Академический Документы

Профессиональный Документы

Культура Документы

Chapter (8) Design of Water Tank

Загружено:

Eng Hala AboalfahemИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter (8) Design of Water Tank

Загружено:

Eng Hala AboalfahemАвторское право:

Доступные форматы

Chapter 8 : Design of Water Tank

C h a p t e r

Design of water tanks

.Introduction 8.1 .Types of water tanks 8.2 Cracks in water tanks 8.3 8.4 A Selected example for design of a water tank .

123

Chapter 8 : Design of Water Tank

:Introduction 8.1

Water tanks are the structural elements that store water, liquid petroleum, petroleum products and similar liquids. Their shapes may be circular, rectangular spherical etc. The force analysis of the reservoirs or tanks is about the same irrespective of the chemical nature of the product.The designer has to design all the tanks as crack free structures to eliminate any leakage. Industrial wastes can also be collected and processed in concrete tanks with few exceptions.The petroleum product such as petrol, diesel oil, etc. are likely to leak through the concrete walls, therefore such tanks need special membranes to prevent leakage.

8.2 Types of water tanks:

1) Concrete Tanks : These are referred to as underground tanks that are built on the site itself, but they can be used above-ground. Concrete tanks are generally long-lasting but are subject to cracking if placed underground in clay soil. The above ground versions have the advantage of keeping the water cooler than other tank types since light can't penetrate.

Figure 8.1: (Concrete Tank).

2) Metal Tanks: This variant can either be made from stainless steel or galvanized steel. They can be transported and assembled easily and can be situated in any place you desire. Metal tanks normally come in standard shapes. If you are having a Metal tank installed you should inspect it thoroughly when it is in place, as they 124

Chapter 8 : Design of Water Tank are prone to transport damage (including the breaking of welds if the tank flexes too much). Metal tanks are usually not used underground.

Figure 8.2: (Metal Tank). 3) Rainwater Tanks: Rainwater tanks are installed for the purpose of collecting all the rainwater that runs off your roof via installation of roof gutters. The water collected can be used for many things like watering your crops, feeding animal, washing your car and the like. However, the water collected by this means needs to undergo a certain process before it can be used for drinking. 4) Fiberglass Tanks: these tanks are strong, durable and able to withstand extreme temperatures. However, their popularity has suffered with the advent of cheaper poly tanks. They are mostly used for above-ground applications

Figure 8.3: (Fiberglass Tank).

8.3 cracks in concrete water tanks:

125

Chapter 8 : Design of Water Tank Cracking may be caused due to restraint to shrinkage, expansion and contraction of concrete due to temperature or shrinkage and swelling due to moisture effects. Such restraint may be caused by : (i) The interaction between reinforcement and concrete during shrinkage due to drying. (ii) The boundary conditions. (iii) The differential conditions prevailing through the large thickness of massive concrete.

To minimize the possibilities of cracking use small size bars placed properly, leads to closer cracks but of smaller width. The risk of cracking due to temperature and shrinkage effects may be minimized by limiting the changes in moisture content and temperature to which the structure as a whole is subjected. The risk of cracking can also be minimized by reducing the restraint on the free expansion of the structure with long walls or slab founded at or below ground level. Restraint can be minimized by the provision of a sliding layer. This can be provided by founding the structure on a flat layer of concrete with interposition of some material to break the bond and facilitate movement. In case length of structure is large it should be subdivided into suitable lengths separated by movement joints, especially where sections are changed the movement joints should be provided. Where structures have to store hot liquids, stresses caused by difference in temperature between inside and outside of the reservoir should be taken into account.

:An example for design of water tank 8.4

126

Chapter 8 : Design of Water Tank

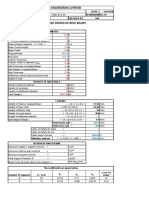

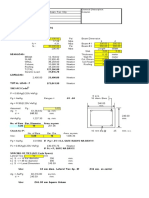

Lx = 4.1m , L y = 3.5m , w = 9.81KN / m 3 , f c ' = 24 Mpa f y = 420 Mpa , h = 4.0m , t = 400mm , d = 360mm

E c =4700 ( f c ' ) = 4700 (24) = 23025 Mpa E s = 200000 Mpa

Figure 8.4: (Water Tank dimensions). 2-way direction Capacity = LxBxh = 4.1 x3.5x4 = 57.4 m3

* Design of Roof Slab: Lb/La = 4.1/3.5 = 1.17<2 "Two-way solid slab" Assume H=300mm then d=260mm. Dead load Calculation:

Total Dead load = 8.78 KN/ m2 Live Load = 2.5 KN/ m2 Wu = 1.2 DL+ 1.6 LL = 1.2 (8.78) + 1.6 (2.5) =14.53 KN/ m2 M = La / Lb = 3.5/4.1 = 0.854

127

Chapter 8 : Design of Water Tank From table of bending coefficient moment find Ca and Cb for dead and live load :

M "short direction " = Ca xWDxl2 + CaxWLx l2 =0.028x1.2x8.78x3.52+0.045x1.6x2.5x3.52 = 5.82 KN.m M "Long direction " = Cb xWDxl2 + CbxWLx l2 =0.009x1.2x8.78x4.1 2+0.014x1.6x2.5x4.1 2 = 2.54 KN.m

* According to ACI thickness of two way slab : L/30 = h " From table 9.5 C " h= 4100/30 = 136.66mm take it 200mm h=200mm then d=160mm * Steel Reinforcement: 1. Short Direction :

2. Long Direction :

128

Chapter 8 : Design of Water Tank

* Design of Tank Walls: Loading Case: The water tanks empty with external earth pressure:

= tan2 (45-(30/2)) = 0.333 Ps = 20x4x0.333 = 26.64 KN/m * Analysis using computer program " prokon " : Required slab depth : assume h=400mm then d=360mm. Mu = 72.23 KN.m

Secondary steel horizontal:

129

Chapter 8 : Design of Water Tank In wall design we use As = 0.002 x 1000 x 400 = 800 mm2

* Check crack:

n=

Es 200000 = = 8.6 Ec 23168 .66

* Designs for Base of tank: Load roof slab weight = L B t = 4.2x3.5x.4x25 =147 KN

Total weight = 147 + 616 = 763 KN. Actual bearing capacity " q " = weight / area = 763 / (4.7x4) = 40.58 KN/ m2 M =La/Lb = 4/4.7 = 0.85 KN.m From table of bending coefficient moment find Ca and Cb for dead and live load : M = 0.04 x 40.58 x 42 = 25.97 KN.m

130

Chapter 8 : Design of Water Tank * According to ACI thickness of two way slab: L/30 = h "From table 9.5 C" h= 4700/30 = 157 mm take h = 200mm then d = 200-70= 130 mm .

131

Вам также может понравиться

- Fall of France PDFДокумент293 страницыFall of France PDFMarian Dragos100% (3)

- Water Tank DesignДокумент37 страницWater Tank DesignWrishad Zia95% (98)

- RectangularTanks PCAДокумент61 страницаRectangularTanks PCAvictorcivОценок пока нет

- World War Cheat Sheet v2.2Документ28 страницWorld War Cheat Sheet v2.2dcichorackiОценок пока нет

- ASL - VFTT 07Документ8 страницASL - VFTT 07deitti333Оценок пока нет

- FM 30-40 (1943) Recognition Pictorial Manual On Armored Vehicles PDFДокумент167 страницFM 30-40 (1943) Recognition Pictorial Manual On Armored Vehicles PDFalferga100% (1)

- Design of Rectangular Water TankДокумент280 страницDesign of Rectangular Water TankNoppolNorasri95% (42)

- The General - Volume 11, Issue 4Документ34 страницыThe General - Volume 11, Issue 4Robbie Coull100% (2)

- Underground Water Tank DesignДокумент24 страницыUnderground Water Tank Designsujan100% (1)

- Phantom Menace RPG For Star WarsДокумент54 страницыPhantom Menace RPG For Star WarsMarcus Baer100% (1)

- Analysis and Design of Water TankДокумент56 страницAnalysis and Design of Water TankKreesthu ReddyОценок пока нет

- Water Tank Design PDFДокумент41 страницаWater Tank Design PDFvipin100% (10)

- Codex Blood Angels 2010Документ49 страницCodex Blood Angels 2010Amnesia_198179% (19)

- Structural DesignДокумент52 страницыStructural Designbaig951Оценок пока нет

- Design of Rectangular Water TankДокумент268 страницDesign of Rectangular Water Tankchetanmale89% (28)

- ACI Rectangular Tanks2010Документ18 страницACI Rectangular Tanks2010Rohn J Jackson86% (7)

- Vehicle Rules in InquisitorДокумент8 страницVehicle Rules in InquisitorGeorge JonesОценок пока нет

- Prepared BY Dr. Mohammed Kadhum FekheraldinДокумент55 страницPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uОценок пока нет

- Analysis and Designe of Water TanksДокумент28 страницAnalysis and Designe of Water TanksJuan Agustin DiazОценок пока нет

- Design of Water TanksДокумент18 страницDesign of Water TanksAmmar Civil100% (2)

- Design of Water TankДокумент26 страницDesign of Water Tankspthebuilder91% (11)

- Circular Water TankДокумент7 страницCircular Water Tanksimon maaaklaОценок пока нет

- Design & Detailing of Water Retaining Structures & Pre Cast Water Tank Floor SystemДокумент69 страницDesign & Detailing of Water Retaining Structures & Pre Cast Water Tank Floor SystemAnonymous ciKyr0t94% (18)

- Reinforced Concrete Slab DesignДокумент70 страницReinforced Concrete Slab DesignLeandro Madeira100% (1)

- Design of Underground Reservoir - 03Документ21 страницаDesign of Underground Reservoir - 03Engr SwapanОценок пока нет

- Design of Underground Water TankДокумент6 страницDesign of Underground Water Tanksijuwolaoluranti100% (1)

- Design and Drawing of RC Structures: Dr. G.S.SureshДокумент40 страницDesign and Drawing of RC Structures: Dr. G.S.SureshLeroy TuscanoОценок пока нет

- Design of Rectangular Water TankДокумент242 страницыDesign of Rectangular Water Tankmumarbsc7244Оценок пока нет

- Alpha Strike Campaign Rules PDFДокумент46 страницAlpha Strike Campaign Rules PDFTest100% (1)

- Design of Elevated Service ReservoirДокумент88 страницDesign of Elevated Service ReservoirNitish Ramdawor86% (7)

- MDG Aug 2005Документ89 страницMDG Aug 2005Prabhjot Singh67% (3)

- UNIT II WATER TANKS Underground Rectangu PDFДокумент42 страницыUNIT II WATER TANKS Underground Rectangu PDFEgyptian ResearcherОценок пока нет

- External Ring BeamДокумент8 страницExternal Ring Beamorode franklynОценок пока нет

- ANALYSIS AND DESIGN OF Elevateted RCC Water Tank PDFДокумент64 страницыANALYSIS AND DESIGN OF Elevateted RCC Water Tank PDFbiniam0% (1)

- Butterfly Valve Chamber Design - 300 - 700mm DIДокумент6 страницButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Molasses Tank 18092020Документ31 страницаMolasses Tank 18092020Keshav GopaulОценок пока нет

- Ww2 PenetrationДокумент33 страницыWw2 Penetrationskarbyhistorii100% (1)

- Guidelines For Structural Design of Small Hydro Projects (AHEC)Документ41 страницаGuidelines For Structural Design of Small Hydro Projects (AHEC)Sambhav PoddarОценок пока нет

- Circular Water Tank With Domcal Top and BaseДокумент20 страницCircular Water Tank With Domcal Top and BaseSourav Chandra83% (6)

- Unit V Military and Combat VehiclesДокумент54 страницыUnit V Military and Combat Vehiclessanthosh rajОценок пока нет

- Floating Concrete StructuresДокумент10 страницFloating Concrete StructuresCyril LongtonОценок пока нет

- Swimming Pool DesignДокумент35 страницSwimming Pool DesignNeil Beeraspat100% (12)

- Design of Pressed Steel Tank PDFДокумент8 страницDesign of Pressed Steel Tank PDFEr Harsh Mahajan89% (19)

- Micro Armour WW2Документ136 страницMicro Armour WW2Anonymous CIy0zd5doОценок пока нет

- Design of Under Ground Water Tank PDFДокумент21 страницаDesign of Under Ground Water Tank PDFbean0% (1)

- Circular+water+tank+ (Rigid+joint) .Xls +designДокумент56 страницCircular+water+tank+ (Rigid+joint) .Xls +designKvvPrasadОценок пока нет

- Design of Circular Water Tank: (Flaxible Joint)Документ6 страницDesign of Circular Water Tank: (Flaxible Joint)firasslmnОценок пока нет

- Tank TruckДокумент80 страницTank Truckjacobpm2010Оценок пока нет

- Design of Circular Water Tank by Using Staad Pro SoftwareДокумент11 страницDesign of Circular Water Tank by Using Staad Pro SoftwarepandianОценок пока нет

- Bearing Capacity of FoundationsДокумент4 страницыBearing Capacity of FoundationsTshepiso NthiteОценок пока нет

- Design of Rectangular RC TankДокумент42 страницыDesign of Rectangular RC TankAllison Alcindor88% (8)

- Analysis and Design of R.C.C. Overhead TankДокумент76 страницAnalysis and Design of R.C.C. Overhead Tankkvr1956958100% (1)

- Operation Kursk (1943)Документ73 страницыOperation Kursk (1943)CAP History Library100% (1)

- Storage TanksДокумент62 страницыStorage Tankstoychom2013Оценок пока нет

- Ribbed Slabs: Design ConsiderationsДокумент6 страницRibbed Slabs: Design ConsiderationsAwadОценок пока нет

- Structural Design of Immersed TunnelsДокумент17 страницStructural Design of Immersed TunnelsTrong TranОценок пока нет

- Water TankДокумент5 страницWater TankHari RamОценок пока нет

- Design Forces For Shaft Supports of Elevated Water TanksДокумент10 страницDesign Forces For Shaft Supports of Elevated Water TanksIrfan MughalОценок пока нет

- Module-IV - Rectangular Water TanksДокумент61 страницаModule-IV - Rectangular Water TanksChinkuОценок пока нет

- Column Design (WSD) Axially LoadedДокумент1 страницаColumn Design (WSD) Axially Loadedapi-19753598100% (2)

- 8.2 Types of Water TanksДокумент6 страниц8.2 Types of Water TanksNusrath HuzeifaОценок пока нет

- MCQ Ed 1Документ7 страницMCQ Ed 1SatyamGupta0% (1)

- Kaid Ahmed Ali Kaid: DR / Zaid ThabetДокумент23 страницыKaid Ahmed Ali Kaid: DR / Zaid ThabetAwadОценок пока нет

- The International Journal of Science & Technoledge: Optimization of Water TankДокумент10 страницThe International Journal of Science & Technoledge: Optimization of Water Tanktvpavan666Оценок пока нет

- ADCSДокумент33 страницыADCSSHUBHAMОценок пока нет

- Mechanical Design Internals Column Notes PDFДокумент14 страницMechanical Design Internals Column Notes PDFMas Arman TewoОценок пока нет

- Design and Study of Floating Roofs For Oil Storage TanksДокумент12 страницDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesОценок пока нет

- Unit IiДокумент42 страницыUnit IiBabu Sundararaman100% (1)

- Water TankДокумент24 страницыWater Tankvishnumani3011Оценок пока нет

- Immersed Cross SectionsДокумент17 страницImmersed Cross SectionsAlexandra MoldovanОценок пока нет

- 1.054/1.541 Mechanics and Design of Concrete Structures (3-0-9) Homework #1Документ2 страницы1.054/1.541 Mechanics and Design of Concrete Structures (3-0-9) Homework #1James PaniaguaОценок пока нет

- Analysis and Design of Intze Type Under The Hydrostatic Pressure by Using SoftwareДокумент29 страницAnalysis and Design of Intze Type Under The Hydrostatic Pressure by Using SoftwareThe UnboxaholicОценок пока нет

- CiviДокумент11 страницCiviSaidi ReddyОценок пока нет

- Chemical Engineering Design1Документ4 страницыChemical Engineering Design1AbdulRahimShaikhОценок пока нет

- QBDC - Season 5-RulebookДокумент50 страницQBDC - Season 5-RulebookHggvgОценок пока нет

- Ufls Ultrasonic Fuel Level Sensor PDFДокумент7 страницUfls Ultrasonic Fuel Level Sensor PDFCarlos Alberto Osorio IngaОценок пока нет

- Men of War Assault Squad ManualДокумент20 страницMen of War Assault Squad ManualNewMaxxОценок пока нет

- PDF 33515Документ63 страницыPDF 33515Chris WhiteheadОценок пока нет

- Ao1 Unit 1Документ3 страницыAo1 Unit 1calbradОценок пока нет

- Battle of Barapind-Jarpal 16 Dec 1971 PDFДокумент16 страницBattle of Barapind-Jarpal 16 Dec 1971 PDFblitzkrieg88Оценок пока нет

- Rops SuspensionДокумент1 страницаRops SuspensionPedroОценок пока нет

- SC 15TW-Stainless Steel 13Документ44 страницыSC 15TW-Stainless Steel 13roherneville100% (1)

- BF2 CommanderДокумент14 страницBF2 CommanderHery GiacchinoОценок пока нет

- Company of Heroes 2 - Winter GuideДокумент15 страницCompany of Heroes 2 - Winter GuideAleksander BielskiОценок пока нет

- CaestusДокумент1 страницаCaestusherrmojoОценок пока нет

- Japanese CannonДокумент2 страницыJapanese CannonAhmed AkmalОценок пока нет

- SensoDrive-P Brochure 15.6.13Документ2 страницыSensoDrive-P Brochure 15.6.13Senso OpticsОценок пока нет

- Red Hill Aoc Section 2 2 Tirm Report 2016-10-11Документ246 страницRed Hill Aoc Section 2 2 Tirm Report 2016-10-11JackОценок пока нет

- Evaporation Loss Measurement For Storage TanksДокумент6 страницEvaporation Loss Measurement For Storage Tankssuman_94103Оценок пока нет