Академический Документы

Профессиональный Документы

Культура Документы

2 Phase Flow Pressure Drop Calc Suresh1

Загружено:

Phani Raj MАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2 Phase Flow Pressure Drop Calc Suresh1

Загружено:

Phani Raj MАвторское право:

Доступные форматы

Client: Project Name: Project No.

Location:

Issued for

Rev

Originated by Suresh R. Asi Date: Document No. Page No.

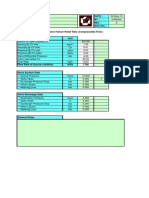

TWO PHASE FLOW PRESSURE DROP DUE TO FRICTION AND ELEVATION

Gas Inputs Description Flowrate(Qg) Density Viscosity Liquid Input Flowrate(Ql) Density Viscocity Surface Tension Pipe Input Inner dia Length Outputs Flowing Liq. Vol. Fraction Liquid Holdup (Hld) Renolds Number

Pressure Drop due to FRICTION

Value Units 425 m^3/hr 20.8 Kg/m^3 1.50E-05 Pa.S

17 m^3/hr 880 Kg/m^3 0.02 Pa.S 1.50E-05 N/m

150 1200

mm m

0.038 0.150 4.16E+04 339.026 30 31.879 370.905

Let Liq. Holdup = Liq. Vol. Fraction ( Initially )

kPa

Elevation

Pressure Drop due to ELEVATION

m kPa kPa

TOTAL PRESSURE DROP = Notes:

OR

55.63574

psi

1. Assume, Liquid Holdup = Flowing Liq. Vol. Fraction, Initially. 2. Use the calculated Reynolds number and Flowing Liq. Vol. Fraction to find out the Liquid Holdup from the Graph in Sheet 2 3. Iterate Liquid Holdup for constant Flowing Liq. Vol. Fraction and for various Reynolds numbers obtained by changing the Liquid Holdup. Iterate until you get the best Liquid Holdup value. 4. Compare the calculated Liquid Holdup with the Liquid Holdup obtained using Ne.

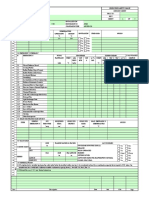

FLOWRATE From To BPD 900 GPM(US) 1

m^3/hr 5.94 0.23 Note

LENGTH From To in 6 ft 19343

mm 150 5802900

FLOWRATE (for Gas) From To lb/hr MMSCFD From lb/hr 10 To 20741.5 20741.5225 m^3/hr 39.2831439

Please enter Molecular weight of Gas below Gas Mol.wt 18.85 Please enter Gas Density in Kg/m^3 below

Density

237.6

From lb/ft^3

DENSITY To Kg/m^3 14.85 237.6

SURFACE TENSION From To N/m dyn/cm 32.2 0.0322

From cP

VISCOSITY To Pa.s 0.0269 0.0000269

Contact: Suresh Reddy Asi Chemical Engineer Email: sureshreddy_asi@yahoo.com Disclaimer: The information and methods included within this spreadsheet are presented for preliminary line sizing review. It is intended to be used by technically skilled persons at their own discretion. I do not warrant the suitability or accuracy of these methods

References: 1 Crane Technical Paper No. 410, Appendix B, 1991. 2 Scott S. Haraburda, "Calculating Two-Phase Pressure Drop" Chemical Processing 3 Ivor R. Ellul, Geir Saether, Mack E. Sheppen, "The Modelling of Multiphase systems under Steady-State Transient Conditions - A Tutorial", Pipeline Simulation Interest Group

ical Processing ltiphase systems under Steady-State and

Вам также может понравиться

- CPF-010 Process Line Sizing Attachment - 0Документ38 страницCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- PSV Sizing For Two Phase FlowДокумент28 страницPSV Sizing For Two Phase FlowSyed Haideri100% (1)

- Safety Valve Blowback Calculation (Optimization2)Документ18 страницSafety Valve Blowback Calculation (Optimization2)Durjoy ChakrabortyОценок пока нет

- PSV Thermal SizingДокумент16 страницPSV Thermal Sizingahmad santoso0% (1)

- Line Sizing - 2PHASEДокумент11 страницLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Vertical Knock Out Drum With Wire Mesh For NДокумент1 страницаVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- PSV Sizing Tool API Based Calc SheetsДокумент11 страницPSV Sizing Tool API Based Calc Sheetsvigneshpingkoo78750% (1)

- Blowdown OrificeДокумент2 страницыBlowdown OrificeOmprakaash MokideОценок пока нет

- CVCALCSДокумент10 страницCVCALCSmishtinilОценок пока нет

- API520 RVsizingДокумент7 страницAPI520 RVsizingdemem09100% (3)

- Air Cooler - DesignДокумент7 страницAir Cooler - Designkarthipetro100% (1)

- Heater Treater CalculationДокумент12 страницHeater Treater Calculationwahyu100% (1)

- Control Valve Analysis1Документ13 страницControl Valve Analysis1Ekundayo JohnОценок пока нет

- Control Valve CalcДокумент7 страницControl Valve Calcartneves100% (1)

- Steam Pressure DropДокумент8 страницSteam Pressure DropDavid Muñoz CastroОценок пока нет

- All Sep CalcДокумент22 страницыAll Sep Calcbharathscds100% (3)

- Process Line SizingДокумент21 страницаProcess Line Sizingsj_scribdОценок пока нет

- Line Sizing LiqДокумент12 страницLine Sizing LiqDana GuerreroОценок пока нет

- Control Valve Failure Relief Rate - Gas ServiceДокумент3 страницыControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Документ33 страницыSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshОценок пока нет

- Line Sizing Criteria As Per Different International StandardsДокумент12 страницLine Sizing Criteria As Per Different International StandardsbadelitamariusОценок пока нет

- 3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Документ1 страница3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Mike DukasОценок пока нет

- Pump CalcДокумент1 страницаPump CalcMoch WildanОценок пока нет

- Spreadsheet To Design SeparatorsДокумент21 страницаSpreadsheet To Design SeparatorsreninbabaskiОценок пока нет

- CFD Modeling Analysis of A Vertical Gas Liquid SeparatorДокумент9 страницCFD Modeling Analysis of A Vertical Gas Liquid SeparatorTanweer HussainОценок пока нет

- 05 Wake Frequency Calculation - 09 DG 005 Rev 0Документ11 страниц05 Wake Frequency Calculation - 09 DG 005 Rev 0vivek_enggОценок пока нет

- Ejercicio 246 PSV438 RESUELTOДокумент2 страницыEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaОценок пока нет

- Tutorial PipeFLoДокумент1 страницаTutorial PipeFLohel hel100% (1)

- Tube Rupture (Two Phase - API App-D Method)Документ5 страницTube Rupture (Two Phase - API App-D Method)Indra Kurniawan WijayaОценок пока нет

- 01 - Fluid FlowДокумент76 страниц01 - Fluid FlowMubarak AhmadОценок пока нет

- Control Valve Sizing PDFДокумент5 страницControl Valve Sizing PDFsivaОценок пока нет

- Control Valve Calculation SpreadsheetДокумент3 страницыControl Valve Calculation Spreadsheetweimar solizОценок пока нет

- 3phase Separator Size 2010 VerAДокумент24 страницы3phase Separator Size 2010 VerACristina BarbulescuОценок пока нет

- Control Valve Sizing - LiquidДокумент4 страницыControl Valve Sizing - Liquidcharro1623Оценок пока нет

- Orifice Plate Showing VenaДокумент6 страницOrifice Plate Showing VenahugepotatoОценок пока нет

- No Yes No Yes No Yes No Yes No Yes No YesДокумент8 страницNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnОценок пока нет

- Flare Example RatingДокумент21 страницаFlare Example RatingRafael ReyesОценок пока нет

- Valve SizingДокумент6 страницValve Sizingcarlosiq37Оценок пока нет

- Fire Relief Dynamic StudyДокумент2 страницыFire Relief Dynamic StudyImtinan MohsinОценок пока нет

- PSV Calcs PDFДокумент8 страницPSV Calcs PDFatulОценок пока нет

- Gas Line Size-1Документ12 страницGas Line Size-1svnaik14Оценок пока нет

- Sizing Calculation SHTДокумент3 страницыSizing Calculation SHT903352100% (1)

- Gas Line SizingДокумент7 страницGas Line SizingTun Naing WinОценок пока нет

- Aspen Dynamics DIERS BenchmarksДокумент9 страницAspen Dynamics DIERS BenchmarksAmir JoonОценок пока нет

- Pressure Drop CalculationДокумент13 страницPressure Drop CalculationknsaravanaОценок пока нет

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Документ2 страницыWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariОценок пока нет

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionДокумент2 страницыM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381Оценок пока нет

- Flare RadiationДокумент4 страницыFlare RadiationSatria 'igin' Girindra NugrahaОценок пока нет

- 2 Phase Flow Pressure Drop Calc Suresh1Документ6 страниц2 Phase Flow Pressure Drop Calc Suresh1NKОценок пока нет

- Ductulator May 2010Документ10 страницDuctulator May 2010Arshavin Watashi WaОценок пока нет

- Pipe Size CalcДокумент19 страницPipe Size Calcnitin_bir100% (1)

- Line Size of Pipe Based On Economic VelocityДокумент19 страницLine Size of Pipe Based On Economic Velocitymabrouk2013Оценок пока нет

- Lab Report Permeability MeasurementДокумент9 страницLab Report Permeability Measurementsher afganОценок пока нет

- Ductulator May 2010Документ8 страницDuctulator May 2010haroub_nasОценок пока нет

- Module 4a - Line Sizing CalculationДокумент9 страницModule 4a - Line Sizing CalculationEkundayo JohnОценок пока нет

- Validation Report On The 2-Phase Line SizingДокумент18 страницValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- Pipeline DesignДокумент60 страницPipeline DesignEduardo Paulini Villanueva0% (1)

- Line SizingДокумент18 страницLine SizingNathaniel Thomas100% (1)

- API 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingДокумент13 страницAPI 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingOmer EkerОценок пока нет

- Flow Meter Sizing MOSДокумент11 страницFlow Meter Sizing MOSra9622Оценок пока нет

- ISF Milk TankДокумент2 страницыISF Milk TankPhani Raj MОценок пока нет

- 0100 3045 PDFДокумент24 страницы0100 3045 PDFPhani Raj MОценок пока нет

- 0100 3045 PDFДокумент24 страницы0100 3045 PDFPhani Raj MОценок пока нет

- Pressure Relief Safety ValvesДокумент52 страницыPressure Relief Safety Valveswah_ma100% (3)

- Condensate Pumps and Energy Recovery PDFДокумент17 страницCondensate Pumps and Energy Recovery PDFPhani Raj MОценок пока нет

- Comprimo® Sulfur Solutions: ApplicationsДокумент1 страницаComprimo® Sulfur Solutions: ApplicationsestudiemosОценок пока нет

- Best Inspirational QuotesДокумент37 страницBest Inspirational Quotessaisuni.mОценок пока нет

- Process Description - ARU Rev BДокумент8 страницProcess Description - ARU Rev BPhani Raj MОценок пока нет

- Process Description - ARU Rev BДокумент8 страницProcess Description - ARU Rev BPhani Raj MОценок пока нет

- Territorial Jurisdiction of Civil Courts in Nalgonda DistrictДокумент6 страницTerritorial Jurisdiction of Civil Courts in Nalgonda DistrictPhani Raj MОценок пока нет

- Basic Antisurge ControlДокумент2 страницыBasic Antisurge ControlPhani Raj MОценок пока нет

- 04 (Equipment Sizing)Документ26 страниц04 (Equipment Sizing)Phani Raj MОценок пока нет

- Heat Transfer QuestionsДокумент6 страницHeat Transfer QuestionsPhani Raj MОценок пока нет

- Sodium Hypochlorite: General Information For The ConsumerДокумент31 страницаSodium Hypochlorite: General Information For The ConsumerMarco Franco0% (1)

- 09 Advanced ColumnsДокумент18 страниц09 Advanced ColumnsPhani Raj MОценок пока нет

- 29eec5 Chapter 20-2Документ78 страниц29eec5 Chapter 20-2Phani Raj MОценок пока нет

- 2 Phase Flow Pressure Drop Calc Suresh1Документ853 страницы2 Phase Flow Pressure Drop Calc Suresh1Phani Raj M100% (1)

- 1.6a Line Sizing SlidesДокумент24 страницы1.6a Line Sizing SlidesPhani Raj M100% (1)

- 1.6a Line Sizing SlidesДокумент24 страницы1.6a Line Sizing SlidesPhani Raj M100% (1)

- Design Process Documentation - John DemeterДокумент2 страницыDesign Process Documentation - John DemeterPhani Raj MОценок пока нет

- 1.6a Line Sizing SlidesДокумент24 страницы1.6a Line Sizing SlidesPhani Raj M100% (1)

- Food Nutrient Analysis LabДокумент2 страницыFood Nutrient Analysis LabHansa BorichaОценок пока нет

- NSTC 13 SamplePaper 2014-16 XIДокумент24 страницыNSTC 13 SamplePaper 2014-16 XIAqeel Ali0% (1)

- Detailed Lesson PlanДокумент5 страницDetailed Lesson PlanGspr BoJoyОценок пока нет

- Week 6,7 - HE - Similitude and Dimensional AnalysisДокумент45 страницWeek 6,7 - HE - Similitude and Dimensional AnalysisRana Asad AliОценок пока нет

- 4CH0 - 2C - Rms - 20170823-May June 2017Документ19 страниц4CH0 - 2C - Rms - 20170823-May June 2017Yasara AbeynayakeОценок пока нет

- Chapter 17Документ60 страницChapter 17Rogerio AndradeОценок пока нет

- Odoriferous Substances - Google Search PDFДокумент1 страницаOdoriferous Substances - Google Search PDFMuhammad Arif ShekhaniОценок пока нет

- Theory of Structures With AnswersДокумент17 страницTheory of Structures With AnswersJoshua OrcalesОценок пока нет

- Perturbation ExamplesДокумент6 страницPerturbation Exampleserad_5Оценок пока нет

- LC Series Oval Gear Flow MeterДокумент6 страницLC Series Oval Gear Flow MeterGuillermo RoblesОценок пока нет

- Paint and Coatings Industry OverviewДокумент3 страницыPaint and Coatings Industry OverviewYash VasantaОценок пока нет

- Diffusion in Metals: The Flux of History: A. A. HoweДокумент7 страницDiffusion in Metals: The Flux of History: A. A. HoweDaniel OrdoricaОценок пока нет

- Polyvinyl Chloride (PVC) : A Petrochemical ProductДокумент21 страницаPolyvinyl Chloride (PVC) : A Petrochemical ProductifyОценок пока нет

- Temephos WHOДокумент24 страницыTemephos WHOMochHabibEl-Huseiny0% (1)

- Physical Processing of MineralsДокумент84 страницыPhysical Processing of MineralsRobbyОценок пока нет

- Astronomy Chapter 1 NotesДокумент4 страницыAstronomy Chapter 1 NoteskrmooshОценок пока нет

- AIPMT 2013 Code W1 Question PaperДокумент43 страницыAIPMT 2013 Code W1 Question PaperNageswarОценок пока нет

- Week 1: Learning Activity 1 Short Quiz 1Документ39 страницWeek 1: Learning Activity 1 Short Quiz 1yagami100% (1)

- Designing For Pressure Safety Valves in Supercritical ServiceДокумент4 страницыDesigning For Pressure Safety Valves in Supercritical ServiceSrinivas BobbyОценок пока нет

- CH 9 AnswersДокумент31 страницаCH 9 AnswersIbrahim A Said100% (2)

- SA Model NasaДокумент9 страницSA Model NasaMohit GuptaОценок пока нет

- Demystifying Quantum MechanicsДокумент10 страницDemystifying Quantum Mechanicsmrbubos0% (1)

- Sheet 3Документ6 страницSheet 3Keroles SabryОценок пока нет

- Radiologic Science For Technologists Physics Biology and Protection 11th Edition Bushong Test BankДокумент26 страницRadiologic Science For Technologists Physics Biology and Protection 11th Edition Bushong Test Bankcostardrivel.4vwhu100% (11)

- Lecture 1Документ31 страницаLecture 1Yingqi SuОценок пока нет

- Tech Note A Look Under The Hood of LunaticДокумент13 страницTech Note A Look Under The Hood of Lunaticd3392104002Оценок пока нет

- Colleen Samantha Dioquino, Christopher Jay RobidilloДокумент5 страницColleen Samantha Dioquino, Christopher Jay RobidilloLohith HRОценок пока нет

- Pages From ASHRAE Laboratory Design Guide Second EditionДокумент1 страницаPages From ASHRAE Laboratory Design Guide Second EditionAhmed NabilОценок пока нет

- Heat and Mass TransferДокумент537 страницHeat and Mass TransferShafeequ RahmanОценок пока нет