Академический Документы

Профессиональный Документы

Культура Документы

Stagepas500 SM C

Загружено:

Jeff BrintonИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stagepas500 SM C

Загружено:

Jeff BrintonАвторское право:

Доступные форматы

STAGEPAS 500

SERVICE MANUAL

Speaker

Mixer

Speaker

CONTENTS

SPECIFICATIONS ............................................... 3

PANEL LAYOUT .................................. 4

DIMENSIONS ......................................................... 4

CIRCUIT BOARD LAYOUT .............. 5

DISASSEMBLY PROCEDURE ........................... 6

LSI PIN DESCRIPTIONLSI ............................ 16

IC BLOCK DIAGRAMIC................................. 18

CIRCUIT BOARDS ..................................... 19

INSPECTIONS ......................................................... 27

ADJUSTMENT OF AMPLIFIER UNIT

..................................................... 30

FACTORY SETTING .................................. 30

TROUBLE SHOOTING ............ 31

PARTS LIST

BLOCK DIAGRAM

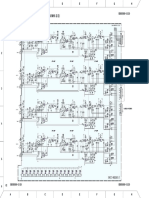

CIRCUIT DIAGRAM

PA 011840

200612-155400

HAMAMATSU, JAPAN

Copyright (c) Yamaha Corporation. All rights reserved. PDF

07.01

STAGEPAS 500

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that basic

service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the users,

and have therefore not been restated.

WARNING :

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components and failure of the product to perform as specified. For these reasons, we advise

all Yamaha product owners that all service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

IMPORTANT :

This presentation or sale of this manual to any individual or firm does not constitute authorization certification,

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and changes in

specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the

distributors Service Division.

WARNING :

Static discharges can destroy expensive components. Discharge any static electricity your body may have accumulated

by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to this bus.)

IMPORTANT :

Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where applicable)

components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly other entities) to cause

cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/

flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance

with the following code:

GREEN-AND-YELLOW

: EARTH

BLUE

: NEUTRAL

BROWN

: LIVE

As the colours of the wires in the mains lead of this apparatus may not

correspond with the coloured markings identifying the terminals in your plug

proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to the

terminal in the plug which is marked by the letter E or by the safety earth

symbol

or colored GREEN or GREEN-and-YELLOW.

The wire which is coloured BLUE must be connected to the terminal which is

marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal which is

marked with the letter L or coloured RED.

WARNING

Components having special characteristics are marked

originally installed.

and must be replaced with parts having specification equal to those

STAGEPAS 500

SPECIFICATIONS

General Specifications

Maximum Output Power

250 W+250 W (10 %)/4 @10 % THD at 1 kHz (SPEAKER L/R)

200 W+200 W/4 @1 % THD at 1 kHz (SPEAKER L/R)

Maximum Output Level

116 dB (1 m)

Frequency Response (Nominal output level @ 1 kHz)

-3 dB, 0 dB, +1 dB @20 Hz20 kHz (MUSIC/SPEECH=MUSIC)

(MONITOR OUT)

-3 dB, 0 dB, +1 dB @80 Hz20 kHz (MUSIC/SPEECH=SPEECH)

(REC OUT)

-3 dB, 0 dB, +1 dB @20 Hz20 kHz, 1 W Output

(MUSIC/SPEECH=MUSIC, without Speaker EQ)

(SPEAKERS L/R)

Total Harmonic Distortion

250W+250W(10%)/4 @10% THD at 1kHz (SPEAKERS L/R)

200W+200W/4 @1% THD at 1kHz (SPEAKERS L/R)

116dB (1m)

( @1kHz)

-3dB, 0dB, +1dB @20Hz20kHz (MUSIC/SPEECH=MUSIC)

(MONITOR OUT)

-3dB, 0dB, +1dB @80Hz20kHz (MUSIC/SPEECH=SPEECH)

(REC OUT)

-3dB, 0dB, +1dB @20Hz20kHz, 1W

(MUSIC/SPEECH=MUSIC, EQ)

(SPEAKERS L/R)

0.5 % @20 Hz, 1 kHz, 20 kHz, +14 dBu GAIN=nominal

(MONITOR OUT, REC OUT)

0.5% @20Hz, 1kHz, 20kHz +14dBu GAIN=

(MONITOR OUT, REC OUT)

Hum & Noise (Equivalent Input Noise, Rs=150 , MIC/LINE=MIC)

&(, Rs=150, MIC/LINE=MIC)

-106 dBu (CH1/2)

-112 dBu (CH3/4)

-65 dBu Residual output noise (SPEAKERS L/R)

Crosstalk (1 kHz)

-70 dB between input channels

Phantom Voltage

+15 V (CH14)

LIMIT/COMP switch

ON=Comp, OFF=Limit (CH1/2)

Power Consumption

65 W

Weight

24 kg (Speaker x 2 + Powered Mixer)

Stereo Input Channel Equalization

15 dB

HIGH 10 kHz shelving

LOW 100 Hz shelving

Accessories

Power Cable, Speaker Cable, Owners Manual

Option

Microphone

Speakers (500S)

Enclosure

2 way bass-reflex type, Polypropylene, Black

Crossover Frequency

4.0 kHz (LF: 12 dB/oct, HF: 12 dB/oct)

Frequency Range

55 Hz20 kHz (-10 dB)

Speaker Unit

LF: 10" (25 cm) Cone

HF: 1" (2.54 cm) Compression Driver

-106dBu (CH1/2)

-112dBu (CH3/4)

-65dBu (SPEAKERS L/R)

(1 kHz)

-70 dB

+15V (CH1-4)

LIMIT/COMP

ON=, OFF=(CH1/2)

65 W

24 kg (2)

(15 dB)

HIGH: 10kHz

LOW: 100Hz

(500S)

2-way, ,

4.0kHz (LF:12dB/oct, HF:12dB/oct)

55Hz20kHz (-10dB)

LF: 10" (25 cm)

HF: 1" (2.54 cm)

STAGEPAS 500

PANEL LAYOUT

MASTER

q [AC IN] jack ([AC IN])

w [POWER] switch ([POWER])

e [SPEAKERS L/R] jacks (for included speakers (500S) only)

([SPEAKERS L/R]((500S)))

r [REC OUT L/R] jacks ([REC OUT L/R])

t [MONITOR OUT L(MONO)/R] jacks

([MONITOR OUT L(MONO)/R])

y Channel input jacks (CH 1 to 4)

( (CH 14))

u Stereo channel input jacks (CH 5/6, 7/8, 9/10)

((CH 5/67/89/10))

i [MIC/LINE] switches ([MIC/LINE])

o [PHANTOM] switch ([PHANTOM])

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

5/6

7/8

9/10

[LIMIT/COMP] switches ([LIMIT/COMP])

Equalizer [HIGH]/[LOW] (EQ())

[REVERB] switches ([REVERB])

[REVERB] control ([REVERB])

[LEVEL] controls ([LEVEL])

[MASTER LEVEL] control

([MASTER LEVEL])

[SPEECH/MUSIC] switch

([SPEECH/MUSIC])

[MONITOR OUT] control

([MONITOR OUT])

[LEVEL] meter ([LEVEL])

[POWER] indicator ([POWER])

DIMENSIONS

Mixer

2

1

MASTER

175

152

342

2-M8 x 25

330

544.5

5/6

7/8

9/10

Speaker

111.5

298

120

Unit: mm

STAGEPAS 500

CIRCUIT BOARD LAYOUT

Front view

Right side view

Speaker HF <Tweeter>

HF <>

NETWORK

NETWORK

POWER

DSP

CONTROL1 (1/3)

CONTROL2 (2/3)

CONTROL3 (3/3)

AMP

JACK

Speaker LF <Woofer>

LF <>

Rear view

CONTROL1 (1/3)

POWER

CONTROL2 (2/3)

DSP

CONTROL3 (3/3)

AMP

JACK

STAGEPAS 500

DISASSEMBLY PROCEDURE

1.

Front Grille Assembly

1.

Ass'y 1

1-1

1-1

(Time required: About 1 minute)

Remove the four (4) screws marked [190]. The front

grille assembly can then be removed. (Fig. 1)

[190]4Ass'y

1

2.

2.

Speaker LF (Woofer)

2-1

2-2

LF

2

Ass'y 1

[170A] 8 LF

1

LF

LF 1

2-1

2-2

2-3

3.

3-1

3-2

3-3

*

(Time required: About 2 minutes)

Remove the front grille assembly. (See procedure 1)

Remove the eight (8) screws marked [170A]. The

speaker LF (woofer) can then be removed. (Fig. 1)

Remove the wire LF (red/black) attached to the

speaker LF (woofer). (Photo 1)

Front Cabinet Unit, Rear Cabinet Unit

(Time required: About 2 minutes)

Remove the fourteen (14) screws marked [150A].

The front cabinet unit and rear cabinet unit can then

be separated. (Fig. 1, Fig. 2)

Remove the wire LF (red/black) attached to the

speaker LF (woofer). (Photo 1)

Remove the wire HF (yellow/blue) attached to the

speaker HF (tweeter). (Photo 2)

Take care not to open the front cabinet unit and

rear cabinet unit too wide or the speaker LF

(woofer) terminal and speaker HF (tweeter)

terminal may be damaged.

<Front view>

2-3

3.

3-1

[150A] 14

12

LF

LF 1

HF

HF

2

LF

HF

3-2

3-3

<Rear view>

[170A]

[150A]

Front cabinet unit

()

[150A]

[150A]

[190]

Rear cabinet unit

()

[190]

Front grille assembly

(Ass'y)

Speaker LF (Woofer)

(LF ())

[170A]

[150A]

[170A]

[150A]

[190]

[190]

[150A]

[150A]

[170A]

[150A]

[170A]: Bind Head Tapping Screw-PP BIND

5.0X18 BL CR3 (WJ559700)

[190]: Bind Head Tapping Screw-PP BIND

4.0X12 NI-BL (WJ329500)

Fig.1 ( 1)

[150A]: Bind Head Tapping Screw-AA BIND

5.0X45 NI-BL (WJ329900)

Fig.2 ( 2)

STAGEPAS 500

Speaker HF (Tweeter)

(HF())

Speaker LF (Woofer)

(LF())

Wire LF (Black)

(LF())

Wire LF (Red)

(LF())

Wire HF (Yellow)

(HF())

Wire HF (Blue)

(HF())

Photo 1 ( 1)

4.

4-1

4-2

5.

5-1

5-2

5-3

5-4

Photo 2 ( 2)

Speaker HF (Tweeter)

4.

HF

(Time required: About 3 minutes)

Separate the front cabinet unit and rear cabinet unit.

(See procedure 3)

Remove the two (2) screws marked [140]. The

speaker HF (tweeter) can then be removed from

the front cabinet unit. (Photo 3)

4-1

3

[140] 2

HF

3

Network Assembly, NETWORK Circuit

Board (Time required: About 4 minutes)

5.

Separate the front cabinet unit and rear cabinet unit.

(See procedure 3)

Remove the SP connector assembly from the

network assembly. (Photo 4)

Remove the four (4) screws marked [30]. The

network assembly can then be removed from the

rear cabinet unit. (Photo 4)

Remove the four (4) screws marked [N40]. The

NETWORK circuit board can then be removed.

(Photo 4-1)

5-1

<Rear view>

4-2

Ass'yNETWORK

4

3

Ass'y SP

4

[30]4

Ass'y 4

[N40] 4 NETWORK

4-1

5-2

5-3

5-4

Network assembly

(Ass'y)

SP connector assembly

(SP)

Front cabinet unit

()

[140]

Rear cabinet unit

()

[30]

[30]

[30]:

Bind Head Tapping Screw-BB BIND

3.0X10 NI-BL (WJ329200)

Photo 4 ( 4)

Speaker HF

(Tweeter)

(HF

())

y

Network AssemblyAss

NETWORK

[N40]

[140]: Bind Head Tapping Screw-BB BIND

4.0X20 NI-BL (WJ329100)

Photo 3 ( 3)

[N40]

[N40]: Pan Head Tapping Screw-BB PAN

3.0X8 CR3 (WJ329000)

Photo 4-1 ( 4-1)

STAGEPAS 500

6.

Mixer Assembly, Cover Mold Assembly

6-1

7.

7-1

7-2

7-3

7-4

(Time required: About 1 minute)

Rotate the two (2) straight slots on the fastener

heads with a coin driver or minus driver until each

straight slot is in alignment with the OPEN position.

The mixer assembly or cover mold assembly can

then be removed. (Photo 5)

6.

6-1

JACK Circuit Board

7.

(Time required: About 1 minute)

Remove the mixer assembly or cover mold

assembly. (See procedure 6)

Remove the three (3) screws marked [50A]. The

mount bracket assembly can then be removed

together with the JACK circuit board. (Photo 6)

Remove the SP connector assembly from the JACK

circuit board. (Photo 6-1)

Remove the hexagonal nut marked [210a]. The

JACK circuit board can then be removed from the

mount bracket assembly. (Photo 6-1)

7-1

7-2

7-3

7-4

Ass'y Ass'y

1

2

OPENAss'y

Ass'y 5

JACK 1

Ass'y Ass'y

6

[50A] 3 JACK

Ass'y 6

JACK SP 6-1

[210a]1

Ass'y JACK

6-1

Fastner head

()

Fastner head

()

Coin driver or minus driver

(

)

Fastner head

()

Fastner head

()

Fastner head

()

Mixer assembly

(Ass'y)

Cover mold assembly

(Ass'y)

Photo 5 ( 5)

[210a]

Mount bracket assembly

(Ass'y)

Mount bracket assembly

(Ass'y)

[50A]

[50A]: Bind Head Tapping Screw-PP BIND

4.0X12 NI-BL (WJ329500)

Photo 6 ( 6)

JACK

SP connector assembly

(SP)

[210a]: Hexagonal NutM15.0 BL

Photo 6-1 ( 6-1)

STAGEPAS 500

8.

8-1

8-2

Rear Case

8.

(Time required: About 2 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the eight (8) screws marked [400]. The rear

case can then be removed from the mixer assembly.

(Photo 7)

8-1

8-2

2

Ass'y 6

[400] 8 Ass'y

7

9.

Shield Bracket 2

9.

9-1

9-2

9-3

(Time required: About 2 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the four (4) screws marked [380]. The

shield bracket 2 can then be removed. (Photo 8)

9-1

9-2

9-3

2 2

Ass'y 6

8

[380]42

8

10.

POWER Circuit Board

10.

10-1

10-2

10-3

10-4

(Time required: About 3 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the six (6) screws marked [290]. The POWER

circuit board can then be removed. (Photo 9)

10-1

10-2

10-3

10-4

Mixer AssemblyAss

y

POWER 3

Ass'y 6

8

2 9

[290] 6 POWER

9

Shield bracket 2 (2)

[400]

[380]

[380]

Rear case ()

[400]

[380]: Bind Head Tapping Screw-BB BIND

3.0X8 CR3 (AAX61980)

[400]: Hexagonal Tapping Screw-B B

3.0X8 NI-BL (AAX62010)

Photo 8 ( 8)

Photo 7 ( 7)

[290]

POWER

[290]

[290]: Pan Head Tapping Screw-BB PAN3.0X8 CR3 (WJ329000)

Photo 9 ( 9)

STAGEPAS 500

11.

11-1

11-2

11-3

11-4

DSP Circuit Board

11.

(Time required: About 2 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the DSP circuit board from the connectors

CN27 and CN33 of the CONTROL2 (2/3) circuit

board. (Photo 10)

11-1

11-2

11-3

11-4

CONTROL2 (2/3)

DSP 2

Ass'y 6

8

2 9

CONTROL2 (2/3)CN27CN33

DSP 10

[CN32]

[CN33]

DSP

[CN27]

[CN28]

Photo 10 ( 10)

12.

12-1

12-2

12-3

12-4

12-5

12-6

12-7

12-8

AMP Circuit Board, CONTROL3 (3/3)

Circuit Board (Time required: About 4 minutes)

12.

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the two (2) hexagonal nuts marked [240aA]

from the panel printing side. (Photo 11)

Remove the two (2) screws marked [270]. The

phone bracket can then be removed together with

the AMP circuit board and CONTROL3 (3/3) circuit

board. (Photo 12)

Remove the two (2) screws marked [260A]. The

AMP circuit board and CONTROL3 (3/3) circuit

board can then be removed from the phone bracket.

(Photo 13)

Remove the screw marked [260B]. The AMP circuit

board A can then be removed from the CONTROL3

(3/3) circuit board. (Photo 13)

Remove the screw marked [260C]. The AMP circuit

board B can then be removed from the CONTROL3

(3/3) circuit board. (Photo 13)

12-1

12-2

12-3

12-4

12-5

12-6

12-7

12-8

AMP CONTROL3 (3/3)

4

Ass'y 6

8

2 9

[240aA] 2

11

[ 2 7 0 ] 2 A M P

CONTROL3 (3/3)

12

[260A]2

AMP CONTROL3 (3/3)

13

[260B]1CONTROL3 (3/3)

AMP A 13

[260C]1CONTROL3 (3/3)

AMP B 13

CONTROL3 (3/3)

Panel assembly

(Ass'y)

[240aA]

[270]

AMP

[270]

Phone bracket ()

[240aA]: Hexagonal NutM15.0 BL

Photo 11 ( 11)

10

[270]: Bind Head Tapping Screw-BB BIND

3.0X8 CR3 (AAX61980)

Photo 12 ( 12)

STAGEPAS 500

[260A]

[260B]

[260C]

[260A]

CONTROL3 (3/3)

AMP B

Phone bracket

()

AMP A

[260A], [260B], [260C]: Bind Head Tapping Screw-BB BIND3.0X8 CR3 (AAX61980)

Photo 13 ( 13)

13.

13-1

13-2

13-3

13-4

13-5

Shield Bracket 1 Assembly

(Time required: About 4 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the two (2) each screws marked [P30]. The

two (2) handles can then be removed. (Photo 14,

Photo15, Photo16)

Remove the six (6) screws marked [170B] and two

(2) hexagonal nuts marked [240aB] from the panel

printing side. (Photo 17)

Remove the shield bracket 2. (See procedure 9)

13.

1 Ass'y

13-1

13-2

13-3

13-4

13-5

4

Ass'y 6

8

[P30] 2 2

14 15 16

[170B] 6 [240aB]

2 17

2 9

[P30]

[P30]: Bind Head Screw BINDM3.0X8 CR3

(AAX61910)

Photo 14 ( 14)

[P30]

[P30]: Bind Head Screw BINDM3.0X8 CR3

(AAX61910)

Photo 15 ( 15)

[170B]

[240aB]

Panel assembly

(Ass'y)

Handle ()

1

5

6

2

Photo 16 ( 16)

[170B]

[170B]: Bind Head Tapping Screw-BB BIND

3.0X10 NI-BL (WJ329200)

[240aB]: Hexagonal NutM15.0 BL

Photo 17 ( 17)

11

STAGEPAS 500

13-6

Disconnect the connectors CN801, CN802 and

CN803 of the POWER circuit board and the connector

CN542 of the CONTROL3 (3/3) circuit board. The

shield bracket 1 assembly (including AMP circuit

board, CONTROL3 (3/3) circuit board and POWER

circuit board) can then be removed. (Photo 18)

When installing the shield bracket 1 assembly,

tighten the screws marked [170B] in numerical

order ( ). (Photo 17)

Shield bracket 1

(1) [CN803]

[CN801]

CONTROL3 (3/3)

13-6

POWER CN801CN802CN803

CONTROL3 (3/3) CN542

1 Ass'yAMP

CONTROL3 (3/3)POWER

18

1 Ass'y

[170B]

17

Shield Bracket 1 Assembly1 Ass'y

POWER

CONTROL3 (3/3)

AMP

AMP

[CN542]

Shield bracket 1

(1)

POWER

[CN802]

Photo 18 ( 18)

14.

14-1

14-2

14-3

14-4

14-5

14.

CONTROL1 (1/3) Circuit Board

(Time required: About 8 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the shield bracket 1 assembly.

(See procedure 13)

Remove the ten (10) hexagonal nuts marked [140a],

ten (10) flat washers marked [140b] and ten (10)

screws marked [150B] from the panel printing side.

(Photo 19)

[140a], [140b]

CONTROL1 (1/3) 8

Ass'y 6

8

2 9

1 Ass'y

13

14-5 [140a] 10

[140b] 10 [150B] 10

19

14-1

14-2

14-3

14-4

[150B]

[150B]

Panel assembly

(Ass'y)

[140a], [140b]

[140a], [140b]

[140a], [140b]

[140a]: Hexagonal NutM11.0

[140b]: Flat WasherM9.2

[150B]: Bind Head Tapping Screw-BB BIND3.0X10 NI-BL (WJ329200)

Photo 19 ( 19)

12

STAGEPAS 500

14-6

Remove the CONTROL1 (1/3) circuit board from

the connectors CN21 and CN26 of the CONTROL2

(2/3) circuit board. (Photo 20)

The four (4) push buttons marked [120] and four

(4) push spacers marked [130] are not parts of

the CONTROL1 (1/3) circuit board. When

replacing the CONTROL1 (1/3) circuit board, be

sure to remove these parts and attach them to

the new CONTROL1 (1/3) circuit board. (Photo 21)

CONTROL1 (1/3)

14-6

CONTROL2 (2/3)CN21CN26

CONTROL1 (1/3) 20

[120] 4 [130]

4CONTROL1 (1/3)

CONTROL1 (1/3)

CONTROL1 (1/3)

21

[120]: Push button

()

[CN22]

[CN25]

[CN21]

[CN26]

[130]: Push spacer

()

CONTROL2 (2/3)

CONTROL1 (1/3)

Photo 21 ( 21)

Photo 20 ( 20)

15.

15-1

15-2

15-3

15-4

15-5

15-6

15-7

CONTROL2 (2/3) Circuit Board

15.

(Time required: About 9 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the DSP circuit board. (See procedure 11)

Remove the shield bracket 1 assembly.

(See procedure 13)

Remove the CONTROL1 (1/3) circuit board.

(See procedure 14)

Remove the seven (7) volume knobs (white) marked

[80] and the volume knob (red) marked [90] from

the panel printing side. (Photo 22)

15-1

15-2

15-3

15-4

15-5

CONTROL2 (2/3) 9

Ass'y 6

8

2 9

DSP 11

1 Ass'y

13

15-6 CONTROL1 (1/3)14

15-7 [80] VR7 [90]

VR1 22

[90]: Volume knob (Red)

(VR())

[80]: Volume knob (White)

(VR())

Panel assembly

(Ass'y)

Photo 22 ( 22)

13

STAGEPAS 500

15-8

Remove the five (5) screws marked [110]. The

CONTROL2 (2/3) circuit board can then be

removed. (Photo 23)

The following parts are not parts of the

CONTROL2 (2/3) circuit board. When replacing

the CONTROL2 (2/3) circuit board, be sure to

remove these parts and attach them to the new

CONTROL2 (2/3) circuit board. (Photo 24)

[40]: Push buttons

7 pcs.

[50B]: Volume knob (S) (white)

1 pc.

[60]: Volume knobs (S) (green) 14 pcs.

[70]: Volume knob (S) (blue)

1 pc.

[110]

CONTROL2 (2/3)

15-8

[110] 5 CONTROL2 (2/3)

23

CONTROL2 (2/3)

CONTROL2 (2/3)

CONTROL2 (2/3)

24

[40]:

7

[50B]: VRS

1

[60]: VRS

14

[70]: VRS

1

[50B]: Volume knob (S) (White) [70]: Volume knob (S) (Blue) (VR(S)())

[40]: Push button ()

(VR(S)())

[110]

[110]: Bind Head Screw BIND

M3.0X8 CR3 (AAX61910)

[40]: Push button

()

16.

16-6

16-7

(Time required: About 5 minutes)

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the shield bracket 1 assembly.

(See procedure 13)

Remove the two (2) connector assemblies

(connector assembly (1P) and connector assembly

(2P)) and earth wire soldered to the power switch

and AC inlet. (Fig. 3)

Remove the power switch by pressing its claws. (Fig. 4)

Remove the AC inlet by pressing its claws. (Fig. 5)

17.

Fan (Time required: About 5 minutes)

17.

17-1

17-2

17-3

17-4

Remove the mixer assembly. (See procedure 6)

Remove the rear case. (See procedure 8)

Remove the shield bracket 2. (See procedure 9)

Remove the shield bracket 1 assembly.

(See procedure 13)

Remove the four (4) screws marked [210]. The fan

can then be removed from the shield bracket 1

assembly. (Photo 25)

The fan is fixed with two-sided tape. Apply

power little by little to remove the fan.

17-1

17-2

17-3

17-4

16-1

16-2

16-3

16-4

16-5

17-5

14

Power Switch, AC Inlet

[60]: Volume knob (S) (Green)

(VR(S)())

Photo 24 ( 24)

Photo 23 ( 23)

16.

CONTROL2 (2/3)

16-1

16-2

16-3

16-4

16-5

16-6

16-7

AC

5

Ass'y 6

8

2 9

1 Ass'y

13

AC

2 1P, 2P

3

4

AC 5

5

Ass'y 6

8

2 9

1 Ass'y

13

17-5 [210] 4 1

Ass'y 25

STAGEPAS 500

Soldering ()

Power switch

()

Panel ()

Connector assembly (1P) (brown)

( 1P ())

Earth wire (green)

( ())

AC inlet

(AC)

(brown)

()

Power switch

()

(blue)

()

Soldering

()

Connector assembly (2P)

( 2P)

Panel ()

Fig.3 ( 3)

Claw ()

Claw ()

Claw

()

Claw ()

AC inlet

(AC)

Panel ()

Fig.5 ( 5)

Fig.4 ( 4)

[210]

Fan ()

Shield bracket 1 assembly

(1 Ass'y)

[210]

[210]: Bind Head Tapping Screw-BB BIND3.0X20 NI-BL (WK008800)

Photo 25 ( 25)

15

STAGEPAS 500

LSI PIN DESCRIPTIONLSI

YMW767-VTZ (X6055A00) CPU (SWL01B)

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

16

NAME

I/O

Vss

I

I

I

I

I

I

O

I

O

I

I

I

I

I

I

I

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

O

I

O

I

I

O

I

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

TESTN

PLLBPN

PLLVDD

CIN

PLLVss

TRSTN

TMS

TCK

TDI

TDO

XI

XO

Vss

VDD

ICN

ECSN

EWRN/PD5

ERDN/PD4

EA3/PD3

EA2/PD2

EA1/PD1

EA0/PD0

IOVDD

ED0/PC0

ED1/PC1

ED2/PC2

ED3/PC3

ED4/PC4

ED5/PC5

ED6/PC6

ED7/PC7

Vss

IRQ0N/PH0

TxD0

RxD0

TxD1/PG2

RxD1/PH1

SCLK1/PH2

SDO

SDI/PH3

BCLK

WCLK/SYO

SYSCLK/PG3

Vss

VDD

IOVDD

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

Vss

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7/SYI

FUNCTION

Ground

Input for TEST

PLL bypass select

PLL Power supply +2.5 V

Capacitor terminal for PLL

PLL Ground

JTAG input

JTAG output

Crystal oscillator

Crystal oscillator

Ground

Power supply +2.5 V

Hardware reset

CPU I/F chip select

CPU I/F write enable / Port D

CPU I/F read enable / Port D

CPU I/F address bus / Port D

Power supply +3.3 V

CPU I/F data bus / Port C

Ground

Interrupt input / Port H

Serial output

Serial input

Serial output / Port G

Serial input / Port H

External synchronization clock / Port H

Serial output

Serial input / Port H

Bit clock output

Word clock output

Clock output / Port G

Ground

Power supply +2.5 V

Power supply +3.3 V

I/O port A

Ground

I/O port B

DSP: IC1007

PIN

NO.

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

NAME

I/O

Vss

IOVDD

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

LBN/LWRN/PF6

UBN/UWRN/PF7

RDN/PF4

MD00

MD08

MD01

MD09

MD02

MD10

MD03

Vss

MD11

MD04

MD12

MD05

MD13

MD06

MD14

MD07

MD15

WRN/PF5

Vss

VDD

IOVDD

MA17

MA16

MA15

MA14

MA13

MA12

MA11

MA10

MA09

MA08

MA07

MA06

MA05

Vss

MA04

MA03

MA02

MA01

CS0N/PG0

MA18

MA19

MA21/PF1

MA22/PF2

MA20

MA23/PF3

CSIN/PG1

MA00/PF0

Vss

VDD

IOVDD

CS2N/PE0

CS3N/PE1

CS4N/CASN/PE2

CS5N/PE3

CS50RDN/PE4

CS51WRN/PE5

CS52WRN/PE6

CS53WRN/RASN/PE7

FUNCTION

Ground

Power supply +3.3 V

External memory lower-byte enable / Port F

External memory upper-byte enable / Port F

External memory read enable / Port F

External memory data bus

Ground

External memory data bus

Ground

Power supply +2.5 V

Power supply +3.3 V

External memory address bus

Ground

External memory address bus

External memory chip select / Port G

External memory address bus

External memory address bus / Port F

External memory address bus

External memory address bus / Port F

External memory chip select / Port G

External memory address bus / Port F

Ground

Power supply +2.5 V

Power supply +3.3 V

External memory chip select / Port E

STAGEPAS 500

AK5381VT (X8575A00) ADC (Analog to Digital Converter)

PIN

NO.

NAME

I/O

1

2

3

4

5

6

7

8

AINR

AINL

CKS1

VCOM

AGND

VA

VD

DGND

I

I

I

O

-

FUNCTION

Rch Analog input pin

Lch Analog input pin

Mode select 1 pin

Common voltage output pin

Analog ground

Analog power supply +5V

Digital power supply +3.3V

Digital ground

PIN

NO.

NAME

I/O

9

10

11

12

13

14

15

16

SDTO

LRCK

MCLK

SCLK

PDN

DIF

CKS2

CKS0

O

I/O

I

I/O

I

I

I

I

DSP: IC1004

DAC1A:

IC401

FUNCTION

Audio serial data output pin

Output channel clock pin

Master clock input pin

Audio serial data clock pin

Power down mode pin

Audio interface format pin

Mode select 2 pin

Mode select 0 pin

PCM1742EK (X8574A00) DAC (Digital to Analog Converter)

PIN

NO.

NAME

I/O

FUNCTION

1

2

3

4

5

6

7

8

BCK

DATA

LRCK

DGND

VDD

Vcc

VOUTL

VOUTR

I

I

I

O

O

Audio data bit clock input

Audio data digital input

L-channel and R-channel audio-data latch-enable input

Digital ground

Digital power supply +3.3V

Analog power supply +5V

Analog output for L-channel

Analog output for R-channel

PIN

NO.

NAME

9

AGND

10

VcoM

11 ZEROR/ZEROA

12 ZEROL/NA

13

MD

14

MC

15

ML

16

SCK

DSP: IC1008

DAC1A:

IC401

I/O

FUNCTION

O

O

I

I

I

I

Analog ground

Common voltage decoupling

Zero-flag output for R-channel/Zero-flag output for L-/R-channel

Zero-flag output for L-channel/No assign

Mode control data input

Mode control clock input

Mode control latch input

System clock input

17

STAGEPAS 500

IC BLOCK DIAGRAMIC

FA3641N (X8570A00)

PWM Control

CS

VCC

POWER: IC803

REF 7

5V

ENB

1

FB

REF

IS(+)/IS(-)

VCC

GND

OUT

15.5V

UVLO

15.5V

5V REF

RTRch

6.5 A

0.82V~0.68V

+

VCC

CS

0.9mA

+

8.5V~7.9V

16.5V/9V

0.8V

ENB

3.0V

+

4V

OUT

GND

OUTPUT

FB

PWM

+

Dmax

OSC

70%

FF

RM RT

R

0.24V

RT

IS +

QB

Q

LB1407-E LF (AAX68710)

AC/DC Voltage Level Meter

CONTROL2 (2/3): IC604

12, 11, 10, 9

Vref Vcc Rch

3

Vcc

14

D7

Rch

13

D6

Vref

12

D5

--

IN+

11

D4

IN--

10

D3

OUT

D2

GND

D1

IN +

IN --

OUT

GND

D6

D1

14

13

R7

R6

R1

5.83 k

4.12 k

1 k

-COM

7

-COM

6

COM

1

NJM2068M-D TE1 (AAX62750)

Dual Operational Amplifier

PC494GS-T2-A (X8569A00)

Switching Regulator

CONTROL1 (1/3): IC101, 201, 501, 701, 704

CONTROL2 (2/3): IC102, 104-106, 108, 202,

203, 205, 206, 302, 402,

502, 503, 702, 703, 901,

902

CONTROL3 (3/3): IC541, 542

IC103, 107, 204, 603, 1009,

DSP:

1011

POWER: IC802

Output A

Inverting

Input A

Non-Inverting

Input A

-DC Voltage Supply

18

D7

+V

3

4

+

+

-V

+DC Voltage

Supply

Output B

6

5

Inverting

Input B

Non-Inverting

Input B

Non-Inv. Inv.

Input Input

16

15

Ref

Out

Output

Control

Vcc

C2

E2

E1

14

13

12

11

10

ERROR

AMP

2

ERROR

AMP

1

Non-Inv. Inv.

Input Input

REFERENCE

REGULATOR

OSCILLATOR

0.1V

3

FeedBack

DeadTime

Control

CT

RT

GND

C1

STAGEPAS 500

INSPECTIONS

1.

Test Conditions

Measuring Voitage:

AC 100 V 50/60 Hz (J)

AC 120 V 60 Hz (U, C)

AC 230 V 50 Hz (B, H)

AC 220 V 50 Hz (O)

Load:

4

Input:

1 KHz

MASTER LEVEL VR VR:

MAX.

Tone-control VR VR:

HIGH, LOW = All channel Center.

REVERB SW SW:

All channel OFF.

REVERB level VR:

MIN.

SPEECH/MUSIC SW / SW: MUSIC

LIMIT/COMP SW / SW:

LIMIT

USE MEASUREMENT FILTER:

DIN-Audio

PHANTOM SW SW:

OFF

NOTE:

q Use a low pass filter (20 KHz) to measure noise at the SP jack (SPEAKERS).

SP SPEAKERS20 KHz

w The sleeve of the SPEAKERS Lch is the hot terminal. So, pay attention not to let it

contact GND.

SPEAKERS Lch

Sleeve

Tip

2.

Electric Characteristic

ITEM

1 OUTPUT POWER

INPUT CONDITIONS

INPUT1-SW=LINE

INPUT1-LEVEL=NOMINBAL

INPUT1-SW=LINE

INPUT1-LEVEL=MAX.

No.

T. H. D.

INPUT1-SW=LINE

INPUT1-LEVEL=MAX.

OUTPUT CONDITIONS

SP OUT:

L, R

1 %THD OUTPUT

1 %

20-20KHz FILTER

SP OUT:

L, R

50 W OUTPUT

50 W

MONITOR OUT:

L, R

+14 dBu OUTPUT

(Load: 10 k)

NOMINAL

210 W

LIMIT

>200 W

0.5 %

<1 %

0.1 %

<0.5 %

27

STAGEPAS 500

ITEM

3 INPUT SENSITIVITY

No.

INPUT CONDITIONS

INPUT 1, 2, 3, 4 (Each)

INPUT=XLR

INPUT-SW=LINE

INPUT-LEVEL=MAX.

OUTPUT CONDITIONS

SP OUT:

L, R

REF: 200 W OUTPUT

MONITOR OUT:

L

+4 dBu OUTPUT

(Load: 10 k)

MONITOR OUT:

L

+4 dBu OUTPUT

(Load: 10 k)

INPUT 1, 2, 3, 4 (Each)

INPUT=XLR

INPUT-SW=MIC

INPUT-LEVEL=MAX.

INPUT 1, 2, 3, 4 (Each)

L

INPUT=PHONE

INPUT-SW=LINE

INPUT-LEVEL=MAX.

INPUT 5 and 6, 7 and 8

L, R

(Each pair)

INPUT=PHONE, RCA

INPUT-LEVEL=MAX.

INPUT 9 and 10 (Each)

REC OUT:

L, R

INPUT=RCA

-10 dBV OUTPUT

INPUT-LEVEL=MAX.

(Load: 10 k)

4 LIMIT/COMP SW

INPUT 1, 2

MONITOR OUT:

L

/ INPUT=PHONE

+4 dBu OUTPUT

INPUT-SW=LINE

(Load: 10 k)

INPUT-LEVEL=MAX.

LIMIT/COMP SW=COMP

5 FREQUENCY

INPUT:

60 Hz

SP OUT:

L, R

RESPONSE

1, 2, 3, 4 (Each)

REF: 1 KHz, 1W OUTPUT

INPUT=XLR

: 1 KHz, 1W

INPUT-SW=LINE

10 KHz

INPUT-LEVEL=MAX.

INPUT:

60 Hz

SP OUT:

L, R

5 and 6, 7 and 8,

REF: 1 KHz, 1W OUTPUT

9 and 10 (Each pair)

: 1 KHz, 1W

INPUT=PHONE, RCA

10 KHz

INPUT-LEVEL=MAX.

6 TONE-CONTROL

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

REF: 300 mV RECOUT

CHARACTERISTIC

(Each)

: 300 mV RECOUT

LOW=MIN.

(Load: 10 k)

REF: 30 Hz, LOW VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

LOW=MAX.

REF: 30 Hz, LOW VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

HIGH=MIN.

REF: 30 KHz, HIGH VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

HIGH=MAX.

REF: 30 KHz, HIGH VR CENTER

INPUT1

HIGH, LOW VR CENTER

SPEECH/MUSIC=SPEECH

REF: 80 Hz, MUSIC MODE

28

NOMINAL

-23 dBu

LIMIT

-23 dBu2 dB

-30 dBu

-30 dBu2 dB

-60 dBu

-60 dBu2 dB

-20 dBu

-20 dBu2 dB

-20 dBu

-20 dBu2 dB

-20 dBu

-20 dBu2 dB

-25 dBu

-24 dBu2 dB

+5.0 dB

+4.02 dB

+1 dB

+12 dB

+5.0 dB

+4.02 dB

+1 dB

+12 dB

-15.0 dB

-15.02 dB

+15.0 dB

+15.02 dB

-15.0 dB

-15.02 dB

+15.0 dB

+15.02 dB

-3.0 dB

-3.02 dB

STAGEPAS 500

ITEM

7 CROSSTALK

No.

SIGNAL TO NOISE

RATIO

9 RESIDUAL NOISE

10

PHANTOM VOLTAGE

11 LEVEL METER

INDICATION

12 POWER CONSUMPTION

INPUT CONDITIONS

INPUT 1, 2, 3, 4, 5, 6, 7, 8 to

Adjacent INPUT

CH

HIGH, LOW VR CENTER

INPUT SHORT

INPUT-SW=LINE

MASTER-LEVEL=MIN.

SW-MIC

INPUT=XLR

INPUT IMPEDANCE=150

PHANTOM SW=ON

INPUT1

OUTPUT CONDITIONS

SP OUT:

REF: 1 KHz, 200 W OUTPUT

: 1 KHz, 200 W

(MEASURE WITH 20 KHz LPF)

SP OUT:

SP OUT

REF: 100 W OUTPUT MONITOR

: 100 W

OUT

SP OUT

NOMINAL

75 dB

LIMIT

>70 dB

53dB

95dB

>50 dB

>90 dB

-54 dBu

<-50 dBu

SP OUT

(MEASURE WITH 20 KHz LPF AES17)

CH1-4 XLR w-q

e-q

SP OUT:

REF: LEVEL METER=0

LEVEL METER0

SP OUT:

REF: 25 W OUTPUT

-70 dBu

<-65 dBu

15V

15V1V

22 dBu

22 dBu2 dB

90 W

<93 W

(NOTE): 0 dBu=0.775 V

3.

Overload Protection

The product shall be set to 25 W output on SP OUT.

When + and - of SP OUT short-circuit, the product should stop the output and should blink POWER LED.

* Cycle power (turn off and then on the POWER switch) to return to normal operation.

SP OUT 25 W SP OUT SP OUT POWER LED

POWER OFF ON

DC Detection Circuit ProtectionDC

When DC is detected in AMP output, the power latch circuit is activated to turn off the power. In this case, it is

impossible to turn on the power until the power switch is turned off to discharge the capacitors C806 to C809. (It will

take about 10 minutes to discharge.)

AMP DC OFF POWER

OFF C806 C809 10

Temperature Elevation Protection

When the temperature of the TH803 (temperature of the heat sink) is 70 C or more, the protection circuit is activated

to turn off the output. The output will be automatically turned on when the temperature comes down.

TH803 70 OFF

POWER Circuit Board

TH803

Part of the TH803

TH803

29

STAGEPAS 500

4.

Limiter Indication

The product shall be set to 32 dBu output on SP OUT.

Then, LIMITER LED(RED) should light on and all LEDs of LEVEL meter should light on.

SP OUT 32 dBu LIMITER LEDLEVEL LED

ADJUSTMENT OF AMPLIFIER UNIT

1.

2.

Connect a 4 of dummy resistor to the SPEAKERS

jacks.

After turning on the power, wait more than 60

seconds until performance is stabilized. Then, adjust

the trimmer potentiometer to make the voltage

across the dummy resistor 3 mV or less.

1.

2.

SPEAKERS4

ON 60

3 mV

AMP Circuit Board

Part of the trimmer potentiometer

FACTORY SETTING

POWER switchPOWER :

MASTER LEVEL volumeMASTER LEVEL :

LEVEL CH 1-10 volumeLEVEL CH 1-10 :

SPEECH/MUSIC switchSPEECH/MUSIC :

REVERB switchREVERB :

LIMIT/COMP switchLIMIT/COMP :

REVERB volumeREVERB :

MONITOR OUT volumeMONITOR OUT :

Equalizer HIGH, LOW volume HIGH, LOW :

MIC/LINE switchMIC/LINE :

PHANTOM switchPHANTOM :

30

OFF

MIN.

MIN.

MUSIC

OFF

LIMIT

MIN.

MIN.

CENTER

MIC

OFF

STAGEPAS 500

TROUBLE SHOOTING

Points marked by A to L in the figure of circuit board are the points to be checked as indicated by the

same marks in the flowchart on the next page or after.

A L

POWER Circuit Board

D , E , F

to CONTROL2

(2/3)-CN1

B ,C

AC IN

Component side

CONTROL3 (3/3) Circuit Board

K

H

Component side

31

STAGEPAS 500

Trouble

Shooting (POWER circuit board)

Note: Check and repair must be done carefully, otherwise the electrical shock may be caused.

[ ]

START

< Fuse: Primary >

A

F801 (Fuse)

OPEN ?

Yes

< Power Supply: -VB >

< Power Supply: +15 V >

< Power Supply: +5 V >

< Power Supply: -15 V >

B

CN804: 1 pin

<+VB> about +44 V(DC)

?

No

Yes

CN804: 3 pin

<-VB> about -44 V(DC)

?

Yes

No

CN802: 2 pin

about +15 V (DC)

?

Yes

No

CN802: 3 pin

about +5 V (DC)

?

Yes

No

CN802: 1 pin

about -15 V (DC)

?

Yes

*Discharge [ ]: +VB,-VB

820 3W

PGND

+VB (-VB)

discharge 1 minute [1]

< Power Circuit Board >

No Load []

No

< Power Supply: +VB >

Check

IC804,D816-819

and peripheral

IC804,D816-819

Check

IC806 and peripheral

IC806

Check

IC805,D816-819

and peripheral

No

IC805,D816-819

*Disconnect AC plug from the wall outlet

before discharging electricity.

[AC

]

< CONTROL3 (3/3) Circuit Board >

Connect the circuit boards. ("CONTROL3 (3/3): CN804-CN541", "AMP (L ch)", "AMP (R ch)")

"CONTROL3 (3/3): CN804-CN541""AMP (L ch)""AMP (R ch)"

< L ch: VDR >

CN543: 3 pin

<VDR> about -35 V (DC)

?

[ AMP ]

Yes

GND: 2124 820/50V (+)

< R ch: VDR >

Check

Q556,D543,R594,R595

Q556,D543,R594,R595

CN545: 3 pin

<VDR> about -35 V (DC)

?

[ AMP ]

Yes

GND: 2124 820/50V (+)

1

32

No

No

Check

Q557,D544,R596,R597

Q557,D544,R596,R597

STAGEPAS 500

< FAN > < Signal Path > < Power LED >

Connect the circuit boards("CONTROL1 (1/3)", "DSP", "CONTROL2 (2/3):CN542-CN24") and a fan.

"CONTROL1(1/3)""DSP""CONTROL2(2/3):CN542-CN24" FAN

Yes

Power LED=BLINKING

[]

?

No

POWER switch: OFF

ON

No

Power LED=BLINKING

[]

?

No ( Q549: ON )

Yes

I

Power LED = ON

[]

?

Yes

( Q549: OFF )

CN544: 11 pin

(CN546: 11 pin)

OUTPUT OK

?

( Q545: OFF )

Q545:

No

Base = 0.6 V (DC)

?

AMP

J

No

Power LED = ON

[]

?

Yes

Yes

Replace the AMP circuit boards.

AMP

Yes ( Q545: ON )

< AMP:Operate Mode>

Replace the AMP circuit boards.

AMP

Q548: ON

No

Check

R564566, 568,569,572,573

R580583, 598

Q541545, 548

C561

L

Q548:

Base = 0 V

?

Q548:OFF

Yes

Check

R577579, 584587

Q550553

C563, 564

R564566,568,569,572,573

R580583,598

Q541545,548

C561

< CONTROL3 (3/3) Circuit Board >

No

Remove the AMP circuit boards.

R577579, 584587

Q550553

C563,564

Check

R563,567,570,571,574576, 535

Q546,547,558,559

C559,562,

D541,542

2

Replace the POWER circuit board.

R563,567,570,571,574576,535

Q546,547,558,559

C559,562,

D541,542

POWER

END

33

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Sap Inventory Query inДокумент4 страницыSap Inventory Query insathiyaspk043960Оценок пока нет

- Py Open GLДокумент324 страницыPy Open GLMartin Cruz OtinianoОценок пока нет

- Table of Specifications MediaДокумент2 страницыTable of Specifications MediaNover Keithley Sicay Mente100% (1)

- LTE in Unlicensed Spectrum: Trials, Deployments and DevicesДокумент18 страницLTE in Unlicensed Spectrum: Trials, Deployments and DevicesMuhammad Jamil Awan100% (1)

- EMX5000-12/20 Circuit DiagramДокумент3 страницыEMX5000-12/20 Circuit DiagramJeff BrintonОценок пока нет

- Emx5000-12/20 Circuit Diagram 2/9 (In8/in16 2/2)Документ2 страницыEmx5000-12/20 Circuit Diagram 2/9 (In8/in16 2/2)Jeff BrintonОценок пока нет

- EMX5000-12/20 Circuit DiagramsДокумент2 страницыEMX5000-12/20 Circuit DiagramsJeff BrintonОценок пока нет

- CN601: To PWR CN101 CN501: To DSPДокумент6 страницCN601: To PWR CN101 CN501: To DSPJeff BrintonОценок пока нет

- EMX5000 PL (E) C PDFДокумент61 страницаEMX5000 PL (E) C PDFJeff BrintonОценок пока нет

- Emx5000 PCB1 (E) PDFДокумент3 страницыEmx5000 PCB1 (E) PDFJeff BrintonОценок пока нет

- Emx5000-12/20 Circuit Diagram 7/9 (DSP-SPX)Документ3 страницыEmx5000-12/20 Circuit Diagram 7/9 (DSP-SPX)Jeff BrintonОценок пока нет

- Panasonic RF 4900 Operating InstructionДокумент12 страницPanasonic RF 4900 Operating InstructionJeff BrintonОценок пока нет

- Stagepas 300 SM CДокумент12 страницStagepas 300 SM CJeff BrintonОценок пока нет

- Stagepas 300 SM CДокумент12 страницStagepas 300 SM CJeff BrintonОценок пока нет

- SeeSnake Parts ManualДокумент39 страницSeeSnake Parts ManualJeff BrintonОценок пока нет

- XR7040 SMДокумент57 страницXR7040 SMJeff BrintonОценок пока нет

- BSC (CS) SlybusДокумент35 страницBSC (CS) SlybusVivek RaghavОценок пока нет

- Lecture+Notes+ +PIGДокумент21 страницаLecture+Notes+ +PIGYuvaraj V, Assistant Professor, BCAОценок пока нет

- Assignment ON Microprocessor AND Microcontroller: Joyal Jose AugustineДокумент63 страницыAssignment ON Microprocessor AND Microcontroller: Joyal Jose Augustineajas777BОценок пока нет

- Information Technology Project Management: by Jack T. MarchewkaДокумент58 страницInformation Technology Project Management: by Jack T. MarchewkaAga AОценок пока нет

- Maidanam Chalam PDFДокумент2 страницыMaidanam Chalam PDFNarasimha CОценок пока нет

- Hw5 SolutionДокумент11 страницHw5 SolutionTun LeОценок пока нет

- 6es5 460 4ua12pdfДокумент4 страницы6es5 460 4ua12pdfLưu Chung KiênОценок пока нет

- Inventory Management atДокумент17 страницInventory Management atroop23dec100% (1)

- UMTS PagingДокумент2 страницыUMTS PagingCauTungОценок пока нет

- Bitalag Integrated School Alumni Tracer With Sms NotificationДокумент4 страницыBitalag Integrated School Alumni Tracer With Sms NotificationflashОценок пока нет

- Advanced Topics in Propagation of Errors, Least Squares Fitting, and Non-Linear FunctionsДокумент8 страницAdvanced Topics in Propagation of Errors, Least Squares Fitting, and Non-Linear FunctionsAlessandro TrigilioОценок пока нет

- Critical Thoughts From A Government Mindset ISBN 9781909287631Документ297 страницCritical Thoughts From A Government Mindset ISBN 9781909287631Chartridge Books OxfordОценок пока нет

- Quiz 02Документ2 страницыQuiz 02Charles BriggsОценок пока нет

- Can You Work Under Pressure - HR Interview Questions and AnswersДокумент7 страницCan You Work Under Pressure - HR Interview Questions and AnswersAhmed TahaОценок пока нет

- Introduction To PHPДокумент17 страницIntroduction To PHPyunusmoha1970Оценок пока нет

- Name: Irish Jane P. Adalim Course & Yr.: BSED English II EL103Документ2 страницыName: Irish Jane P. Adalim Course & Yr.: BSED English II EL103Hsiri Enaj MiladaОценок пока нет

- Self MVДокумент16 страницSelf MVhtalibОценок пока нет

- Abb Irb 6700Документ574 страницыAbb Irb 6700rx7000100% (1)

- How To Create Newswrap Server (Main Server)Документ34 страницыHow To Create Newswrap Server (Main Server)Naveen PandeyОценок пока нет

- Core 1Документ2 страницыCore 1RidhiОценок пока нет

- DAA Questions-AДокумент2 страницыDAA Questions-AA Raghava Chowdary maddipatiОценок пока нет

- C Multiple Choice Questions and Answers MCQ With AnsДокумент22 страницыC Multiple Choice Questions and Answers MCQ With AnsVishwa KrishnanОценок пока нет

- BBC Service ManualДокумент90 страницBBC Service ManualJeremy VinesОценок пока нет

- Micom S1 V2 For Micom Px40Документ58 страницMicom S1 V2 For Micom Px40Insan AzizОценок пока нет

- Asymptotic NotationДокумент2 страницыAsymptotic NotationAbhay BaranwalОценок пока нет

- TQ7 Complete GuideДокумент46 страницTQ7 Complete Guidetyler112Оценок пока нет