Академический Документы

Профессиональный Документы

Культура Документы

MGN 38 Guidelines For The Provision of Food and Fresh Water On Merchant Ships and Fishing

Загружено:

sumaker1986Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MGN 38 Guidelines For The Provision of Food and Fresh Water On Merchant Ships and Fishing

Загружено:

sumaker1986Авторское право:

Доступные форматы

MARINE GUIDANCE NOTE

MGN 38 (M+F)

Contamination of Ships Air Conditioning Systems by Legionella Bacteria

Notice to Shipowners, Masters, Fishing Vessel Skippers, Shipbuilders and Repairers This Notice supersedes Merchant Shipping Notice No. 1215

Summary

This note warns against the risk of Legionnaires Disease being transmitted to humans via air conditioning plants. The Guidance Note identifies main danger areas within the air conditioning system. Examples of counter measures are given in section 3.

1. PREAMBLE The risk of Legionnaires Disease being transmitted to humans via air conditioning plants fitted ashore in large buildings, for example hotels or hospitals, is well documented. The bacteria flourishes in stagnant water or sludge or, for example, in cooling tower elements where the wet matrix material may be encrusted with scale, dirt or organic matter such as dead insects, birds and leaves. It is possible that sites may exist in ships air conditioning systems where similar contamination can arise notwithstanding that these are of fundamentally different design and the normal ambient air is salt laden. 2. MAIN DANGER AREAS 2.1 Air Inlet Arrangements - These may be direct or indirect from the air conditioning room via a jalousie. The design of jalousie fins is relevant in either case because with direct air inlets rain water may be driven into the filter; and with indirect inlets stagnant rain water may accumulate within the space unless efficient drainage and scuppering is fitted.

2.2 Filter - A normal filter comprises a mat of synthetic material of resin bonded fibres approximately 25 millimetres thick. Such filters are washable whereas others of the fibreglass variety have to be replaced. As the filter can become quite wet from inducted rain water, and dirty with matter such as insects, soot and cargo dust, nutrients may be available in ideal temperature conditions which could breed the bacteria. This could be quite a rapid process. 2.3 Cooler Unit (Dehumidifier) - Condensate sumps and their drainage arrangements if not properly designed and maintained can result in stagnant water accumulating in the units sump in way of the air flow and, in the event of blocked drains, an overflow of stagnant condensate from the unit into the air conditioning room itself can occur. A further problem is the possibility of water carryover into the distribution air stream if the face velocity over the cooler block is greater than 2 metres per second (400 feet per minute), unless an effective moisture eliminator is fitted after the cooler.

2.4 Humidifier - This item is usually fitted according to the owners requirements. The normal practice of using steam humidification should not be a problem. However adiabatic humidifiers of the water spray type may offer a special hazard. The enclosed tank and matrix elements provide ideal opportunities for contamination. A further problem may occur with the carry over of water droplets into the distribution air stream unless means are provided to avoid this. 2.5 Plenum Insulation - The main air conditioning unit chamber in modern equipment is acoustic and heat insulated with a PVC GRP scrim faced Rockwool or similar material exposed to the air stream and this could harbour bacteria if the facing fails to keep the insulation dry: noting that in the region of the cooler unit, or the humidifier when fitted, considerable quantities of water are present. 3. RECOMMENDED COUNTER MEASURES 3.1 Intakes - The jalousie design and the intake arrangements should be designed to eliminate spray and there should be proper attention to efficient drainage where necessary. 3.2 Filters - These should be readily accessible for regular maintenance or replacement. Weekly inspection of filters is recommended, washing or replacing them as necessary. Washable filters should be thoroughly rinsed in a superchlorinated solution of 50 ppm. The frequency of routine inspection cleaning or replacement may require to be increased when the current rate of fouling caused by polluted ambient air at the intake is high.

3.3 Cooler - Careful design of the condensate sump and its drainage is necessary. The sump drains should be regularly inspected and cleaned to ensure that there is no spillage or accumulation of stagnant condensate. It is recommended that the sump be washed through with a super-chlorinated solution of 50 ppm at intervals not exceeding 3 months. 3.4 Adiabatic Spray Type Humidifiers - This type should be installed in new ships unless special measures are taken to reduce the risk. In existing ships an effective moisture eliminator should be introduced if water carryover into the discharge air stream is found to occur. Regular maintenance and sterilisation of the water spray system is necessary. Modification of humidifier drains and circulating tank pipe suctions and drains should be considered if these are not sited in the bottom face of the unit or tank respectively. 3.5 Plenum Insulation - In new ships a watertight facing should be fitted. In existing ships the facing of the insulation should be examined at refit periods to ensure that the insulation itself is not becoming saturated. 4. SUMMARY The probability of legionella contamination in ships air conditioning systems is uncertain. However opportunities are available for this to occur. It is therefore recommended that such systems should be properly designed with this in view and thereafter regularly cleaned and maintained. The frequency of cleaning will depend on the arrangements in each system and its susceptibility to fouling but cleaning is recommended nevertheless at intervals of not more than 3 months.

The Maritime and Coastguard Agency Spring Place 105 Commercial Road SOUTHAMPTON SO15 1EG Tel: 01703 329175 Fax: 01703 329161 April 1998 [MC 025/006/0016] Crown Copyright 1998

An executive agency of the Department of the Enviroment, Transport and the Regions

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- ScheduleДокумент1 страницаSchedulesumaker1986Оценок пока нет

- Beech Baron58 Checklist VALДокумент3 страницыBeech Baron58 Checklist VALNeto Rubio100% (2)

- TB 20 PohДокумент323 страницыTB 20 PohSun Yat-senОценок пока нет

- GlossaireДокумент127 страницGlossairesumaker19860% (1)

- EuroFPL-ICAO Flightplan Form Basics-Latest PDFДокумент7 страницEuroFPL-ICAO Flightplan Form Basics-Latest PDFsumaker1986Оценок пока нет

- Imcam182 - GT Sgi 11.09Документ45 страницImcam182 - GT Sgi 11.09sumaker1986Оценок пока нет

- 54mm IWRC WireДокумент1 страница54mm IWRC Wiresumaker1986Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

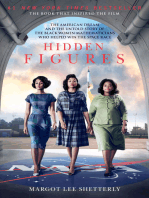

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- DPWH ReviewerДокумент597 страницDPWH Reviewercharles sedigoОценок пока нет

- Questionpaper Unit1WCH01 January2018 IAL Edexcel ChemistryДокумент24 страницыQuestionpaper Unit1WCH01 January2018 IAL Edexcel Chemistryshawon.sbd06Оценок пока нет

- Samsung Bd-p4600 SMДокумент101 страницаSamsung Bd-p4600 SMIonel CociasОценок пока нет

- Consent For Diagnostic And/or Therapeutic ParacentesisДокумент2 страницыConsent For Diagnostic And/or Therapeutic ParacentesisnaveenОценок пока нет

- WorldShop CatalougeДокумент200 страницWorldShop Catalougee2ashОценок пока нет

- 1.toyotamarklogo Standard Jan 2021 eДокумент43 страницы1.toyotamarklogo Standard Jan 2021 eMercadeo TosakaОценок пока нет

- Shadow UAV HandbookДокумент57 страницShadow UAV HandbookGasMaskBob100% (2)

- VENUS e CatalogueДокумент38 страницVENUS e CatalogueGanesh BabuОценок пока нет

- Book 1Документ1 страницаBook 1PES SAFETYОценок пока нет

- Aipl2009 V120000001Документ7 страницAipl2009 V120000001Olof HedinОценок пока нет

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsДокумент21 страницаEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoОценок пока нет

- PPP-B-676 e PDFДокумент34 страницыPPP-B-676 e PDFffincher4203Оценок пока нет

- Pre-Test First QTR 2022-2023Документ3 страницыPre-Test First QTR 2022-2023anna marie mangulabnanОценок пока нет

- Food ProductionДокумент106 страницFood ProductionAna Marie100% (1)

- Method Statement For Painting WorksДокумент2 страницыMethod Statement For Painting Worksmustafa100% (3)

- MC 1Документ109 страницMC 1ricogamingОценок пока нет

- Circle Theorems, Class 10Документ7 страницCircle Theorems, Class 10Susan MathewОценок пока нет

- Glamour Secrets Prices For Products and ServicesДокумент1 страницаGlamour Secrets Prices For Products and ServiceslocalintheknowОценок пока нет

- Dense NetДокумент28 страницDense NetFahad RazaОценок пока нет

- DA-42 Performance Calculator v2.3.1Документ23 страницыDA-42 Performance Calculator v2.3.1DodgeHemi1Оценок пока нет

- Acute Coronary Syndrome: Diagnosis and Initial Management: Each YearДокумент9 страницAcute Coronary Syndrome: Diagnosis and Initial Management: Each YearGabriela Pacheco0% (1)

- Load ScheduleДокумент8 страницLoad SchedulemerebookОценок пока нет

- .... Applicant Versus: Cri. Appln. No. 4353/16 & Anr. 1Документ11 страниц.... Applicant Versus: Cri. Appln. No. 4353/16 & Anr. 1Manashree EngineerОценок пока нет

- Relatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaДокумент56 страницRelatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaMagda RuanoОценок пока нет

- Catalogue Mp200Документ33 страницыCatalogue Mp200Adrian TudorОценок пока нет

- Electro-Mechanical SectorДокумент22 страницыElectro-Mechanical SectorKen LeeОценок пока нет

- Alternatives To Shifting Cultivation-248Документ9 страницAlternatives To Shifting Cultivation-248Chandrashekhar KhobragadeОценок пока нет

- Academic Program Required Recommended Academic Program Required RecommendedДокумент1 страницаAcademic Program Required Recommended Academic Program Required Recommendedonur scribdОценок пока нет

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleДокумент8 страницAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Dynamic-Light-Scattering - MDLДокумент5 страницDynamic-Light-Scattering - MDLJose Daniel Izquierdo MorenoОценок пока нет