Академический Документы

Профессиональный Документы

Культура Документы

Hydraulic Flushing Rolls Royse

Загружено:

msmldxbАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydraulic Flushing Rolls Royse

Загружено:

msmldxbАвторское право:

Доступные форматы

Fact Sheet

Oil flushing services

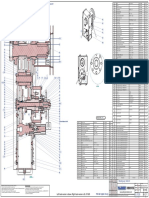

Marine services Oil flushing for - hydraulic oil, motor oil and gear oil. The systems are also suitable for flushing complex pipework and new engines.

Flushing units are housed in easily transported ISO containers

Benefits of the service Increased equipment life - Regular flushing of the system significantly reduces the potential for system failure due to oil contamination, as old oil and residues left in the lines and system, as the reservoir is drained, cannot be easily re moved in another way. Reduced expensive downtime - Using one of our high performance flushing units and trained technician is quick and efficient, helping to minimise downtime. Optimised maintenance intervals - Regular oil sampling and analysis provides an effective, preventive maintenance programme. Reduced maintenance costs & improved productivity - The cost of new oil is saved as it can be recovered, filtered and reused after flushing. Clean oil ensures consistent machine performance with reduced down time.

21.Marine services-1 of 4-29.06.11

Consistent quality and safety - All units are equipped with inline laser particle counters & oil sampling, and have level/ pressure monitoring with automatic shutdown on adjustable set values.

Fact Sheet

Reduce expensive hydraulic system downtime

As the cost of sophisticated, high pressure systems continues to rise, proactive maintenance is imperative to maximise the system service life and minimise operating costs. The single most important preventive maintenance procedure is regular oil sampling and analysis. Over 96% of all hydraulic failures can be traced directly to oil that has been improperly cared for. As long as the oil has not lost viscosity and has not been damaged by overheating, it can normally be reused by flushing the system. When the oil is just drained from the reservoir and the system replenished, several gallons of old oil and residues are left in the lines and components. As new clean oil is introduced, it mixes with the old oil, absorbing the contaminants, circulating them through the system again to cause further damage. Flushing the system is the only way to remove these potentially damaging residues as part of the maintenance regime. At Rolls-Royce, we recommend the following process to reduce expensive downtime: 1. Clean the hydraulic system properly 2. Keep the system clean 3. Monitor the hydraulic fluid 4. Maintaining cleanliness levels

Self contained high performance flushing units are available for deployment worldwide together with a trained technician.

As a doctor can see signs of illness in a patient by analysis of body fluids, a trained hydraulic technician can find signs of component wear by oil analysis

All flushing system units are based on ISO containers and are designed to operate virtually anywhere. Strategically located at hubs around the world, we aim to service our customers globally by working around your vessels schedule.

21.Marine services-2 of 4-29.06.11

Fact Sheet

Keeping your hydraulic system clean

1. Flushing cleans the system properly As the cost of sophisticated, high pressure systems continues to rise, proactive maintenance is imperative to maximise the system service life and minimise operating costs. Always flush a new or a rebuilt hydraulic system, filter the oil up to the required NAS level or ISO code. Rolls-Royce provides this service and will inspect and verify that the system, the hydraulic piping, storage tanks and filling routines meet the required standards. Our flushing units are hired out with a trained technician, as no matter how good the machine, it is only as good as the man operating it. We provide a full flushing report and plus documention to customer specification. 2. Keeping your system clean Once the system has been fully flushed, always fill the tank with oil, filtered to the manufacturers standards. New equipment, hoses, pipework must never be installed without checking they have been properly cleaned. The Rolls-Royce flushing unit supplies the filtered oil and a variety of filter units, custom made or in stock filter trolleys can be made available. Filters for our units in stock High pressure hydraulic work 3. Monitoring your hydraulic fluid Rolls-Royce can monitor your hydraulic fluid for you and optimise your maintenance intervals. Hydraulic equipment not in regular use must be checked for bacteria growth before connecting to a hydraulic circuit. Our periodic oil sampling allows for early discovery of: Water contents Lubricant quality Contamination level 4. Maintaining cleanliness levels Do you know what standard of system cleanliness you have? A trained Rolls-Royce technician can find signs of component wear through oil analysis. The investment in a proactive approach will quickly be recovered through improved performance and reduced operating costs. Vendors including Hgglunds, Rexroth, Danfoss, Parker and Poclain Hydraulics have the same NAS/ISO standard for oil cleanliness. ISO code 17/15/12 or better. (NAS1638 6 or better)

Complex onboard hydraulic systems must have clean oil to be reliable. The small cost of flushing the system far outweighs the cost of an expensive system failure and the associated downtime.

All flushing units are built on the same principle Fixed displacement pump Stepless regulation of the pumps Frequency converter controlled electric motor for hydraulic pump Heating for right viscosity to loose build-up in the system Huge filter capacity Easy change of flow direction Level/pressure monitoring with automatic shutdown on adjustable set values. Online laser particle counter and oil sampler

21.Marine services-3 of 4-29.06.11

Fact Sheet Fact Sheet

Regular flushingyour assurance of system Regular flushing is is your assurance of cleanliness system cleanliness

CLEANLINESS LEVEL CORRECTION TABLE Particles / Milliltre ISO Code >2 Micrometers >5 Micrometers >15 Micrometers NAS 1638 Disavowed SAE

Three sizes of flushing unit available: Three sizes of flushing unit areare available 3600 Flushing Unit: 3600 Flushing Unit Size 20 ISO container Size Weight 20 ISO Ton n/o container 10 Weight 100-954 Tong.p.m n/o Flow Flow 0-954 g.p.m 3600 lpm 3600 lpmBAR Pressure 0-20 Heating 18-30-45 BARkW Pressure 0-20 Tank ca.21000 kW gallon Heating 18-30-45 ca.8000 gallon liter Tank ca.21000 Return Filterca.8000 microns) 1- 4 (2 liter 4 pc 2lines / directions simultaneously Return Filter 1- 4 (2 microns) 4 pc 2lines / directions simultaneously

(1964) 12 11 10 9 8 7 6 5 4 3 2 1 -

Level (1963) 6 5 4 3 2 1 0 -

23/21/18 22/20/18 22/20/17 22/20/16 21/19/16 20/18/15 19/17/14 18/16/13 17/15/12 16/14/12 16/14/11 15/13/10 14/12/9 13/11/8 12/10/8 12/10/7 12/10/6

80,000 40,000 40,000 40,000 20,000 10,000 5,000 2,500 1,300 640 640 320 160 80 40 40 40

20,000 10,000 10,000 10,000 5,000 2,500 1,300 640 320 160 160 80 40 20 10 10 10

2,500 2,500 1,300 640 640 320 160 80 40 40 20 10 5 2.5 2.5 1.3 .64

This chart illustrates why operating with hydraulic oil at a cleanliness level below ISO code hydraulic oil at level below ISO code 17/15/12 can have a significant impact on system performance. 17/15/12 can have a significant impact on system performance.

2400 Flushing Unit: (NEW) 2400 flushing unit (NEW) 10 Size Size 10 ISO ISO container container Weight 6 Ton n/o Weight 6 Ton n/o Flow 0-630 g.p.m Flow 0-630 g.p.m 2400 lpm 2400 lpm Pressure 0-20 BAR Pressure 0-20 BAR Heating 18-30-45 kW Heating 18-30-45 kW gallon Tank Ca.634 Tank Ca.634 Ca.2400 gallon liter liter Return FilterCa.2400 microns) 1- 3 (2 Return pc 2lines (2directions simultaneously 4 Filter 1- 3 / microns) 4 pc 2lines / directions simultaneously

1200 Flushing 1200 flushing unit Unit: Size Size Weight Weight Flow Flow 20 ISO ISO container container 20 55 TonTon n/o n/o 0-370 g.p.m 0-370 g.p.m 1200 1200 lpmlpm Pressure 0-20 Pressure 0-20 BARBAR Heating 18-30-45 kW Heating 18-30-45 kW Tank ca.528 gallon Tank ca.528 gallon ca.2000 liter ca.2000 liter Return Filter 1- 2 (2 microns) Return Filter 1- 2 (2 microns) 2 pc 2lines / directions simultaneously 2 pc 2lines / directions simultaneously

From experience we have found that the quality of new oil can vary. Typically we see ISO code 22/20/17 have 1638 that From experience we or NASfound 11. the Only by flushing as part of the quality of new oil can vary. Typically we see maintenance routine can system ISO code 22/20/17 or NAS 1638 11. cleanliness be assured. Only by flushing as part of the maintenance routine can system cleanliness be assured. Rolls-Royce as a Total Solutions Provider Flushing Services is just one of the many services Rolls-Royce provides in our wide Rolls-Royce as a total solutions provider range of service offerings. At Rolls-Royce, we pride ourselves in our ability to work Flushing services is just one of the many services Rolls-Royce provides in our wide range of in partnership with our customers where we listen, establish requirements, and service offerings. At Rolls-Royce, we pride ourselves in our ability toof services is then offer service solutions to match. Our comprehensive menu work in partnership with our customers where we different operational environments to offer varying solutions to designed to accomodate listen, establish requirements, and then offer service support needs, and manage the of services is designed to accomodate different operational match. Our comprehensive menu balance between operational availability and cost. Create the peace of mind by support needs, and manage the balance between environments to offer varyingmaking Rolls-Royce your single point of contact. operational availability and cost. Create the peace of mind by making Rolls-Royce your single point of contact.

Rolls-Royce AS Rolls-Royce Marine AS Deck Machinery Seismic and Deck Machinery Seismic and Subsea services Ulsteinvik Subsea services Ulsteinvik PO BOX 193, NO-6069 Hareid PO BOX 193, NO-6069 Hareid Tel: +47 70 01 33 00 Tel: +47 70 01 33 00 Service tel: +47 916 22 336 Service tel: +47 916 22 336 E-mail: osc@odim.com E-mail: osc@odim.com

2011 Rolls-Royce plc 2011 Rolls-Royce plc Whilst this information is given in good faith, Whilst this information is given in good faith, no no warranty or representation is given concerning such warranty or representation is given concerning such information, which must not be taken as establishing information, which must not be taken as establishing any contractual or or other commitment binding upon any contractualother commitment binding upon Rolls-Royce plc or any of its subsidiary or associated Rolls-Royce plc or any of its subsidiary or associated companies. companies.

21.Marine services-4 of 4-29.06.11

Вам также может понравиться

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineДокумент5 страницHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- A Complete Mechanics of Solid Lab Test ManualДокумент38 страницA Complete Mechanics of Solid Lab Test ManualAli ZafarОценок пока нет

- Flushing Hydraulic System (Rexroth)Документ3 страницыFlushing Hydraulic System (Rexroth)Eric CОценок пока нет

- Environmental Product Declaration For Tin Coated Steel TinplateДокумент20 страницEnvironmental Product Declaration For Tin Coated Steel TinplatemsmldxbОценок пока нет

- Leroy SomerДокумент86 страницLeroy SomerSimón Klein100% (1)

- Manual Técnico Hydraulic Power Unit EM217030 PDFДокумент141 страницаManual Técnico Hydraulic Power Unit EM217030 PDFAlexander Cordova RosalesОценок пока нет

- Slayer Series Product BookletДокумент16 страницSlayer Series Product BookletLorcán McGrathОценок пока нет

- Apron Feeders: The Ideal Solution For Feed and Discharge Conveyors in Crushing PlantsДокумент5 страницApron Feeders: The Ideal Solution For Feed and Discharge Conveyors in Crushing PlantstonyОценок пока нет

- BLN 9884Документ24 страницыBLN 9884Rachan EngchanilОценок пока нет

- Hydraulic Commissioning ManualДокумент7 страницHydraulic Commissioning Manualranjit2150Оценок пока нет

- EU Emission Standards PDFДокумент5 страницEU Emission Standards PDFStephanie StewartОценок пока нет

- fm60c 0Документ8 страницfm60c 0Srinivas NandikantiОценок пока нет

- 5500 Centrifuge Hydraulic Backdrive Operations ManualДокумент138 страниц5500 Centrifuge Hydraulic Backdrive Operations ManualTaher Yusuf0% (1)

- H-E Parts Case Study C160 & C200 Jaw PerformanceДокумент1 страницаH-E Parts Case Study C160 & C200 Jaw PerformanceJorge VillalobosОценок пока нет

- H67H2 M3 ManualДокумент84 страницыH67H2 M3 ManualGerardo GeronimoОценок пока нет

- Deepak Project On Jaw CrusherДокумент96 страницDeepak Project On Jaw CrusherAnil Kumar KnОценок пока нет

- 2001, Casappa, Flow DividersДокумент20 страниц2001, Casappa, Flow DividersVelibor KaranovićОценок пока нет

- Wind RowerДокумент234 страницыWind RowercengizyurdalОценок пока нет

- Systems: WashingДокумент6 страницSystems: WashingVinОценок пока нет

- Use and Maintenance Manual: Spider 13.80 RadioДокумент146 страницUse and Maintenance Manual: Spider 13.80 RadioMario HurtadoОценок пока нет

- Hyd Power Unit 5831Документ119 страницHyd Power Unit 5831Victor RoblesОценок пока нет

- Optitooth Jaw Plates - Customer Testimonial Data - 2017Документ8 страницOptitooth Jaw Plates - Customer Testimonial Data - 2017danielОценок пока нет

- Repair Parts Sheet RC-25 Series Hydraulic Cylinders RC-256, RC-258, RC-2510, RC-2512, RC-2514Документ2 страницыRepair Parts Sheet RC-25 Series Hydraulic Cylinders RC-256, RC-258, RC-2510, RC-2512, RC-2514JonathanDavidDeLosSantosAdornoОценок пока нет

- HPFi Hydraulic Support System 0700Документ35 страницHPFi Hydraulic Support System 0700g665013Оценок пока нет

- Natural RubberДокумент7 страницNatural RubberFrancis AdrianОценок пока нет

- Shaft and House Design PDFДокумент3 страницыShaft and House Design PDFm2110100% (1)

- Industrial Semi-Solid MixersДокумент7 страницIndustrial Semi-Solid MixersSpaynkterОценок пока нет

- Floor Loading BrochureДокумент19 страницFloor Loading BrochurefgfdgfdgdfgОценок пока нет

- 518 Centrifuge PsДокумент2 страницы518 Centrifuge PsVideoKesitОценок пока нет

- Block Making Machine - Types & FeaturesДокумент6 страницBlock Making Machine - Types & FeaturesVikas MishraОценок пока нет

- Cone Ranger: Mobile Cone Crushing UnitsДокумент2 страницыCone Ranger: Mobile Cone Crushing UnitsYousef AlipourОценок пока нет

- SANDVIK CapabilitiesДокумент16 страницSANDVIK CapabilitiesNenadОценок пока нет

- Rochi 2019 PDFДокумент26 страницRochi 2019 PDFGautamОценок пока нет

- Vertical Shaft Impactor - Sand Making MachineДокумент37 страницVertical Shaft Impactor - Sand Making Machineaaronshakti100% (1)

- Steel SAE O-Rings AdaptersДокумент3 страницыSteel SAE O-Rings Adaptersgeav25653855Оценок пока нет

- Product Catalogue Hägglunds CBM: Radial Piston Hydraulic MotorДокумент36 страницProduct Catalogue Hägglunds CBM: Radial Piston Hydraulic MotorsoniaОценок пока нет

- Air Driven Hydraulic PumpsДокумент32 страницыAir Driven Hydraulic Pumpsdejanr111Оценок пока нет

- CEDARAPIDS (2015) - Quality Paving Guide BookДокумент96 страницCEDARAPIDS (2015) - Quality Paving Guide BookRodrigo DíazОценок пока нет

- Rótulas SKFДокумент136 страницRótulas SKFxataraОценок пока нет

- Combination Module PVGI Tech NoteДокумент8 страницCombination Module PVGI Tech NoteHYDRAULICGURU100% (1)

- Solids HandlingДокумент12 страницSolids HandlingAlberto darianОценок пока нет

- Rigmaster Manual 8204Документ122 страницыRigmaster Manual 8204Rodrigo MirandaОценок пока нет

- Screw Washer A 01Документ15 страницScrew Washer A 01joule357Оценок пока нет

- Moduldokumentation HydraulicsДокумент66 страницModuldokumentation HydraulicsJordi El MariachetОценок пока нет

- HDM HDS - 100 P 000040 e 02Документ10 страницHDM HDS - 100 P 000040 e 02Eng-Mohammed SalemОценок пока нет

- Hs E10101 1-03-09 Hydrosaar SystemДокумент6 страницHs E10101 1-03-09 Hydrosaar SystemAlaa saidОценок пока нет

- Fds Series: Fiber Dosing-Feeding SystemДокумент15 страницFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteОценок пока нет

- Twogether Article 22 en 24 TranbyДокумент4 страницыTwogether Article 22 en 24 TranbyelcarpaneziОценок пока нет

- Nagel PLC Upgradtion ProjectДокумент35 страницNagel PLC Upgradtion Projectnarendramaharana39Оценок пока нет

- 3L 101238FДокумент1 страница3L 101238FsjsshipОценок пока нет

- Belt Filter PressДокумент4 страницыBelt Filter PressPukhraj DagaОценок пока нет

- VibrexДокумент2 страницыVibrexjorgew2050Оценок пока нет

- Vibrating Screens - Circular Motion Rev 1Документ2 страницыVibrating Screens - Circular Motion Rev 1Ziggy Gregory100% (1)

- Catalog Marine Engineering Interactive PDFДокумент67 страницCatalog Marine Engineering Interactive PDFakın ersözОценок пока нет

- Belt RipДокумент18 страницBelt Ripgopi_ggg20016099Оценок пока нет

- Thyssenkrupp - Jaw Crusher PDFДокумент7 страницThyssenkrupp - Jaw Crusher PDFFernando MilmanОценок пока нет

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Документ15 страницSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselОценок пока нет

- Donaldson Purify and Pressure FiltersДокумент132 страницыDonaldson Purify and Pressure FiltersCentral HydraulicsОценок пока нет

- Control de La Contaminacion CaterpillarДокумент7 страницControl de La Contaminacion Caterpillarnikle_DОценок пока нет

- Alfa Laval PurifiersДокумент4 страницыAlfa Laval PurifiersNasim AbbasОценок пока нет

- Proactive Maintenance at WeyerhaeuserДокумент5 страницProactive Maintenance at Weyerhaeuserocto widodoОценок пока нет

- Tantro-Astro-Vartu (Eng) For Sahasrabuddhe StudentsДокумент4 страницыTantro-Astro-Vartu (Eng) For Sahasrabuddhe StudentsmsmldxbОценок пока нет

- Surge Protection Devices SPD PDFДокумент14 страницSurge Protection Devices SPD PDFmsmldxbОценок пока нет

- Sua RT 3kva To 10kva PDFДокумент35 страницSua RT 3kva To 10kva PDFmsmldxbОценок пока нет

- Vastu MathematicsДокумент28 страницVastu MathematicsmsmldxbОценок пока нет

- Cargo Securing Guidelines enДокумент208 страницCargo Securing Guidelines enAndrejs Meļņikovs100% (2)

- GrahapraveshaДокумент8 страницGrahapraveshaSuresh PoonkavanamОценок пока нет

- From The Desk of Astrologer E K Dhilip KumarДокумент4 страницыFrom The Desk of Astrologer E K Dhilip KumarmsmldxbОценок пока нет

- Process Instruction Technical Data Sheet: Ardrox 800/3Документ2 страницыProcess Instruction Technical Data Sheet: Ardrox 800/3antonioОценок пока нет

- 1st Yr Lec3Документ16 страниц1st Yr Lec3abhijeetnarkhede69198Оценок пока нет

- Greenhouse EffectДокумент15 страницGreenhouse EffectNoor AdlinОценок пока нет

- Air Break and Air GapДокумент2 страницыAir Break and Air GapZarex BorjaОценок пока нет

- Atoms and Elements, Compounds and Mixtures - ExercisesДокумент8 страницAtoms and Elements, Compounds and Mixtures - ExercisesLim Kok PingОценок пока нет

- 1MVA Spare Parts ListДокумент3 страницы1MVA Spare Parts ListEduardoMorcilloОценок пока нет

- Indian Automobile Sector Analysis January 2023 1693838553Документ1 страницаIndian Automobile Sector Analysis January 2023 1693838553Rohit PareekОценок пока нет

- New Microsoft Office Word DocumentДокумент6 страницNew Microsoft Office Word DocumentHosam ElgoharyОценок пока нет

- Rpa Chemical Recycling StatementДокумент5 страницRpa Chemical Recycling StatementPruthvi Mundalamane JagadishchandraОценок пока нет

- Study of Power System Security in Indian Utility 62 Bus SystemДокумент10 страницStudy of Power System Security in Indian Utility 62 Bus SystempjОценок пока нет

- Cabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterДокумент2 страницыCabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterCirtiu SandaОценок пока нет

- LMTD CalculatorДокумент2 страницыLMTD CalculatorSATISH PAWARОценок пока нет

- E-10 Storage Batteries - 1465729800 - E-10Документ10 страницE-10 Storage Batteries - 1465729800 - E-10nicolas.travailОценок пока нет

- Detailed Comparative Case Study On Environmentally Sustainable BuildingДокумент8 страницDetailed Comparative Case Study On Environmentally Sustainable BuildingEditor IJTSRDОценок пока нет

- Module Lab 6 FKMP UTHMДокумент60 страницModule Lab 6 FKMP UTHMwhosamiruladliОценок пока нет

- Docs 20734729484bb2a5e6983c8Документ14 страницDocs 20734729484bb2a5e6983c8Jegan NathОценок пока нет

- Sample Project Report Format of 2020 Passout.Документ84 страницыSample Project Report Format of 2020 Passout.Prem sharmaОценок пока нет

- 20CMHДокумент41 страница20CMHMuhammad Safri Adi ZamilОценок пока нет

- EN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFДокумент5 страницEN 3P LIQUID LEVEL CONTROL RELAY MANUAL English PDFdio39saiОценок пока нет

- NCP1653, NCP1653A Compact, Fixed-Frequency, Continuous Conduction Mode PFC ControllerДокумент21 страницаNCP1653, NCP1653A Compact, Fixed-Frequency, Continuous Conduction Mode PFC ControllerEfrén GonzálezОценок пока нет

- 2013 Tuli Kivi CatalogДокумент34 страницы2013 Tuli Kivi Catalogمحمدحنيدق محمد غنيمОценок пока нет

- QSL9-G3: Emissions Compliance: EU Stage IIIA at 50 HZ EPA NSPS Stationary Emergency Tier 3Документ10 страницQSL9-G3: Emissions Compliance: EU Stage IIIA at 50 HZ EPA NSPS Stationary Emergency Tier 3mohsen_cumminsОценок пока нет

- Honeywell Mag Meter 4000Документ28 страницHoneywell Mag Meter 4000cgasior1Оценок пока нет

- Recovery PDFДокумент164 страницыRecovery PDFAzizi AbdullahОценок пока нет

- SCERT Kerala State Syllabus 9th Standard Physics Textbooks English Medium Part 2Документ64 страницыSCERT Kerala State Syllabus 9th Standard Physics Textbooks English Medium Part 2SafarОценок пока нет

- KP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFДокумент27 страницKP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFUtku Can Kılıç100% (1)

- Renewable and Sustainable Energy Reviews: MD Maruf Hossain, Mohd. Hasan AliДокумент9 страницRenewable and Sustainable Energy Reviews: MD Maruf Hossain, Mohd. Hasan AliJuan MОценок пока нет

- Pressure-Compensated Flow Control Valves - Hydraulic ValveДокумент3 страницыPressure-Compensated Flow Control Valves - Hydraulic ValveAlamin SiddiqueОценок пока нет