Академический Документы

Профессиональный Документы

Культура Документы

Manage bills of materials and track assembly details with this Excel BOM template

Загружено:

wahid 786Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manage bills of materials and track assembly details with this Excel BOM template

Загружено:

wahid 786Авторское право:

Доступные форматы

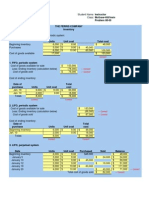

Template column Parent assembly Parent assembly Child items Assembly details Source items Source items Find

Owner Type Number Description Quantity Units RefDes Supplier Identifier UnitCost Extended

Function or usage to be specified by BOM author should not need to change contents of these cells these are common item properties shared by all assemblies these values may be unique for this assembly these supplier source items are related to child items, and independent of assembly details do not change contents of these cells

Item locator on assembly drawing, so that assembly drawing does not have to maintain actual part number Company responsible for creating or specifying the capabilities and performance of applied item (usually the assembly owner, or "hom Classification of the item, typically with a unique set of business rules Item identifier, typically corresponding to an inventory location Summarizes the major characteristics of item Number of units required for current assembly Units of measure Identifies the schematic and/or physical location a single instance of a child item Company responsible for creating or specifying the capabilities and performance of supplied item (the "partner" organization) Supplier's part number Cost of a single unit in same Units as child item Cost of a single unit, multiplied by the Quantity

Note: Many people hope to use Excel to manage bills of materials because it's commonly available, relatively cheap, and very familiar. While we've tried to make a useable BOM template, the fact is that Excel makes a really poor BOM tool compared to a specialized PLM database, and in most cases we don't recommend its use. Some of the risks of using Excel: 1 Use caution when sorting. Since cells are not tied together, sorting a list by, say, part Number or Type risks mismatching adjacent cells. Any SUM() that relies on rows should also be checked. 2 Inspect each BOM carefully after every edit. You'll be entering the same data over and over again and any cell can be changed (even accidentally), so it's likely that a child part number or description on one assembly may not match the same part on a different assembly. 3 Changes in one place won't get propagated across all other assemblies. Each spreadsheet must be separately discovered and updated (imagine changing the supplier source for a single screw or resistor). 4 Watch out for proprietary data, which may need to be cleaned before sharing with your supply chain (do you want your new suppliers to know what you pay your current suppliers?). 5 Carefully verify that units of measure are consistent (no mixing "each" and "gram") and calculated to ensure that the cost roll-up is correct. If a wire is specified in mm, and purchased in cm, will that conversion be caught? 6 When you decide to adopt a true BOM database system, you'll find that spreadsheets with little or no formatting will import easier than highly formatted (and more readable) spreadsheets. This BOM spreadsheet template will be somewhat useful for importing into a PLM database, but be careful about making significant changes (for example, do not put supplier parts directly below home parts). 7 Ensure you have access to all released BOMs every time you revise an item. Searching across spreadsheets to discover where a specific item is used is difficult, slow and error-prone. 8 Keep good records. There is no audit trail to identify why or when a change was made, or who authorized it. 9 Review and enforce business rules, such as item numbering and data revisioning, change approval authority, and using approved suppliers. 10 Verify each item's release status (pending, released, canceled) and lifecycle (prototype, production, obsolete) to ensure production assemblies aren't using prototype, unreleased or canceled parts. Excel is a very cheap solution that could easily cost you a lot of money in time & errors. On the other hand, PDXpert PLM offers: 1 Automatic assignment of part numbers according to specified rules 2 Free-form text searches to precisely locate exact matches and possible alternate parts 3 Snapshot duplication of an existing BOM for modification

4 Drag and drop of complete items onto the BOM 5 automatic application of each child item's current revision to existing BOMs; the released assembly always shows the latest released child item revision 6 Built-in "where used" lists for each item in your database: what assemblies use it, where it appears as a source, and what changes have affected it 7 Instant information about each item's release status and lifecycle 8 Unlimited supplier sources with preferred rank 9 Design, production and acceptance files attached directly to database items, for immediate viewing by engineers, quality personnel and supply chain managers 10 Data export for supply chain data exchange 11 A full audit trail of all changes You can download a free, fully-functional evaluation of PDXpert PLM now. Visit us at www.BuyPLM.com

(usually the assembly owner, or "home" organization)

m (the "partner" organization)

BOM Find 1 2 3 4 5 6 7 8 9 10 11

YourCompany Owner Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike Dirt Bike

Assembly Type Cable padel Pad Frot Pump Rear Pump Front Caliper Rear Caliper Front Disk Rear Disk Pipe Cover

Number B052 B0876 B0678 B0232 B0987 B0123 B0675 B0243 B0657 B0912 B0176

Description Brake Cable Brake padel Brake pad Front Brake Punp Rear Brake Pump Front Brake caliper rear Brake caliper Front Brake Disk Rear Brake Disk Brake Pipe Brake Lever Cover

Quantity

1 each Units 27.81 6.03 27.05 66.05 54 105.2 106.78 143.8 56.42 28.52 2.62

RefDes 110011 110012 110013 110014 110015 110016 110017 110018 110019 110020 110021

1.0000 2.0000 2.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

13.0000

624.28

Source Supplier Nissan harrison billet Russell Brembo Nissin Nissin Russell Russell harrison billet Brembo Brembo

Identifier M0593 M0546 M3203 M0959 M4739 M5930 M5942 M3920 M0588 M0943 M1059

Total cost: 657.3600 UnitCost Extended 27.8100 6.0300 27.0500 66.0500 54.0000 105.2000 106.7800 143.8000 56.4200 28.5200 2.6200 27.8100 12.0600 54.1000 66.0500 54.0000 105.2000 106.7800 143.8000 56.4200 28.5200 2.6200

624.2800

657.3600

Вам также может понравиться

- Oracle Inventory TablesДокумент6 страницOracle Inventory TablesANJUNEER81810% (1)

- Digests IP Law (2004)Документ10 страницDigests IP Law (2004)Berne Guerrero100% (2)

- The Diaper Industry in YearsДокумент13 страницThe Diaper Industry in YearsEric PassОценок пока нет

- Introduction To Sap: Summer Workshops 2010Документ30 страницIntroduction To Sap: Summer Workshops 2010saptechОценок пока нет

- SurvivalguideДокумент605 страницSurvivalguideThomasGarciaTDVAОценок пока нет

- EM Evaluation Final Report For NIJДокумент207 страницEM Evaluation Final Report For NIJtorrencialОценок пока нет

- Methods and Stats in I/O: - Science - Research - Data Analysis - Correlation and Regression - PsychometricsДокумент44 страницыMethods and Stats in I/O: - Science - Research - Data Analysis - Correlation and Regression - PsychometricsDave NemthОценок пока нет

- Project Investment CriteriaДокумент19 страницProject Investment Criteriajahid.coolОценок пока нет

- 0 AngelList LA ReportДокумент18 страниц0 AngelList LA ReportAndrés Mora PrinceОценок пока нет

- E-Procurnment 1Документ28 страницE-Procurnment 1smilealwplz100% (1)

- Invoicing Plan Enhancement in Purchase Order PDFДокумент17 страницInvoicing Plan Enhancement in Purchase Order PDFbalu4indiansОценок пока нет

- ASN Supplier How To Document Aug 09Документ35 страницASN Supplier How To Document Aug 09mccarthdОценок пока нет

- Change Request Template v1.1Документ6 страницChange Request Template v1.1Nikhil SatavОценок пока нет

- AP Invoice Entry Training: Application: Accounts Payable Process: Enter Invoices Objectives: PrerequisitesДокумент24 страницыAP Invoice Entry Training: Application: Accounts Payable Process: Enter Invoices Objectives: PrerequisiteshanharinОценок пока нет

- 02-QGG CS Functional Location UATДокумент8 страниц02-QGG CS Functional Location UATAbd El Rhman MostafaОценок пока нет

- Operations ManagementДокумент300 страницOperations Managementsrcool100% (1)

- Bill of Materials-PsДокумент20 страницBill of Materials-PsMauricio SeibelОценок пока нет

- Asia Pacific Return InstructionsДокумент2 страницыAsia Pacific Return InstructionsAdnan MohammadОценок пока нет

- ACCOUNTING CONTROL ACCOUNTSДокумент8 страницACCOUNTING CONTROL ACCOUNTSMehereen AubdoollahОценок пока нет

- Business Plan On Mineral Water.Документ36 страницBusiness Plan On Mineral Water.Robin Saha93% (14)

- The Role of Business ResearchДокумент23 страницыThe Role of Business ResearchWaqas Ali BabarОценок пока нет

- Vendor Evaluation in SAPДокумент8 страницVendor Evaluation in SAPJani Basha100% (1)

- SAP PM Fiori AppsДокумент16 страницSAP PM Fiori AppsVijayaw Vijji100% (1)

- Discrete Repetitive Manufacturing ERP Software System RFP Template 05-08-13Документ359 страницDiscrete Repetitive Manufacturing ERP Software System RFP Template 05-08-13SusanLKОценок пока нет

- Account StatementДокумент46 страницAccount Statementogagz ogagzОценок пока нет

- Warehouse Layout Giving A Man Space Is Like Giving A Dog A Computer: The Chances Are He Will Not Use It Wisely. (Bette-Jane Raphael)Документ4 страницыWarehouse Layout Giving A Man Space Is Like Giving A Dog A Computer: The Chances Are He Will Not Use It Wisely. (Bette-Jane Raphael)Malik SheikhОценок пока нет

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDДокумент29 страницSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngОценок пока нет

- SS ISO 9004-2018 - PreviewДокумент12 страницSS ISO 9004-2018 - PreviewKit ChanОценок пока нет

- O2C Cycle in CloudДокумент24 страницыO2C Cycle in Cloudmani100% (1)

- Third Party ProcessingДокумент3 страницыThird Party ProcessingVishnu Kumar SОценок пока нет

- AgribusinessДокумент6 страницAgribusinessshevadanzeОценок пока нет

- 13.SCM - Make Vs BuyДокумент2 страницы13.SCM - Make Vs BuyWah KhaingОценок пока нет

- Nestle Pure Life Water Marketing Plan For PakistanДокумент30 страницNestle Pure Life Water Marketing Plan For PakistanWaleed Butt67% (15)

- 8d-Report (Ishikawa)Документ12 страниц8d-Report (Ishikawa)Miro Vincek100% (1)

- LR WmsДокумент40 страницLR WmsRajeshDM73Оценок пока нет

- SAFETY STOCKS DEFINED AND CALCULATEDДокумент44 страницыSAFETY STOCKS DEFINED AND CALCULATEDSangeeth BhoopaalanОценок пока нет

- Oniqua Mat. DescriptionДокумент2 страницыOniqua Mat. Descriptionashwanibharadwaj1Оценок пока нет

- Warehouse KPI MetricsДокумент41 страницаWarehouse KPI MetricsABU YEROMEОценок пока нет

- HP-Cisco Alliance Strategy ChallengesДокумент6 страницHP-Cisco Alliance Strategy ChallengesSAHIL100% (1)

- RPA Use Cases in Finance and Profit & Loss:: Supplier On Boarding and Market IntelligenceДокумент1 страницаRPA Use Cases in Finance and Profit & Loss:: Supplier On Boarding and Market Intelligencechandana1465Оценок пока нет

- Evolution of Supply Chain ManagementДокумент7 страницEvolution of Supply Chain ManagementBryanОценок пока нет

- Report On Baby DiaperДокумент39 страницReport On Baby Diaperwahid 786Оценок пока нет

- Reporting ManualДокумент75 страницReporting ManualAlem VigarОценок пока нет

- Lean Operations: MRP vs. JitДокумент32 страницыLean Operations: MRP vs. JitSamantha SiauОценок пока нет

- Software Application and Products in Data ProcessingДокумент17 страницSoftware Application and Products in Data ProcessingCruisecodersОценок пока нет

- Investment Appraisal Techniques: Prepared By: Ms ShazДокумент37 страницInvestment Appraisal Techniques: Prepared By: Ms Shazshazlina_liОценок пока нет

- Psych Assessment Practice TestДокумент24 страницыPsych Assessment Practice TestCyrylle PagatpatanОценок пока нет

- Monthly Product Inventory TemplateДокумент3 страницыMonthly Product Inventory TemplateLukas Puguh SantosaОценок пока нет

- Cycle Counting InventoryДокумент6 страницCycle Counting InventoryAlex RomeroОценок пока нет

- Global inventory visibility with cloud networksДокумент17 страницGlobal inventory visibility with cloud networksArvin PagarОценок пока нет

- Bill of Material for Francis Turbine Control PanelДокумент7 страницBill of Material for Francis Turbine Control Panelneeraj_kalaОценок пока нет

- MES Short Lists Feature Plex, FlexNet, Even HighJump and SAPДокумент4 страницыMES Short Lists Feature Plex, FlexNet, Even HighJump and SAPashish.khangar9358Оценок пока нет

- Chap 008Документ11 страницChap 008dbjnОценок пока нет

- Implement Oracle ECO ProcessДокумент12 страницImplement Oracle ECO Processschak20Оценок пока нет

- Config Guide For Shipment & Shipment Cost DocumentДокумент57 страницConfig Guide For Shipment & Shipment Cost DocumentRanjeet DasОценок пока нет

- Inventory Management System A Complete Guide - 2019 EditionОт EverandInventory Management System A Complete Guide - 2019 EditionОценок пока нет

- Warehouse ReceiptДокумент14 страницWarehouse ReceiptPriyatham ReddyОценок пока нет

- SCLM ChecklistДокумент38 страницSCLM ChecklistMayur GaidhaneОценок пока нет

- Vendor Application Form - LAFONДокумент9 страницVendor Application Form - LAFONmusewejamesoumaОценок пока нет

- 8UEJ7B-OTC Community Webinar Advance Returns ManagementДокумент23 страницы8UEJ7B-OTC Community Webinar Advance Returns ManagementlastuffОценок пока нет

- Oracle Applications 11i Documentation ListДокумент6 страницOracle Applications 11i Documentation ListAmarjeet PatraОценок пока нет

- The Ten Principles of Material Handling: The Key To Greater Productivity, Customer Service and ProfitabilityДокумент43 страницыThe Ten Principles of Material Handling: The Key To Greater Productivity, Customer Service and ProfitabilitySajid Yasin100% (1)

- Sales Order Cycle Review ReportДокумент36 страницSales Order Cycle Review Reportjoe_sagi85Оценок пока нет

- Comprehensive ERP Solution for ManufacturersДокумент17 страницComprehensive ERP Solution for ManufacturersericonasisОценок пока нет

- Military and Veterans' Benefits Observations On The Concurrent Receipt of Military Retirement and VA Disability CompensationДокумент15 страницMilitary and Veterans' Benefits Observations On The Concurrent Receipt of Military Retirement and VA Disability CompensationpolitixОценок пока нет

- Accenture High Performance Cost AccountingДокумент16 страницAccenture High Performance Cost AccountingogbomoshoОценок пока нет

- Creating Purchase OrderДокумент43 страницыCreating Purchase Ordermark443r100% (1)

- MRP Part IДокумент48 страницMRP Part IDanielle David AbandoОценок пока нет

- SAP Transaction Codes for Production & Maintenance PersonnelДокумент10 страницSAP Transaction Codes for Production & Maintenance PersonnelWajid NizamiОценок пока нет

- New Layout PlanningДокумент21 страницаNew Layout PlanningamuОценок пока нет

- Inventory Improvement QuestionnaireДокумент6 страницInventory Improvement QuestionnaireShailesh SoniОценок пока нет

- Odette Transport Label GuidelineДокумент15 страницOdette Transport Label GuidelinePedro LaçoОценок пока нет

- Sir, You Are Requested To Change The Address of The Following POS. Current Address: Cooperative Housing Society Canal Road LahoreДокумент1 страницаSir, You Are Requested To Change The Address of The Following POS. Current Address: Cooperative Housing Society Canal Road Lahorewahid 786Оценок пока нет

- DiaperДокумент15 страницDiaperwahid 786Оценок пока нет

- Problem Solving MethodsДокумент1 страницаProblem Solving Methodswahid 786Оценок пока нет

- NSU FALL 2012 FIN254.9 Term Paper On Aramit LimitedДокумент24 страницыNSU FALL 2012 FIN254.9 Term Paper On Aramit LimitedSamaan RishadОценок пока нет

- 1 MDL299356Документ4 страницы1 MDL299356Humayun NawazОценок пока нет

- Lessons From The Enron ScandalДокумент3 страницыLessons From The Enron ScandalCharise CayabyabОценок пока нет

- Bangalore University SullabusДокумент35 страницBangalore University SullabusJayaJayashОценок пока нет

- 09 - Chapter 2 PDFДокумент40 страниц09 - Chapter 2 PDFKiran PatelОценок пока нет

- Supply Chain Management Abbot Pharmaceutical PDFДокумент23 страницыSupply Chain Management Abbot Pharmaceutical PDFasees_abidОценок пока нет

- Assignment 2 - IPhonesДокумент6 страницAssignment 2 - IPhonesLa FlâneurОценок пока нет

- Competitive Advantage in Mature Industries: OutlineДокумент9 страницCompetitive Advantage in Mature Industries: OutlineRohanОценок пока нет

- SAVAYA The Martinez-Brothers PriceListДокумент2 страницыSAVAYA The Martinez-Brothers PriceListnataliaОценок пока нет

- Gestion de La Calidad HoqДокумент8 страницGestion de La Calidad HoqLuisa AngelОценок пока нет

- IB Economics Notes - Macroeconomic Goals Low Unemployment (Part 1)Документ11 страницIB Economics Notes - Macroeconomic Goals Low Unemployment (Part 1)Pablo TorrecillaОценок пока нет

- QMS PrinciplesДокумент5 страницQMS PrinciplesShankar AsrОценок пока нет

- Edvinsson, L. - 1997 - Developing Intellectual Capital at Skandia PDFДокумент10 страницEdvinsson, L. - 1997 - Developing Intellectual Capital at Skandia PDFreg_kata123Оценок пока нет

- Hire PurchaseДокумент16 страницHire PurchaseNaseer Sap0% (1)

- Marketing ChannelДокумент21 страницаMarketing ChannelNikhil DubeyОценок пока нет

- AdvancingДокумент114 страницAdvancingnde90Оценок пока нет

- Basic Economic Questions ExplainedДокумент20 страницBasic Economic Questions ExplainedRiemann SolivenОценок пока нет

- Importance of Entrepreneurship EducationДокумент8 страницImportance of Entrepreneurship EducationRansel Burgos100% (1)