Академический Документы

Профессиональный Документы

Культура Документы

Aluminum

Загружено:

mousaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aluminum

Загружено:

mousaАвторское право:

Доступные форматы

United States Patent [19]

Prewo et al. .

[54] INTERNAL COMBUSTION ENGINE AND

COMPOSITE PARTS FORMED FROM

SILICON CARBIDE FmERREINFORCED

CERAMIC OR GLASS MATRICES

[75] Inventors: Karl M. Prewo, Vernon; John J.

Brennan, Portland, both of Conn.

[73] Assignee: United Technologies Corporation,

Hartford, Conn.

[21] Appl. No.: 149,603

[22] Filed: May 14, 1980

Related U.S. Application Data

[631 Continuation-in-part ofSer. No. 121,081, Feb. 13, 1980,

and Ser. No. 147,672, May 7, 1980, Pat. No. 4,314,852.

[51] Int. Cl.3 ........................ B32B 5/12; C04B 35/74;

C04B 35/80; F02B 77/00

[52] U.S. Cl. ................................. 428/35; 123/193 R;

156/89; 428/36; 428/110; 428/112; 428/113;

428/114;428/294; 428/302;428/303;428/428;

428/446; 428/698; 428/701; 123/657

[58] Field of Search ....................... 123/191 R, 193 R;

428/294, 35, 36, 428, 446, 698, 701, 302, 303,

110, 112, 113, 114; 156/89

[56]

[11]

[45]

References Cited

4,341,826

Jul. 27, 1982

U.S. PATENT DOCUMENTS

3,892,583 7/1975 Winter et al. .

OTHER PUBLICATIONS

Kamo et al., "Ceramics for Adiabatic Diesel Engine",

Proceedings 0/ the Workshop on High Temperature Mate-

rials/or Advanced Military Engines, vol. II, pp. 367-390,

Institute of Defense Analysis, Wash., D.C., Paper No.

P-1421, published Sep. 1979.

Primary Examiner-James C. Cannon

Attorney, Agent, or Firm-Harry J. Gwinnell

[57] ABSTRACT

A high strength, fracture tough, high temperature oxi-

datively stable, heat insulating internal combustion en-

gine combustion chamber component is described made

of a silicon carbide fiber reinforced ceramic matrix or a

silicon carbide fiber reinforced glass matrix material.

An internal combustion engine containing combustion

chamber components as above described is also dis-

closed.

20 Claims, 8 Drawing Figures

0'/90' Cross - piled

u. S. Patent Jui. 27, 1982 Sheet 1 of 6 4,341,826

Unidirectional

FIG. I

0/90 Cross - plied

FIG. 2

~

1001'

u.s. Patent Jui. 27, 1982 Sheet 2 of 6 4,341,826

C')

0

-0

<.I)

a...

)

I'-- CO

Ol

CO I.()

(\J

0

0

CO

0

R

0

0

)

8

I.()

0

oU

0 0.;"

~

~

::E

w

~

co

l-

ll:

0

0

rt)

0

0

(\J

0

0

6

0

0 0 0 0

0 0 0 0

co

)

~ (\J

.-J:::r:

I-- ?

a::: (,!)

::::> Z a...

xW::E

w a:::---

---11-

l.J... <.I)

u.s. Patent Jui. 27, 1982 Sheet 3 of 6 4,341,826

-I:::C

<x:t-_

0::<..::> ~

:::::>z Cl-

xw:::':iE

we:: -....

~

u...t;

0 0 0

o 0 0

0

0

0 0

0

o 0 0

0

0

~

N o en co

I""- <0

0

0

co

0

0

I""-

0

Q:l

0

fto)

co

(.!) 0

~

0

U

1.0

o ~

a..:.

0 :::':iE

~

w

I-

0

0

C")

0

0

N

0

Q

0

0 0 0 0 0 0

0

0 co

co <;t

N 0 co

N

-

-

C")

..........

0

.;::.

(/")

Cl-

u.s. Patent Jul. 27, 1982 Sheet 5 of 6 4,341,826

~

<D 0

~

<;t

co

C\I

~

1.0 co

0 N

1.0

<D

!2 co

1.0

N.

8

co

g

0

0

co

0

~ oU

..

a..:

::e

L...J

0

I--

0

.q-

Lt..J

0

0

('t)

0

0

N

0

0

~ - r - - ' - ~ - - ' - - . - - ' - - - r - - r - - r - - . - - . - - + O

o

~

o

o

C\J

o

co

o

N

o

co

o

u.s. Patent Jui. 27, 1982 Sheet 6 of 6 4,341,826

1

FIG. 6

/(}-D

9

J

FIG. 7

4,341,826

1 2

One aspect of the invention includes the use of com-

ponents comprising a multilayered-fiber reinforced ce-

ramic made up of a plurality of ceramic layers, each

layer reinforced with a plurality of unidirectional, con-

INTERNAL COMBUSTION ENGINE AND

COMPOSITE PARTS FORMED FROM SILICON

CARBIDE FIBER-REINFORCED CERAMIC OR

GLASS MATRICES

This application is a continuation-in-part of copend-

ing U.S. patent applications Ser. Nos. 121,081, filed Feb.

13, 1980 and 147,672, filed May 7, 1980, now U.S. Pat.

No. 4,314,852.

S tinuous length silicon carbide fibers, each layer having

an axial flexural strength greater than 70,000 psi and a

high fracture toughness, exemplified by a critical stress

intensity factor greater than lOX 10

3

psi

Another aspect of the invention includes the use of

DESCRIPTION

1. Technical Field

10 components comprising silicon carbide fiber reinforced

borosilicate glass with flexural strengths above about

60,000 psi maintainable at temperatures up to about 600

C.

The field of art to which this invention pertains is

internal combustion engines, and specifically combus- 15

tion chamber components.

2. Background Art

In an attempt to make motorized vehicles more en-

ergy efficient, recent attention has turned to the use of

nonmetal composite materials. For example, as de- 20

scribed by V. A. Chase ("Automotive Applications of

Composite Materials" published on pages 388-398 in

the Proceedings of the 11th National SAMPE Technical

Conference, Nov. 13-15, 1979, Boston, Mass.), General

Motors has been using fiber reinforced plastics in their 25

automobiles as body components since 1953, but few

other applications have received attention until re-

cently. Automotive areas where these fiber reinforced

plastics have begun to receive attention are in such 30

things as leaf-springs, coil-springs, stabilizer bars, and

even such things as drive shafts. And while non-metallic

composites have been considered for use in internal

engine components, because of the high temperature

instability of such components, their use has generally 35

been limited to the lower temperature components of

the internal engine environment. For example, Chase

documents the fact that attempts at using a fiberglass-

epoxy composite piston in an internal engine environ-

ment resulted in gradual degradation of the piston sur- 40

face due to the thermal effects produced in the engine.

Similarly, Kamo et al ("Ceramics for Adiabatic Die-

sel Engine", Proceedings of the Workshop on High-Tem-

perature Materials for Advanced Military Engines, Vol.

Another aspect of the invention includes the use of

components comprising silicon carbide fiber reinforced

high silica content glass with flexural strengths above

about 60,000 psi maintainable at temperatures up to

about 1150 C.

Another aspect of the invention includes the use of

components comprising silicon carbide fiber reinforced

aluminosilicate glass with flexural strengths above

about 75,000 psi maintainable at temperatures up to

about 700 C.

Another aspect of the invention includes an internal

combustion engine containing combustion chamber

components made of the above recited composite mate-

rials.

The foregoing, and other features and advantages of

the present invention, will become more apparent in

light of the following description and accompanying

drawing.

BRIEF DESCRIPTION OF THE DRAWINGS

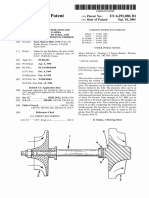

FIG. 1 shows in cross section an actual uniaxial sili-

con carbide fiber reinforced ceramic matrix composite

component according to the present invention.

FIG. 2 shows in cross section an actual multiaxial

silicon carbide fiber reinforced ceramic matrix compos-

ite component according to the present invention.

FIG. 3A shows graphically flexural strength data for

a borosilicate glass composite component reinforced

with silicon carbide yarn according to the present in-

vention.

FIG. 3B shows graphically flexural strength data for

a borosilicate glass composite component reinforced

with large diameter silicon carbide mono filaments ac-

cording to the present invention.

FIG. 4 shows graphically flexural strength data for a

high silica content glass composite component accord-

ing to the present invention.

FIG. 5 shows flexural strength data for an aluminosil-

icate glass composite component according to the pres-

ent invention.

II, pages 367-390, Institute of Defense Analysis, Wash- 45

ington, D.C., Paper No. P-1421, published September

1979) discloses that while cenimics have many desirable

properties which would suggest their use as metal re-

placements in the internal combustion engine environ-

ment, such things as their low material strength and 50

distortion under heating has made their use impractical.

Accordingly, what is needed in the art are non-metallic

internal combustion engine components with high

strength, high fracture toughness, and oxidation stabil-

FIG. 6 shows in cross section an internal combustion

55 engine combustion chamber with components accord-

ing to the present invention.

ity at high temperatures.

DISCLOSURE OF INVENTION

The present invention is directed to a solution to the

use of non-metallic composites in an internal combus-

tion engine, which composites can withstand the high 60

temperatures produced in such engine and still maintain

their high strength and oxidative stability. The solution

to this problem is the use of fracture tough silicon car-

bide fiber reinforced ceramic or silicon carbide fiber

reinforced glass with high temperature strength, high 65

temperature oxidation stability, and good heat insulat-

ing properties as internal combustion engine combus-

tion chamber components.

FIG. 7 shows a cylinder head hot plate component

according to the present invention.

BEST MODE FOR CARRYING OUT THE

INVENTION

A glass, which can be converted to a ceramic, is the

preferred matrix material to form the composite compo-

nents of the present invention. During composite densi-

fication the matrix is retained in the glassy state, thus

avoiding fiber damage and promoting densification

under low applied pressure. After densification to the

desired fiber plus matrix configuration, the glassy ma-

4,341,826

:3

trix can be converted to the crystalline state, the degree

and extent of crystallization being controlled by the

matrix composition and heat treatment schedule em-

ployed. A wide variety of glasses can be used in this

manner, however, a strict limitation on the amount and 5

activity of titanium present in the glass is of controlling

importance. Accordingly, if titania nucleating agents

are used, they must be inactivated or kept below one

percent by weight. This can be accomplished by simply

substituting another nucleating agent such as zirconia 10

for the conventional titania or adding an agent, such as

lead, to mask the reactivity of the titania toward the

silicon carbide fiber. However, in any case it is neces-

sary to either eliminate or mask the effects of the titania

on the silicon carbide fiber to attain a composite with 15

the improved properties disclosed. This problem is be-

lieved attributable to the reactivity of the titanium to

the silicon carbide fiber. And while conventional lith-

ium alumino silicate is the preferred glass ceramic, other

20

conventional glass ceramics such as aluminosilicate,

magnesium aluminosilicate, and combinations of the

above can be used as long as the ceramic matrix material

is titanium free. By titanium free is meant that the com-

position contains less than about I % by weight titanium 25

or additional components (such as lead) which either

mask or inactivate the reactivity of the titanium toward

the SiC fibers. It has also been found that the reactivity

of the titanium and its adverse composite effects can be

lessened by a combination of decreased titania nucleat- 30

ing agent concentration and lower hot pressing tem-

peratures-e.g., a glass ceramic composition with less

that 2% by weight titania, hot pressed at temperatures

below about 11O{t C. And, as stated above, Zr02 is a

preferred substitute for the titania nucleating agent in 35

amounts up to about 5% by weight, producing no ad-

verse effects on the composite properties. Other nucle-

ating agents may also be successful substitutes for the

titania. It should also be noted that in general the start-

ing glass ceramic material can be obtained in the glassy 40

state in powder form. If however, the ceramic material

is obtained in crystalline form, it will be necessary to

melt the material to form it into the glassy state, solidify

it and subsequently crush it into powder form, prefera-

bly about - 325 mesh. An important part of the inven- 45

tion is to select glass ceramic matrix material such as

that described above which can be densified (in combi-

nation with the SiC fibers) in the glassy state with a

viscosity low enough to permit complete densification

with subsequent transformation into a substantially 50

complete crystalline state providing a composite with a

use temperature in excess of 1000 C. It is also possible

to convert the starting crystalline powder to the glassy

state during preheat treatment prior to application of

pressure for densification. 55

While any silicon carbide fiber system with the requi-

site strength can be used with the ceramic matrix, a

multifilament silicon carbide yarn with an average fila-

ment diameter up to 50 microns is preferred and yarn

with average filament diameter of 5-15 microns espe- 60

cially preferred. Nippon Carbon Co. of Japan produces

such a yarn with about 250 fibers per tow and an aver-

age fiber diameter of about 10 microns. The average

strength of this fiber is approximately 2000 MPa

(300,000 psi), and it has a use temperature of up to 1500 65

C. The yarn has a density of approximately 2.7 gm. per

cc and an elastic modulus of approximately 221 GPa

(32X 10

6

psi).

The method of forming both the ceramic and glass

matrix composite components is also important for ob-

taining the improved properties described. The glass or

ceramic constituents are generally obtained in powder

form (preferably about - 325 mesh) in the glassy state

(noncrystalline form) and are combined in this powder

state with the silicon carbide fibers by hot press consoli-

dation. In the case of the ceramic, after densification the

composite is held for a time and at a temperature suffi-

cient to transform the noncrystalline ceramic into the

crystalline state by controlled nucleation and growth of

the appropriate crystalline phases. The ceramic or glass

composite components are preferably formed by laying

up layers containing continuous silicon carbide fibers

and the powdered ceramic or the powdered glass. The

articles formed are then hot pressed at elevated temper-

atures to form the composite components. The process-

ing parameters and composition of the material can

vary widely depending on component design consider-

ations. The preferred method for forming the articles of

the present invention is by hot pressing the mixture of

silicon carbide fibers and noncrystalline ceramic pow-

der or glass as mentioned above. This method gives

particular design flexibility in orienting the fibers, and

sheets formed by such method are particularly adapted

to hot pressing into desired shapes. An exemplary

method comprises continuously unwinding a tow of

silicon carbide fibers (yarn) from a spool at a moderate

rate of speed and passing such fibers through a slip of

the powdered ceramic or powdered glass, solvent and

plasticizer to impregnate the tow. The impregnated

fibers are then rewound onto a larger rotating spool. An

exemplary slip composition may be composed of 40 gm.

of powdered glass or powdered ceramic and 780 ml of

propanol. An alternative composition may comprise 85

gm. of the glass or ceramic and 200 gm. of propanol, 10

gm. of polyvinyl alcohol and 5 drops (approximately I

cc.) of a wetting agent such as Tergitol @. The receiv-

ing drum is preferably run at one revolution per minute

or linear speed of 5 f1. per minute. Excess glass or ce-

ramic and solvent can be removed by pressing a squee-

gee against the drum as it winds. Preferably the ground

ceramic or glass is sized so that 90% of it passes through

a -325 mesh sieve. The thus impregnated tape is then

dried either at ambient temperature or with a radiant

heat source to remove solvent.

Following impregnation, the fiber is removed from

the drum and cut into strips to conform to the dimen-

sions of the article to be fabricated. The fibers are then

laid up in alternating ply stacks in any sequence desired,

e.g., each layer unidirectional, alternating plies of 0 and

900, or 0/30/60/90, 00/4SO/90, etc. In a key pro-

cessing step the assembled composite is then hot pressed

either under vacuum or under inert gas such as argon in

metal dies coated with colloidal boron nitride or graph-

ite dies sprayed with boron nitride powder at pressures

of 6.9-13.8 MPa (1000-2000 psi) and temperatures of

1100-1500 C. Time of hot pressing will vary depend-

ing on composite makeup but generally will be accom-

plished between about 10 minutes and I hour. Addi-

tional glass or ceramic also in powder form may be

inserted between each layer as it is laid. SiC fiber load-

ing in the composite is preferably at least about 50% by

volume. The mold can also be vibrated to ensure uni-

form distribution of the ceramic powder or glass pow-

der over the laid fiber surfaces. In the case of the ce-

ramic, processing by starting with the matrix material in

the glassy state to permit composite densification by hot

5

4,341,826

pressing, followed by converting the ceramic into the

crystalline state largely contributes to the superior

properties of the resulting composite. If after hot press-

ing any significant portion of the ceramic matrix mate-

rial is found to be in the glassy state, further heat treat- 5

ment may be necessary to substantially completely crys-

tallize the matrix for optimum high temperature perfor-

mance. And although it is preferred to have the ceramic

matrix material in the fully ceramic state, acceptable

composite properties are attainable even. if some of the 10

ceramic matrix is retained in the composite in the glassy

state, e.g. up to 25% by weight.

Based on the composition of the matrix material, the

particular fiber reinforcement, and the process of form-

ing the composite, an article with exceptional high 15

strength, fracture toughness, and oxidation resistance

especially at high temperatures is obtained. Each fiber

reinforced layer of the ceramic composite component

regardless of the number of layers or orientation has an

axial flexural strength greater than 70,000 psi and in 20

some instances greater than 100,000 psi. As for fracture

toughness, each layer has a critical stress intensity fac-

tor greater than lOX 10

3

This is clearly superior

to any known ceramic matrix composite currently

available, especially with the low density and oxidation 25

resistance at high temperatures exhibited by the com-

posites of the present invention. An indication of this

oxidation resistance can be seen from the data in Table

I.

6

layer in the composite is oriented such that all the unidi-

rectionally laid fibers in all layers are oriented in sub-

stantially the same axial direction (5). Note FIG. 1

which demonstrates an actual sectional view of a com-

posite containing a plurality of unidirectionally laid SiC

fibers in a lithium aluminosilicate ceramic (LAS) matrix

where the composite layers are uniaxially oriented; and

FIG. 2 which demonstrates an actual sectional view of

a SiC fiber-lithium aluminosilicate ceramic matrix

containing a plurality of unidirectional fiber layers

which are multiaxially oriented in the composite-in

this case oriented in an alternating 0/90 multiaxial

orientation.

The fracture toughness of this composite system has

also been measured using a notched beam test with

unidirectionally reinforced samples exhibiting critical

stress intensity factor (K1C) values of 19X 10

3

psi (inc-

at room temperature (RT); 24X 10

3

psi (inch)! at

800 C.; 27X 10

3

psi at 1000 C.; and 18X 10

3

psi

at 1100 C. These values are only slightly less

than some aluminum alloys possess. Even the cross-

plied (0/90) LAS/SiC yarn composites exhibit KIC

values of over 11 X 10

3

psi from RT to 1100 C.

Monolithic Corning 9608 lithium aluminosilicate, on the

other hand, has very low fracture toughness with a KIC

of approximately 1.3 X 10

3

psi (inch)! from RT to 1000

C.

It is particularly noteworthy that, even after initial

TABLE I 30 fracture, composites of the present invention retain a

--------------------- substantial fraction of their original untested strength.

Bend Strength (3-pt) in Air vs. Temperature This resistance to fracture, even in the presence of initi-

for SiC Yarn/Lithium Aluminosilicate

Composites (50 Volume Percent SiC). ated damage, is distinctly different from the brittle na-

Bend Strength (10

3

psi) ture of conventional ceramic materials.

Temp. - 'C.

20

600

800

1000

1I00

1200

Unidirectional 0'/90' Cross- 35 If a glass matrix is employed, any borosilicate glass

Composite plied Composite which will impart the described properties can be used

90

100

120

140

90

40

50

60

70

70

70

40

with the present invention. Corning 774{) (Corning

Glass Works) was found particularly suitable to pro-

duce the desired component properties. Similarly, Cor-

40 ning 7930 (about 96% by wt. silica), obtained by leach-

ing the boron from a borosilicate glass, and Corning

1723 are the preferred high silica content glass and

From Table I, it can be seen that the ceramic compos- aluminosilicate glass, respectively. While the borosili-

ite components of the present invention exhibit excel- cate glass and the aluminosilicate glass can be used in its

lent flexural strengths in an oxidizing environment well 45 as received - 325 mesh size form, the desired properties

in excess of 1000 C. It is also felt that based on the type for the high silica content glass composites can only be

of matrix employed, these strengths can be maintained satisfactorily fabricated with the glass after it has been

over BOO C. It should be noted that while each indi- ball-milled in propanol for more than 100 hours. It

vidual layer will have an axial flexural strength greater should also be noted that mixtures of the above glasses

than 70,000 psi the overall composite could have a flex- 50 may also be used, with properties tailored accordingly.

ural strength of a lesser value. A uniaxially fiber ori- As with the ceramic matrix, any silicon carbide fiber

ented composite would have an overall axial flexural system with the requisite strength can be used, although

strength greater than 70,000 psi, however, while each a multi-filament silicon carbide yarn with an .average

individual layer in a 0/90 multiaxially oriented lay-up filament diameter up to 50 microns is preferred and yarn

of individual fiber layers would have an axial flexural 55 with average filament diameter of 5 to 15 microns is

strength greater than 70,000 psi. The composite would especially preferred. As stated above, Nippon Carbon

have a flexural strength of greater than 35,000 psi be- Company of Japan produces such a yarn. If a silicon

cause half the fibers would not be in the principal test carbide monofilament is used, a typical silicon carbide

direction. However, such composite would have better monofilament of approximately 14{) microns diameter is

overall strength and impact resistance than, say a totally 60 available from AVCO Systems Division, Lowell, Mass.

uniaxially oriented composite because of the multiaxial This fiber exhibits an average tensile strength of up to

orientation of the fibers. Such multiaxially oriented 3450 MPa, has a temperature capability of over BOO C.

fiber composites can be impacted with significant veloc- and is stable in oxidizing environments.

ity without fracture, unlike conventional monolithic While a variety of methods can also be used to pro-

ceramic articles. 65 duce the glass composite components of the present

By unidirectional is meant all the SiC fibers are ori- invention, e.g. methods conventionally used to produce

ented in each individual layer in substantially the same glassware articles, the preferred method is, as described

axial direction (5). By uniaxial is meant that each above, by hot pressing a mixture of the silicon carbide

4,341,826

7

fibers and powdered glass. As with the ceramic matrix,

this method provides particular design flexibility in

orienting the fibers, and composites formed by such

method are particularly well adapted to hot pressing

into desired shapes. 5

In addition to exhibiting excellent fracture toughness

and high flexural strength, the glass composites of the

present invention maintain these properties even up to

exceptionally high temperatures which makes their use

particularly suitable in the internal combustion engine. 10

FIG. 3A demonstrates the exceptional flexural strength

of a borosilicate glass-silicon carbide fiber reinforced

composite component utilizing silicon carbide yarn. For

a 0/90 fiber orientation (curve A), flexural strengths

of over 40,000 psi up to temperatures of about 600 C. 15

were attained. For 0 fiber orientation (curve B) flexural

strengths of over 60,000 psi up to temperatures of about

600 C. were attained. And as seen in FIG. 3B, the (0

oriented) silicon carbide fiber monofilament reinforced

borosilicate glass (Corning 7740) composites also ex- 20

hibit high flexural strengths above 60,000 psi and as

specifically demonstrated by curves A and B above

75,000 psi for curve A (35% by volume fiber loading)

and above 100,000 psi for curve B (65% by volume fiber

loading) which flexural strengths are maintainable at 25

temperatures up to about 600 C. The 0/90. silicon

carbide fiber orientation in the borosilicate glass matrix

produces a flexural strength above about 40,000 psi and

preferably above about 50,000 psi maintainable to tem-

peratures up to about 600 C. 30

FIG. 4 demonstrates an exemplary high silica content

glass, silicon carbide fiber (0 oriented) reinforced com- .

posite. Curves C and D represent lower and upper

bounds, respectively, for sample data obtained with

composites containing between 30% and 40% fiber 35

loading, by volume. These high silica content glass

composites show flexural strengths in excess of 60,000

psi, and preferably in excess of 70,000 psi, even to tem-

peratures up to about 1150 C.

FIG. 5 demonstrates the exceptional flexural strength 40

of an aluminosilicate glass-silicon carbide fiber rein-

forced composite. FIG. 5 (fiber loading of 50% by

volume) shows for a 0/90 fiber orientation (curve E)

flexural strengths of over 75,000 psi and preferably over

100,000 psi maintained to temperatures up to about 700 45

C.; and for a O fiber orientation (curve F) flexural

strengths of over 150,000 psi and preferably over

200,000 psi are maintained to temperatures up to about

700 C. Fracture toughness, as measured by a three-

point notched beam test, results in critical stress inten- 50

sity factors (KId above 15,000 psi (inch)! for the 0./90

orientation and above 25,000 psi (inch)! for the O orien-

tation that are maintained up to about 700 C.

While the components of the present invention can be

used in any suitable area of the internal combustion 55

engine, their primary utility is in those areas of the" en-

gine which see temperatures over about 500 C. up to

about 1000 C., which consists primarily of the combus-

tion chamber. Accordingly, by combustion chamber

components is meant any component in the internal 60

combustion engine which will be subjected to tempera-

tures over approximately 500 C. The composite mate-

rial strength, both hot and cold, and stability both in

distertion and oxidation resistance, coupled with high

fracture toughness make the components of the present 65

invention particularly useful in this environment. For

example, graphite epoxy materials are generally not

useful above 200 C. and graphite glass composites are

usually impractical in environments which see tempera-

tures above 350 C. As such, the components of the

present invention are far superior to anything previ-

ously attempted in this environment.

The materials of the present invention also provide a

wide variety of choice of matrix material based on the

particular engine temperature that the components will

encounter. For example, if only temperatures up to

about 600 C. will be seen by the components, the glass

matrix, and particularly the borosilicate glass will be

suitable. At use temperatures up to 700 C., the alumino-

silicate glass can be used. And at component tempera-

tures of up to 1000 C. (and higher) and high silica

content glass and the ceramic matrix materials can be

used. Of course, matrices suitable for components

which will see the higher temperatures would naturally

also be suitable for use in the lower temperature envi-

ronments.

Representative combustion chamber components

according to the present invention which see such tem-

peratures are the piston head hot plate, piston, piston

cap, cylinder wall sleeve, exhaust ports, exhaust mani-

fold, fluid injectors and valves. It should also be noted

that the use of the components according to the present

invention, which have excellent insulating properties,

compared to, for example conventional metallic compo-

nents, will increase the efficiency of the engines they are

used in and also have the potential to reduce and even

eliminate the need for conventional cooling.

Potential applications of component parts according

to the present invention can be seen in FIG. 6 where 1

indicates the engine block, 2 a composite piston accord-

ing to the present invention, 3 a composite cylinder

liner according to the present invention 4, a composite

exhaust port-liner according to the present invention,S

a composite cylinder head hot plate according to the

present invention, 6 a composite piston head according

to the present invention, 7 and 8 composite valves ac-

cording to the present invention, 9 a connecting rod, 10

wrist pin and 11 bearing.

In FIG. 7, 20 is a composite cylinder head hot plate

according to the present invention, 21 a composite cyl-

inder liner according to the present invention, 22 the

engine block, and 23 the cylinder head.

Although the invention has been shown and de-

scribed with respect to detailed embodiments thereof, it

should be understood by those skilled in the art that

various changes and omissions in form and detail may

be made therein without departing from the spirit and

the scope of the invention.

We claim:

1. An internal combustion engine combustion cham-

ber component comprising a plurality of substantially

titanium-free ceramic layers selected from the group

consisting of (a) aluminosilicate, (b) lithium aluminosili-

cate, (c) magnesium aluminosilicate, and (d) mixtures

thereof, each layer reinforced with a plurality of unidi-

rectional, continuous length silicon carbide fibers, each

layer having an axial flexural strength greater than

70,000 psi, a high fracture toughness exemplified by a

critical stress intensity factor greater than 10 X 10

3

psi

(inch)!, high temperature strength, high temperature

oxidation stability, and good insulating properties.

2. An internal combustion engine combustion cham-

ber component comprising a silicon carbide fiber rein-

forced glass composite consisting essentially of about

30% to about 70% by volume silicon carbide fibers in a

glass matrix selected from the group consisting of boro-

9

4,341,826

10

silicate glass, high silica content glass, aluminosilicate

glass and mixtures thereof, the composite having a frac-

ture toughness exemplified by a critical stress intensity

factor above about 15,000 psi (inch)!, high temperature

strength, high temperature oxidation stability and insu- 5

lating properties.

3. The component of claims 1 or 2 wherein the silicon

carbide fiber containing layers are uniaxially oriented.

4. The component of claims 1 or 2 wherein the silicon

carbide fiber containing layers are multiaxially oriented. 10

5. The component of claims 1 or 2 wherein the silicon

carbide fibers comprise a multifilament silicon carbide

yam with an average filament diameter of up to 50

microns.

6. The component of claim 5 wherein the yam has an 15

average filament diameter of 5-15 microns.

7. The component of claims 1 or 2 wherein the silicon

carbide fibers are present in an amount of at least about

40% by volume.

8. The component of claim 4 wherein the fibers are 20

oriented to 0/900, 0/45/90, or 0/30/60/90

orientation.

9. The component of claim 1 wherein the composite

is formed by starting with the ceramic in the glassy state

and converting it from the glassy state to the ceramic 25

state after densification of the composite.

10. The composite of claim 2 having a flexural

strength above about 60,000 psi up to a temperature of

about 600 C.

11. The composite of claim 2 wherein the fibers have 30

a substantially 0/90 orientation within the composite.

12. The composite of claim 11 wherein the silicon

carbide fiber is present in an amount about 50% by

volume.

13. The component of claim 2 having a flexural 35

strength above about 150,000 psi at temperatures up to

about 700 C.

40

45

50

55

60

65

14. The component of claim 2 having a fracture

toughness above about 25,000 psi (inch)!.

15. The component of claims 1 or 2 wherein the com-

ponent is a cylinder head' hot plate.

16. The component of claims 1 or 2 wherein the com-

ponent is a piston, piston cap, cylinder wall sleeve, or

valve.

17. An internal combustion engine containing at least

one combustion chamber component comprising a plu-

rality of substantially titanium-free ceramic layers se-

lected from the group consisting of (a) aluminosilicate,

(b) lithium aluminosilicate, (c) magnesium aluminosili-

cate, and (d) mixtures thereof, each layer reinforced

with a plurality of unidirectional, continuous length

silicon carbide fibers, each layer having an axial flexural

strength greater than 70,000 psi, a high fracture tough-

ness exemplified by a critical stress intensity factor

greater. than lOX 10

3

psi (inch)!, high temperature

strength, high temperature oxidation stability, and good

insulating properties.

18. An internal combustion engine containing at least

one combustion chamber component comprising a sili-

con carbide fiber reinforced glass composite consisting

essentially of about 30% to about 70% by volume sili-

con carbide fibers in a glass matrix selected from the

group consisting of borosilicate glass, high silica con-

tent glass, aluminosilicate glass and mixtures thereof,

the composite having a fracture toughness exemplified

by a critical stress intensity factor above about 15,000

psi (inch)!, high temperature strength, high temperature

oxidation stability and insulating properties.

19. The engine of claims 17 or 18 wherein the compo-

nent is a cylinder head hot plate.

20. The engine of claims 17 or 18 wherein the compo-

nent is a piston, piston cap, cylinder wall sleeve, or

valve.

'" '" '" '" '"

Вам также может понравиться

- United Patent: StatesДокумент11 страницUnited Patent: Statesmick.pride81Оценок пока нет

- PMR v39 I3 117 126Документ10 страницPMR v39 I3 117 126rezaeibehrouzОценок пока нет

- Carbon C / SicДокумент9 страницCarbon C / SichaddanОценок пока нет

- United States Patent 1191: Suzi, Gallo, Turin, My Foreign Patent DocumentsДокумент3 страницыUnited States Patent 1191: Suzi, Gallo, Turin, My Foreign Patent DocumentsAbhinav BhargavОценок пока нет

- Development of The Copper Motor RotorДокумент13 страницDevelopment of The Copper Motor RotorIjabiОценок пока нет

- Superalloys 2001 57 70Документ14 страницSuperalloys 2001 57 70htdk312Оценок пока нет

- United States Patent: (10) Patent N0.: (45) Date of PatentДокумент9 страницUnited States Patent: (10) Patent N0.: (45) Date of Patentravi242Оценок пока нет

- Hardy2020 Article SolvingRecentChallengesForWrouДокумент25 страницHardy2020 Article SolvingRecentChallengesForWrouV SОценок пока нет

- United States Patent: Nguyen-Dinh Sep. 18, 2001Документ10 страницUnited States Patent: Nguyen-Dinh Sep. 18, 2001KrozeОценок пока нет

- July 19, 1960: ObjectДокумент3 страницыJuly 19, 1960: ObjectVansala GanesanОценок пока нет

- SAE Material and Design Guidelines For Reinforces Thermoplastic Body PanelsДокумент16 страницSAE Material and Design Guidelines For Reinforces Thermoplastic Body PanelsRobby RenzОценок пока нет

- Thermal Barrier Coatings On Ic Engines 13012013123658 Thermal Barrier Coatings On Ic EnginesДокумент32 страницыThermal Barrier Coatings On Ic Engines 13012013123658 Thermal Barrier Coatings On Ic EnginesNagaraj KundapuraОценок пока нет

- Airostatic BearingДокумент6 страницAirostatic BearingJayachandran SenguttuvanОценок пока нет

- Steam SurbinesДокумент12 страницSteam Surbinesmahmood750Оценок пока нет

- The Manufacturing Process of Jet Turbine BladesДокумент17 страницThe Manufacturing Process of Jet Turbine BladesThinesh Rau KrishnamurtyОценок пока нет

- Remanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingДокумент9 страницRemanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingSujay NahaldeОценок пока нет

- IJAEMS-Design, Modeling and Analysis of Structural Strength of Cylinder and Cylinder Head of 4-Stroke (10 H.P.) C.I. Engine - A ReviewДокумент7 страницIJAEMS-Design, Modeling and Analysis of Structural Strength of Cylinder and Cylinder Head of 4-Stroke (10 H.P.) C.I. Engine - A ReviewInfogain publicationОценок пока нет

- FEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonДокумент14 страницFEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonIJRASETPublicationsОценок пока нет

- Method For Repairing A CastingДокумент10 страницMethod For Repairing A Castingtyhello21Оценок пока нет

- NS Ladle Refractory 2020Документ4 страницыNS Ladle Refractory 2020Zaini MahdiОценок пока нет

- Effect of Hardness, Tensile and Wear Behavior of Al-4.5Wt%Cu Alloy/Flyash/Sic Metal Matrix CompositesДокумент5 страницEffect of Hardness, Tensile and Wear Behavior of Al-4.5Wt%Cu Alloy/Flyash/Sic Metal Matrix CompositesIJMERОценок пока нет

- Turbine Parts and MaterialsДокумент8 страницTurbine Parts and Materialsdheerudu100% (1)

- High-Temperature Tensile Properties and Oxidation Behavior of Carbon Fiber Reinforced Silicon Carbide Bolts in A Simulated Re-Entry EnvironmentДокумент4 страницыHigh-Temperature Tensile Properties and Oxidation Behavior of Carbon Fiber Reinforced Silicon Carbide Bolts in A Simulated Re-Entry Environmentnitheeshgmenon5Оценок пока нет

- Nasa 1977 TBC FT50 ProgramДокумент60 страницNasa 1977 TBC FT50 Programatfrost4638100% (1)

- Us 4921761Документ13 страницUs 4921761library nuОценок пока нет

- 2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanyДокумент13 страниц2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanySumit RaiОценок пока нет

- ENGIN - Heat Treatment For Stronger Aerospace GearsДокумент15 страницENGIN - Heat Treatment For Stronger Aerospace GearsGG_04100% (1)

- Advanced Materials and Protective Coating in Aeroengines ApplicationДокумент10 страницAdvanced Materials and Protective Coating in Aeroengines ApplicationSyavash EnshaОценок пока нет

- Modern Alloys: Figure 1. Schematic of A Gas Turbine EngineДокумент3 страницыModern Alloys: Figure 1. Schematic of A Gas Turbine EngineFauzi Oki100% (1)

- Advances in Solid Oxide Fuel Cells XОт EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffОценок пока нет

- AlSiC Composite in Engine Valve GuidesДокумент9 страницAlSiC Composite in Engine Valve GuidesSebastianAftanasăОценок пока нет

- Yeovil College Design Assignment Unit 6Документ15 страницYeovil College Design Assignment Unit 6kenwarОценок пока нет

- FPR SpecificationsДокумент15 страницFPR SpecificationsHector Manuel Leon JimenezОценок пока нет

- Plasma Spray Coating On PistonДокумент45 страницPlasma Spray Coating On Pistonrajkiran_rajОценок пока нет

- Heat Plat ApplicationДокумент6 страницHeat Plat ApplicationJDC - Export ManagerОценок пока нет

- Effect of Carbonitiriding On Endurance Life of Ball Bearing Produced From Sae52100Документ6 страницEffect of Carbonitiriding On Endurance Life of Ball Bearing Produced From Sae52100mans2014Оценок пока нет

- CMSX Single CrystalДокумент10 страницCMSX Single Crystal7022315Оценок пока нет

- Diesel Storage TankДокумент13 страницDiesel Storage Tankalmadhagi100% (1)

- Sinter Diffusion Bonded Idler Sprocket of Automotive EngineДокумент10 страницSinter Diffusion Bonded Idler Sprocket of Automotive Engineمحمد تانزيم ابراهيمОценок пока нет

- 6 Advanced Polymer Composite Propeller BladesДокумент12 страниц6 Advanced Polymer Composite Propeller BladesThomas MouraОценок пока нет

- Turbine BladesДокумент11 страницTurbine BladesTheWorrior ChayranОценок пока нет

- 2007 - Thermal Analysis of A CeramicДокумент5 страниц2007 - Thermal Analysis of A CeramicekremОценок пока нет

- Ceramic Engineering: Jump To Navigationjump To SearchДокумент15 страницCeramic Engineering: Jump To Navigationjump To SearchPeter LuvisОценок пока нет

- Material Aspects of A 700 C Power Plant 4Документ7 страницMaterial Aspects of A 700 C Power Plant 4malsttarОценок пока нет

- Tanaka 1996 Development and Fabrication of CeraДокумент8 страницTanaka 1996 Development and Fabrication of Ceraabolfazl faramarziОценок пока нет

- Nasa Technical Note NASA TN D-4630Документ18 страницNasa Technical Note NASA TN D-4630이주성Оценок пока нет

- Groover/Introduction To Manufacturing ProcessesДокумент3 страницыGroover/Introduction To Manufacturing ProcessesGabriel BarbieriОценок пока нет

- Progress of Ceramic Matrix Composites Brake Materials For Aircraft ApplicationДокумент13 страницProgress of Ceramic Matrix Composites Brake Materials For Aircraft Applicationanon_82671922Оценок пока нет

- On The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive ManufacturingДокумент28 страницOn The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive Manufacturingmrkshitij.sОценок пока нет

- Gas TurbineДокумент51 страницаGas TurbineratchagarajaОценок пока нет

- Turbine Blade Manufacturing OverviewДокумент17 страницTurbine Blade Manufacturing Overviewwiley_01Оценок пока нет

- Ceramic Engineering: From Wikipedia, The Free EncyclopediaДокумент6 страницCeramic Engineering: From Wikipedia, The Free EncyclopediaFaiz AbdullahОценок пока нет

- MSC24495 1Документ4 страницыMSC24495 1John Melanathy IIОценок пока нет

- The Effects of Heat Treatment On The Tensile PropeДокумент9 страницThe Effects of Heat Treatment On The Tensile PropeMetin YilmazОценок пока нет

- The Die-Cast Copper Motor RotorДокумент17 страницThe Die-Cast Copper Motor Rotoruuur35Оценок пока нет

- TP04 Flores PDFДокумент11 страницTP04 Flores PDFJefreyMatuanMondranoОценок пока нет

- KManuscript66 RGДокумент10 страницKManuscript66 RGRajesh Kumar SahuОценок пока нет

- Light Weight Non-Metals To Replace Steel: A Term Paper OnДокумент15 страницLight Weight Non-Metals To Replace Steel: A Term Paper OnJatinderjot SinghОценок пока нет

- Journal 1 (Impact Factor 5.684, Citescore 7.6)Документ11 страницJournal 1 (Impact Factor 5.684, Citescore 7.6)Meby MathewОценок пока нет

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIОт EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiОценок пока нет

- Journal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesДокумент6 страницJournal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesANJALI TMU StudentОценок пока нет

- Analysis of Item Rates: Norms 2041Документ11 страницAnalysis of Item Rates: Norms 2041Saurav LamichhaneОценок пока нет

- Na2Xfgby 2 X (10-300) MM 0.6/1 KVДокумент4 страницыNa2Xfgby 2 X (10-300) MM 0.6/1 KVHajie OmenОценок пока нет

- Thermo-Physical Properties of Petroleum Coke During CalciningДокумент7 страницThermo-Physical Properties of Petroleum Coke During CalciningJean RisquezОценок пока нет

- Progress Card HUMSSДокумент35 страницProgress Card HUMSSwiljhon sunioОценок пока нет

- LCC M150 500 3 LCCPump Metal PDFДокумент8 страницLCC M150 500 3 LCCPump Metal PDFFrancisco Loyola CarrascoОценок пока нет

- Basic Wilderness Survival (By Jim Buller) - WorksheetsДокумент6 страницBasic Wilderness Survival (By Jim Buller) - WorksheetsJo OhОценок пока нет

- Atmospheric Storage Tank Fire - 2016 Rev 2 Dec 2016 - OkДокумент51 страницаAtmospheric Storage Tank Fire - 2016 Rev 2 Dec 2016 - OkEki RamadhaniОценок пока нет

- PMA - Manufacturing ProcessДокумент7 страницPMA - Manufacturing ProcessreezmanОценок пока нет

- Mercer - Seat Materials GuideДокумент4 страницыMercer - Seat Materials GuidejoshОценок пока нет

- Ceresit Global Ce40 Aquastatic TdsДокумент3 страницыCeresit Global Ce40 Aquastatic TdsSurush ZikrilobekovОценок пока нет

- Davies Color Book For WebДокумент13 страницDavies Color Book For WebKristelle GazmenОценок пока нет

- Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)Документ7 страницShaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)Anonymous uux1ScsОценок пока нет

- Specific Gravity ChartДокумент2 страницыSpecific Gravity ChartApril Trish Albaña0% (1)

- Modules, Tools, Aplications ZUND G3, S3 and L3Документ8 страницModules, Tools, Aplications ZUND G3, S3 and L3Sérgio VieiraОценок пока нет

- Chemical Principles 8th Edition by Zumdahl DeCoste ISBN Test BankДокумент23 страницыChemical Principles 8th Edition by Zumdahl DeCoste ISBN Test Bankstephanie100% (27)

- Lecture 1 Pulp and Paper Technology CHE 510Документ12 страницLecture 1 Pulp and Paper Technology CHE 510Christian Nweke100% (2)

- Laboratory Test Report: Faculty of Engineering & TechnologyДокумент6 страницLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaОценок пока нет

- 1231 - Water For Pharmaceutical PurposesДокумент58 страниц1231 - Water For Pharmaceutical PurposesMaleja Suarez100% (1)

- Jama Seminar 2019 LCM WG - FinalДокумент1 страницаJama Seminar 2019 LCM WG - Finalgilar herliana putraОценок пока нет

- Chlor-Alkali ProcessДокумент6 страницChlor-Alkali ProcessEduardo Tonino Chavez Gaytan100% (1)

- This Is The Story of Three Plastic BottlesДокумент1 страницаThis Is The Story of Three Plastic BottlesDuong NguyenОценок пока нет

- 0620 s08 QP 2Документ16 страниц0620 s08 QP 2Hubbak KhanОценок пока нет

- K26 Concrete Deterioration and RepairДокумент68 страницK26 Concrete Deterioration and RepairPaul LunaОценок пока нет

- SSM ECE Engineering Chemistry Assignment 2Документ6 страницSSM ECE Engineering Chemistry Assignment 2knowledge2intelligenceОценок пока нет

- Mechanical, Rheological and Degradation Properties of PBAT Nanocomposites Reinforced by Functionalized Cellulose NanocrystalsДокумент10 страницMechanical, Rheological and Degradation Properties of PBAT Nanocomposites Reinforced by Functionalized Cellulose NanocrystalsAime Alejandra Hernández LópezОценок пока нет

- U2S3-4 - Environmental Impact of Textile IndustriesДокумент9 страницU2S3-4 - Environmental Impact of Textile IndustriesHieu100% (7)

- IlssДокумент6 страницIlssAnandОценок пока нет

- AISI 1040: Typical AnalysisДокумент2 страницыAISI 1040: Typical Analysisho_chauhanОценок пока нет

- Etea 2019Документ7 страницEtea 2019Izhar RahmanОценок пока нет