Академический Документы

Профессиональный Документы

Культура Документы

Surface Roughness

Загружено:

Rahul BetgeriИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Surface Roughness

Загружено:

Rahul BetgeriАвторское право:

Доступные форматы

R3

R

V=

1000

DN

T

e

c

h

n

i

c

a

l

I

n

f

o

r

m

a

t

i

o

n

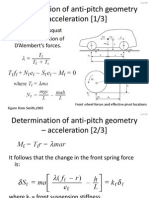

Theoretical (Geometrical) Surface Roughness

How to Obtain Surface Roughness Values

Theoretical Surface Roughness at Turning indicates the minimum

roughness value from the cutting conditions and it is shown by the

formula as follows:

Surface Roughness Symbol Caution

Relationship with Triangle Symbol

Indication in JIS Standard

Arithmetical

Mean Roughness

Ra(m)

0.025

0.05

0.1

0.2

0.4

0.8

1.6

3.2

6.3

12.5

25

Max. Height

Roughness

Rz(m)

0.1

0.2

0.4

0.8

1.6

3.2

6.3

12.5

25

50

100

Ten PointsMean

Roughness

RzJIS(m)

Note:

(Relationship

with Triangle)

3.2

6.3

25

50

100

12.5

0.8

0.4

0.2

1.6

0.1

Note: Finishing symbol (Triangleand wave~) was

abolished from JIS standard from 1994 Revision.

How to Indicate

Example

When Ra is 1.6m1.6mRa

When Rz is 6.3m6.3mRz

When RzJIS is 6.3m6.3mRzJIS

Rz(h)

f

8R(r)

2

10

3

Rz(h)Theoretical Surface Roughnessm

Feed Ratemm/rev

(r)Corner Radius of Insertmm

The above information is based on JIS B 0601-2001.

However, some symbols were revised as shown in the right table in

accordance with ISO Standard from JIS B 0601-2001 version.

Ten Points Mean Roughness (Rz) was eliminated from 2001 version

but it still remains as RzJIS reference, since it was popular in Japan.

Type

Max. Height

Roughness

Ten Points

Mean Roughness

Arithmetical Mean

Roughness

Ry

Rz

Ra

Rz

RzJIS

Ra

Symbol of

JIS B 0601-1994

Symbol of

JIS B 0601-2001

Example of Ra Indication

Note: The indications of Ra and Rz are different.

When indicating upper limit onlyIndicate

surface roughness following the parameter

symbol.

When indicating both lower and upper limit

Indicate surface roughness as (upper limit ~

lower limit) following the parameter symbol.

When indicating the upper limit only

(when upper limit is 6.3mRa)

When indicating both lower and upper limit

(when upper limit is 6.3mRa, lower limit is 1.6mRa)

6.3

1.6

6.3 Rz6.3

Rz6.3~1.6

Example of Ry, (Rz) Indication

Type Symbol

Rz

RzJIS

Ra

How to Obtain Explanation

Ry is obtained from the distance in micron

meter between the highest peak and the

lowest valley in the range of sampled

reference length () to the direction of mean

line of the roughness curve.

Rz is obtained from the total in micron meter

of the mean value of the each distance

between the mean line and 5 peaks (Yp)

from the highest one, and the mean value of

the each distance between the mean line

and the 5 valleys (Yv) from the lowest one,

of the roughness curve in the range of

sampled reference length .

Yp1,Yp2,Yp3,Yp4,Yp5:

Distance from the mean line to highest 5

peaks in the range of sampled reference

length

Yv1,Yv2,Yv3,Yv4,Yv5:

Distance from the mean line to the lowest 5

valleys in the range of sampled reference

length

Ra is obtained from the following formula in

micron meter when the roughness curve is

expressed by y=f(x), taking X-axis to the mean

line direction and Y-axis to the vertical

magnification of the roughness curve in the

range of sampled reference length .

RzRpRv

RzJIS

Yp1Yp2Yp3Yp4Yp5Yv1Yv2Yv3Yv4Yv5

5

Ra

f(x)dx

1

m

R

p

R

y

R

v

m

Y

v

5

Y

v

5

Y

p

1

Y

p

2

Y

p

3

Y

p

4

Y

v

4

Y

v

1

Y

v

3

Y

v

2

X

Y

R

a

m

T

e

n

P

o

i

n

t

s

M

e

a

n

R

o

u

g

h

n

e

s

s

M

a

x

.

H

e

i

g

h

t

R

o

u

g

h

n

e

s

s

A

r

i

t

h

m

e

t

i

c

a

l

M

e

a

n

R

o

u

g

h

n

e

s

s

Surface Roughness (JIS B 0601-2001)

R

r

R

z

(

h

)

f

2839 2840

M

3.2 3.2

6.3

1.6

6.3

1.6

25

6.3 25

25 6.3

25

Milled

FC-24 1

1.PositionsofAuxiliarySymbolsforSurfaceSymbol

A surface roughness value, cut-off value or reference length, machining method, grain direction, surface undulation, etc. are

indicated around the surface symbol as shown in Fig. 1 below.

Fig.1PositionsofAuxiliarySymbols

a : Ra Value

b : Machining Method

c : Cut-Off Value, Evaluation Length

c' : Reference Length, Evaluation Length

d : Grain Direction

f : Parameter other than Ra(tp:Parameter/Cut-Off Level)

g : Surface Undulation(JIS B 0610)

Reference These symbols except a and f are provided when they are needed.

Reference Under ISO 1302, a fnish range should be indicated as e in Fig. 1.

Examples ofGraphicalRepresentation ofSurface Texture

Surface Symbol

Removal of Material by Machining is required

Removal of Material is Prohibited

Upper Limit of Ra

(a) (b) (c)

Grain Direction

Upper and Lower Limits of Ra

(a) (b)

Machining Method

(a) (b)

1.VarietiesofSurfaceRoughnessIndicators

Defnitions and presentations of arithmetic average roughness(Ra), maximum height(Ry), 10 spot average roughness(Rz), average concave to

convex distance(Sm), average distance between local peaks S and load length rate tp are given as parameters indicating the surface roughness

of an industrial product. Surface roughness is the arithmetical average of values at randomly extracted spots on the surface of an object.

[Centerline average roughness(Ra75)is defned in the supplements to JIS B 0031 and JIS B 0601.]

Typicalcalculationsofsurfaceroughness

Reference RelationbetweenArithmeticAverageRoughness(Ra)andConventionalParameters

c a

g d

b

f

c'

d e g e

[TechnicalData]

SurfaceRoughness

JISB0601(1994)

ExcerptsfromJISB0031(1994)

[TechnicalData]

DrawingIndicationsofSurfaceTexture

Excerptsfrom

JISB0031(1994)

Code Meaning Illustration

The trace left by a cutting instrument

is parallel to the projection plane in

the drawing.

Ex. Shaped Surface

The trace left by a cutting instrument

is perpendicular to the projection

plane in the drawing.

Ex. Shaped Surface(Side View)

Circular Cut, Cylindrical Cut

The pattern left by a cutting instrument

diagonally crosses the projection plane

in the drawing.

Ex. Honed Surface

The pattern left by a cutting instrument

crosses in various directions or has no

grain direction.

Ex. Lapped Surface, Superfnished

Surface and Surface Finished

with a Front Mill or End Mill

The pat t er n l ef t by a cut t i ng

instrument is virtually concentric

around the center of the plane in the

drawing.

Ex. Faced Surface

The pattern left by a cutting instrument

is virtually radial around the center of

the plane in the drawing.

ArithmeticAverageRoughnessRa

A portion stretching over a reference length in the direction in which the

average line extends is cut out from the roughness curve. This portion

is presented in a new graph with the X axis extending in the same

direction as the average line and the Y axis representing the magnitude.

Ra is represented by the equation shown at right, in microns(m).

MaximumHeightRy

A portion stretching over a reference length in the direction in which

the average line extends is cut out from the roughness curve. The gap

between the peak line and the trough line is measured in the direction in

which the magnitude axis extends, in microns(m).

Reference A portion without an abnormally high peak or abnormally low trough,

which may be regarded as a faw, is cut out over the reference length.

Ten-spotAverageRoughnessRz

A portion stretching over a reference length in the direction in which

the average line extends is cut out from the roughness curve. The

average of the levels(Yp)of the highest peak to the ffth highest peak as

measured from the average line and the average of the levels(Yp)of the

lowest trough to the ffth lowest trough similarly measured in the said

portion are added together. Rz is this sum, in microns(m).

ArithmeticAverageRoughness

Ra

Maximum Height

Ry

Ten-spot Average

Roughness Rz

Reference Length

ofRy(Rz)

(mm)

Conventional

FinishSymbol

StandardSeries

Cut-offValue

c(mm) GraphicalRepresentation ofSurface Texture StandardSeries

0.012 a

0.025 a

0.05 a

0.1 a

0.2 a

0.08

0.012 ~ 0.2

0.05 s

0.1 s

0.2 s

0.4 s

0.8 s

0.05 z

0.1 z

0.2 z

0.4 z

0.8 z

0.08

0.25

0.25

0.8

0.8

0.4 a

0.8 a

1.6 a

0.4 ~ 1.6

1.6 s

3.2 s

6.3 s

1.6 z

3.2 z

6.3 z

3.2 a

6.3 a

2.5 3.2 ~ 6.3

12.5 s

25 s

12.5 z

25 z 2.5

12.5 a

25 a 8

12.5 ~ 25

50 s

100 s

50 z

100 z

8

50 a

100 a

50 ~ 100

200 s

400 s

200 z

400 z

~

*Interrelations among the three types shown here are not precise, and are presented for convenience only.

*Ra:The evaluation values of Ry and Rz are the cut-off value and the reference length each multiplied by fve, respectively.

Yp1, Yp2, Yp3, Yp4, Yp5 : Levels of the highest peak to the ffth highest peak in the

said portion with the reference length .

Yv1, Yv2, Yv3, Yv4, Yv5 : Levels of the lowest trough to the ffth lowest trough in the

said portion with the reference length .

X 0

R

a

Y

m

R

p

Ry=Rp+Rv

m

R

v

R

y

m

5

Y

p Y

p

4

V

5

Y

3

Y

p Y

p

2

Y

V

4

Y

V

3

Y

V

2

1

V

1

Y

Y

p

Rz=

Yp1 + Yp2 + Yp3 + Yp4 +Yp5 + Yv1 + Yv2 + Yv3 + Yv4 + Yv5

5

Ra =

1

f ( ) dx

0

Trace Left by a Cutting Instrument

Trace Left by a Cutting Instrument

Trace Left by a Cutting Instrument

FC-24-1_E.indd 2839-2840 08.4.7 11:42:03 AM

Technical Data

Surface Roughness by Different Processing Methods

Technical Data

Indications of Geometrical Tolerance on Drawings

Excerpt from

JISB00211984

S! a n d a r d va l u e s

o ! s! a n d a r d l e n g! h

(m m)

0 .1

S S

0 .Z

S

0 .4

S

0 .8

S

1 .6

S

3 .Z

S

6 .3

S

1 Z .6

S

Z 6

S

6 0

S

1 0 0

S

Z 0 0

S

4 0 0

0 .Z 6 0 .8 Z .6 8 Z 6

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_ _

_ _

_

1r ia n gu l a r in d ica ! io n

la x im u m pe a k H y

H m a x .

/ r i! hm e ! ica l m e a n

r o u ghn e ss H a

0 .0 Z 6 0 .0 6 0 .1 0 .Z 0 .4 0 .8 1 .6 3 .Z 6 .3 1 Z .6 Z 6 6 0 1 0 0

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_ _

_

_

_

_

_

_

_

_

_

_ _

_

_

_

_

_

Kin d s a n d Sym b o l s o ! G e o m e ! r ica l 1o l e r a n ce s

For m e r

d e sign a ! ion s

o!

su r !a ce

r o u ghn e ss

W or k in g

m e ! hod

_

_

_

Ex a m pl e s o ! d ia gr a m m a ! ica l in d ica ! io n a n d i! s in ! e r pr e ! a ! io n Kin d o ! ! o l e r a n ce

S! r a igh! n e ss

! o l e r a n ce

Sym b o l

Fl a ! n e ss

! o l e r a n ce

C ir cu l a r i! y

! o l e r a n ce

C yl in d r ici! y

! o l e r a n ce

Pr o !il e ! ol e r a n ce

o ! l in e

L e !in i! io n o ! ! ol e r a n ce zo n e

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Pr o !il e ! ol e r a n ce

o ! su r !a ce

Pa r a l l e l ism

! o l e r a n ce

Pe r pe n d icu l a r i! y

! ol e r a n ce

/ n gu l a r i! y

! o l e r a n ce

_

Po si! io n a l

! o l e r a n ce

C o a x ia l i! y

! o l e r a n ce

o r

co n ce n ! r ici! y

! o l e r a n ce

Sym m e ! r y

! o l e r a n ce

C ir cu l a r r u n -o u !

! o l e r a n ce

_

_

_

_ _

_

_

_

_ _

_

_ _

_

_

_

_

1o ! a l r u n -o u !

! o l e r a n ce

_ _ _

_ _ _

_ _

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Fo r m

! o l e r a n ce

r ie n ! a ! io n

! o l e r a n ce

Lo ca ! io n

! o l e r a n ce

H u n -o u !

! o l e r a n ce

_ _ _

_ _______ _

_ _ ______ _

_ _ _______

_

_

_

1 1 3 0 1 1 Z 9

Вам также может понравиться

- SCDL ProjectДокумент139 страницSCDL ProjectChetan Shitole67% (6)

- Surface Roughness (JIS B 0601-2001)Документ3 страницыSurface Roughness (JIS B 0601-2001)Prashantha Raju100% (3)

- Handbook of Fat ReplacersДокумент295 страницHandbook of Fat Replacersgoldennanuk100% (1)

- Voltage Drop CalculatorДокумент1 страницаVoltage Drop CalculatorparodoxxОценок пока нет

- Surface Roughness - Geometrical Dimensioning & Tolerancing (GD&T)Документ24 страницыSurface Roughness - Geometrical Dimensioning & Tolerancing (GD&T)Kishor kumar Bhatia100% (27)

- Intro To PneumaticsДокумент30 страницIntro To PneumaticskabirbОценок пока нет

- Refractive Index Principle PDFДокумент7 страницRefractive Index Principle PDFsalmanОценок пока нет

- OpticsHW Ch11KeyДокумент12 страницOpticsHW Ch11KeyJane Winner100% (1)

- 1984 Surf Roughness PGДокумент8 страниц1984 Surf Roughness PGSajjan SОценок пока нет

- Tolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsДокумент10 страницTolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsAmirtharaaj VijayanОценок пока нет

- Boring and Jig Boring MachineДокумент17 страницBoring and Jig Boring MachineRohit SahaiОценок пока нет

- Passivation Info For Laser Marked PartsДокумент8 страницPassivation Info For Laser Marked Partssaddleman100% (1)

- Geometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical TolerancesДокумент30 страницGeometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical Tolerancessohkimfai6340100% (3)

- Sensor Controller Catalog PDFДокумент418 страницSensor Controller Catalog PDFRicardo GonzalezОценок пока нет

- Experiment No 10 - Exercises in Preparation of Detailed Production DrawingsДокумент29 страницExperiment No 10 - Exercises in Preparation of Detailed Production DrawingsS S PatilОценок пока нет

- Surface RoughnessДокумент28 страницSurface RoughnessNeelesh PatkiОценок пока нет

- CP, CPK, CM, CMK, Control LimitsДокумент5 страницCP, CPK, CM, CMK, Control LimitsMaitreyee GoswamiОценок пока нет

- Surface Roughness by Different Processing MethodsДокумент1 страницаSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- 5) DOE Design and Analysis Using MinitabДокумент48 страниц5) DOE Design and Analysis Using MinitabLibyaFlowerОценок пока нет

- GD&T Glossary and Resource - GD&T Symbols and TermsДокумент4 страницыGD&T Glossary and Resource - GD&T Symbols and TermsMohammed Adil100% (1)

- 05 StraightnessMeasurement90Документ90 страниц05 StraightnessMeasurement90maddy_scribdОценок пока нет

- Advance Product Quality Planning Status ReportДокумент30 страницAdvance Product Quality Planning Status ReporttapanОценок пока нет

- Corrosion Guide - Material BehaviorДокумент11 страницCorrosion Guide - Material Behaviorkaruna346Оценок пока нет

- NADCA StandardsДокумент8 страницNADCA StandardsmathiprakashОценок пока нет

- Casting ToleranceДокумент1 страницаCasting ToleranceTrushant NakumОценок пока нет

- JIS B0419-1991 (Dung Sai Kich Thuoc)Документ1 страницаJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáОценок пока нет

- Tolerance Chart For Casting For Intolerable Dimensional As Per ISO 8062, IS 2102Документ2 страницыTolerance Chart For Casting For Intolerable Dimensional As Per ISO 8062, IS 2102Umesh Sakhareliya100% (1)

- Fits TolerancesДокумент26 страницFits TolerancesHardeep Singh BaliОценок пока нет

- 08 - Eng Castingdesign ShrinkagesДокумент2 страницы08 - Eng Castingdesign ShrinkagesAlex Kiko VillalobosОценок пока нет

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetДокумент6 страницCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITОценок пока нет

- CPK & PPK Calculator V4.1aДокумент9 страницCPK & PPK Calculator V4.1aE-Games E-GamesОценок пока нет

- GDT TutorialДокумент76 страницGDT TutorialSrk ChowdaryОценок пока нет

- Surface Finish TerminologyДокумент30 страницSurface Finish TerminologyXin YuОценок пока нет

- Marking Work InstructionДокумент1 страницаMarking Work InstructionSUBODHHОценок пока нет

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Документ5 страницTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Ulllted States Patent (19) (11) Patent Number: 5,897,223: Tritchew Et Al. (45) Date of Patent: Apr. 27, 1999Документ18 страницUlllted States Patent (19) (11) Patent Number: 5,897,223: Tritchew Et Al. (45) Date of Patent: Apr. 27, 1999Wilson Walas LlanqmОценок пока нет

- Design Specification For Gauges Revision 005Документ27 страницDesign Specification For Gauges Revision 005rubenОценок пока нет

- Tool Design TerminologyДокумент5 страницTool Design Terminologyanmol6237Оценок пока нет

- GD&TДокумент5 страницGD&Travindra_2011Оценок пока нет

- MM DiagramsДокумент31 страницаMM DiagramsDhaval PatelОценок пока нет

- 13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Issue Number OrderДокумент22 страницы13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Issue Number OrderOmar MokhtarОценок пока нет

- Torque Measurements MetrologyДокумент20 страницTorque Measurements MetrologymukhilОценок пока нет

- Your Source For GD&T Training and MaterialsДокумент6 страницYour Source For GD&T Training and Materialskharsh23Оценок пока нет

- Metrology 1CДокумент44 страницыMetrology 1CRadhaMadhavОценок пока нет

- EPM212 - Chapter 9 Slides GD T HandoutДокумент15 страницEPM212 - Chapter 9 Slides GD T HandoutJosephRomeraloОценок пока нет

- 8d's y 5 Por Que de NissanДокумент8 страниц8d's y 5 Por Que de NissanSergio RuizОценок пока нет

- V3I2IJERTV3IS21239Документ5 страницV3I2IJERTV3IS21239erwindОценок пока нет

- Broaching PrsДокумент41 страницаBroaching PrsParag PatelОценок пока нет

- Measurement Systems Analysis: Total Quality ManagementДокумент17 страницMeasurement Systems Analysis: Total Quality Managementtlatuani1000Оценок пока нет

- Electro Optics - Handbook of Image Quality 2002-Marcel DekkerДокумент537 страницElectro Optics - Handbook of Image Quality 2002-Marcel Dekkeroscar bohorquezОценок пока нет

- Training at CaparoДокумент36 страницTraining at Caparopilaniabhupesh_81404Оценок пока нет

- GD & TДокумент63 страницыGD & THemanth KumarОценок пока нет

- Astm A827-14Документ3 страницыAstm A827-14Артем Титов100% (1)

- Jis B 0601 1994Документ1 страницаJis B 0601 1994amsubra8874Оценок пока нет

- 09 Mo1517Документ2 страницы09 Mo1517TombongОценок пока нет

- Surface FinishДокумент38 страницSurface FinishSunilОценок пока нет

- 1984 Surf Roughness PGДокумент8 страниц1984 Surf Roughness PGHussn YazdanОценок пока нет

- Explanation of Surface RoughnessДокумент8 страницExplanation of Surface RoughnessN.Palaniappan100% (6)

- 22 - Kyocera Technical Information 2010-2011 (ENG)Документ42 страницы22 - Kyocera Technical Information 2010-2011 (ENG)HEMANTKHERAОценок пока нет

- Metropro Surface Texture ParametersДокумент20 страницMetropro Surface Texture ParametersAnandan NatarajanОценок пока нет

- ZYGO - Surface Texture ParametersДокумент20 страницZYGO - Surface Texture ParametersramadanОценок пока нет

- Motif Parameters of ISO 12085: '96Документ2 страницыMotif Parameters of ISO 12085: '96ubllc100% (1)

- MITSUBISHI MATERIALS CORPORATION Surface RoughnessДокумент2 страницыMITSUBISHI MATERIALS CORPORATION Surface Roughnessjames.anitОценок пока нет

- 1984 Surf Roughness PGДокумент8 страниц1984 Surf Roughness PGMaey AkimОценок пока нет

- A Critical Study of The Work Vaimanika ShastraДокумент8 страницA Critical Study of The Work Vaimanika ShastraMauroBonolloОценок пока нет

- Engineering Design I Lecture Part 5Документ14 страницEngineering Design I Lecture Part 5Miguel Cruz IIIОценок пока нет

- TI Polymer Periodic TableДокумент1 страницаTI Polymer Periodic TableRahul BetgeriОценок пока нет

- 15-Suspension Systems and Components v2Документ42 страницы15-Suspension Systems and Components v2Ismail AmlaОценок пока нет

- Fasteners StandardsДокумент98 страницFasteners StandardsRahul Betgeri100% (4)

- Design GuidelinesДокумент15 страницDesign GuidelinesdolonbgdОценок пока нет

- 16 Suspension 3Документ37 страниц16 Suspension 3Sunilkumar ReddyОценок пока нет

- Fasteners StandardsДокумент98 страницFasteners StandardsRahul Betgeri100% (4)

- Material StandardsДокумент5 страницMaterial StandardsamitkumarkarmakarОценок пока нет

- Start End Time Lapse Glucose Mol Glucose Mol: /L /minДокумент45 страницStart End Time Lapse Glucose Mol Glucose Mol: /L /minRahul BetgeriОценок пока нет

- Samenvatting Sterkteleer BASFДокумент86 страницSamenvatting Sterkteleer BASFdroessaert_stijnОценок пока нет

- Spring DesignДокумент112 страницSpring Designchshbt80% (5)

- Screw Size and ToleranceДокумент92 страницыScrew Size and Tolerancenick10686100% (1)

- 2013 Calendar Portrait 1 Page LetterДокумент1 страница2013 Calendar Portrait 1 Page LetterRahul BetgeriОценок пока нет

- 2013 Weekly Calendar With Holidays MondayДокумент4 страницы2013 Weekly Calendar With Holidays MondayRahul BetgeriОценок пока нет

- EbooksДокумент12 страницEbooksRahul BetgeriОценок пока нет

- Mead Pneumatic HandbookДокумент40 страницMead Pneumatic Handbookjoydeep100% (5)

- 2013 Calendar Portrait 1 Page LetterДокумент1 страница2013 Calendar Portrait 1 Page LetterRahul BetgeriОценок пока нет

- Workout SheetДокумент8 страницWorkout SheetRahul BetgeriОценок пока нет

- Fod - NasaДокумент23 страницыFod - NasaRahul BetgeriОценок пока нет

- Equivalent MaterialДокумент5 страницEquivalent MaterialRahul Betgeri50% (2)

- Aeroprobe ScannerДокумент7 страницAeroprobe ScannerRahul BetgeriОценок пока нет

- FL LinearThrustersДокумент49 страницFL LinearThrustersRahul BetgeriОценок пока нет

- Surface RoughnessДокумент3 страницыSurface RoughnessRahul BetgeriОценок пока нет

- FOD Prevention GuidelineДокумент16 страницFOD Prevention GuidelinejamilvoraОценок пока нет

- Fasteners StandardsДокумент98 страницFasteners StandardsRahul Betgeri100% (4)

- THK Rail CatalogueДокумент2 страницыTHK Rail CatalogueRahul BetgeriОценок пока нет

- Failure TheoriesДокумент21 страницаFailure TheoriesMadhan Krishnamurthy100% (1)

- Pneumatic SymbolsДокумент1 страницаPneumatic SymbolsRahul BetgeriОценок пока нет

- Thapar University, Patiala Department of Chemical Engineering E To D (February 2018)Документ2 страницыThapar University, Patiala Department of Chemical Engineering E To D (February 2018)Vinay DograОценок пока нет

- TM-4143 Slide Metoda EOR (Week IX)Документ51 страницаTM-4143 Slide Metoda EOR (Week IX)AwabОценок пока нет

- TikZ Package - Overleaf, Editor de LaTeX OnlineДокумент13 страницTikZ Package - Overleaf, Editor de LaTeX OnlinechkornarosОценок пока нет

- tmp327F TMPДокумент228 страницtmp327F TMPFrontiersОценок пока нет

- P-ToLUENESULFONIC ANHYDRIDE Ts2O From TsOH P2O5 Kieselguhr Then DCE Extraction EtcДокумент3 страницыP-ToLUENESULFONIC ANHYDRIDE Ts2O From TsOH P2O5 Kieselguhr Then DCE Extraction Etcfchem11Оценок пока нет

- Fat ManДокумент18 страницFat ManYasir Khan0% (1)

- Optical Based Non Invasive Glucometer With IoTДокумент3 страницыOptical Based Non Invasive Glucometer With IoTSuwetha I GОценок пока нет

- Geo-Synthetics: Specifications For Railway SectorДокумент51 страницаGeo-Synthetics: Specifications For Railway SectorVISHWAJITОценок пока нет

- Tribology of Polymers and Their Composites - Environmental EffectsДокумент45 страницTribology of Polymers and Their Composites - Environmental EffectsJigar M. UpadhyayОценок пока нет

- N-Containing Secondary CompoundsДокумент16 страницN-Containing Secondary CompoundsNasiha el KarimaОценок пока нет

- 2 3 - 2 3 25 1Документ4 страницы2 3 - 2 3 25 1GoGUtkokAОценок пока нет

- Chapter-6 ThermodynamicsДокумент11 страницChapter-6 ThermodynamicsDaksh ChothaniОценок пока нет

- Rochelle's Salt As An Alternative PiezoelectricДокумент10 страницRochelle's Salt As An Alternative PiezoelectricSudharshan KomandurОценок пока нет

- News From Vietnam Chemical DatabaseДокумент3 страницыNews From Vietnam Chemical DatabasequýОценок пока нет

- Biotech Fourth QuarterДокумент4 страницыBiotech Fourth QuarterRodge BuereОценок пока нет

- Homework-5 2Документ3 страницыHomework-5 2Dorothy CastilloОценок пока нет

- Science Magazine April 07 2006 PDFДокумент144 страницыScience Magazine April 07 2006 PDFAndrés FrankowОценок пока нет

- Ma 333 MДокумент13 страницMa 333 MdeztruktorОценок пока нет

- Biomass Gasification For Hydrogen Production - Process Description and Research NeedДокумент10 страницBiomass Gasification For Hydrogen Production - Process Description and Research Needapi-3799861100% (1)

- Semiconductor - Experiment PDFДокумент116 страницSemiconductor - Experiment PDFMuthu KumarОценок пока нет

- Radiative Heat Transfer in Participating Media A ReviewДокумент20 страницRadiative Heat Transfer in Participating Media A ReviewSanjeevan Lakra0% (1)

- DN Iso 5817Документ13 страницDN Iso 5817Phani Sridhar ChОценок пока нет

- Low Cycle Fatigue in AnsysДокумент20 страницLow Cycle Fatigue in AnsysSuvarnaОценок пока нет

- The World of CyclophanesДокумент6 страницThe World of CyclophanesDivya NarayanОценок пока нет

- Example 9.2 1Документ3 страницыExample 9.2 1jthaaschОценок пока нет

- Broadband Drop CableДокумент28 страницBroadband Drop CableAngel LopezОценок пока нет