Академический Документы

Профессиональный Документы

Культура Документы

KTG2820 S Lalkoh

Загружено:

Iftikhar HussainИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

KTG2820 S Lalkoh

Загружено:

Iftikhar HussainАвторское право:

Доступные форматы

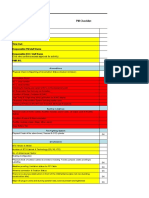

Quality Audit Form

Site Name : KTG2820__S_Lalkoh Mobilink Eng Name : Iftikhar Hussain Audit Date :03/08/11

Weight Audit Weight Reserves

Subcontractor :Mobiserve

Criteria 1- Power Meter Enclosure & 100A C.B Enclosure securing Presence of 100A CB Appearnce of 100A C.B (cleanning & Corrossion & Lock) Power cable Enterance to 100A C.B Electrical Terminals connection 100 Route of the power cable Route of earth cable 2-Cooling system A/C s operation A/Cs outdoor status A/C drain pipes A/Cs indoor status & filters status Indoor units Lables A/C Stands A/C grounding Insulation for cooling Pipes Stauts of sensors ( HT Sensor) Status of Fan Blades A/C control (24 Hour Timers , A/C contactors , Fuses ) Electrical Connections for A/C contactors (Thimbles) 3-Rectifier: 3 phases connected to rectifier cabinet Grounding for rectifier Cabient Positive output (0 vdc) connected to site ground All modules are output balanced No alarms present on the rectifier controller or in the OMC-R Float voltage on rec bus bar is 54..6 v DC cables labels ( + AND - ) Fuses and D/C circuit breakers Labels Rectifier cabinet labels (if more than one cabinet is present) Cleanning Status of the rectifier Modules and rectifier Cabient Fuse Panel of the MW Rack Coneected to the Recifier 4- Batteries: Batteries Cables are well tight Cleanning of the Batteries Poles & Surface Battery racks are connected to site ground

Last PM Date:26/07/11

Corrective Action Date

100%

10% 20% 20% 15% 15% 10% 10% 10 20 20 15 15 10 10

100%

15% 10% 10% 10% 5% 5% 5% 5% 10% 5% 10% 10% 15 10 10 10 5 5 5 5 10 5 10 10

100%

10% 10% 10% 10% 10% 10% 5% 5% 10% 10% 10% 10 10 10 10 10 10 5 5 10 10 10

100%

20% 15% 10% 20 15 10

Fixiation of the battery Bank All battery hoods are present Battery ( racks & Strings) Labels Status of the batteries (ok , Reshapped ) Battery cables are organized and inserted inside ducts to rectifier 4- Fire alarm and Fire fighting system Control panel operations Status of Fire Sensor Fire extinguisher inspection Fire Extingusher PIN Lock Fire extinguisher certificate of validity 5 External alarms & Lighting system Rectifier alarms operation (Minor ,Major ,Low Voltage ) Fire alarm operation Alarms connection to BSC & BTS (Routing & Fixation) Intruder alarm operation High Temperature alarm operation Genset ON alarm Operation Normal lighting status Oudoor Lightining Status

10% 10% 10% 15% 10%

10 10 10 15 10

100%

30% 20% 20% 15% 15% 0 20 20 15 15

100%

30% 10% 10% 10% 10% 10% 10% 10% 30 10 10 10 10 10 10 10

Criteria 6 - Distribution Panel Electrical cables connections & Entrance & Glandes Electrical Jumpers Thimbling Dist panel status (Fixiation & Lock) C.B labeling Wires arrangement DP Grounding Electric Component (Timers, Contactors , C.B, Fuses) DP Status ( Label & Cleanning ) Electric switches and Power sockets Status 7- shelter body & Building Room

Weight

Audit Weight

Corrective Action Date

100%

20% 10% 10% 10% 10% 10% 10% 10% 10% 20 10 10 10 10 10 10 10 10

100%

20 10 10 10 10 10 10 10 10

Shelter or Room Status (ground , walls, floor, ceilling) appearance 20% Shelter isolation outside & inside Shelter Double roof status Shelter or Room door status & appearance Shelter or Room door fixation & sealing Shelter or Room Door Hook Earth Strib Inside The Room or the shelter inside Earth Plate connected to the outsde earth Plate Cleanning of the earh Plates 8 Cable trays & Ladder Ducts installation & covering Cables ducting Cables outlet from ducts Cable tray or Ladder fixation Cables arrangement on the ladder or on the Cable tray Cable tray or Ladder grounding Sharp edges for cable trays Cable tray fixation out side the shelter Cover fixation for cable tray outside the shelter Cable tray or ladder earthing outside the site 9 Equipment & DDF General appearance for equipments Feeder connectors and IF Connectors tightness MW Rack and equipments Grounding General appearance for DDF Metal Labels on jumpers BTS and Equipment Filters Cleanning Lower jumper attached to cable tray 10 Fence, Mast & Pylons & Tower 10% 10% 10% 10% 10% 10% 10% 10%

100%

10% 10% 10% 10% 10% 10% 10% 10% 10% 10% 10 10 10 10 10 10 10 10 10 10

100%

30% 15% 15% 10% 10% 10% 10% 30 15 15 10 10 10 10

100%

Fence status (Cleanning & Securing) Main Gate and the lock Feeders entrance isolation (Feeded Box) Outside earth plate(s) is coating with antistatic grease RF surge arrestors Grounding Pylon or masts corrosion and cleanning status RF cables arrangement on pylon or on the mast Antenna Connectors & MW ODU connectors Isolation Beacon light operation Status of the photo cell (Appearnce and fixiation) Total Percentage

10% 10% 10% 10% 10% 10% 10% 10% 10% 10% 1100% 90%

10 10 10 10 10 10 10 10 0 10 1060

Mobilink Eng Decision (Satisfactory)

Genset Audit

Genset Status ( T Prime , Stand by ,Prime) Hour Meter Reading: 23425 Criteria Generator Automatic start of each at power fail or fail of other Generator alarms status ( Oil sensor,Temperature Sensor) Radiator cleaning status Radiator green water status Generator engine cleaning status Oil or water leakage Oil Level Air Filter Status Fuel leakage Earthing for Engine and the base Exhasut pipes isolation Indicator counters operation( Volt, Amp, Htz, Oil ) Batteries connection status (Grease Applied) Batteries Water Level ATS Panel & ATS label status ATS wiring & componante ATS indicators Status of the canopy Total Percentage Weight Audit Weight Reserves Corrective Action Date T-Prime

Last PM date

26/7/11

400%

50% 40% 25% 20% 15% 20% 20% 20% 20% 15% 10% 20% 10% 15% 20% 30% 20% 30% 400% 100% 50 40 25 20 15 20 20 20 20 15 10 20 10 15 20 30 20 30 400

Mobilink Eng Decision (Satisfactory)

Вам также может понравиться

- 4263 SQI New ID - RT GDДокумент102 страницы4263 SQI New ID - RT GDMohamed SaidОценок пока нет

- SQIДокумент84 страницыSQIEng-Mohamed SaifОценок пока нет

- Daily Progress Report As On 25.07.16Документ2 страницыDaily Progress Report As On 25.07.16துரைராஜ் இலட்சுமணன்Оценок пока нет

- Functional test checklist for critical site infrastructureДокумент4 страницыFunctional test checklist for critical site infrastructureHassan Mody TotaОценок пока нет

- Optimize UFONE PM site checks withДокумент14 страницOptimize UFONE PM site checks withAmjad AzeemiОценок пока нет

- Kalsel 2 x 65MW power plant scheduleДокумент1 страницаKalsel 2 x 65MW power plant schedulePrastya DeejayОценок пока нет

- ENMED301055EN - Flite 210 - 042013Документ2 страницыENMED301055EN - Flite 210 - 042013Tirthankar DattaОценок пока нет

- PM Checklist: Visit Date: Time In: Time Out: Responsible PM Staff Name Responsible NOC Staff NameДокумент107 страницPM Checklist: Visit Date: Time In: Time Out: Responsible PM Staff Name Responsible NOC Staff NameKeiko JeyaОценок пока нет

- Maintenace ScheduleДокумент48 страницMaintenace ScheduleRanu JanuarОценок пока нет

- Execution of Hydro Power Plant - PLANNING AND OPERATIONДокумент49 страницExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaОценок пока нет

- Emergency Siren System-T 128 ManualДокумент42 страницыEmergency Siren System-T 128 ManualUsman Zouque100% (1)

- (A) Transformer Specification SheetДокумент2 страницы(A) Transformer Specification SheetPranay KharbeОценок пока нет

- Substation Commissioning Procedures PDFДокумент65 страницSubstation Commissioning Procedures PDFGanesan Anand100% (2)

- Electrical and Instrumentation Specifications for Water Supply ProjectДокумент36 страницElectrical and Instrumentation Specifications for Water Supply ProjectPrashant MohokarОценок пока нет

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateДокумент46 страницElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Project Electrical Boq Feb 10-1Документ40 страницProject Electrical Boq Feb 10-1Vijaya Sarathi RaviОценок пока нет

- Checklist of C&i For Full Load OperationДокумент9 страницChecklist of C&i For Full Load Operationrohit_me083Оценок пока нет

- PIU - Training ModuleДокумент23 страницыPIU - Training ModuleMohit Mahi100% (1)

- Questionnaire For Safety AuditДокумент5 страницQuestionnaire For Safety Auditakhilesh_kabra17100% (1)

- REcon Inverter SpecsДокумент3 страницыREcon Inverter SpecsVipin KhandelwalОценок пока нет

- RFQ for Transformers from SinotecДокумент6 страницRFQ for Transformers from Sinotecasim469Оценок пока нет

- Procedure for Power Receiving of Khabat Thermal Power PlantДокумент18 страницProcedure for Power Receiving of Khabat Thermal Power Plantkamil100% (1)

- Oral ExaminationДокумент14 страницOral ExaminationClarence Clar100% (2)

- Checklist For Erection Power TransformerДокумент6 страницChecklist For Erection Power Transformersasikumar67% (3)

- Commissioning Proc. Doc ListДокумент9 страницCommissioning Proc. Doc ListErlanggaBonaparte100% (1)

- Undercowl Pocket Guide RRДокумент32 страницыUndercowl Pocket Guide RRbnmmauricio100% (3)

- R8538C KVTL 100Документ72 страницыR8538C KVTL 100Rinda_Rayna100% (1)

- MCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsДокумент8 страницMCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsjosecarlosvjОценок пока нет

- Air Conditioning Telecommunications ShelterДокумент16 страницAir Conditioning Telecommunications ShelterLuis Hewson100% (1)

- MCДокумент300 страницMCdiegobenitezОценок пока нет

- SK DIR PLN 520 Lampiran 1 Pedoman Pemeliharaan Transformator Tenaga Rev 2-1Документ53 страницыSK DIR PLN 520 Lampiran 1 Pedoman Pemeliharaan Transformator Tenaga Rev 2-1RCBM SMGОценок пока нет

- Timers Time Switches Hour Meters Supply Monitors PDFДокумент24 страницыTimers Time Switches Hour Meters Supply Monitors PDFanandsoggyОценок пока нет

- Inspection Test and Measurement Procedures For LV and MV Up To 36kV SwitchgearsДокумент5 страницInspection Test and Measurement Procedures For LV and MV Up To 36kV Switchgearspayolin77Оценок пока нет

- Vatech SB6-2YДокумент4 страницыVatech SB6-2YAlexander GuzmánОценок пока нет

- Mantto y ProbledddmrasДокумент24 страницыMantto y ProbledddmrasSandra AristaОценок пока нет

- G3516 (975 Ekw 1218 kVA)Документ7 страницG3516 (975 Ekw 1218 kVA)Antwon CharlesОценок пока нет

- Preventive Maintenance of Substation EquipmentДокумент37 страницPreventive Maintenance of Substation Equipmentameer036100% (3)

- Maintain HVDC Equipment EfficientlyДокумент19 страницMaintain HVDC Equipment EfficientlyDante FilhoОценок пока нет

- Timers, Time, Switches, Hour Meters & Supply MonitorsДокумент24 страницыTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarОценок пока нет

- Materials and ComponentsДокумент121 страницаMaterials and ComponentskishoreОценок пока нет

- Omicron CPC 100 BrochureДокумент48 страницOmicron CPC 100 Brochureharsha_iitm100% (1)

- Ds Acopos1022 1045 1090Документ19 страницDs Acopos1022 1045 1090Simon DrumsОценок пока нет

- Omicron CPC 100 BrochureДокумент48 страницOmicron CPC 100 BrochureMichael Angelo Vidal100% (1)

- 29fu1rg ZK CW 91aДокумент20 страниц29fu1rg ZK CW 91aNina PankovskaОценок пока нет

- Project WBS EstimateДокумент6 страницProject WBS EstimateSatria PinanditaОценок пока нет

- CPC 100 Brochure ENUДокумент48 страницCPC 100 Brochure ENUkenlavie1Оценок пока нет

- C18Документ6 страницC18Asif Mehmood100% (1)

- Datasheet K1010Документ11 страницDatasheet K1010Klema HanisОценок пока нет

- Technical Data Sheet: PXW Ac Ups SystemДокумент4 страницыTechnical Data Sheet: PXW Ac Ups SystemANKQОценок пока нет

- Uchc+Marb+Rtu 1 SFДокумент12 страницUchc+Marb+Rtu 1 SFDLFlowtechОценок пока нет

- Tuty Court Genset ESTIMATES NewДокумент42 страницыTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanОценок пока нет

- 60 PV 450Документ56 страниц60 PV 450Dan PrewittОценок пока нет

- RCB1200 :: ROAL Living EnergyДокумент10 страницRCB1200 :: ROAL Living EnergyroalscribdОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОт EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОценок пока нет

- Delta Rectifier PSC3Документ1 страницаDelta Rectifier PSC3Iftikhar HussainОценок пока нет

- Start Time NE Name Period (Min)Документ6 страницStart Time NE Name Period (Min)Iftikhar HussainОценок пока нет

- Muraad Saeed DegreeДокумент4 страницыMuraad Saeed DegreeIftikhar HussainОценок пока нет

- Cable Connectivity For V4, MX, Paso+ and C-NodeДокумент3 страницыCable Connectivity For V4, MX, Paso+ and C-NodeIftikhar HussainОценок пока нет

- Wireless equipment inventory listДокумент2 страницыWireless equipment inventory listIftikhar HussainОценок пока нет

- SCPC Two Dedicated Channels (Trans and RCV)Документ3 страницыSCPC Two Dedicated Channels (Trans and RCV)Iftikhar HussainОценок пока нет

- Genset OH Progress 2014Документ10 страницGenset OH Progress 2014Iftikhar HussainОценок пока нет

- S.No Site Name Site Code CityДокумент1 страницаS.No Site Name Site Code CityIftikhar HussainОценок пока нет

- EE 315 Electromagnetic Field TheoryДокумент2 страницыEE 315 Electromagnetic Field TheoryIftikhar HussainОценок пока нет

- Skilled Migrant Subclass 189 PointДокумент5 страницSkilled Migrant Subclass 189 Pointfamousp16Оценок пока нет

- Resume WritingДокумент3 страницыResume WritingIftikhar HussainОценок пока нет

- BSS HardwareДокумент1 страницаBSS HardwareIftikhar HussainОценок пока нет

- Clusture ZДокумент2 страницыClusture ZIftikhar HussainОценок пока нет

- Theft CasesДокумент1 страницаTheft CasesIftikhar HussainОценок пока нет

- Guards roster security personnelДокумент3 страницыGuards roster security personnelIftikhar HussainОценок пока нет

- Transformer Protection Relay GRE160 Brochure 12027-1 0Документ22 страницыTransformer Protection Relay GRE160 Brochure 12027-1 0tanujaayerОценок пока нет

- Durable and Powerful HF-525Plus X-ray SystemДокумент2 страницыDurable and Powerful HF-525Plus X-ray SystemVictor RiquelmeОценок пока нет

- AEG Electric Motors Mechanical Design and Technical SpecificationsДокумент13 страницAEG Electric Motors Mechanical Design and Technical SpecificationsJosé Eduardo Gaete DuarteОценок пока нет

- Computer Introduction (Fundamental Computer)Документ22 страницыComputer Introduction (Fundamental Computer)write2anoopОценок пока нет

- Micro MT Laser Tag System V18-01Документ19 страницMicro MT Laser Tag System V18-01Dylan SenkicОценок пока нет

- EV Charging Ali BahramiДокумент58 страницEV Charging Ali BahramiSenapathi TejaОценок пока нет

- PV-TJ - 225WpДокумент2 страницыPV-TJ - 225WpVenu GopalОценок пока нет

- 022 - 01 - 03 - Fuel GaugeДокумент2 страницы022 - 01 - 03 - Fuel GaugeJaucafoОценок пока нет

- 140-710 BIMG 11 - 2012 - TCM - 12-114679Документ144 страницы140-710 BIMG 11 - 2012 - TCM - 12-114679AbdulОценок пока нет

- Ira - c9070 - 7065i - Series PC 29 3 11Документ256 страницIra - c9070 - 7065i - Series PC 29 3 11Rabel Luciano100% (1)

- NoteДокумент264 страницыNoteBelayneh TadesseОценок пока нет

- Bearings Seals Greases Chapter 53 Page 762Документ13 страницBearings Seals Greases Chapter 53 Page 762AbdurhamanОценок пока нет

- D300Документ10 страницD300franciscotorosazoОценок пока нет

- Card Reading Accessories: Tps900 Eft PosДокумент2 страницыCard Reading Accessories: Tps900 Eft PosEris Osman RifkiОценок пока нет

- Book Parts E-WE 1204-55 INGДокумент138 страницBook Parts E-WE 1204-55 INGricardo assaf marchetiОценок пока нет

- Ultramatch Pro Src2496: User ManualДокумент16 страницUltramatch Pro Src2496: User ManualLuka TrengovskiОценок пока нет

- Installation, Operation and Maintenance Manual: APP Pumps (APP 16-22)Документ76 страницInstallation, Operation and Maintenance Manual: APP Pumps (APP 16-22)mbgprsmsОценок пока нет

- TURBO 400: Electromechanical Gear Motor For Sliding Gates Up To 4000 KG, 400 VacДокумент2 страницыTURBO 400: Electromechanical Gear Motor For Sliding Gates Up To 4000 KG, 400 VacAndri IrawanОценок пока нет

- Siłowniki UMB, Power-PackДокумент6 страницSiłowniki UMB, Power-PackLitsaОценок пока нет

- SL0005 Hydronix RangeДокумент6 страницSL0005 Hydronix RangeP.S.J.SarmaОценок пока нет

- How Do I Know If My Blower Relay Fuse Is BlownДокумент3 страницыHow Do I Know If My Blower Relay Fuse Is BlownWaleed MuzafarОценок пока нет

- Hyundai County 2002Документ158 страницHyundai County 2002Bigfair HD78100% (1)

- Schematic - 131675901 3512 Electronico PDFДокумент2 страницыSchematic - 131675901 3512 Electronico PDFkhanghanh2017 a0% (1)

- 11 KV Ring Main Units and AccessoriesДокумент35 страниц11 KV Ring Main Units and AccessoriesAbdus Salam0% (1)

- Honda GX 670 Propane Engine Ws Repair Manual 13zn10e4Документ20 страницHonda GX 670 Propane Engine Ws Repair Manual 13zn10e4annette100% (48)

- NMDC Limited Hyderabad: Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline ProjectДокумент935 страницNMDC Limited Hyderabad: Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline Projectarindam_925024954Оценок пока нет

- Amerex Vs Manual 13980hДокумент95 страницAmerex Vs Manual 13980hMiguel Carlin Jimenez100% (1)

- Plan OrientationДокумент32 страницыPlan OrientationMoises RondonОценок пока нет

- BobcatДокумент3 страницыBobcatJorge CabreraОценок пока нет

- Sumex Drill BrochureДокумент2 страницыSumex Drill Brochurealexandresjr7Оценок пока нет