Академический Документы

Профессиональный Документы

Культура Документы

DSC Lc105dgb

Загружено:

Imi Michał SmulskiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DSC Lc105dgb

Загружено:

Imi Michał SmulskiАвторское право:

Доступные форматы

LC-105DGB

Shock & Glass Breakage Detector

Installation Instructions

LC-105DGB belongs to the new generation of glass breakage detectors. The LC-105DGB can detect glass cutting by diamond in addition t o t h e im p r o ved de t ect io n o f g las s b r eak ag e. T h is is ach ie ved b y o u r n ew all- d ig it a l si g n al p r o ces sin g . The LC-105DGB offers the solution for the false-alarms problem. The LC-105DGB detects the unique patterns of sound emitted by breaking or cutting glass. The LC-105DGB does not have to be attached to the window, providing volume protection, and allows the protection of several windows using one detector. TYPICAL INSTALLATION Mounting The detector offers flexible installation. It can be either ceiling mounted or wall mounted as shown in Fig. 1. Selecting mounting location If heavy blinds or curtains cover the glass, you must locate the detector behind the blinds on the window frame or above it, otherwise the blinds might block the sound. Make sure to test the unit thoroughly using a glass break simulator for proper detection. Install the detector in a direct line of sight with the protected glass. Do not mount the unit in front of air ducts, or close to bells (measuring 0.5m or larger in diameter). For pr otecting s everal windows i n one room, locate the detec tor at opti mal distance from them to achi ev e the bes t detec tion. Note: for symmetrical cover of the detection area it is recommended to place the detector on the ceiling. CONNECTING THE DETECTOR (Fig. 2,3&4) 1. Use a small screwdriver to release the top of the case and lift open the case (Fig. 3-1,2) There is no need to remove the PCB (Printed Circuit Board) from the case). 2. Insert the wires through the wiring hole (Fig. 3-3). 3. Use the mounting holes (Fig. 2-A) to mount the detector. 4. Connect the wires to the terminal. (Fig.4). 5. Close the case. JUMPERS LED ON: LEDS enabled LED OFF: LEDS disabled Shock ON: This is the normal working mode. Both breaking glass sound and breaking glass shock-wave are necessary for generating an alarm. Shock OFF: This mode i s used only for ins tallation settings. The sound of breaking glass is enough to generate an alarm. WIRE CONNECTIONS Terminal Block Connections (See fig. 4). Terminal 1 (Marked "-"). Connect to the return Voltage or ground of the control panel. Term in al 2 ( Marked "+") . Connec t to the posi tive Voltage of 9- 16 VDC sour ce (us ually fr om the alar m control unit). Terminals 3 & 4 (Marked TAMPER). If a Tamper function is required connect these terminals to a 24 hours normally closed protective zone in the c ontr ol unit. If the fr ont cover of the detector is opened, an imm edi ate alarm signal wi ll be sent to the c ontr ol unit. Term in als 5 & 6 ( Marked RE LAY) . T hese ar e the output relay c ontacts of the detector. Stand by - N.C / A larm - N.O

Fig. 1 - Dete ctor Mo unnting Fig. 2 - Detecto r Instal latio n Fig. 3 - Detector Insta llation

2 3 A

1 4

- 12V +

TAMPER

RELAY

Fig. 4 - Termina l blo ck

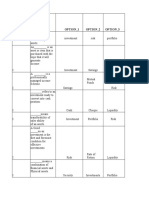

TESTING THE DETECTOR Set the jumpers as follows: LED=ON, SHOCK=ON. 1. Use the simulator in manual mode to simulate the noise of glass breaking . Check that the yellow LED is ON. If it does not light, a sensitivity calibration is necessary. Rotate the "SENS" potentiometer clockwise to increase the sensitivity, and counterclockwise to decrease it. 2. Use your hand or a padded object to firmly strike on door or table. If the green LED does not light, adjust the sensitivity as necessary. 3. Use the Simulator in automatic mode and check that the red LED lights. If the red LED, yellow LED and green LEDS are ON, your detector is working properly. * Cutting of glass by a diamond causes only the red LED to light. If the red LED does not light try adjusting the sensitivity until the red LED lights. FINAL TESTING * Set the jumpers as follows: LED=ON, SHOCK=OFF. * To ensure maximum protection against false alarms, activate any device in the area, which might automatically activate, like cycle pumps, generator s, heating/ai r conditioni ng units , etc. If thes devi ces trigger an alar m, mount the unit i n a different location. * Set the jumpers to their normal working position: SHOCK = ON. WIRE SIZE REQUIREMENTS Use #22 AWG (0.5mm) or wires with a larger diameter. Use the following table to determine required wire gauge (diameter) and length of the wire between the detector and the control panel. Wire Length m 200 300 400 800 Wire Diameter mm .5 .75 1.0 1.5 Wire Length ft 800 1200 2000 3400 Wire Gauge # 22 20 18 16 TECHNICAL SPECIFICATION Power Input Current Consumption Detection Range Mounting 9-16VDC Standby: 15mA at 12 Vdc Active: 40mA at 12Vdc 10m (33ft), Max. Cutting 3m Ceiling or Wall

Fig. 5 - PCB Layout

Fig. 6 - Detector test

Alarm Output Relay N.C. 50mA/24Vdc 10 Ohm in line resistor Tamper Switch N.C. 50mA/24Vdc with 10Ohm in line resistor

Operating -20 oC to 50 oC Temperature Range (-4o F to 122o F) Operating Humidity 95% max relative humidity Range non condensing Storage -30 oC to 70 oC Temperature Range (-22 oF to 158 oF) RFI Protection EMI Protection Dimensions Weight 30V/m 10 -1000 MHz 50,000V electrical interference from lightning 79mm x 48mm x 21mm 40gr. ( 1.41oz.)

BLOCK CONNECTOR

LIMIT ED WARRAN TY: Digital Security Controls Ltd, w arrants that for a period of 12 m onths from the date of purchase, the product shall be free of defe cts in materials and workm anship unde r normal use a nd that in fulfillment of any breach of such warranty. D igital Security Controls Ltd shall, at it s opt ion, repair or re place the defective equipment u pon ret urns of the e quipm ent to its repair d epot. This warranty applies only to de fects in parts and workmanship and no t to damage incurred in shippin g or ha ndling, or damag e due to causes beyond the control of Digit al Security Con trols Ltd, such as lightning, excessive voltage me chan ical sho ck, wate r damage, or damage arising out o f abuse, alteration or improper a pplication of the equipment. The forego ing w arranty sh all apply only to the original buyer, and is and shall be in lieu of any and all o ther w arranties, whether expressed or implied and o f all othe r obligations o r lia bilities on th e part of Digital Security Controls Ltd . Digital Security Controls Ltd neith er assumes responsib ility for, nor au thorizes an y oth er perso n purpo rting to act on its behalf to modify or t o cha nge this w arranty, nor to assume for it a ny ot her w arranty or liability concerning this product. In no event shall Digita l Security Con trols Ltd be lia ble f or any direct, indirect or conseq uential da mages, lo ss of anticip ated profits, loss o f time or an y oth er losses incurred by the buyer in conne ction with th e purchase, in stallation or operation or failure of t his pro duct. Motion det ecto rs can only detect mo tion within the de signated are as as Sh own in th eir re spe ctive inst allation instructions. Th ey can not discriminate betwe en intrud ers and inte nded occupants. Mot ion detectors do not provide vo lumetric area prote ction. The y have multiple bea ms of d etection and mo tion can only be detected in unobstructed area s covered by these beams. They cannot detect motion which occurs beh ind w alls, ceilings, flo or, closed doors, g lass partitions, g lass doors or windows. Any type of tamperin g whe ther in tentional or unintentional such as m asking , painting, or spra ying of any ma terial on the lenses, mirrors, windows or any o ther part of th e detection system w ill impair its proper operation. Passive infrared motion detectors operate by sensing changes in temperature. Howe ver their effectiven ess can be reduced when the ambient temperature rises ne ar or above body temperature or if there are intentional or u nin ten tion al so urces of he at in or n ea r th e d et ectio n a rea. So me of t hese h eat so urces could be h ea ters, radia tors, sto ves, barb equ es, firep laces, su nligh t, stea m vent s, lig ht in g and so o n. WARNI NG: Di gital Security Co ntrols Ltd , reco mm end s that th e en tire sys tem be com pletely tested o n a reg ula r basis. However, d espite fre qu ent testing , an d d ue to , bu t n ot lim ited to , crim inal tam perin g or electrical d isru ption , it i s po ssible for this p rod uct to fail to p erfo rm as exp ecte d. Im p ortan t in form a tio n : Ch an g es or mo d ifica ti on s no t ex pre ssl y ap p ro ved b y D ig ital Secu ri ty Co n tro ls L td c ou ld v oi d th e u se r's a uth or ity to op er ate thi s e qu ip m en t.

2005 Digital Security Controls Ltd Toronto, Canada www.dsc.com

Вам также может понравиться

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityДокумент2 страницыLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaОценок пока нет

- Bravo 5 Pir - Manual Instalare PDFДокумент2 страницыBravo 5 Pir - Manual Instalare PDFDarie SilviuОценок пока нет

- GBD PlusДокумент2 страницыGBD PlusseinnationalОценок пока нет

- Detector Quiebre Paradox DG-50Документ2 страницыDetector Quiebre Paradox DG-50Pablo Garay NarváezОценок пока нет

- Bravo 2&3 Pir - Manual Instalare PDFДокумент1 страницаBravo 2&3 Pir - Manual Instalare PDFDarie SilviuОценок пока нет

- Detector Geam Spart DSCДокумент0 страницDetector Geam Spart DSCTibiОценок пока нет

- Monitor 913Fw UserManualДокумент20 страницMonitor 913Fw UserManualPubg MobileОценок пока нет

- Heat Detector Maintenance Testing ProcedureДокумент2 страницыHeat Detector Maintenance Testing ProcedureAlvin MiraОценок пока нет

- AntiefractieДокумент149 страницAntiefractieStanciu SimonaОценок пока нет

- 525d Manual Instalare Detector Paradox Cu MicroundeДокумент2 страницы525d Manual Instalare Detector Paradox Cu MicroundeGheorghiescu AndreiОценок пока нет

- M1 Installation&Programming ManualДокумент72 страницыM1 Installation&Programming ManualNguyen LeОценок пока нет

- Elk-M1g Installation ManualДокумент72 страницыElk-M1g Installation ManualaktnrzyyjjiztqanziОценок пока нет

- Everspring Sm103 ManualДокумент4 страницыEverspring Sm103 ManualLokanatha ReddyОценок пока нет

- Video Security Intercom System: Complete With 1 Monitor and 1 Camera Expandable Up To 2 Monitors and 2 CamerasДокумент13 страницVideo Security Intercom System: Complete With 1 Monitor and 1 Camera Expandable Up To 2 Monitors and 2 Cameraskalu_fazendaОценок пока нет

- Crazy Taxi Naomi ManualДокумент87 страницCrazy Taxi Naomi ManualbrtnomОценок пока нет

- Manual Aoc 1619swaДокумент32 страницыManual Aoc 1619swaLuis TegelОценок пока нет

- LM520Документ19 страницLM520diggitydougОценок пока нет

- 3d Video Wizard User Manual 101711Документ30 страниц3d Video Wizard User Manual 101711Hernan ErasmoОценок пока нет

- LCD TV Plasma TV: Owner'S ManualДокумент94 страницыLCD TV Plasma TV: Owner'S ManualAride4everОценок пока нет

- PC585 Installation GuideДокумент52 страницыPC585 Installation GuideAnas QumsiehОценок пока нет

- DCR-SR45/SR46/SR65/SR85: Operating Guide Guía de OperacionesДокумент68 страницDCR-SR45/SR46/SR65/SR85: Operating Guide Guía de OperacionesefrainОценок пока нет

- Manual TV LG 55la9650Документ64 страницыManual TV LG 55la9650aldometanyОценок пока нет

- Honeywell Fg1625rfm Install GuideДокумент2 страницыHoneywell Fg1625rfm Install GuideAlarm Grid Home Security and Alarm MonitoringОценок пока нет

- GSP1101ManualSpanish Original PDFДокумент64 страницыGSP1101ManualSpanish Original PDFArturo Mayoral100% (1)

- JVC Dr-m1 Service ManualДокумент116 страницJVC Dr-m1 Service ManualvideosonОценок пока нет

- Blu-Ray Recorder JVC SR-HD1500USДокумент104 страницыBlu-Ray Recorder JVC SR-HD1500USPaul KupasОценок пока нет

- Honeywell Fg1625 Install GuideДокумент2 страницыHoneywell Fg1625 Install GuideAlarm Grid Home Security and Alarm MonitoringОценок пока нет

- Sony Handycam DCR-SR45 ManualДокумент171 страницаSony Handycam DCR-SR45 ManualRichard BalonglongОценок пока нет

- Operating Guide: DCR-DVD105/DVD205/DVD305/ DVD605/DVD705/DVD755Документ156 страницOperating Guide: DCR-DVD105/DVD205/DVD305/ DVD605/DVD705/DVD755Renee WyattОценок пока нет

- JamMan Stereo Manual 18-0707V-BДокумент68 страницJamMan Stereo Manual 18-0707V-Bwaldemirm35Оценок пока нет

- Installation Manual: - Warn IngДокумент60 страницInstallation Manual: - Warn IngdpopsorОценок пока нет

- LC320SS9 B LC320SS9 A LC320SS9: Need Help?Документ76 страницLC320SS9 B LC320SS9 A LC320SS9: Need Help?budgetpcrepairОценок пока нет

- G 195 HQДокумент55 страницG 195 HQronaldОценок пока нет

- MODEL 5406A: Instruction ManualДокумент24 страницыMODEL 5406A: Instruction ManualFILID MADОценок пока нет

- LG Plasma TV ManualДокумент360 страницLG Plasma TV ManualDejan StankovikОценок пока нет

- Manual Monitor Qbex 2216SwДокумент16 страницManual Monitor Qbex 2216SwJose AlfonsoОценок пока нет

- Acer AT1921/22 Service GuideДокумент61 страницаAcer AT1921/22 Service GuideAlberto UdoviciОценок пока нет

- DX-32L200NA14 - 13-0215 - IMP INFO - V3 - EN - Final - LRДокумент8 страницDX-32L200NA14 - 13-0215 - IMP INFO - V3 - EN - Final - LRMarkWoodxxxОценок пока нет

- LG Plasma TV 42PC3D 42PC3DV 50PC3DДокумент68 страницLG Plasma TV 42PC3D 42PC3DV 50PC3DAdam LenzОценок пока нет

- CCTV 030Документ24 страницыCCTV 030WilfredoRodriguezОценок пока нет

- Digital PSC Loop Tester Model 4118A Instruction ManualДокумент24 страницыDigital PSC Loop Tester Model 4118A Instruction Manualpoci11Оценок пока нет

- User Guide Spectrum SeriesДокумент4 страницыUser Guide Spectrum SeriesPeter OraveczОценок пока нет

- Service Manual SDS1000CML Service ManualДокумент61 страницаService Manual SDS1000CML Service Manualg4okk8809Оценок пока нет

- 917Vw User Manual: 1. PrefaceДокумент28 страниц917Vw User Manual: 1. Prefacelucasfigueiredo23Оценок пока нет

- DG85 - Detector ExteriorДокумент2 страницыDG85 - Detector ExteriorLucian ManolicaОценок пока нет

- LM700Документ22 страницыLM700zixbixОценок пока нет

- AOC Computer Monitor 2236SWAДокумент30 страницAOC Computer Monitor 2236SWAgamusino2Оценок пока нет

- Glasstrek - UputstvoДокумент2 страницыGlasstrek - UputstvoKimberly KennedyОценок пока нет

- System Sensor B112LP - Installation ManualДокумент4 страницыSystem Sensor B112LP - Installation ManualAlarm Grid Home Security and Alarm MonitoringОценок пока нет

- Sony Manual PDFДокумент60 страницSony Manual PDFFco JavierОценок пока нет

- The IEE Wiring Regulations Explained and IllustratedОт EverandThe IEE Wiring Regulations Explained and IllustratedРейтинг: 4 из 5 звезд4/5 (14)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Ultimate Guide: Wiring, 8th Updated EditionОт EverandUltimate Guide: Wiring, 8th Updated EditionРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Mikrotik VlanДокумент5 страницMikrotik VlanImi Michał SmulskiОценок пока нет

- Log Management ManualДокумент4 страницыLog Management ManualImi Michał SmulskiОценок пока нет

- Mikrotik WinboxДокумент7 страницMikrotik WinboxImi Michał SmulskiОценок пока нет

- MikroTik FirewallДокумент2 страницыMikroTik FirewallMenghong Chhun0% (2)

- Mikrotik Router Operating System GotchasДокумент5 страницMikrotik Router Operating System GotchasImi Michał SmulskiОценок пока нет

- Hotspot ManualДокумент31 страницаHotspot ManualImi Michał SmulskiОценок пока нет

- Mikrotik Router PDFДокумент1 страницаMikrotik Router PDFSebastian FerraroОценок пока нет

- Ip Routes ManualДокумент8 страницIp Routes ManualImi Michał SmulskiОценок пока нет

- Mikrotik Basics Guide for BeginnersДокумент31 страницаMikrotik Basics Guide for BeginnersOscar Ortiz ChoqueОценок пока нет

- Intro To NetworkingДокумент60 страницIntro To NetworkingJay SorianoОценок пока нет

- MikroTik AP SetupДокумент23 страницыMikroTik AP SetupuntungpriyantoОценок пока нет

- How Do I Set Up Wds Using MikrotikДокумент6 страницHow Do I Set Up Wds Using Mikrotikoffline71Оценок пока нет

- Ca8-4 Stacja1Документ2 страницыCa8-4 Stacja1Imi Michał SmulskiОценок пока нет

- General Settings For User Authentication and AccountingДокумент20 страницGeneral Settings For User Authentication and AccountingImi Michał SmulskiОценок пока нет

- Firewall ManualДокумент13 страницFirewall ManualImi Michał SmulskiОценок пока нет

- DNS Client and Cache ManualДокумент4 страницыDNS Client and Cache ManualImi Michał SmulskiОценок пока нет

- GregSowell Mikrotik SecurityДокумент22 страницыGregSowell Mikrotik SecurityMarco Vinicio Rojas GarciaОценок пока нет

- Dude Manual - Mikrotik WikiДокумент13 страницDude Manual - Mikrotik WikiImi Michał SmulskiОценок пока нет

- Test RB Ethernet Ports Damaged by OvervoltageДокумент13 страницTest RB Ethernet Ports Damaged by Overvoltageazul_xpОценок пока нет

- Eoip ManualДокумент5 страницEoip ManualImi Michał SmulskiОценок пока нет

- Ca8-4 Stacja2Документ2 страницыCa8-4 Stacja2Imi Michał SmulskiОценок пока нет

- BGP ManualДокумент5 страницBGP ManualImi Michał SmulskiОценок пока нет

- Setting Up Internet Access Server On Basis of Mikrotik Routeros and Isp Billing System Netup Utm5Документ9 страницSetting Up Internet Access Server On Basis of Mikrotik Routeros and Isp Billing System Netup Utm5Vijay Kumar TitarmareОценок пока нет

- Setting Up Internet Access Server On Basis of Mikrotik Routeros and Isp Billing System Netup Utm5Документ9 страницSetting Up Internet Access Server On Basis of Mikrotik Routeros and Isp Billing System Netup Utm5Vijay Kumar TitarmareОценок пока нет

- BGP ManualДокумент5 страницBGP ManualImi Michał SmulskiОценок пока нет

- Bandwidth TestДокумент4 страницыBandwidth TestImi Michał SmulskiОценок пока нет

- Bandwidth Management ManualДокумент16 страницBandwidth Management ManualImi Michał SmulskiОценок пока нет

- Basic Setup GuideДокумент16 страницBasic Setup GuideImi Michał SmulskiОценок пока нет

- About Your Security System: Fire DetectionДокумент19 страницAbout Your Security System: Fire DetectionImi Michał SmulskiОценок пока нет

- Tl265gs Na FinalДокумент2 страницыTl265gs Na FinalImi Michał SmulskiОценок пока нет

- 321 Service Manual - Part1Документ46 страниц321 Service Manual - Part1Eloy Enriquez Dominguez100% (1)

- Instructor GuideДокумент63 страницыInstructor GuidegurungeОценок пока нет

- Linux HA Using LVS/Heartbeat+DRBD+OCFS2Документ10 страницLinux HA Using LVS/Heartbeat+DRBD+OCFS2Adzmely MansorОценок пока нет

- GDM Ch-17 Abuts Ret WallsДокумент136 страницGDM Ch-17 Abuts Ret WallsNguyen Ngoc DuyenОценок пока нет

- Acknowledement: An Ostentatious Use of Words Will Not Suffice in Acknowledging TheДокумент40 страницAcknowledement: An Ostentatious Use of Words Will Not Suffice in Acknowledging TheRishi BhatiaОценок пока нет

- Numerical Control - Wikipedia, The Free EncyclopediaДокумент4 страницыNumerical Control - Wikipedia, The Free EncyclopediazidaaanОценок пока нет

- Sequences WorksheetДокумент8 страницSequences WorksheetAsh LoopsОценок пока нет

- Mech4005y 5 2010 2Документ4 страницыMech4005y 5 2010 2Balgo BalgobinОценок пока нет

- Global Payroll Peoplesoft 9.1Документ1 420 страницGlobal Payroll Peoplesoft 9.1alencarr7759Оценок пока нет

- P6Документ33 страницыP6adaptive4u4527Оценок пока нет

- Cisco Expressway Administrator Guide X8 7Документ369 страницCisco Expressway Administrator Guide X8 7testОценок пока нет

- 219 Ho SBC (WJB) 9-30-02Документ36 страниц219 Ho SBC (WJB) 9-30-02arkhom1Оценок пока нет

- Physics 157 Homework 5 Thermodynamics SkillsДокумент5 страницPhysics 157 Homework 5 Thermodynamics SkillsSherin HamidОценок пока нет

- Motion Sensor For Security Light Using Pir SensorДокумент3 страницыMotion Sensor For Security Light Using Pir SensorSamaira Shahnoor Parvin100% (1)

- Level Past Paper Questions - Physics O: TOPIC-24 Elasticity PAPER-1 Multiple ChoiceДокумент4 страницыLevel Past Paper Questions - Physics O: TOPIC-24 Elasticity PAPER-1 Multiple Choiceelty TanОценок пока нет

- 2015NOACatalogfor PISTON RING NPR PDFДокумент582 страницы2015NOACatalogfor PISTON RING NPR PDFali4299100% (9)

- Revised ListДокумент10 страницRevised List5paisaОценок пока нет

- Introductory Chemistry 5th Edition Tro Solutions ManualДокумент6 страницIntroductory Chemistry 5th Edition Tro Solutions Manualjonathantruongylunfl100% (16)

- Dark Knight Application Using AndroidДокумент15 страницDark Knight Application Using AndroidIJRASETPublicationsОценок пока нет

- MCQ Iapm Double Final 1Документ48 страницMCQ Iapm Double Final 1moamen BОценок пока нет

- 10 Chapter 1Документ44 страницы10 Chapter 1Abeera Hassan ChohanОценок пока нет

- MMA-707: Analytical Finance I Lookback Options Excel VBAДокумент10 страницMMA-707: Analytical Finance I Lookback Options Excel VBAPadawan De WookieeОценок пока нет

- ND As350 Manual FSXДокумент32 страницыND As350 Manual FSXBreno Santana100% (1)

- Finalterm Exam-TOA PDFДокумент2 страницыFinalterm Exam-TOA PDFEnayat KhanОценок пока нет

- JAFM - Volume 11 - Issue (Special Issue) - Pages 141-150Документ10 страницJAFM - Volume 11 - Issue (Special Issue) - Pages 141-150Fauzi Hussin LeoОценок пока нет

- Cleanroom LED: CR434B LED48/840 PSD W60L60 AC-MLO PIДокумент8 страницCleanroom LED: CR434B LED48/840 PSD W60L60 AC-MLO PIMihaiAnastasiuОценок пока нет

- Assignment Atomic Structure JH Sir-2611Документ30 страницAssignment Atomic Structure JH Sir-2611Shivam KumarОценок пока нет

- Daily Lesson Plan in MathematicsДокумент5 страницDaily Lesson Plan in MathematicsAlyana Joy AribanОценок пока нет

- Soil Stabilization of Road by Using Spent WashДокумент7 страницSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Fundamentals of The Electromagnetic MethodДокумент8 страницFundamentals of The Electromagnetic MethodEder VacaОценок пока нет