Академический Документы

Профессиональный Документы

Культура Документы

Design of The Low Head Slide Gate: A) Structural Steel

Загружено:

Alok SarkarИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of The Low Head Slide Gate: A) Structural Steel

Загружено:

Alok SarkarАвторское право:

Доступные форматы

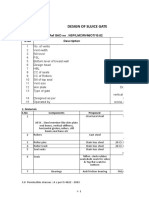

Design of the Low Head Slide Gate

Basic Parameters Gate Width: Gate Height: Maximum head difference in the opening: C/C of Side Seal: C/C of Track: Design head to Seal: Allowable stresses Allowable stresses as specified for in Annexx "B" of IS-5620-1985 as applicable to wet and inaccessible conditions a) Structural Steel Tension in bending: Compression in bending: Shear Stress: Combined Stress: Bearing Stress: b) Bronze or Brass Bearing Stress: Material Structural Steel conforming to IS-2062, for thickness less than or equal to 20 mm, YP = 250 Mpa UTS = 410 MPa Hydraulic Load on the Gate Area of the Gate: Water pressure at top: Water pressure at bottom: Total Hydraulic load: Placement of Girder 1.69 0.00 1300.00 1098.5 Sqm Kg/m2 Kg/m3 Kg 0.03 UTS 0.4 0.4 0.3 0.5 0.25 YP = YP = YP = YP = UTS = 100 100 75 125 102.5 Mpa Mpa Mpa Mpa Mpa 1.30 m 1.30 m 0.00 m 1.30 m 1.31 m 1.30 m

Horizontal Girders are to be located as per cl 6.1.2.1 of IS 5620 Adoption of two girder design makes the system statically determinate, so, the selection of L1 equalling H/6 and L2 = H/3 gives equal loads on the t Distance of gorder 1 form bottom = Distance of gorder 2 form bottom = H/6 H/6 + H/3 0.22 m 0.65 m

1300.00 Kg/m2

1083.33 Kg/m2

650 Kg/m2

0.00

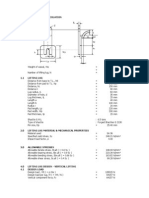

Kg/m2 0.22 m R1 1.30 m Reaction / width at girder 1, R1 = Reaction / width at girder 2, R2 = 422.5 Kg/m 422.5 Kg/m 0.433 m R2 0.65 m

Design of Skin Plate Boundary condition of the plate is all edges simply supported Bending Stress, = K/100 X p X a /s

2 2

where K= non-dimensional factor depending on values of a & b p = water pressure (relative to the plate center), in N/mm = a,b = bay width in mm s = plate thickness, in mm =

2

0.0119 N/mm2 6.5

III

L3

II I

L2 L1

PANEL I : Three edges fixed and one longer edge free Maxim distance between vertical stiffeners, b = Distance to girder 1, a = Ratio, b/a = Stress Values of K Values of K Values of K Bending Stress, = So, maximum stress is well below allowable. PANEL II : All four edges fixed. Maxim distance between vertical stiffeners, b = Distance between girder 1 & 2, a = Ratio, b/a = 0.430 m 0.433 m 0.99 b/a 1.75 2 1.98 11x 23 19.49 19.71 2.61 0.43 m 0.216667 m 1.98 11y 14 6.72 7.18 0.95 12x 25.8 33.98 33.46 4.43 12y 87 113.28 111.61 14.78 13x 67.5 72.96 72.61 9.61 13y 20.8 21.89 21.82 2.89

Stress Values of K Values of K Values of K Bending Stress, =

b/a 1 1.25 0.99

2x 13.7 18.8 13.54 1.79

2y 13.7 13.5 13.71 1.82

3x 40.3 30.9 40.77 5.4

3y 12.09 9.27 12.23 1.62

4x 10.17 9.27 10.21 1.35

4y 33.9 30.9 34.03 4.51

So, maximum stress is well below allowable. Design of Horizontal Girders Loading on Horizontal Girders Load on the girders: Distance between vert seals: Distance between supports: Reaction from plate: Maximum Bending Moment: Required section modulus: Girder 1 422.5 1.30 1.31 274.625 90.63 9.063 Kg/m m m Kg Kgm cm3 Girder 2 422.5 1.30 1.31 274.625 90.63 9.063 Kg/m m m Kg Kgm cm3

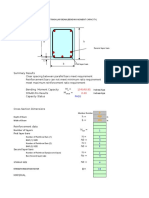

Co-acting width of Skin plate for Horizontal Girders Girder 1 0.65 m 0.43 m 1.32 0.25 0.16 m Girder 2 0.433 m 0.43 m 1.98 0.38 0.16 m

Spacing between horizontal girders, 2B: Span length, L: L/B = Applicable factor, V1: Co-acting width, 2VB:

The coacting width is the least of the following value: i) Value calculated as above : 0.16 m ii) 40 X t: iii) 0.11 X span(length of girder): Hence, co-acting width adopted : Selection of Horizontal Girder W 14.41 t 0.65 8 Area 9.37 12.25 21.62

16 cm 32.00 cm 14.41 cm 14.41 cm

Moment 90.63

Ixx 0.33 71.2 71.53

Skin Plate ISNT 80

Ax 3.04 78.65 81.69

h 3.455 2.64

Moment of Inertia of the built up section, Ixx: 268.72 cm4 Moment of Inertia of the built up section, Iyy: 194.38 cm4 C G of built up Section: 3.78 cm from top 4.87 cm from bottom Section modulus at top: Section modulus at bottom: Calculation of stress Bending Stress, y : 16.4 N/mm2 71.09 cm3 55.18 cm3

> Required section modulus,

9.063

Moment at Girder 1, M1 = Section modulus of skin plate: Bending Stress, x : Shear Stress, xy: Combined Stress, v : VQ/I =

28.82

Kgm

4.58 cm3 62.93 N/mm2 33.07 N/mm2 < 92.42 N/mm2 < Hence OK. 75 N/mm2 125

(x2 + y2 -xy + 3xy2) =

Deflection Formula for deflection: Deflection = where, A = and B = E= q Girder 1 Girder 2 Allowable deflection: Design of Vertical Stiffeners Bending moment distribution Distance from top 0 0.65 1.08 1.30 So, maximum B M: Required section modulus: Due to variable load 0 45.77 211.90 366.17 45.77 Kgm 4.577 cm3 Due to R1 Due to R2 Total 0 45.77 28.82 0 4.225 422.5 a 65.5 0.655 > AXB q x a4/(24 x I x E) 12 x b/a - 6 x b2/a2 - 1 2 x 10 I 268.72 268.72

6

2000000 A 0.01 0.01 Actual deflectin B 5 5 Deflection (mm) 0.50 0.50 Hence OK.

1.64 mm

0 -183.08 -274.63

0 -91.54

Co-acting width of Skin plate for Vertical Stiffeners Girder 1 0.43 m 0.22 m 1.01 0.15 0.06 m Girder 2 0.430 m 0.433 m 2.02 0.31 0.13 m

Spacing between Vertical Stiffeners, 2B: Span length, L: L/B = Applicable factor, V2: Co-acting width, 2VB:

The coacting width is the least of the following value: i) Value calculated as above : 0.06 m ii) 40 X t: iii) 0.11 X span(length of girder): Hence, co-acting width adopted :

6 cm 32.00 cm 14.3 cm 6.00 cm

Selection of Vertical Stiffeners W 6.00 0.8 t 0.65 7 Area 3.90 5.60 9.50 Moment 45.77 Ixx 0.14 22.87 23.01 Ax 1.27 23.24 24.51 h 2.255 1.57

Skin Plate Vertical Stiffeners

Moment of Inertia of the built up section, Ixx: 56.64 cm4 Moment of Inertia of the built up section, Iyy: 44.00 cm4 C G of built up Section: 2.58 cm from top 5.07 cm from bottom Section modulus at top: Section modulus at bottom: Hoist capacity Hoisting force for operation comprises the following i) Weight of the gate ii) Bearing pad friction ii) Side seal friction Weight of the Gate Skin plate Horizontal Girder Vert Stiffeners Top edge Stiffeners Lifting plates Side seal clamp plates Bearing pad support Bearing pad Bottom seal support Bottom seal clamp plate Support angles 50 x 30 x 5 Stem base Stiffeners L (m) 1.31 1.31 1.30 1.31 0.15 1.30 0.065 0.05 1.31 1.31 0.15 0.065 0.05 C G of Gate : i) Structural weight of the gate: ii) Rubber seal friction: Say, water surcharge of gate: Calculated Hudrostatic load: Length of Seal: Width subjected to water pressure: Water Load/width: Total Water Load: Co-efficient of friction : Friction of force: 0.00 cm 1.0985 MT 1.30 0.05 845 42.25 Starting 1.5 63.375 m m Kg/m Running 1.2 50.7 Kg @

2 195 Kg/m =

21.95 cm3 11.17 cm3

> Required section modulus,

4.577

B/D (m) 1.30 0.07 0.07 0.15 0.045 0.05 0.04 0.016 0.08 0.063 0.025

T (cm) 0.65 0.8 0.8 2.0 0.8 2.5 1.6 0.8 0.8 5.0 0.6

Unit Weight 7800 9.6 7800 7800 7800 7800 7800 7800 7800 7800 3.0 7800 7800

No 1 2 4 2 2 2 6 6 1 1 4 1 4

Weight X (cm) 86.34 0.325 25.15 6.42 22.71 4.15 11.44 4.15 7.02 1.325 7.30 1.60 3.80 1.25 1.50 0.80 1.31 0.325 6.54 1.05 1.80 1.39 1.60 3.15 0.23 0.95 176.75 Kg 2.11 Cm

329.55 Kg

Kg

Total Rubber Seal Friction: iii)Bearing pad friction Pad friction Co-eff of friction Load on the pad (Kg) Total pad friction: iv) Seal Interference Force due to interference: Total Length: Total force: Co-efficient of friction : Friction of force: Lifting force: i + ii + iii Adding for reserve capacity: Total force: Selected lifting force: Selection of Stem Size Designed capacity: Required unsupported length: The safe adequate size of stem: whose load capacity is 1.5 Ton 1.65 m 44 mm dia 1972.9 Kg and unsupported length is 1440.66 Kg 1.5 Ton Material Starting Running Bronze on 0.5 0.3 Steel 274.625 137.31 82.39 549.25 329.55

126.75 Kg

101.4 Kg

50.00 2.6 130 Starting 1.5 195 1200.55 Kg 20%

Kg/m m Kg Running Kg 1.2 156 Kg

240.11 Kg

2.3125 m

qualling H/6 and L2 = H/3 gives equal loads on the two girder.

14x 112 134.4 132.96 17.6

A x h2 111.81 85.38 197.19

cm3

N/mm2

A x h2 19.83 13.80 33.63

cm3

WX 28.06 161.48 94.26 47.49 9.30 11.68 4.75 1.20 0.43 6.87 2.50 5.03 0.22 373.27

and L2 = H/3 gives equal loads on the two girder.

14y 34.8 40.32 39.97 5.29

15x 61 69.88 69.32 9.18

c 5.77

Iyy 162.08 32.3 194.38

c 0.325 3.5

Iyy 11.70 32.30 44.00

Вам также может понравиться

- Design of The Low Head Slide GateДокумент15 страницDesign of The Low Head Slide GateAlok Sarkar100% (1)

- Verticaal Gate DesignДокумент12 страницVerticaal Gate Designsuranga dadallageОценок пока нет

- Design of Slide Gate Size 1.6 X 2 MДокумент4 страницыDesign of Slide Gate Size 1.6 X 2 MTarunPatraОценок пока нет

- Design of Vertical Lift Service Gates of Budaun Irrigation ProjectДокумент33 страницыDesign of Vertical Lift Service Gates of Budaun Irrigation ProjectVikash Yadav83% (6)

- Kodaikanal Weir GateДокумент32 страницыKodaikanal Weir GateHarish Kumar MahavarОценок пока нет

- Design of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsДокумент23 страницыDesign of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsRanjeet Singh MoreyОценок пока нет

- Phawa Khola Hydropower Project: Q Q Q D LДокумент5 страницPhawa Khola Hydropower Project: Q Q Q D LVijay TamrakarОценок пока нет

- Ring Girder (Japan-1)Документ26 страницRing Girder (Japan-1)ewanz89100% (2)

- Vertical GatesДокумент243 страницыVertical GatesSannyBombeoJomocОценок пока нет

- Vertical Lift Hydraulic Gate DesignДокумент40 страницVertical Lift Hydraulic Gate Designmesam100% (3)

- Radial Gate Design ProcedureДокумент2 страницыRadial Gate Design ProcedureSangyt Karna100% (2)

- Steel Structure ST 37Документ11 страницSteel Structure ST 37aliОценок пока нет

- Design of Hydraulic GateДокумент20 страницDesign of Hydraulic GateTarunPatra100% (1)

- Silt Gravel Removal GateДокумент16 страницSilt Gravel Removal GateRaja SinghОценок пока нет

- Emergency GateДокумент14 страницEmergency GateQC&ISD1 LMD COLONYОценок пока нет

- Design of Radial GatesДокумент23 страницыDesign of Radial GatesWilliam MataОценок пока нет

- Radial GateДокумент47 страницRadial Gatenidhisasidharan100% (2)

- Hoist Capacity Calculation For Vertical Lift Fixed Wheel Type Gate With Rope Drum Hoist System (Size 6.50 M X 3.10 M HEAD 2.90 M)Документ4 страницыHoist Capacity Calculation For Vertical Lift Fixed Wheel Type Gate With Rope Drum Hoist System (Size 6.50 M X 3.10 M HEAD 2.90 M)amardeepОценок пока нет

- 1 Contents: Design Note On Level Crossing InletДокумент12 страниц1 Contents: Design Note On Level Crossing Inletsuranga dadallage100% (1)

- Design Calculations of Trash RackДокумент3 страницыDesign Calculations of Trash RackDheeraj Thakur100% (4)

- Is 4622 2003Документ27 страницIs 4622 2003Apurba Haldar100% (1)

- Skin PlateДокумент12 страницSkin Platerupesh dangolОценок пока нет

- Gate and Hoist DesignДокумент15 страницGate and Hoist DesignRajivОценок пока нет

- Gates and HoistsДокумент184 страницыGates and HoistsVikas Shrimali86% (7)

- Vertical Gates Design PDF FreeДокумент33 страницыVertical Gates Design PDF FreeAbdul wahid ButtОценок пока нет

- Designs of Gates in Minor IrrigationДокумент130 страницDesigns of Gates in Minor IrrigationacesrspОценок пока нет

- Canal RegulatorДокумент13 страницCanal RegulatorBibhuti Bhusan Sahoo100% (1)

- 16 Screw Hoist For Sluice Gate PDFДокумент10 страниц16 Screw Hoist For Sluice Gate PDFsamОценок пока нет

- Sample Calculation - CR GateДокумент5 страницSample Calculation - CR GateRose Mary100% (1)

- Design of Check DamДокумент4 страницыDesign of Check DamArnab Saha50% (2)

- Radial Gates Drawing Design - 2pgsДокумент2 страницыRadial Gates Drawing Design - 2pgsPaolo AfidchaoОценок пока нет

- Headworks DesignДокумент6 страницHeadworks Designrajeshsapkota123100% (2)

- Penstock Thickness CalculationДокумент2 страницыPenstock Thickness Calculationrakesh1987_careers100% (6)

- Design Sanjeev 1Документ18 страницDesign Sanjeev 1riteshreplyОценок пока нет

- 1offtake Gates DesignДокумент26 страниц1offtake Gates Designprasadnn2001Оценок пока нет

- This Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingДокумент2 страницыThis Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingXamiPati50% (2)

- Radial Gate-Design CheckДокумент5 страницRadial Gate-Design Checksuranga dadallage100% (1)

- 120kl OhsrДокумент21 страница120kl OhsrSrinivasa_DRao_6174100% (1)

- Gate Design PDFДокумент12 страницGate Design PDFJohn Emmanuel Nicole S. PalomaresОценок пока нет

- 3D Hydro Mechanical (Gates)Документ52 страницы3D Hydro Mechanical (Gates)api-19871259100% (2)

- Sickle PlateДокумент26 страницSickle PlateSambhav Poddar100% (1)

- Design of Intake Stoplog R0Документ25 страницDesign of Intake Stoplog R0Sujeet Kumar50% (2)

- Hoist CapacityДокумент10 страницHoist CapacityDheeraj ThakurОценок пока нет

- Khani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalДокумент10 страницKhani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalAsmita Koirala100% (1)

- Draft Tube GateДокумент23 страницыDraft Tube GateAnonymous sfkedkymОценок пока нет

- Sluice GateДокумент24 страницыSluice GateEldhoThomas100% (1)

- A New Improved Formula For Calculating Trashrack LossesДокумент8 страницA New Improved Formula For Calculating Trashrack LossesNikom KraitudОценок пока нет

- Hydro Dynamic ForcesДокумент34 страницыHydro Dynamic Forcesvikasgahlyan100% (1)

- Revised Jack WellДокумент1 страницаRevised Jack WellSandeep VaishnavОценок пока нет

- Anchor Block Stability AnalysisДокумент9 страницAnchor Block Stability AnalysisPrayas Subedi100% (1)

- Computation of Penstock Pipe For Pinacanauan, Scheme BДокумент6 страницComputation of Penstock Pipe For Pinacanauan, Scheme BAziz ul HakeemОценок пока нет

- Gate Slot LossesДокумент13 страницGate Slot LossesRex ImperialОценок пока нет

- Design of Clear Water Reservoir and Pump House of MahishnadiДокумент25 страницDesign of Clear Water Reservoir and Pump House of MahishnadiMukhlish AkhatarОценок пока нет

- Design Calculation of Spillway GateДокумент11 страницDesign Calculation of Spillway GateAnonymous sfkedkymОценок пока нет

- Spillway DesignДокумент6 страницSpillway DesignguildkeyОценок пока нет

- API 650 Design TanksДокумент34 страницыAPI 650 Design TanksSyedZainAli100% (13)

- Composite Steel GirderДокумент10 страницComposite Steel GirdersorowareОценок пока нет

- PurlinДокумент29 страницPurlinanbukgi100% (2)

- Lifting LugДокумент8 страницLifting LugAzwan ShahОценок пока нет

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОт EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОценок пока нет

- E NIT2 SWIC1819Документ6 страницE NIT2 SWIC1819Alok SarkarОценок пока нет

- Charges WBPHIDCL 230518Документ1 страницаCharges WBPHIDCL 230518Alok SarkarОценок пока нет

- 190-1991 (Coniferous Sawn Timber (Baulks and Scantlings) ) PDFДокумент8 страниц190-1991 (Coniferous Sawn Timber (Baulks and Scantlings) ) PDFvenkateswara rao pothinaОценок пока нет

- Calculation of Live Load Reaction For AbutmentsДокумент4 страницыCalculation of Live Load Reaction For Abutmentsvasu7900Оценок пока нет

- Guidelines On Construction & Maintenance of Borewells and TubewellsДокумент35 страницGuidelines On Construction & Maintenance of Borewells and TubewellsgauravОценок пока нет

- Positioning of Irc Live Loads:: Coventions Used Below Are in Reference With The Above FigureДокумент4 страницыPositioning of Irc Live Loads:: Coventions Used Below Are in Reference With The Above FigurejayrajlukoseОценок пока нет

- Powers and DutyДокумент10 страницPowers and DutyAlok SarkarОценок пока нет

- Sbi PPF 13000 301018Документ1 страницаSbi PPF 13000 301018Alok SarkarОценок пока нет

- Government of West Bengal: 11 A, Mirza Galib Street, Kolkata-87Документ2 страницыGovernment of West Bengal: 11 A, Mirza Galib Street, Kolkata-87Alok SarkarОценок пока нет

- Sample Investigative ReportДокумент3 страницыSample Investigative ReportQuennie QuiapoОценок пока нет

- Reference No. Debit Account Number Debit Branch Remarks Transaction Date Amount Status ReasonДокумент1 страницаReference No. Debit Account Number Debit Branch Remarks Transaction Date Amount Status ReasonAlok SarkarОценок пока нет

- Cost Material CalculatorДокумент10 страницCost Material Calculatoranamik00180% (5)

- Bridge FootДокумент19 страницBridge FootAlok SarkarОценок пока нет

- B.C - Nadanghat - Ballah PilingДокумент2 страницыB.C - Nadanghat - Ballah PilingAlok Sarkar100% (1)

- Progress Report 02.06.2017Документ11 страницProgress Report 02.06.2017Alok SarkarОценок пока нет

- Input SheetДокумент1 страницаInput SheetAlok SarkarОценок пока нет

- SL. No Type of Admixture Dosage Usage 1 Sikament FF (T/D) Trade Name of AdmixtureДокумент2 страницыSL. No Type of Admixture Dosage Usage 1 Sikament FF (T/D) Trade Name of AdmixtureAlok SarkarОценок пока нет

- DAWB Kalyani CivilДокумент1 страницаDAWB Kalyani CivilAlok SarkarОценок пока нет

- Cdac CeДокумент2 страницыCdac CeAlok SarkarОценок пока нет

- AkankshaДокумент2 страницыAkankshaAlok SarkarОценок пока нет

- IdiatorДокумент2 страницыIdiatorAlok SarkarОценок пока нет

- Govt - Accounting Rules 1990Документ63 страницыGovt - Accounting Rules 1990kandukurisrimanОценок пока нет

- ExpenseДокумент93 страницыExpenseAlok SarkarОценок пока нет

- Bridge FootДокумент19 страницBridge FootAlok SarkarОценок пока нет

- Utilisation of Fund Under Lwe P.S As Stood On 31.01.2017 West Bengal Police Housing & Infrastructure Development Corporation LTDДокумент8 страницUtilisation of Fund Under Lwe P.S As Stood On 31.01.2017 West Bengal Police Housing & Infrastructure Development Corporation LTDAlok SarkarОценок пока нет

- Rectangle BeamДокумент5 страницRectangle BeamAlok SarkarОценок пока нет

- Article - Screw Threads DesignДокумент7 страницArticle - Screw Threads DesignjdfdfererОценок пока нет

- MP LadДокумент5 страницMP LadAlok SarkarОценок пока нет

- Bridge FootДокумент19 страницBridge FootAlok SarkarОценок пока нет

- PHNCДокумент6 страницPHNCAmit MangaonkarОценок пока нет

- JKSSB Panchayat Secretary Adfar NabiДокумент3 страницыJKSSB Panchayat Secretary Adfar NabiSHEIKHXUNIОценок пока нет

- EnglishFile4e Intermediate TG PCM Vocab RevДокумент1 страницаEnglishFile4e Intermediate TG PCM Vocab RevB Mc0% (1)

- Eaap Critical Approaches SamplesДокумент2 страницыEaap Critical Approaches SamplesAcsana LucmanОценок пока нет

- CabillanДокумент12 страницCabillanvivivioletteОценок пока нет

- Cardiovascular System Heart ReviewerДокумент8 страницCardiovascular System Heart ReviewerImmanuel Cris PalasigueОценок пока нет

- What If The Class Is Very BigДокумент2 страницыWhat If The Class Is Very BigCamilo CarantónОценок пока нет

- M40 Mix DesignДокумент2 страницыM40 Mix DesignHajarath Prasad Abburu100% (1)

- Chapter - 2: Project AdministrationДокумент69 страницChapter - 2: Project AdministrationRenish RanganiОценок пока нет

- Cassandra Training 3 Day CourseДокумент5 страницCassandra Training 3 Day CoursedsunteОценок пока нет

- ElectionДокумент127 страницElectionRaviKumar50% (2)

- Catalogue Raisonne, Occult Sciences, Vol 2, Astrological Books - F Leigh GardnerДокумент194 страницыCatalogue Raisonne, Occult Sciences, Vol 2, Astrological Books - F Leigh GardnerWaterwind100% (4)

- Castigliano's 2nd TheoremДокумент29 страницCastigliano's 2nd TheoremMiddle East100% (4)

- PREETI and RahulДокумент22 страницыPREETI and Rahulnitinkhandelwal2911Оценок пока нет

- Summary of All Sequences For 4MS 2021Документ8 страницSummary of All Sequences For 4MS 2021rohanZorba100% (3)

- Abcs Booklet Kidney-Stones PDFДокумент20 страницAbcs Booklet Kidney-Stones PDFDendhy Dwi Handana SagitaОценок пока нет

- VW Golf 2 Sam Naprawiam PDFДокумент3 страницыVW Golf 2 Sam Naprawiam PDFScottОценок пока нет

- Oral Communication in Context Quarter 2: Week 1 Module in Communicative Strategies 1Документ10 страницOral Communication in Context Quarter 2: Week 1 Module in Communicative Strategies 1Agatha Sigrid GonzalesОценок пока нет

- Florida Firearm Bill of SaleДокумент4 страницыFlorida Firearm Bill of SaleGeemoОценок пока нет

- The Flowers of May by Francisco ArcellanaДокумент5 страницThe Flowers of May by Francisco ArcellanaMarkNicoleAnicas75% (4)

- An Aging Game Simulation Activity For Al PDFДокумент13 страницAn Aging Game Simulation Activity For Al PDFramzan aliОценок пока нет

- Literary Terms Practice Worksheet 3Документ11 страницLiterary Terms Practice Worksheet 3Jiezl Abellano AfinidadОценок пока нет

- How To Manage Asthma: A GuideДокумент44 страницыHow To Manage Asthma: A GuideSrinivas YerriboinaОценок пока нет

- LESSON 6 Perfect TensesДокумент4 страницыLESSON 6 Perfect TensesAULINO JÚLIOОценок пока нет

- AMBROSE PINTO-Caste - Discrimination - and - UNДокумент3 страницыAMBROSE PINTO-Caste - Discrimination - and - UNKlv SwamyОценок пока нет

- Correct Translation of 2-16Документ19 страницCorrect Translation of 2-16muhammad_zubair708110Оценок пока нет

- Ready For First TB Unit3Документ10 страницReady For First TB Unit3Maka KartvelishviliОценок пока нет

- Department of Education: Republic of The PhilippinesДокумент3 страницыDepartment of Education: Republic of The PhilippinesReno TadashiОценок пока нет

- Remarkings AirportsДокумент1 страницаRemarkings AirportsJuan Jose CaleroОценок пока нет

- BTCTL 17Документ5 страницBTCTL 17Alvin BenaventeОценок пока нет