Академический Документы

Профессиональный Документы

Культура Документы

HTST

Загружено:

Darwin Barra TorresИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HTST

Загружено:

Darwin Barra TorresАвторское право:

Доступные форматы

Notes for Guidance on High Temperature Short Time (HTST) Milk Pasteurisation Plant

Revised October 1998

INTRODUCTION PART I

CONTENTS OPERATION OF PASTEURISING PLANT Design and Installation Methods of Pasteurisation Indicating Thermometers Recording Equipment Plant Safeguards Flow Controller and Holding Tube Filtration

Paragraphs

1 2-5 6-9 10-12 13-23 24 25-29 30 31-33 34-46 47-55 56-59 60-67 68-80 81 82-85 86-87 88 89 90 91

PART II

PLANT HYGIENE Cleaning Cleaning Procedure Disinfection Procedures Descaling Storage and Use of Chemicals

PART III PART IV

OPERATIONAL CHECK LIST FAULT FINDING Phosphatase Failure Plate Count and Coliform Failures Extraneous Water in Milk Chemical Composition Taints Bitty Cream

APPENDICES 1. 2. 3. Illustration of a Thermograph Chart Bacteriological Standards for Pasteurised Milk Technical Documentation

AMW0029P

INTRODUCTION These Notes for Guidance1 have been updated and are issued by The Scottish Office Agriculture, Environment and Fisheries Department (SOAEFD) for the purpose of giving advice on the operation, cleaning and disinfection of HTST pasteurisation plants. The Notes also include advice on fault finding in relation to statutory requirements for pasteurised milk. They are directed to those involved in the production of pasteurised milk who are responsible for compliance with the provisions of the Food Safety Act 1990, The Dairy Products (Hygiene) (Scotland) Regulations 1995 and amendments, and other relevant legislation. They are also designed to assist Food Enforcement Officers and others concerned with securing, maintaining and monitoring acceptable standards of hygiene. These Notes for Guidance have no statutory force; they should not be regarded as an interpretation of the requirements of the law. However, the word must is used where there is an obvious statutory requirement and for convenience of drafting the word should is frequently used in the text to describe desirable methods of construction or practice and not to rule out other methods or practices equally conducive to good hygiene. Similarly, the expressions should not and should never do not imply statutory prohibitions; nevertheless, they are intended to express disapproval of the methods and practices to which they refer. Reference should be made to Code of Practice No 18 which gives guidance on the Enforcement of the Dairy Products (Hygiene) (Scotland) Regulations 1995. The Dairy Products Hygiene (Scotland) Regulations guidance notes issued by SOAEFD give additional information on enforcement of these regulations. The types of pasteurisation plant covered by these notes are those normally operated by producer retailers or small scale processors. The Notes are in four parts with 3 Appendices.

These Notes for Guidance have been updated by the Food and Dairy Officers Unit, The Scottish Office Agriculture, Environment and Fisheries Department, 47 Robb Loan, Edinburgh, EH14 1TY. s

AMW0029P

PART 1 OPERATION OF PASTEURISING PLANT

DESIGN AND INSTALLATION

1. All equipment, utensils and fittings used in connection with the pasteurisation of milk should be:a. designed to be capable of being easily cleaned and disinfected and must be kept clean and in good physical condition. sited in such a way that all parts are easily accessible for cleaning and maintenance. constructed of materials that are smooth durable, impervious and corrosion resistant, and must also comply with current regulations for surfaces in contact with food. capable of withstanding repeated contact with cleaning agents used at the recommended temperature and concentration.

b.

c.

d.

METHODS OF PASTEURISATION 2. The Dairy Products (Hygiene) (Scotland) Regulations 1995 as amended prescribe the processing conditions required to produce pasteurised milk. There are essentially 2 methods of pasteurisation: a. Batch Pasteurisation (see SOAEFD Notes for Guidance on Batch s Pasteurisers). High Temperature Short Time Pasteurisation (HTST).

b. 3.

The HTST method requires that the milk:be obtained by means of a heat treatment involving a high temperature for a short time (at least 71.7C for 15 seconds or equivalent combination) or a pasteurisation process using different time and temperature combinations to obtain equivalent effect.

4. All apparatus in which milk is pasteurised and any modification to the apparatus should be approved by the Local Authority.

AMW0029P

2.

5. There are two types of equipment used for pasteurising milk by the HTST method. These are:a. Plate Heat Exchanger in which hot water or steam is used to transfer heat indirectly to the milk. Shell and Tube Heat Exchanger in which the milk is heated by infra-red radiation through quartz tubes.

b.

INDICATING THERMOMETERS 6. All continuous HTST pasteurisers must be fitted with indicating thermometers installed in suitable places in the apparatus so as to indicate the temperature to which milk is heated to and cooled to during the heat treatment process. 7. Thermometers can be:a. b. c. Mercury-in-glass; Alcohol-in-glass; or Electronic digital.

Some premises prefer not to use mercury in glass thermometers and for safety reasons are replacing them with other types of thermometer. 8. These indicating thermometers are one of the most important components of the pasteurising plant and their accuracy should be checked at the time of installation and at regular intervals thereafter. NPL TRACEABLE THERMOMETER 9. The owner of the business should ensure that the indicating thermometers are checked regularly against an National Physics Laboratory (NPL) Class A thermometer by a competent person. Any errors on the plant indicating thermometer should be marked as ADD or SUBTRACT, eg add 2C. Current calibration certification should be dated and retained for inspection by the food authority. RECORDING EQUIPMENT 10. All HTST pasteurisers must be fitted with a suitable recording device which will automatically record when the flow of milk is diverted and when the automatic flow diversion device is not activated. Thermographs (see Annex 1)

11. Each chart should be marked with the date of operation, signed and kept for a period of not less than 2 months as part of an operator duties. s

AMW0029P

3.

12.

The chart provides a permanent record of: a. The temperature to which the milk has been heated and cooled during processing. The length of time of the processing run. The length of time and temperatures of the cleaning and disinfection operations. The operation of the flow diversion valve.

b. c.

d.

PLANT SAFEGUARDS FLOW DIVERSION VALVE (FDV) 13. All HTST plants must be provided with an automatic safety device which is capable of automatically diverting the flow of any milk which has not reached a temperature of at least 71.7C. 14. The FDV is normally fitted at the end of the milk holding section and performs the important function of diverting underheated milk back to the balance tank thus preventing it from passing forward into the cooling section. 15. The FDV is normally operated by the use of air pressure and any power failure eg electrical failure will result in the milk being diverted. 16. The FDV is controlled by a heat sensitive element designed to react quickly to any temperature below 71.7C. 17. The valve seatings should be regularly checked to ensure that they are in good condition and operating efficiently. OPERATING TEMPERATURE OF FDV 18. The temperature at which the FDV is activated is controlled by either:a. The diversion set point which has the appearance of a thermograph pen without a nib. This is set manually on each occasion a new recording chart is fitted and checked on a daily basis; or The diversion temperature adjusting screw which is located inside the thermograph instrument. This should be set by a qualified engineer and should not be adjusted

b.

Care must be taken when replacing a recording chart, to ensure that the diversion set point in (a) is accurately re-set.

AMW0029P

4.

19. Since the FDV is activated by the temperature set by the Diversion Set Point, it is important that the temperature set MUST NOT be less than 71.7C. If set any lower than this, unpasteurised milk would go forward through the system, instead of being diverted. Only when the temperature of the Set Point is reached would the milk be automatically diverted. Similarly if the position of the Diversion Set Point is well above 71.7 C then the plant will continually divert until that temperature is reached. 20. The correct operation of the FDV should be checked daily whilst running the plant on water. Ensure the control switch is in the auto or run position. Allow the plant to fall below pasteurising temperature and check the temperature of diversion on the hot milk indicating thermometer. AUDIBLE AND VISUAL WARNINGS 21. When the FDV is activated to divert the milk flow, automatically and simultaneously a warning bell or Klaxon should sound and a red warning light should show to alert the operator. CLEAN AND RUN SWITCH 22. During certain operations such as disinfection, it will be necessary to maintain forward flow when the temperature is below 71.7C. This is achieved by the inclusion of a manual/auto or clean/run switch on the control panel. When the switch is in the manual or clean position the plant safeguards are cancelled. During normal pasteurisation of milk, the switch MUST ALWAYS be in the auto or run position to ensure that the safeguards are in operation. SAFEGUARDS OR EVENTS PEN 23. An illustration of the operation of the safeguards or events pen is given at Appendix 1. The pen must record the following:a. when the plant safeguards are ON ie when the plant is in the auto or run position. when a diversion is occurring when the plant safeguards are ON ie when the plant is in the autoor runposition. when the plant safeguards are OFF ie when the plant is in the manual or cleanposition.

b.

c.

Some pasteurising plants may have recording devices which differ from that shown in Appendix 1. The important point is that the positions detailed in (23a-b) are clear and understood by operators. FLOW CONTROLLER AND HOLDING TUBE

AMW0029P

5.

24. The rate at which milk passes through the plant and the length of the holding tube will influence the effect of heat treatment. Where a centrifugal pump is fitted in a pasteurising plant, a form of flow control system should be installed to ensure a constant rate of milk flow through the plant by the use of either:a. b. FILTRATION 25. Filtration in a HTST plant is accomplished by passing milk, under pressure, through a filter at approximately 37C to remove any extraneous matter. 26. A filter can be of the following type:a. b. c. d. cotton filter cloth with a nap side; man made fibre membrane; stainless steel mesh; or disposable. an automatic flow control valve; or flow restrictor.

27. An increase in pressure within the plant may be an indication that the filter requires to be changed. 28. In some dairies separators/clarifiers are used instead of filters.

29. Information on the cleaning and disinfection of filters is contained in SOAEFD s Notes for Guidance on the Cleaning and Disinfection of Ancillary Equipment associated with Milk Pasteurisers .

AMW0029P

6.

PART II PLANT HYGIENE 30. Milk is a highly perishable product and any deficiency in plant hygiene may lead to bacteriological contamination of the milk. The daily cleaning and disinfection of all pasteurising plants is therefore of great importance. The occupier of a dairy establishment must ensure that samples are taken for the purpose of checking, cleaning and disinfection methods. It is important that any sample failures are investigated. CLEANING 31. The cleaning procedure should remove all milk deposits from the internal surface of the plant and should be carried out immediately after the plant is used. Care should be taken to ensure external surfaces of the plant are kept clean to avoid opportunities for post process contamination. 32. Great care should be taken in the selection of a detergent as no single detergent is suitable for use in the cleaning of all plant and equipment. The selection will depend on whether the equipment has to be cleaned:a. b. 33. manually; or cleaned in place.

The cleaning process consists of three separate operations: a. b. c. pre-rinsing; cleaning with a suitable detergent; and final rinsing.

CLEANING PROCEDURE PRE-RINSING 34. Immediately after use rinse the plant with cold water until clean water issues from the plant. 35. When the rinsing procedure is completed the water supply to the balance tank should be disconnected and the milk pump switched off. CLEANING WITH A SUITABLE DETERGENT 36. Remove the flow controller and screens, thoroughly wash them using a suitable detergent, rinse and store carefully to avoid damage or contamination. 37. The filter medium should also be removed, cleaned, rinsed and stored carefully.

AMW0029P

7.

38. Ensure that the plant safeguards are switched off and set the plant to circulate on clean water. 39. Raise the water temperature to that required for circulation cleaning.

40. When the correct water temperature has been reached, add the detergent solution to the balance tank (see paragraphs 62-65). 41. Circulate the mixture for the required length of time, ensuring that the return pipe to the balance tank is below the liquid surface to prevent aeration of the solution. 42. The flow diversion valve should be operated during the circulation period to clean the valve and the milk diversion line to the balance tank. 43. The balance tank and its lid should be brushed and the outside surfaces of the pasteuriser should be cleaned with the detergent solution and rinsed with clean water. 44. At the end of the circulation period the heat source should be switched off but circulation continued until the temperature is reduced to 40C or lower. This prevents precipitation of the detergent solution on the internal surfaces of the plant. FINAL RINSING 45. When the temperature of 40C is reached, the return detergent flow should be directed to waste and cold water admitted to the balance tank to remove the detergent solution. 46. Continue rinsing with clean water until all traces of detergent have been removed.

DISINFECTION PROCEDURES 47. The disinfection process should destroy most of the remaining micro-organisms from the plant. This should be carried out immediately prior to the commencement of the heat treatment of the milk. 48. All components of the plant including the flow controller, screens and filter membranes, should be fully assembled prior to plant disinfection. 49. The flow diversion valve should be operated during the disinfection period to disinfect the valve and the milk diversion line to the balance tank. This also helps to raise the outlet temperature. Automatic systems can now be installed so that the plant will go from forward flow to divert when the plant is in the clean/manual position only. 50. Two common methods of disinfection in an HTST plant are:a. b. Hot water; or Chemical agents

AMW0029P

8.

Hot Water 51. This is a popular method of disinfection which avoids the possibility of plant corrosion. Disinfection is achieved by circulation of hot water at 85C for at least 15 minutes. The circulation period must be timed after the water has reached the required temperature. It is important to ensure that the treated milk regeneration and chill water section of the plant are subjected to full heat treatment during disinfection to ensure that the outlet side of the pasteurising plant does not contaminate pasteurised product. Chemical Agents 52. Disinfection can be achieved by the circulation of a chemical solution. There are a number of chemical disinfectants on the market. Manufacturers instructions on dosage and usage should be carefully adhered to. 53. CIP solutions which have previously been used for cleaning raw milk lines should not then be used to clean and disinfect pasteurised milk lines as this can lead to contamination of the plant. 54. Disinfectants shall be kept in clearly identifiable containers bearing labels with instructions for their use. 55. Use of disinfectants shall be followed by thorough rinsing of equipment with potable water except where the disinfectant is specifically designed not to be rinsed after application. Where private water supplies are used it is important to ensure that contamination of the plant does not occur. DESCALING 56. A descaling acid treatment may be required from time to time if milk stone deposits build up in the plant. 57. The acid solution should be circulated at the temperature, concentration and time prescribed by the product manufacturer. It is unlikely that the temperature will exceed 60C as a higher temperature may cause damage to the plate gaskets. 58. When the circulation period is completed, thoroughly flush out with clean water to remove all acid residues. 59. Clean and disinfect the plant after descaling.

It is recommended that records be kept to demonstrate that plant has been cleaned and disinfected.

AMW0029P

9.

STORAGE AND USE OF CHEMICALS 60. Chemicals must be stored in a secure place and be kept in clearly identifiable containers bearing labels with instructions for their use. 61. All chemicals should be stored tidily and accessibly in a clean, dry, well ventilated place. The Control of Substances Hazardous to Health Regulationswill apply. 62. Chemicals should be used within their use-by date.

63. The correct quantity of chemical should be used with the correct volume of water at the correct temperature for the correct length of time. 64. Make up chemicals using smooth impervious containers eg stainless steel, rubber or plastic. 65. 66. 67. Always add chemicals to water. DO NOT add water to chemicals. Always wear suitable protective clothing when handling chemicals. Phenol based disinfectants should not be used as they can cause taints in the milk.

AMW0029P

10.

PART III OPERATIONAL CHECK LIST TEMPERATURE 68. The temperature of the raw milk supply should be checked to ensure that it is within the limits set by the plant manufacturer - normally 6C. a. Too low a temperature within the raw milk supply will result in continual diversions. Too high a temperature within the raw milk supply will result in inadequate cooling of the pasteurised milk.

b.

69. The temperature indicated on the hot water thermometer should be regularly checked against that of the hot milk indicating thermometer. If there is an increase in the temperature difference between the two ie an increase in the temperature of the hot water indicating thermometer then this trend may indicate a build up of milk stone deposit (see paragraphs 5659). AGITATION 70. Thoroughly agitate the raw milk supply prior to processing.

THERMOGRAPH CHART 71. The thermograph chart should be in position and marked with the correct date of operation. All pens on the thermograph should be checked to ensure that they provide a legible record of events. Efforts should be made to have all charts and thermometers marked in degrees centigrade. 72. Set the diversion set pointer at a temperature no lower than 71.7C.

73. The temperature recorded on the thermograph chart should agree with the reading on the indicating thermometer. The recording pen should be adjusted if necessary to ensure that the correct temperature is recorded. 74. The plant safeguards should be in operation.

PRESSURE GAUGE 75. Regularly check the pressure gauge throughout the processing run. increase could be an indication of a clogged filter. MILK PUMP 76. Never allow the milk pump to run dry. If air is drawn into the system the milk flow stops, resulting in the milk burning onto the plates. A pressure

AMW0029P

11.

START UP AND SHUT DOWN 77. The volume of milk within circulation in the plant should be accurately determined to minimise the risk of adulteration of the milk by water during the start up and shut down procedure where it is common practice to chase out the water with milk or vice versa. PLANT INSPECTION 78. Consideration should be given to opening up the plant at regular intervals (6 monthly) for inspection of the plates to ensure that they are clean, free from any debris, cracks or pinholes. Care must be taken to ensure that the plates are replaced in the correct order. 79. On reassembly, tighten the plates to the plate pack length specified by the manufacturer. 80. All pasteurising plants should be checked by a competent dairy engineer at least once a year. You should retain any service certificate for inspection by the local authority.

AMW0029P

12.

PART IV FAULT FINDING 81. If these Notes for Guidance are followed carefully, faults should be kept to a minimum. The occupier of a dairy establishment must ensure that critical points in the operation are identified, monitored and controlled. Where a critical point is not controlled and a failure occurs, the following checklist may assist in identifying the problem. PHOSPHATASE FAILURE 82. The enzyme phosphataseis present in all raw milk, but is destroyed by pasteurisation. The presence of this enzyme above a reading of 4 g2 of phenol/ml in pasteurised milk is an indication of faulty processing. In the event of a phosphatase failure occurring check:a. the accuracy of the indicating thermometer against a thermometer of known accuracy. If the thermometer is battery powered ensure the batteries are in good working order; the diversion set pointer is set at a temperature of at least 71.7C; that the clean/runor manual/autoswitch is in the correct position; that the flow controller is in position; that the FDV is operating correctly; that the valve seatings within the FDV are not leaking; the plates for debris, cracks or pinholes; that the pipeline system is not connected in such a way as would allow mixing of raw or underheated milk with pasteurised milk; that the milk is being retained in the holding section for at least 15 seconds.

b. c. d. e. f. g. h.

i.

HEAT RESISTANT PHOSPHATASE 83. Although uncommon, it is possible that high numbers of certain organisms in raw milk can produce a heat resistant phosphatase which can account for the failure of the phosphatase test in pasteurised milk. 84. This can be checked by laboratory pasteurisation of a sample of the pasteurised milk. Milk taken directly from the plant pasteuriser should be used as a control. If the laboratory pasteurised milk still shows a test fail similar to the control, then the presence of microbial phosphatase is confirmed. NB Since all pasteurised drinking milk leaving a plant must be

91/180 EEC OJ No. L93, 13.4.91 pl.

AMW0029P

13.

phosphatase negative it is important to carry out checks at various points throughout the process eg, prior to filling, to ensure that all pasteurised milk leaving the plant is phosphatase negative. 85. Peroxidase is another milk enzyme, which is denatured at 78C, therefore pasteurised milk, shall be peroxidase positive. PLATE COUNT AND COLIFORM FAILURES 86. The presence of coliform organisms, other indicator organisms and/or high bacterial numbers is usually indicative of poor plant hygiene. Routine sampling should be used to check the effectiveness of cleaning methods. In the event of a failure check a. that the tanks, pipelines, valves and joints associated with the pasteurising plant are being effectively cleaned and disinfected; that the thermometer and instrument pockets are cleaned on a regular basis; that the raw milk pump is being regularly maintained to ensure its effective operation; the hosepipes and being kept clean and stored off the floor, and that water from high pressure hoses is not recontaminating clean plant; the plates, particularly in the cooling section, for debris, cracks or pinholes. that the chemicals are being used in accordance with manufacturers recommendations particularly in respect of concentration, time, temperature and minimum durability date, and that disinfectants being used are effective. check that dairy staff are not contaminating equipment or product.

b. c.

d.

e. f.

g. 87. (a)

Plate count and coliform failures are often associated with post pasteurisation of ancillary equipment. It is recommended that spare valve rubbers are kept by operators (see SOAEFD s Notes for Guidance on Ancillary Equipment associated with Milk/Pasteurisers ). Pre-incubation test Where pasteurised milk samples fail this test, then a further laboratory pasteurisation check can be carried out to determine whether the initial raw milk quality is the source of the problem or whether post-process areas need to be investigated.

(b)

Additional advice on dealing with coliform failures is contained in the Scottish Office Agriculture, Environment and Fisheries Department - Notes for Guidance - Coliform Chart s (issued September 1996).

AMW0029P

14.

EXTRANEOUS WATER IN MILK (FREEZING POINT DEPRESSION - FPD)

88. The FPD is an indication of the presence of extraneous water in milk and should be checked on a regular basis. In the event of a failure check:a. b. c. d. the FPD of the raw milk supply and history of results (seasonal variation); the start up and shut down procedures; that all ancillary equipment, including pipes, are being properly drained; that the emergency water valve in shell and tube plants is not leaking. The function of this valve is to flood the plant with water if the milk pump stops.

CHEMICAL COMPOSITION 89. To ensure that the milk has a uniform butterfat and solids-not-fat content check:a. b. c. the composition of the raw milk; all milk contained within storage tanks is being properly agitated; when whole milk and separated milk are handled and/or stored there is no possibility of mixing of these different milks. (This can be helped by the correct labelling of storage tanks).

TAINTS 90. Taints can often be caused by certain feedstuffs or more usually the presence of chemicals in milk. If a taint is detected check:a. b. the raw milk supply for taints, eg feedstuffs; that the cleaning and disinfecting chemicals are being used at the correct concentration; that phenol based chemicals are NOT in use within the dairy or the vicinity of the dairy.

c.

AMW0029P

15.

BITTY CREAM 91. Bitty cream has the appearance of clusters of fat globules and when added to hot beverages has the appearance of creamy particles floating on the surface. It is caused by the presence of Bacillus cereus in the milk. If present in the pasteurised milk check:a. b. the bacteriological quality of the raw milk supply; that all plant and equipment are being properly disinfected immediately prior to use; that the disinfection process is effective. Chemical disinfection is often more effective than hot water disinfection in resolving this problem. that the pasteurised milk is stored at 6C or lower.

c.

d.

AMW0029P

16.

APPENDIX 1

1. Start up. Plant is switched on at 06.00 hours. Control switch is turned to 'clean/manual' position. 2. Disinfection. Where steam is available HOT disinfection of the whole plant is preferred such that the hot pen records at least 85C for 15 minutes. * The control switch is turned to manual divert to disinfect the FDV. This also raises the outlet temperature. The disinfection time should only start when the outlet temperature reads 85C. 3. Normal running. Plant reaches pasteurising temperature of 72C at 07.00 hours. Control switch is turned to 'auto/run' position. Safeguads are in place and the events pen moves to the middle position. Raw milk is admitted to the plant. Pasteurised milk is cooled to 5C. 4. Diversion. At 08.45 hours the temperature of the milk falls below 72C resulting in the milk being diverted. Diversion lasts for 30 minutes. The safeguards pen records this event in the lower position. NOTE 1 Flow diversion is normally for a shorter period - the 30 minutes is used for diagrammatic purposes only. NOTE 2 It is recommended that the flow diversion system is tested daily on water for correct operation. 5. Normal running. At 09.15 hours the temperature returns to 72C and the plant resumes its normal running with the safeguards pen returns to the middle position. 6. Detergent circulation. At 11.00 hours pasteurisation ceases, the plant is shut off and the filter and flow controller removed. Control switch is turned to 'clean/manual'. The safeguards pen moves to the upper position. At 11.15 hours detergent curculation starts and is maintained at 85C for 40 minutes. Control switch is turned to 'manual/divert' for 10 minutes to clean FDV. 7. Shut down. At 11.50 hours the plant is rinsed out and switched off.

AMW0029P

APPENDIX 2

BACTERIOLOGICAL STANDARDS FOR PASTEURISED MILK Bacteriological standards relating to the production of pasteurised milk are laid down in The Dairy Products (Hygiene) (Scotland) Regulations 1995 as amended. A sample of pasteurised milk taken at the heat treatment establishment MUST conform to the following standards when tested using the formal laboratory methods:PHOSPHATASE TEST: COLIFORM TEST: Less than 4 g of phenol/ml. n = 5 c = 1 m = 0 M = 5. ie of 5 samples analysed only 1 can have a result between 0-5, the other 4 samples must be 0 @ 21C (per ml) after incubation at 6C for five days. n = 5 c = 1 m = 5 x 104 M = 5 x 105 ie: Of 5 samples analysed only one can have a result between 50,000 and 500,000, the other 4 samples must be less than 50,000/ml. Positive reaction

PLATE COUNT TEST:

PEROXIDASE TEST

Note: For routine monitoring purposes, other methods of analysis can be used in accordance with The Dairy Products (Hygiene) (Scotland) Regulations 1995.

AMW0029P

APPENDIX 3 TECHNICAL DOCUMENTATION Comprehensive technical documentation on pasteurising equipment should be provided by the manufacturer or engineer responsible for the installation of the plant and should include the following:a. b. c. d. e. engineering drawings showing the sequence or layout of plates or tubes; numbering sequence of the plates; the flow patterns of the milk and the heating and cooling mediums; capacity of the plant in litres/hour; the overall measurement of the plate pack to ensure there is no leakage of milk without subjecting the plates to excessive pressure; the total volume of liquid contained within the plant to ensure correct milk-towater or water-to-milk changeover procedures; a detailed wiring diagram; grade(s) of stainless steel or quartz used in the construction of the pasteurising plant; type and mode of operation of the flow controller or restrictor; and a recommended list of spare parts.

f.

g. h.

i. j.

In addition, a dated record should be kept detailing any plant modifications and any maintenance or service certification.

Further copies of this and any other SOAEFD guidance document mentioned in these notes may be obtained from: The Scottish Office Agriculture, Environment and Fisheries Department, The Food and Dairy Unit, Room 356, Pentland House, 47 Robb Loan, s Edinburgh EH14 1TY.

AMW0029P

Вам также может понравиться

- Journal of Bacteriology 1991 Gormley 6705.fullДокумент4 страницыJournal of Bacteriology 1991 Gormley 6705.fullDarwin Barra TorresОценок пока нет

- T Carbopol 2016 UK 2Документ4 страницыT Carbopol 2016 UK 2Darwin Barra TorresОценок пока нет

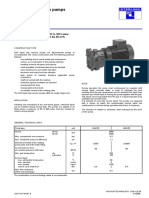

- MD0106E GE Series 170629Документ8 страницMD0106E GE Series 170629Darwin Barra TorresОценок пока нет

- Molinos SkioldДокумент227 страницMolinos SkioldDarwin Barra TorresОценок пока нет

- Modelling in Crystallography: What Is X-Ray Crystal Structure Analysis?Документ49 страницModelling in Crystallography: What Is X-Ray Crystal Structure Analysis?Darwin Barra TorresОценок пока нет

- Liquid ring vacuum pumps in compact designДокумент7 страницLiquid ring vacuum pumps in compact designDarwin Barra TorresОценок пока нет

- Spray Dry Manual: ©2005 BETE Fog Nozzle, IncДокумент25 страницSpray Dry Manual: ©2005 BETE Fog Nozzle, IncDarwin Barra TorresОценок пока нет

- The New E-Series Fume Hoods CatalogДокумент48 страницThe New E-Series Fume Hoods CatalogDarwin Barra TorresОценок пока нет

- 3-A Sanitary Standards, IncДокумент81 страница3-A Sanitary Standards, IncDarwin Barra TorresОценок пока нет

- Aiche J 47 - 2001 - 929-934Документ6 страницAiche J 47 - 2001 - 929-934Darwin Barra TorresОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Geotechnical Elements and Models in OpenSeesДокумент21 страницаGeotechnical Elements and Models in OpenSeesUmut AkınОценок пока нет

- Pd3c CV Swa (22kv)Документ2 страницыPd3c CV Swa (22kv)เต่า วีไอОценок пока нет

- Rapid Communication: Spontaneous Abortions and Policies On COVID-19 mRNA Vaccine Use During PregnancyДокумент14 страницRapid Communication: Spontaneous Abortions and Policies On COVID-19 mRNA Vaccine Use During PregnancyStéphane BoucherОценок пока нет

- Answer Section B and C and Paper 3Документ21 страницаAnswer Section B and C and Paper 3Adnan ShamsudinОценок пока нет

- Regular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionsДокумент3 страницыRegular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionshumbyxОценок пока нет

- Civil Eng Internship ReportДокумент6 страницCivil Eng Internship ReportAromatic-O PОценок пока нет

- The Karnataka Maternity Benefit (Amendment) Rules 2019Документ30 страницThe Karnataka Maternity Benefit (Amendment) Rules 2019Manisha SОценок пока нет

- Demo DLLДокумент2 страницыDemo DLLArlene Diokno100% (1)

- Hart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inДокумент1 страницаHart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inAmishaОценок пока нет

- Engineering Mechanics Lectures PDFДокумент83 страницыEngineering Mechanics Lectures PDFluay adnanОценок пока нет

- CIVL-365 Tutorial 8 SolutionДокумент3 страницыCIVL-365 Tutorial 8 SolutionIvsОценок пока нет

- Carl Sagan Wonder and Skepticism SecДокумент13 страницCarl Sagan Wonder and Skepticism SecAndreea BanagaОценок пока нет

- 1B Cosmos-Standard - Technical - Guide - v40Документ45 страниц1B Cosmos-Standard - Technical - Guide - v40carla deiddaОценок пока нет

- Why Check Valves SlamДокумент2 страницыWhy Check Valves SlamBramJanssen76Оценок пока нет

- 322439480MVR Single Page Single Page Booklet - OPTДокумент12 страниц322439480MVR Single Page Single Page Booklet - OPTlarry vargas bautistaОценок пока нет

- Proceedings of National Conference on Landslides held in LudhianaДокумент8 страницProceedings of National Conference on Landslides held in LudhianaAniket PawarОценок пока нет

- MSC Syllabus AllДокумент13 страницMSC Syllabus AllOmSilence2651Оценок пока нет

- CEFIC Guidelines Transport Equipment Packed Cargo (2010)Документ7 страницCEFIC Guidelines Transport Equipment Packed Cargo (2010)sl1828Оценок пока нет

- ASIAN LIVESTOCK PERSPECTIVESДокумент18 страницASIAN LIVESTOCK PERSPECTIVESMuadz AbdurrahmanОценок пока нет

- 11 F.Y.B.Sc - Chemistry PDFДокумент22 страницы11 F.Y.B.Sc - Chemistry PDFmalini PatilОценок пока нет

- Earthbag House For HaitiДокумент22 страницыEarthbag House For HaitiRaymond KatabaziОценок пока нет

- Carta Psicrometrica PDFДокумент2 страницыCarta Psicrometrica PDFJuliethОценок пока нет

- South African Flora GlossaryДокумент47 страницSouth African Flora Glossarymr.bryceОценок пока нет

- HistorydylaneditДокумент6 страницHistorydylaneditapi-19858424Оценок пока нет

- List of Computer Networking DevicesДокумент1 страницаList of Computer Networking Deviceskamit17102900100% (1)

- Dr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Документ63 страницыDr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Blyden NoahОценок пока нет

- January 2010 QP - Unit 1 Edexcel Physics A-LevelДокумент23 страницыJanuary 2010 QP - Unit 1 Edexcel Physics A-Levelpraveen alwisОценок пока нет

- Operator Manual T2100-ST2 - ST1Документ50 страницOperator Manual T2100-ST2 - ST1Nurul FathiaОценок пока нет

- Fundamentals of VolleyballДокумент2 страницыFundamentals of VolleyballLawrence CezarОценок пока нет

- Large and Medium Manufacturing Industry Survey Report 2018Документ778 страницLarge and Medium Manufacturing Industry Survey Report 2018melakuОценок пока нет