Академический Документы

Профессиональный Документы

Культура Документы

04 Steering and Turning Vehicles

Загружено:

Dinesh KumarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

04 Steering and Turning Vehicles

Загружено:

Dinesh KumarАвторское право:

Доступные форматы

ME 360/390 Prof. R.G.

Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Steering and Turning Vehicles

Prof. R.G. Longoria

Spring 2012

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Overview

Steering mechanisms

Differentially-steered vehicle kinematic

Ackermann steered vehicle kinematic

Simulation examples

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

5

th

wheel

steering

Likely developed by the Romans, and preceded only by a 2

wheel cart.

Consumes space

Poor performance unstable

Longitudinal disturbance forces have large moment arms

'hand wheel' angle =

H

Articulated-vehicle steering

Tractors, heavy industrial

vehicles

turntable steering

Classical steering mechanisms

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Differential steer Synchro-drive Tricycle

and some systems also employ Ackermann-type.

What is minimum

# of actuators?

Common Steering Mechanisms

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

X

Recall the simple 2D turning vehicle with kinematic state quantified by,

x

y

Y

cos sin 0

( ) sin cos 0

0 0 1

(

(

=

(

(

[ ]

I

X Y = q

The velocities in the local (body-fixed) reference frame

are transformed into a global frame by the rotation

matrix,

cos sin 0

( ) sin cos 0

0 0 1

(

(

=

(

(

R

Inverting, we arrive at the velocities in the global reference frame,

( )

I

= q R q

( )

I

= q q

and the velocities are then,

where,

Lets apply these relations to the case of a single-axis vehicle that has two wheels

differentially driven with controlled speed.

X

Kinematic model of single-axle turning vehicle

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

X

We defined the vehicles kinematic state in the inertial frame by,

x

y

Y

I

X

Y

(

(

=

(

(

q

Velocities in the local (body-fixed)

reference frame are transformed

into the inertial frame by the

rotation matrix,

cos sin 0

( ) sin cos 0

0 0 1

(

(

=

(

(

R

Inverting, we arrive at the velocities in the global reference

frame,

( )

I

= q R q

cos sin 0

( ) sin cos 0

0 0 1

x

I y

z

X U v

Y V v

(

( ( (

(

( ( (

= = = =

(

( ( (

(

( ( (

q q

or, specifically,

So, for our simple (single-axle) vehicle,

the velocities in the inertial frame in

terms of the wheel velocities are,

X

2

1 2 1 2

2

1 2 1 2

1 2

( ) cos ( ) sin

2

( ) sin ( ) cos

2

( )

w w

w w

I

w

R l R

B

X

R l R

Y

B

R

B

(

+

(

(

(

(

(

= = + +

(

(

(

(

(

(

q

Recall: position and velocity in inertial frame

1

l

2

l

B

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

X

For a kinematic model of a differentially-driven vehicle, we assume there is no slip, and

that the wheels have controllable speeds,

1

and

2

. If the CG is on the rear axle,

x

y

Y

the velocities in the global reference frame are,

track width B =

1 2

1 2

1 2

( ) cos

2

( ) sin

2

( )

w

w

I

w

R

X

R

Y

R

B

(

+

(

(

(

(

(

= = +

(

(

(

(

(

(

q

1

2

0

l L

l

=

=

Example: Differentially-driven basic vehicle

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

% Differentially-steered kinematic vehicle model

% Requires right (#1) and left (#2) wheel velocities, omegaw1 and omegaw2,

% as controlled inputs for single axle, to be passed as global parameters

% Wheel radius, R_w, and axle track width, B, are also required

% Updated 2/20/12 RGL

function Xidot = DS_vehicle(t,Xi)

global R_w B omegaw1 omegaw2

X = Xi(1); Y = Xi(2); psi = Xi(3);

% NOTE: these are global coordinates

% These equations assume CG on single axle

Xdot = 0.5*cos(psi)*R_w*(omegaw1+omegaw2);

Ydot = 0.5*sin(psi)*R_w*(omegaw1+omegaw2);

psidot = R_w*(omegaw1-omegaw2)/B;

Xidot=[Xdot;Ydot;psidot];

% test_DS_vehicle.m

clear all

global R_w B omegaw1 omegaw2

% Rw = wheel radius, B = track width

% omegaw1 = right wheel speed

R_w = 0.05; B = 0.18;

omegaw1 = 4; omegaw2 = 2;

Xi0=[0,0,0];

[t,Xi] = ode45(@DS_vehicle,[0 10],Xi0);

N = length(t);

figure(1)

plot(Xi(:,1),Xi(:,2)), axis([-1.0 1.0 -0.5 1.5]), axis('square')

xlabel('X'), ylabel('Y')

A simple code in Matlab to compute and plot out the vehicle trajectory is given below.

Vehicle trajectory in XY

Simulation of the differentially-steered single-axle vehicle trajectory

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

-1 -0.5 0 0.5 1

-0.5

0

0.5

1

1.5

X

Y

1. Specify and plot initial location

and orientation of the vehicle CG.

2. Initiate some handle graphics

functions for defining the body.

3. Perform a fixed wheel speed

simulation loop to find state, q.

4. The state of the robot is used to

define the position and orientation

of the vehicle over time.

5. A simple routine is used to

animate 2D motion of the vehicle

by progressive plotting of the

body/wheel positions.

A code in Matlab to plot out the vehicle trajectory including a simple graphing animation of

the vehicle body/orientation is provided on the course log. This provides visual feedback on

the model results.

The key elements of this code are:

Simulation of differentially-steered vehicle with 2D animation

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

1. Steering arm

2. Drag link

3. Idler arm

4. Tie rod/rack

5. Steering wheel

6. Steering shaft

7. Steering box

8. Pitman arm

Rigid axle with

kingpin

Divided track rods

for independent

suspension.

knuckle

Lankensperger/Ackermann-type steering

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

What is low-speed?

Negligible centrifugal forces

Tires need not develop lateral

forces

Pure rolling, no lateral sliding

(minimum tire scrub).

For proper geometry in the turn,

the steer angles, , are given by:

The average value (small angles)

is the Ackerman angle,

B

L

o

R

Turn Center

Ref. Wong, Ch. 5

cot cot

steer angle of outside wheel

steer angle of inside wheel

track

wheelbase

o i

o

i

B

L

B

L

=

=

=

=

=

Ackermann steering geometry

2 2

o i

L L

B B

R R

<

+

Ackermann

L

R

=

Simple relationship between

heading and steering wheel angle.

Turning at low (Ackermann) speed

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

*To align the wheel with heading direction

(vector), you would have to go .

The lateral force should simply always

oppose the motion the lateral force is a

dissipative force!

A positive slip angle is said to give a

negative force on the wheel (to the left).

y

F C

=

The slip angle is the angle between the

wheels direction of heading (wheel plane)

and its direction of travel. So, to compute

the slip angle, need to track tire velocity

components, as shown below.

Gillespie (1992)

Excerpt from Liljedahl, et al (1996)

Wheel slip angle definition

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

At low speed the wheels will roll without slip angle.

If the rear wheels have no slip angle, the center of the turn lies

on the projection of the rear axle. Each front steered wheel has

a normal to the wheel plane that passes through the same center

of the turn. This is what Ackermann geometry dictates.

Correct Ackermann reduces tire wear and is easy on terrain.

Ackermann steering geometry leads to steering torques that

increase with steer angle. The driver gets feedback about the

extent to which wheels are turned. With parallel steer, the trend

is different, becoming negative (not desirable in a steering

system positive feedback).

Off-tracking of the rear wheels, , is related to this geometry.

The is R[1-cos(L/R)], or approximately L

2

/(2R).

Additional notes/comments on Ackermann steering

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

B

L

o

Can you pass the vehicle

through a given position?

Using the basic geometry of Ackermann steering

1. Assume low-speed turning

2. Project along rear-axle

3. Define R = L/

max

4. Project from CG

5. Project ideal turning path

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

A wheeled vehicle is said to have kinematic (or Ackermann) steering when a wheel is

actually given a steer angle, , as shown. A kinematic model for the steered basic vehicle

in the inertial frame is given by the equations,

cos cos

sin sin

tan

w

w

X v R

Y v R

v

L

= =

= =

=

where it is assumed that the wheels do not slip, so we

can control the rotational speed and thus velocity at each

wheel-ground contact.

So, the input control variables are velocity, v=R

w

,

and steer angle, .

In this example, the CG is located on the rear axle.

These kinematic equations can be readily simulated.

Y

X

( )

1 2

1

2

v v v = +

X

x

y

wheel base L =

tricycle

Note:

tan

t

z

t

v

L

v

v

= =

=

Example: 2D vehicle with front-steered wheel

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Y

X

( )

1 2

1

2

v v v = +

X

x

y

wheel base L =

Derivation of equations

Note that the forward velocity at the front wheel

is simply, v, but because of kinematic steering

the velocity along the path of the wheel must be,

cos

v

v

=

tan

z

v

L

=

This means that the lateral velocity at the front

steered wheel must be,

sin tan

t

v v v

= =

Now we can find the angular velocity about the CG, which is located at the

center of the rear axle as,

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

% -----------------------------------------------------

% tricycle_model.m

% revised 2/21/12 rgl

% -----------------------------------------------------

function qdot = tricycle_model(t,q)

global L vc delta_radc delta_max_deg R_w

% L is length between the front wheel axis and rear wheel axis [m]

% vc is speed command

% delta_radc is the steering angle command

% State variables

x = q(1); y = q(2); psi = q(3);

% Control variables

v = vc;

delta = delta_radc;

% kinematic model

xdot = v*cos(psi);

ydot = v*sin(psi);

psidot = v*tan(delta)/L;

qdot = [xdot;ydot;psidot];

Example: simulation and animation of steered tricycle kinematic model

% Physical parameters of the tricycle

L = 2.040; % Length between the front wheel axis and rear wheel axis [m]

B = 1.164; % Distance between the rear wheels [m]

m_max_rpm= 8000; % Motor max speed [rpm]

gratio = 20; % Gear ratio

R_w = 13/39.37; % Radius of wheel [m]

% desired turn radius

R_turn = 3*L;

delta_max_rad = L/R_turn; % Maximum steering angle [deg]

R = 6.12 m

= 0.33 rad = 19.1 deg

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

The models introduced here provide additional review of

fundamental kinematics principles and how they can be applied

to vehicle systems.

The concepts of differential and Ackermann steering are

demonstrated through simulations.

The kinematic models are commonly used in mobile robot

applications for path planning, estimation, and control.

These kinematic models cannot tell you anything about the

effect of forces or stability.

Summary of kinematic vehicle turning

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Directional stability refers to a vehicles ability to

stabilize its direction of motion against disturbances.

So, we are typically concerned with:

Unforced transient operations (natural response)

Forced response aperiodic inputs (step, ramp, etc.)

Forced response periodic forcing (sine)

Steady-state directional response

Well discuss both lateral and longitudinal stability.

Vehicle directional stability

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

One of the earliest analyses of vehicle stability was

conducted by Y. Rocard (1954) (Steeds, 1960).

The vehicle was simplified as a rigid rectangular

frame with a wheel at each corner and the plane of

each wheel is vertical and parallel to the frame.

The steering force is assumed to be directly related to

slip angle,

and the contact forces are assumed not to be affected

by vehicle motion.

There is no steering angle in this model.

First, lets review the lateral forces using modern

notation.

F K =

2D vehicle of Rocard

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

2 1

tan

z y

r

x

l v

v

| |

=

|

\

1 1

tan

y z

f f

x

v l

v

+ | |

=

|

\

1 1

2 1

rear steer

tan

tan

y z

f f

x

y z

r r

x

v l

v

v l

v

+ | |

=

|

\

| |

=

|

\

Wong (2001)

From Liljedahl, et al (1996)

The slip angle, , is derived using body-fixed variables.

Lateral tire forces induced by slip angles

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

The slip angle, , is the angle between direction of

heading and direction of travel of a wheel (OA).

A lateral force, F

y

, also referred to as a cornering

force (camber angle of the wheel is zero), is

generated at a tire-surface interface, but this may not

be collinear with the applied force at the wheel

center.

A torque is induced, referred to as a self-aligning

torque. This torque helps a steered wheel return to

its original position after a turn.

The distance between these two applied forces is

called the pneumatic trail.

The self-aligning torque is given by the product of

the cornering force and the pneumatic trail.

For more on self-aligning moment and pneumatic

trail, see Wong, Section 1.4.

Wong

side slip is due to the

lateral elasticity of the

tire.

s

F

y

F

s

F

y

F

p

t

Tire cornering forces

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Fig. 1.23 from Wong

Fig. 1.24 from Wong

linear region

Maximum cornering forces:

passenger car tires: 18 degrees

racing car tires: 6 degrees

(Wong)

Ratio to normal load

Variables that impact cornering force:

Normal load

Inflation pressure

Lateral load transfer

Size

Typical data on tire cornering forces

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

The cornering stiffness will depend on tire

properties such as:

tire size and type (e.g., radial, bias-ply, etc.),

number of plies,

cord angles,

wheel width, and

tread.

Dependence on load is taken into account

through the cornering coefficient,

where F

z

is the vertical load.

z

C

CC

F

=

Cornering stiffness and coefficient

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Fig. 1.27 from Wong

Fig. 1.28 from Wong

Cornering stiffness for car, light truck

and heavy truck tires

Effect of normal load

on the cornering

coefficient

Cornering stiffness and coefficients

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Rocard derived two 2nd order ODEs for this

problem*, and for linear approximations found

the characteristic equation,

2

2

1 3

1 3

2 ( )

( )

c

K K a b

V

M K a K b

+

=

3 1

K b K a > Stable for all speeds if:

( )

( )

2 2

2 2

1 3

2 2

2

1 3 1 3

2 2

0

2

1 1

4 ( ) 2( )

s Rs S s

a b

R K K

MV k k

K K a b K a K b

S

Mk

MkV

+ + =

(

| | | |

= + + +

( | |

\ \

+

=

A critical speed

is defined by:

choose the position of the mass center of the

vehicle and the steering force characteristics for

the front and rear tires

If the steering force are equal, then stability is

assured if b is greater than a, or putting the CG in

front of the midpoint of the wheelbase.

*Refer to Steeds handout for details; well

come back to this later

2

I Mk =

Now, Rocards linearized model

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Lets match this up with modern notation:

2

2

2

1 3

1 3 1 2

2

2 ( )

( ) ( )

+

= =

f r

c

f r

C C L

K K a b

V

M K a K b M C L C L

1

3

=

=

f

r

K C

K C

2 1

0 (for stability at all speeds)

= >

factor r f

R C L C L

So, only compute a critical speed if R

factor

is less than or equal to zero.

A critical speed is defined by,

(Steeds, 1960)

Directional Stability per Rocard

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Assume: symmetric vehicle, no roll or pitch

Represent the two wheels on the front and rear

axles by a single equivalent wheel.

The bicycle model will have at least three states:

forward translational momentum or velocity of

the CG

lateral translational momentum or velocity of the

CG

yaw angular momentum or velocity about the CG

( )

( )

rear drive

front drive lateral force effect

1 2 1

cos( ) sin( )

cos( ) sin( )

cos( ) sin( )

x y z xf f xr yf f

y x z yr yf f xf f

z z yf f yr xf f

m v V F F F

m v V F F F

I l F l F l F

= +

+ = + +

= +

Refer to Wong, Chapter 5, Eqs. 5.25 5.27:

How would you add a disturbance?

Need to determine the external forces.

Adapted from Wong

The Bicycle or Single-Track Model

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

f

f

l

1

r

X

Y

x

y

Z

y

t

x

t

l

2

z

x

v

y

v

1

sideslip tan

y

x

v

v

| |

= =

|

\

2 1

tan

y z

r r

x

v l

v

| |

=

|

\

1 1

tan

y z

f f

x

v l

v

+ | |

=

|

\

A more general bicycle model schematic

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

( )

rear drive

front drive lateral force effect

small steering angle

cos( ) sin( )

x

f

x y z xf f xr yf f

v V

m v V F F F

=

= =

= +

0

1 2 1

0

y yr yf xf f x z

z z yf yr xf f

mv F F F mv

I l F l F l F

= + +

= +

Note how falls out, but it enters again in the lateral forces, since,

2 2 1

tan

z y z y

r

x x

l v l v

v v

| | | |

=

| |

\ \

1 1 1

tan

y z y z

f f f

x x

v l v l

v v

+ + | | | |

=

| |

\ \

Reduced bicycle model: 2 DOF by assuming V

x

= constant = V

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

cos( ) sin( )

sin( ) cos( )

x y

x y

z

X v v

Y v v

=

= +

=

Recall, these models solve for forward and lateral velocity and yaw

velocity, resulting from input steer angles, , relative to the body-

fixed axes.

To find the trajectory of the CG in the Earth-based coordinates, we

use transformation equations for basic 2-D trajectory simulations,

As before, we can calculate vehicle trajectory calculations

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

We examine directional stability, reviewing Steeds form of

Rocards (linearized) model (see class handout), which is

essentially the bicycle model with steer angle, = 0.

Determine if this vehicle with baseline parameter data given

(next slide) is stable, and compare with results from a

simulation of the bicycle model subjected to a force

perturbation at the front wheel applied in the +y direction.

Additional car specification data is provided as Appendix B.

Example: directional stability with zero steer + disturbance

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

(In Matlab script form)

% Baseline values

g = 9.81;

L = 3.075; L1 = 1.568; L2 = L-L1;

% Inertia parameters

m = 1945; % total mass, kg

W = m*g; % weight, N

iyaw = 0.992; % yaw dynamic index

% the following is a defined relation between yaw dynamic index and

% the yaw moment of inertia (see Dixon reference and table of car specs)

Iz = iyaw*m*L1*L2; % moment of inertia about z, kg-m^2

Wf = L2*W/L; % static weight on front axle

Wr = L1*W/L; % static weight on rear axle

% Refer to Wong, Section 1.4 for guide to the following parameters

CCf = 0.171*180/pi; % front corning stiffness coefficient, /rad

CCr = 0.5*0.181*180/pi; % rear corning stiffness coefficient, /rad

Cf = CCf*Wf/2; % corning stiffness per tire, N/rad (front)

Cr = CCr*Wr/2; % rear cornering stiffness per tire, N/rad (rear)

Example: baseline vehicle parameter data (from simple_bicycle.m)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

if (t>=tdon & t<=tdoff)

Fd = Fyfd;

else

Fd = 0;

end

Vy_dot = (-m*Vx*omegaz + Fyr + Fyf*cos(deltaf) + Fxf*sin(deltaf) + Fd)/m;

omegaz_dot = (L1*Fyf*cos(deltaf) - L2*Fyr + L1*Fxf*sin(deltaf) + Fd*L1)/Iz;

d

F

Add disturbance as a lateral

force and related moment.

don

t

d

F

yfd

F

doff

t

Pulse disturbance

Disturbance force application

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

0 5 10 15

-6

-4

-2

0

2

4

x 10

-3

Lateral Velocity

0 5 10 15

-2

0

2

4

6

x 10

-3

Yaw Velocity

0 50 100 150 200

-50

0

50

Position

0 5 10 15

0

1

2

3

x 10

-3

Yaw

Given case:

R

factor

= 4200.4

V

c

= non-existent

v

x

=V= 5L/sec

A lateral pulse disturbance is

applied at front wheel.

Afterwards, the vehicle

stabilizes (lateral and yaw

velocities go to zero).

Used: simple_bicycle.m

For Nominal Case, Vehicle Stabilizes

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

In this case, the rear lateral

stiffness was cut in half.

R

factor

= 33814.

V

c

= 18.2 m/s

Let (since vehicle is now

unstable for V > Vc)

V = 1.2* V

c

=21.8

After the pulse disturbance,

the vehicle does not stabilize.

0 5 10 15

-100

-50

0

50

Lateral Velocity

0 5 10 15

0

5

10

15

Yaw Velocity

0 100 200

-50

0

50

100

Position

0 5 10 15

0

5

10

15

Yaw

Used: simple_bicycle.m

Change rear lateral stiffness (i.e., the cornering stiffness values of tires)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Using the stable case for the

simple_bicycle model, an

open loop lane change is

achieved by:

(put right into function file):

% double lane change

if (t<1) deltaf = 0; end;

if (t>=1 & t<2) deltaf = steer_angle; end;

if (t>=2 & t<3) deltaf = -steer_angle; end;

if (t>=3 & t<4) deltaf = 0; end;

if (t>=4 & t<5) deltaf = -steer_angle; end;

if (t>=5 & t<6) deltaf = steer_angle; end;

if (t>=6) deltaf = 0; end;

0 2 4 6 8

-1

-0.5

0

0.5

1

Lateral Velocity

0 2 4 6 8

-0.4

-0.2

0

0.2

0.4

Yaw Velocity

0 50 100 150

-2

0

2

4

6

Position

0 2 4 6 8

-0.4

-0.2

0

0.2

0.4

Yaw

Used: simple_bicycle_lanechange.m

Example: a double lane change using simple bicycle model

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

The classic bicycle (or single-track) model forms the basis for

understanding steering and steering control.

Lateral forces induced by tires depend on wheel slip angle and

play a key role in lateral stability. See also the Rocard handout.

We saw earlier that longitudinal traction (driving or braking)

influences lateral forces, so driven bicycle models (where there

are traction/braking forces) require us to model the coupling

between longitudinal and lateral tire forces (friction ellipse).

In extreme maneuvers, for example, it would be possible to

predict yaw instability if lateral forces were significantly

reduced.

Bicycle model summary

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

References

1. Den Hartog, J.P., Mechanics, Dover edition.

2. Dixon, J.C., Tires, Suspension and Handling (2nd ed.), SAE, Warrendale, PA,

1996.

3. Greenwood, D.T., Principles of Dynamics, Prentice-Hall, 1965.

4. Gillespie, T.D., Fundamentals of Vehicle Dynamics, SAE, Warrendale, PA, 1992.

5. Hibbeler, Engineering Mechanics: Dynamics, 9th ed., Prentice-Hall.

6. Meriam, J.L. and L.G. Kraige, Engineering Mechanics: Dynamics (4th ed.), Wiley

and Sons, Inc., NY, 1997.

7. Rocard, Y., Linstabilite en Mecanique, Masson et Cie, Paris, 1954.

8. Segel, L., Theoretical Prediction and Experimental Substantiation of the

Response of the Automobile to Steering Control, The Institution of Mechanical

Engineers, Proceedings of the Automobile Division, No. 7, pp. 310-330, 1956-7.

9. Steeds, W., Mechanics of Road Vehicles, Iliffe and Sons, Ltd., London, 1960.

10. Wong, J.Y., Theory of Ground Vehicles, John Wiley and Sons, Inc., New York,

2001 (3rd ed.).

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Example Car Specifications*

*Table C.1 from J.C. Dixon, Tires, Suspension and Handling (2

nd

ed.), SAE, Warrendale, PA, 1996.

APPENDIX

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Appendix:

More on Steering Mechanisms

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

DaNI: 4-wheeled, differentially driven

Motor: Tetrix DC (handout)

Gear Ratio: 2:1

Shaft Diameter: 4.73 mm

Wheel Diameter: 100 mm

Wheel base: 133 mm.

Under what conditions would you need to

use a dynamic model?

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

General Steering System Requirements

A steering system should be insensitive to disturbances from the ground/road

while providing the driver/controller with essential feedback as needed to

maintain stability.

The steering system should achieve the required turning geometry. For

example, it may be required to satisfy the Ackermann condition.

The vehicle should be responsive to steering corrections.

The orientation of the steered wheels with respect to the vehicle should be

maintained in a stable fashion. For example, passenger vehicles require that

the steered wheels automatically return to a straight-ahead stable equilibrium

position.

It should be possible to achieve reasonable handling without excessive

control input (e.g., a minimum of steering wheel turns from one locked

position to the other).

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Passenger Steering Requirements

Driver should alter steering wheel angle to keep deviation from course low.

Correlation between steering wheel and driving direction is not linear due to:

a) turns of the steering wheel, b) steered wheel alterations, c) lateral tire

loads, and d) alteration of driving direction.

Driver must steer to account for compliance in steering system, chassis, etc.,

as well as need to change directions.

Driver uses visual as well as haptic feedback. For example, roll inclination

of vehicle body, vibration, and feedback through the steering wheel (effect of

self-centering torque on wheels).

It is believed that the feedback from the steering torque coming back up

through the steering system from the wheels is the most important

information used by many drivers.

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Impact of Steering Geometry

Ref. Milliken & Milliken

0.56

B

L

=

Ref. Wong

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Steering Results and

Error in Ackermann

Ref. Wong

0.56

B

L

=

Steering error curves for a front beam axle

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Impact on Steering Geometry

of using Ackermann in High Speed

A car with a steering geometry chosen for low-speed (Ackermann)

will not be as effective at higher vehicle speeds.

In a high speed turn, the inside tire will have a lower normal force,

which means it could achieve the same amount of lateral cornering

force with a smaller slip angle.

Using Ackermann will result in more instances in which the inside

tire is dragged along at too high a slip angle, unnecessarily raising

the temperature and slowing the vehicle down with excessive slip

induced drag.

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

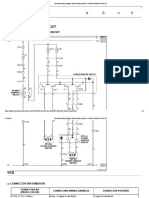

Steering Systems Rigid Axle

Rack and pinion is not suitable for steering wheels on rigid

front axles, as the axles tend to move in the longitudinal

direction. This movement between the wheels and steering

system can induce unintended steering action.

Only steering gears (1) with rotational movement are used.

Design must minimize effects from motion.

1. Steering arm

2. Drag link

3. Idler arm

4. Tie rod/rack

5. Steering wheel

6. Steering shaft

7. Steering box

8. Pitman arm

7

8

2

1

You may see some older model

Toyota Land Cruisers that use

this type of steering design.

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Axle-Beam Steering Linkage

Heisler (1999)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Axle-Beam Steering Linkage

Heisler (1999)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Front Axle and Tie Rod Assembly

From: J.W. Durstine, The Truck Steering System From

Hand Wheel to Road Wheel, SAE, SP-374, 1973 (L. Ray

Bukendale Lecture).

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Steering Gearbox and Ratio

From Gillespie (Fig. 8.18).

Experimentally measured steering

ratio on a truck.

The gearbox provides the primary means for reducing the rotational input from

the steering wheel and the steering axis.

Steering wheel to road wheel ratios may vary

with angle, but have values of 15:1 in passenger

cars and may go as high as 36:1 for heavy

trucks.

Rack and pinions are commonly designed to

have a variable gear ratio depending on steer

angle.

The actual steer ratio can be influenced by

steering system effects, such as compliance.

The plot here from Gillespie shows how much

this can change.

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Rack-and-Pinion 1

Used on most passenger cars and some light trucks,

as well as on some heavier and high speed vehicles.

Used on vehicles with independent suspensions.

Some advantages: simple, manufacturing ease,

efficient, minimal backlash, tie rods can be joined

to rack, minimal compliance, compact, eliminate

idler arm and intermediate rod

Some disadvantages: sensitive to impacts, greater

stress in tie rod, since it is efficient you feel

disturbances, size of steering angle depends on rack

travel so you have short steering arms and higher

forces throughout, cannot be used on rigid axles

3 Steering arms

7 Tie rod joints

8 Steering rack

Steering ratio is ratio of pinion revolutions to rack travel.

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Rack-and-Pinion 2

Heisler (1999)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Split track-rod with relay-rod

Heisler (1999)

ME 360/390 Prof. R.G. Longoria

Vehicle System Dynamics and Control

Department of Mechanical Engineering

The University of Texas at Austin

Summary

Steering mechanisms were reviewed briefly

Steering geometry how do you select steering

system?

Steering control how does it translate into

steering mechanism design?

There is a complex relationship to suspension

(see Segel, Gillespie)

Вам также может понравиться

- HDP, HDO Series: Installation, Operation and Maintenance ManualДокумент88 страницHDP, HDO Series: Installation, Operation and Maintenance ManualDinesh KumarОценок пока нет

- Brochure Automotive 2018Документ4 страницыBrochure Automotive 2018Dinesh KumarОценок пока нет

- Connection Diagrams PDFДокумент5 страницConnection Diagrams PDFDinesh KumarОценок пока нет

- Creo Tutorial - How To Make and Edit UDFs (User Defined Features) - Creating FoДокумент28 страницCreo Tutorial - How To Make and Edit UDFs (User Defined Features) - Creating FoDinesh Kumar100% (1)

- Electric Vehicle Business Models Global Perspectives by David Beeton and Gereon MeyerДокумент266 страницElectric Vehicle Business Models Global Perspectives by David Beeton and Gereon MeyerDinesh Kumar100% (1)

- AdorДокумент280 страницAdorDinesh KumarОценок пока нет

- Active Suspension System: Presented by Jobin JacobДокумент15 страницActive Suspension System: Presented by Jobin JacobDinesh Kumar100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Viewing Dash Displayed Fault Code Instructions-1Документ7 страницViewing Dash Displayed Fault Code Instructions-1Jaider Cruz CruzОценок пока нет

- BMW Motorrad Model Range 2020: SportДокумент2 страницыBMW Motorrad Model Range 2020: SportLuis Miguel OrbeОценок пока нет

- Ario User GuideДокумент4 страницыArio User Guideish996Оценок пока нет

- 10.13.11 The NickelДокумент16 страниц10.13.11 The Nickelliz6085Оценок пока нет

- Trailer 40 PiesДокумент2 страницыTrailer 40 Piesmaomischo3992Оценок пока нет

- Tasac Pes 2000Документ426 страницTasac Pes 2000Alan Reyes SzinavelОценок пока нет

- BMW NSC Bsi Bri Specsheet May 2023 x1.pdf - Asset.1684842582589Документ1 страницаBMW NSC Bsi Bri Specsheet May 2023 x1.pdf - Asset.1684842582589VickОценок пока нет

- Audi A4 No. 6 / 1: Convenience ElectricsДокумент27 страницAudi A4 No. 6 / 1: Convenience ElectricsmbpajaОценок пока нет

- Part List SAMSUNG SCX - 4216F - 4116 - 4016Документ23 страницыPart List SAMSUNG SCX - 4216F - 4116 - 4016Nicola RizziОценок пока нет

- Campaign Toyota November 2022 (011122)Документ10 страницCampaign Toyota November 2022 (011122)mitramotorsbyОценок пока нет

- FM Tuning CalculatorДокумент12 страницFM Tuning CalculatorAndrew ChanОценок пока нет

- VW (Cod Eroare Diagnostic) - 982691461210 - 20220923143809Документ2 страницыVW (Cod Eroare Diagnostic) - 982691461210 - 20220923143809Marius ButaciuОценок пока нет

- Michigan Driving Automatic Failures List For Driving TestДокумент0 страницMichigan Driving Automatic Failures List For Driving TestSrinivas ChinnamОценок пока нет

- Manual de Motores Cummins 350 Big CamДокумент3 страницыManual de Motores Cummins 350 Big Camlalo67% (3)

- 2006 IVECO DAILY 3 Service Repair Manual PDFДокумент50 страниц2006 IVECO DAILY 3 Service Repair Manual PDFjksmmmdd100% (5)

- Yamaha Nouvo S Service Manual: Read/DownloadДокумент2 страницыYamaha Nouvo S Service Manual: Read/DownloadYasser Widadi50% (2)

- CORREIASДокумент2 страницыCORREIASLilianeGomesОценок пока нет

- Power Windows OptraДокумент12 страницPower Windows OptraAndres Colina Carico100% (1)

- DCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormДокумент3 страницыDCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormchoadleyОценок пока нет

- Terex 990Документ1 354 страницыTerex 990Hernan Csmaquinaria Reyes60% (5)

- Catalogo de Fajas de Tiempo Gates PDFДокумент28 страницCatalogo de Fajas de Tiempo Gates PDFTommy CamposОценок пока нет

- Cat 120 GC Full Line of Choices LRCДокумент1 страницаCat 120 GC Full Line of Choices LRCMohammad Fikri Aditya RamadhanОценок пока нет

- Mag 10 94 - PartsДокумент4 страницыMag 10 94 - PartsleonardosjrОценок пока нет

- History of MustangДокумент3 страницыHistory of MustangMarvin BerrensteinОценок пока нет

- Konpar 2018 KatalogДокумент92 страницыKonpar 2018 KatalogEndeveurs AlienОценок пока нет

- Manual Mazda Allegro 1.6 PDFДокумент23 страницыManual Mazda Allegro 1.6 PDFBrandon K'RicoОценок пока нет

- Illinois Vehicle ClassesДокумент3 страницыIllinois Vehicle ClassesAlisa HОценок пока нет

- PDFДокумент9 страницPDFRanjitОценок пока нет

- Special Trailer Bearing: Arvin Meritor (Ror)Документ27 страницSpecial Trailer Bearing: Arvin Meritor (Ror)MapleОценок пока нет

- Ducati Cat Accessori ENGДокумент35 страницDucati Cat Accessori ENGJoão MarrazesОценок пока нет