Академический Документы

Профессиональный Документы

Культура Документы

AMPLA Features

Загружено:

praty888Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AMPLA Features

Загружено:

praty888Авторское право:

Доступные форматы

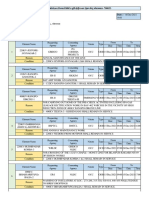

Sl.No.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Features

Process Control Entry Anode Change Schedule Tapping Schedule Master Schedule Anode Covering Beam raising activity capturing along with compliance Alf3 Schedule 24hr ACD Anode Skip Unplanned Anode Change Unplanned Alf3/Beam Raising Automation of Anode change & Beam Raising Tracking of wrong entries Work Schedule Compliance Work Schedule generation Shift Worklist Export of data & graphs Quality data & Analysis Six Sigma Tool & SPC analysis Dashboards Metrics Trend,Summary & Average Analysis Alumina Movement tracking Potwise Production Rodded Anode inventory, bath inventory, alumina inventory Bath Correction planning & compliance Weighbridge Application Enhanced relaibility Silo Level(FTP/Storage/Primary Silo) FTP/AHS Process parametres Alarms & Alerts through email Pending Activities Breaker/Feeder Change Downtime Notification Employee Productivity provision Automatic Production & Consumption booking PTM Realtime RCA/FTP/AHS Realtime RCA Automatic Notification through CBM Scrap Management WIP Tracking Metal Transfer Relining Activities & Consumption Startup material Consumption

PMIS

Not in use Not in use only data only data OLAP application Not in use

43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86

Startup Normalization Parameters Startup preheat data capture to enable proper handover Automatic generation of measurement Schedules Ladle Cleaning Service Bath Analysis report integration Advance Tapping provision & tracking Shift Communication Pot parameters through GAMI Anode effect frequency and duration logs and reports Energy Consumption Automatioc detection of mushrooming Automation of Critical Pots Analysis of potline process parametres Setvoltage corelations Excess Alf3 Corelation Metal/Bath Corelation Work Volt Vs Bath temp corelation Metal Level Vs Feeding quantity corelation Bath Temp Vs Work Volt corelation Purity Fe/Si Corelation Production Purity Vs CE Corelation Power Vs Work Volt Vs AEF corelation Prod Vs Excess Alf3 corelation Excess Alf3 addition corelation Fluoride addtion Vs Noise Vs alumina corelation Noise Vs Bath Temp Vs Excess Alf3 corelation Si Fluoride Vs Avg Volt Corelation Prod Age VsCE Vs Noise corelation Quality Trend Quality Regression Analysis Purity of Plant Performance of equipments Potline analytical reports Daily Parametres Online support for Marketting Dept Shift Exception report Flash Report Tracking of duplicate record through flag Actual Vs Planned tapping and devialtion tracking through flag Dynamic Screen customization Analytical tools Detection of anoidic problem Automatic/manual downtime capture for all potline equipments PTM Utilization report

In excel Not in use Not in use

87 88 89 90 91 92 93 94 95 96 97 98 99 100

Capturing Running hours of equipment Auto notification in SAP Maintenance Data Accuracy Single source for potline data Availability of lab data to potline officials automatically Historical Analysis of all potline data Asset Management Report Spares management through local store Capturing of pot and pot controller maintenance activities Dashboard on Pot status Provision for filtering data as per the user requirements Option to save as favourities available Role based authorisation User manual and documentation

AMPLA

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- LNG Man Es Methane Slip Technical PaperДокумент20 страницLNG Man Es Methane Slip Technical PaperLeo TvrdeОценок пока нет

- Linux Lab ManualДокумент373 страницыLinux Lab ManualsrinubasaniОценок пока нет

- Electrical Findings 6Документ13 страницElectrical Findings 6Lester Musca100% (1)

- t182 Og Ewm 700 FinalДокумент56 страницt182 Og Ewm 700 FinalIwona FiedorowiczОценок пока нет

- t182 Og Ewm 700 FinalДокумент56 страницt182 Og Ewm 700 FinalIwona FiedorowiczОценок пока нет

- CH09 Maneuver Support (FY22) 12 Oct21Документ114 страницCH09 Maneuver Support (FY22) 12 Oct21geraldwolford1100% (1)

- ERP FundamentalsДокумент23 страницыERP Fundamentalspraty888Оценок пока нет

- KeyFigure List For Supply Planning Using SAP IBPДокумент9 страницKeyFigure List For Supply Planning Using SAP IBPpraty8880% (1)

- Tank 44M3Документ15 страницTank 44M3Tech DesignОценок пока нет

- How To Load Data Into Planning Book From Flat FileДокумент10 страницHow To Load Data Into Planning Book From Flat FileSiva Prakash PandianОценок пока нет

- ABAP OOPS TutorialsДокумент212 страницABAP OOPS Tutorialsannhjk71% (7)

- Demand Driven Supply ChainДокумент41 страницаDemand Driven Supply Chainpraty888Оценок пока нет

- Step by Step On Changing ECC Source Systems Without Affecting Data Modeling Objects in SAP BWДокумент16 страницStep by Step On Changing ECC Source Systems Without Affecting Data Modeling Objects in SAP BWosvperezОценок пока нет

- GATP ConfigurationДокумент94 страницыGATP Configurationpraty88850% (2)

- GATP ConfigurationДокумент94 страницыGATP Configurationpraty88850% (2)

- Learning Hub CatalogueДокумент1 990 страницLearning Hub Cataloguepraty8880% (1)

- Ariba Procurement Content SolutionДокумент2 страницыAriba Procurement Content Solutionpraty888Оценок пока нет

- SAP Core InterfaceДокумент6 страницSAP Core Interfacepraty888Оценок пока нет

- SAP IBP Production Source Header - Sample DataДокумент12 страницSAP IBP Production Source Header - Sample Datapraty888100% (1)

- What Is Supply Chain CollaborationДокумент4 страницыWhat Is Supply Chain Collaborationpraty888Оценок пока нет

- Sample Prog Date ChangeДокумент4 страницыSample Prog Date Changepraty888Оценок пока нет

- How Chamberlain Improved Supplier CollaborationДокумент16 страницHow Chamberlain Improved Supplier Collaborationpraty888Оценок пока нет

- How To Write Cover LetterДокумент1 страницаHow To Write Cover Letterpraty888Оценок пока нет

- The Windows 7 Boot ProcessДокумент2 страницыThe Windows 7 Boot ProcessGerard DijkstraОценок пока нет

- SNC Supplier Collaboration at PepsiCoДокумент23 страницыSNC Supplier Collaboration at PepsiCopraty888Оценок пока нет

- SNC Implementation ReccomendationДокумент8 страницSNC Implementation Reccomendationpraty888Оценок пока нет

- SNC Implementation ReccomendationДокумент8 страницSNC Implementation Reccomendationpraty888Оценок пока нет

- Charles Dickens - A Tale of Two CitiesДокумент670 страницCharles Dickens - A Tale of Two CitiesnegrutzzzОценок пока нет

- APO DoubtsДокумент4 страницыAPO Doubtspraty888Оценок пока нет

- APO DoubtsДокумент4 страницыAPO Doubtspraty888Оценок пока нет

- JDBC Driver and Its TypesДокумент8 страницJDBC Driver and Its Typespraty888Оценок пока нет

- 03TaskPerformance1 PECHONДокумент4 страницы03TaskPerformance1 PECHONAbug Jaime Jr.Оценок пока нет

- Pmguru OnlineДокумент167 страницPmguru OnlineGaurav KhamkarОценок пока нет

- Pressman CH 3 Prescriptive Process ModelsДокумент36 страницPressman CH 3 Prescriptive Process ModelsPriyadarshini NОценок пока нет

- Computer Graphics Schaum Series PDF Download PDFДокумент2 страницыComputer Graphics Schaum Series PDF Download PDFDivya SoodОценок пока нет

- Bills 2018 NehaДокумент24 страницыBills 2018 NehaAkhil GulatiОценок пока нет

- Jennifer-Leigh Oprihory's ResumeДокумент1 страницаJennifer-Leigh Oprihory's ResumejenniferleighoОценок пока нет

- Datasheet of DS-KIS204 Video Door Phone V1.1.0 20180502 PDFДокумент3 страницыDatasheet of DS-KIS204 Video Door Phone V1.1.0 20180502 PDFNareshОценок пока нет

- 12 CS - SQPДокумент5 страниц12 CS - SQPkumaran mudОценок пока нет

- Internship Report at A Telecommunication Company / SyriaДокумент5 страницInternship Report at A Telecommunication Company / Syriawaelmahainy10% (1)

- PHD 2021 Entrance and Admission NoticeДокумент1 страницаPHD 2021 Entrance and Admission Noticevivek soniОценок пока нет

- Read This FirstДокумент21 страницаRead This FirstNíkolas BorgesОценок пока нет

- Workflow API Reference Guide PDFДокумент340 страницWorkflow API Reference Guide PDFRaghugovindОценок пока нет

- Rail and Safety ConceptДокумент4 страницыRail and Safety ConceptJoseОценок пока нет

- General Concepts and Historical Antecedents of Science and TechnologyДокумент20 страницGeneral Concepts and Historical Antecedents of Science and TechnologyZarina PajarillagaОценок пока нет

- Er Shutdown For 15.12.21 Rev1Документ8 страницEr Shutdown For 15.12.21 Rev1Gitesh PatelОценок пока нет

- The Motherboard NotesДокумент5 страницThe Motherboard NotesPritima RamalinggamОценок пока нет

- Visvesvaraya Technological University Belagavi - 590018: Developments in Solar Dryers, Collectors and Absorber MaterialsДокумент1 страницаVisvesvaraya Technological University Belagavi - 590018: Developments in Solar Dryers, Collectors and Absorber MaterialsM.A rajaОценок пока нет

- UML DIAGRAMS For Hospital ManagementДокумент8 страницUML DIAGRAMS For Hospital ManagementDeepak M Krishna100% (4)

- Evolis Zenius Troubleshooting GuideДокумент2 страницыEvolis Zenius Troubleshooting GuideAdorjan Sandor Zoltan100% (1)

- Integrating Images and External MaterialsДокумент2 страницыIntegrating Images and External Materialskuirt miguelОценок пока нет

- OCP - 15 - GrindingДокумент2 страницыOCP - 15 - GrindingNagendra Kumar SinghОценок пока нет

- Library Managemnt Information SystemДокумент8 страницLibrary Managemnt Information SystemHạnh Nguyễn NgọcОценок пока нет

- StdlinearcrossДокумент50 страницStdlinearcrossKostas KitharidisОценок пока нет

- 2464 Manual v1 07eДокумент0 страниц2464 Manual v1 07eDota NgОценок пока нет

- Authentication GuideДокумент60 страницAuthentication GuideCon CacОценок пока нет