Check for continuity between the steering column half of the horn switch feed wire harness connector and a good ground. There should be no continuity. If OK, go to Step 3. If not OK, repair the short circuit as required. (3) Check for continuity between the steering column half of the horn switch feed wire harness connector and the horn relay control circuit cavity for the horn relay in the PDC. There should be continuity. If OK, go to Step 4. If not OK, repair the open circuit as required. (4) Check for continuity between the horn switch feed wire and the horn switch ground wire on the airbag module. There should be no continuity. If OK, go to Step 5. If not OK, replace the faulty horn switch.

REMOVAL AND INSTALLATION HORN RELAY

(1) Disconnect and isolate the battery negative cable. (2) Remove the cover from the Power Distribution Center (PDC) (Fig. 1).

Fig. 1 Power Distribution Center

(3) Refer to the label on the PDC for horn relay identification and location. (4) Unplug the horn relay from the PDC. (5) Install the horn relay by aligning the relay terminals with the cavities in the PDC and pushing the relay firmly into place. (6) Install the PDC cover. (7) Connect the battery negative cable.

8G - 4

HORN SYSTEMS

ZG

REMOVAL AND INSTALLATION (Continued)

(8) Test the relay operation.

HORN SWITCH

WARNING: ON VEHICLES EQUIPPED WITH A DRIVER SIDE AIRBAG, THE HORN SWITCH IS INTEGRAL TO THE AIRBAG MODULE TRIM COVER. SERVICE OF THIS COMPONENT SHOULD BE PERFORMED ONLY BY CHRYSLER-TRAINED AND AUTHORIZED DEALER SERVICE TECHNICIANS. FAILURE TO TAKE THE PROPER PRECAUTIONS OR TO FOLLOW THE PROPER PROCEDURES COULD RESULT IN ACCIDENTAL, INCOMPLETE, OR IMPROPER AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL INJURY. REFER TO GROUP 8M - PASSIVE RESTRAINT SYSTEMS FOR THE SERVICE PROCEDURES.

Fig. 2 Horn Remove/Install

(5) Remove the screw that secures the horn mounting bracket to the radiator closure extension panel. (6) Remove the horns and mounting bracket from the vehicle. (7) Reverse the removal procedures to install. Tighten the horn mounting bracket screw to 30 Nm (22 ft. lbs.).

HORN

(1) Disconnect and isolate the battery negative cable. (2) Raise and support the vehicle. (3) Remove the radiator lower air deflector. Refer to Group 7 - Cooling System for the procedures. (4) Unplug the horn wire harness connectors (Fig. 2).

Вам также может понравиться

- Op Amps: Design, Application, and TroubleshootingОт EverandOp Amps: Design, Application, and TroubleshootingРейтинг: 5 из 5 звезд5/5 (2)

- Horn SystemsДокумент4 страницыHorn SystemsArt DoeОценок пока нет

- 08G - Horn SystemsДокумент6 страниц08G - Horn SystemsEinar OftebroОценок пока нет

- 93ZJ Secc 8L LampsДокумент18 страниц93ZJ Secc 8L Lampshelgith74Оценок пока нет

- Chime Buzzer Warning SystemsДокумент4 страницыChime Buzzer Warning SystemsArt DoeОценок пока нет

- Horns: Description and OperationДокумент6 страницHorns: Description and OperationLilisbethBasantaОценок пока нет

- PL Horns 8G - 1Документ4 страницыPL Horns 8G - 1Pelis CloneОценок пока нет

- Electrically Heated Systems: Defogger SystemДокумент10 страницElectrically Heated Systems: Defogger SystemensmartisОценок пока нет

- La-Ser Talon: PartialДокумент29 страницLa-Ser Talon: Partialredleader3675% (4)

- Lamps: Lamp DiagnosisДокумент18 страницLamps: Lamp DiagnosisMRPITYINGER1Оценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- Lamps: Lamp DiagnosisДокумент14 страницLamps: Lamp DiagnosisPelis CloneОценок пока нет

- Epl 8WДокумент256 страницEpl 8Wapi-3777439Оценок пока нет

- Horn SystemДокумент15 страницHorn Systemandres rangelОценок пока нет

- Push Button Typical WiringДокумент12 страницPush Button Typical Wiringstrob1974Оценок пока нет

- EXPLORER II 75-85-95 Special 1 Section 40Документ25 страницEXPLORER II 75-85-95 Special 1 Section 40dimos KARAMATZIARISОценок пока нет

- ZJ Horn Systems 8G - 1Документ4 страницыZJ Horn Systems 8G - 1Dalton WiseОценок пока нет

- Description: WarningДокумент7 страницDescription: WarningmaxОценок пока нет

- Windshield Wipers and WashersДокумент10 страницWindshield Wipers and WashersPelis CloneОценок пока нет

- Automotive Horn System CompleteДокумент6 страницAutomotive Horn System CompleteTaha Kassala100% (1)

- Level Switches: General InstructionsДокумент16 страницLevel Switches: General InstructionsazitaggОценок пока нет

- PL Turn Signal and Flashers 8J - 1Документ4 страницыPL Turn Signal and Flashers 8J - 1Pelis CloneОценок пока нет

- Clutch: Fig. 1 Clutch Pedal ComponentsДокумент10 страницClutch: Fig. 1 Clutch Pedal ComponentsPelis CloneОценок пока нет

- XR-A4800 PioneerДокумент73 страницыXR-A4800 Pioneerchermy025Оценок пока нет

- Horn and Wiper System m5Документ9 страницHorn and Wiper System m5linita7577jasmne.comОценок пока нет

- Horn and Wiper SystemДокумент9 страницHorn and Wiper Systemlinita7577jasmne.comОценок пока нет

- 73 Johnson 35HP-SMДокумент111 страниц73 Johnson 35HP-SMJim PiperОценок пока нет

- Manual - Jarrell Ash 82-410Документ26 страницManual - Jarrell Ash 82-410acgrecoОценок пока нет

- Epl 8LДокумент16 страницEpl 8Lapi-3777439Оценок пока нет

- Eja 8LДокумент18 страницEja 8LLuis Oswaldo Roa PerezОценок пока нет

- Jeep TJ 1998 FSM Audio SystemsДокумент10 страницJeep TJ 1998 FSM Audio SystemsArt DoeОценок пока нет

- 73 53HP SMДокумент95 страниц73 53HP SMpellboyzpowersportsОценок пока нет

- 93FWD 8LДокумент40 страниц93FWD 8LChristian MartinezОценок пока нет

- Service Manual: CDP-X5000Документ34 страницыService Manual: CDP-X5000张井荣Оценок пока нет

- Lamps: Lamp DiagnosisДокумент16 страницLamps: Lamp DiagnosisArt DoeОценок пока нет

- 93ZJ Secc 8D Ignition SystemsДокумент40 страниц93ZJ Secc 8D Ignition Systemshelgith74Оценок пока нет

- PL Clutch 6 - 1Документ12 страницPL Clutch 6 - 1Pelis CloneОценок пока нет

- REA105 OperencДокумент24 страницыREA105 Operencluijos1Оценок пока нет

- Transfer: Workshop ManualДокумент92 страницыTransfer: Workshop ManualmailforspamОценок пока нет

- Sony TV Service ManualДокумент64 страницыSony TV Service ManualRené Eric Urbano EhijoОценок пока нет

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsДокумент6 страницChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomОценок пока нет

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsДокумент6 страницChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomОценок пока нет

- 73 30HP2 SMДокумент97 страниц73 30HP2 SMpellboyzpowersportsОценок пока нет

- Eja 8FДокумент16 страницEja 8FLuis Oswaldo Roa PerezОценок пока нет

- XR200 18vOperatorsManual OCT2015Документ15 страницXR200 18vOperatorsManual OCT2015Farhan MuttaqinОценок пока нет

- Silente Guitar SIG 100SДокумент22 страницыSilente Guitar SIG 100SVICTOR MARTINОценок пока нет

- (H) HornДокумент4 страницы(H) HornJosé Miguel GonzálezОценок пока нет

- DVD Video Player: Service ManualДокумент30 страницDVD Video Player: Service ManualMoyses MoyОценок пока нет

- Keb Combivert f4 Power Stage Instruction ManualДокумент52 страницыKeb Combivert f4 Power Stage Instruction ManualsrikrishОценок пока нет

- 98DN - 8B Starting SystemsДокумент8 страниц98DN - 8B Starting SystemsylescorОценок пока нет

- Olympus MX61 & MX61LMicroscope SETUP ManualДокумент48 страницOlympus MX61 & MX61LMicroscope SETUP ManualALEXANDRE SANTOSОценок пока нет

- Rotary Paddle SwitchДокумент10 страницRotary Paddle SwitchPriyanshu GuptaОценок пока нет

- ZG Turn Signal and Hazard Warning Systems 8J - 1Документ6 страницZG Turn Signal and Hazard Warning Systems 8J - 1ensmartisОценок пока нет

- Fundamentals of Automation and Remote Control: International Series of Monographs in Automation and Automatic ControlОт EverandFundamentals of Automation and Remote Control: International Series of Monographs in Automation and Automatic ControlРейтинг: 5 из 5 звезд5/5 (1)

- Radio Frequency Transistors: Principles and practical applicationsОт EverandRadio Frequency Transistors: Principles and practical applicationsРейтинг: 4 из 5 звезд4/5 (3)

- Emission Control Systems: On-Board DiagnosticsДокумент28 страницEmission Control Systems: On-Board Diagnosticsensmartis100% (1)

- Dok 1Документ13 страницDok 1ensmartisОценок пока нет

- General Information: Vehicle Identification Number Decoding ChartДокумент10 страницGeneral Information: Vehicle Identification Number Decoding ChartensmartisОценок пока нет

- Ezg 22Документ10 страницEzg 22ensmartisОценок пока нет

- Ezg 19Документ32 страницыEzg 19ensmartisОценок пока нет

- General Service InformationДокумент48 страницGeneral Service InformationensmartisОценок пока нет

- Fuel System: General InformationДокумент108 страницFuel System: General InformationensmartisОценок пока нет

- ZG Power Window Systems 8S - 1Документ8 страницZG Power Window Systems 8S - 1ensmartisОценок пока нет

- ZG Turn Signal and Hazard Warning Systems 8J - 1Документ6 страницZG Turn Signal and Hazard Warning Systems 8J - 1ensmartisОценок пока нет

- Ezg 13Документ12 страницEzg 13ensmartisОценок пока нет

- 08V Overhead Console SystemsДокумент8 страниц08V Overhead Console SystemsDane WallaceОценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- Ezg 8WLДокумент990 страницEzg 8WLensmartisОценок пока нет

- ZG Exhaust System and Intake Manifold 11 - 1Документ14 страницZG Exhaust System and Intake Manifold 11 - 1ensmartisОценок пока нет

- Ezg 8TДокумент8 страницEzg 8TensmartisОценок пока нет

- ZG Vehicle Theft/Security Systems 8Q - 1Документ22 страницыZG Vehicle Theft/Security Systems 8Q - 1ensmartisОценок пока нет

- 08R Power Seat SystemsДокумент8 страниц08R Power Seat SystemsDane WallaceОценок пока нет

- 08M Passive Restraint SystemsДокумент12 страниц08M Passive Restraint SystemsDane WallaceОценок пока нет

- ZG Audio Systems 8F - 1Документ18 страницZG Audio Systems 8F - 1ensmartisОценок пока нет

- 08K Wiper & Washer SystemsДокумент14 страниц08K Wiper & Washer SystemsDane WallaceОценок пока нет

- Electrically Heated Systems: Defogger SystemДокумент10 страницElectrically Heated Systems: Defogger SystemensmartisОценок пока нет

- 08H Vehicle Speed Control SystemДокумент12 страниц08H Vehicle Speed Control SystemDane WallaceОценок пока нет

- ZG Starting Systems 8B - 1Документ14 страницZG Starting Systems 8B - 1ensmartisОценок пока нет

- ZG Cooling System 7 - 1Документ72 страницыZG Cooling System 7 - 1ensmartisОценок пока нет

- 08E Instrument Panel SystemsДокумент70 страниц08E Instrument Panel SystemsDane WallaceОценок пока нет

- 08D Ignition SystemДокумент24 страницы08D Ignition SystemDane WallaceОценок пока нет

- ZG Charging System 8C - 1Документ10 страницZG Charging System 8C - 1ensmartisОценок пока нет

- ZG Battery 8A - 1Документ18 страницZG Battery 8A - 1ensmartisОценок пока нет

- What Is A Maglev Train?Документ3 страницыWhat Is A Maglev Train?Jhenson SiiОценок пока нет

- Generator HRG CalculationsДокумент3 страницыGenerator HRG CalculationsnoneofyabiznasОценок пока нет

- tdr100 - DeviceДокумент4 страницыtdr100 - DeviceSrđan PavićОценок пока нет

- K3NV Omron Meter Calibration and Selection WhyДокумент25 страницK3NV Omron Meter Calibration and Selection WhyNishant Sinha80% (5)

- DCM Dispersion Compensation Modules Data SheetДокумент2 страницыDCM Dispersion Compensation Modules Data SheetPОценок пока нет

- An Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsДокумент11 страницAn Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsRiad TifaОценок пока нет

- Acting Commissioner of Customs v. Meralco, G.R. No. L-23623Документ4 страницыActing Commissioner of Customs v. Meralco, G.R. No. L-23623maryryomaОценок пока нет

- Service Manual: Minidisc ChangerДокумент38 страницService Manual: Minidisc ChangerAnonymous Lfgk6vygОценок пока нет

- C-Cores PDFДокумент32 страницыC-Cores PDFbpchimeraОценок пока нет

- Digsilent Powerfactory: Technical Reference DocumentationДокумент29 страницDigsilent Powerfactory: Technical Reference DocumentationHar HarОценок пока нет

- PDFДокумент8 страницPDFNorng VibolОценок пока нет

- 00960a PDFДокумент20 страниц00960a PDFrosaОценок пока нет

- Simple Comfort ThermostatДокумент20 страницSimple Comfort Thermostattalonscorer100% (1)

- David EsseiniДокумент10 страницDavid Esseiniশুভ MitraОценок пока нет

- A6. Design Features of Low Speed Permanent Magnet GeneratorДокумент4 страницыA6. Design Features of Low Speed Permanent Magnet Generatorwalidghoneim1970Оценок пока нет

- Physics Projjecc EpiccДокумент14 страницPhysics Projjecc EpiccRahul AvdhaniОценок пока нет

- Governor BasicsДокумент80 страницGovernor Basicsajaysitaula8478100% (8)

- DTC P0017 Codigo AvengerДокумент6 страницDTC P0017 Codigo Avengerflash_24014910Оценок пока нет

- GATE 2014 2015 Exam Syllabus For Electrical Engineering - EEE PDF DownloadДокумент2 страницыGATE 2014 2015 Exam Syllabus For Electrical Engineering - EEE PDF Downloadarun kumarОценок пока нет

- Using GigaProbes Agilent TDR D5Документ12 страницUsing GigaProbes Agilent TDR D5yadamyugandharОценок пока нет

- The Hourmeter Range - 3ppДокумент3 страницыThe Hourmeter Range - 3ppN.I.C.E spares & serviceОценок пока нет

- CSC-121 Breaker Protection IED Engineering and Operation Manual - V1.00Документ221 страницаCSC-121 Breaker Protection IED Engineering and Operation Manual - V1.00mentongОценок пока нет

- Mobile SubstationsДокумент12 страницMobile Substationsengineer_2009Оценок пока нет

- Areva&hvdc PDFДокумент167 страницAreva&hvdc PDFAbdallah Salem100% (1)

- Kota RailwayДокумент40 страницKota RailwayMulayam Singh Choudhary0% (1)

- RegtrpoДокумент46 страницRegtrpomarjorieqlОценок пока нет

- Interconnect PDFДокумент84 страницыInterconnect PDFjeanclaudelclarke_92Оценок пока нет

- 45586301TH - R1 - Es9465 - Es9475 MFPДокумент1 558 страниц45586301TH - R1 - Es9465 - Es9475 MFPsmrizalОценок пока нет

- XR C7200Документ37 страницXR C7200Selvin ReyesОценок пока нет

- Magnetic HysteresisДокумент10 страницMagnetic HysteresisHarsh PurwarОценок пока нет