Академический Документы

Профессиональный Документы

Культура Документы

QMS PROCEDURE IDENTIFICATION & TRACEABILITY

Загружено:

Rainer-SlawetzkiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

QMS PROCEDURE IDENTIFICATION & TRACEABILITY

Загружено:

Rainer-SlawetzkiАвторское право:

Доступные форматы

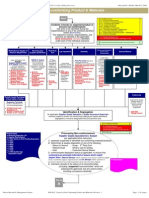

QUALITY MANAGEMENT SYSTEM PROCEDURE

Title: Identification No.: Revision No.: No. of effective pages: Prepared by: Approved by: Issued by: Revision date:

Identification and Traceability QMSP-753 5 2 S.O. F.H. Quality Department February 10th 2011

This Quality Assurance procedure is proprietary and must not be reproduced without the written consent of the Quality Assurance Manager of AP&C

Quality Management System Procedure

.

QMSP-753

IDENTIFICATION & TRACEABILITY

Page 1 of 2

1.0

PURPOSE 1.1 To describe the methods employed and the personnel responsible for controlling, documenting and performing product identification and traceability, where appropriate, through all stages of production and service operations.

2.0

SCOPE 2.1 This procedure applies to the identification of all materials and items upon receipt and throughout all stages of production, delivery and installation, when required by the contract, to provide traceability of individual components and/or batches.

3.0

DEFINITIONS 3.1 Traceability refers to the ability to trace the history, application or location of an entity by means of recorded identification.

4.0

RESPONSIBILITIES 4.1 All personnel are responsible for ensuring that product is identified and traceable as per this procedure

5.0

PROCEDURE 5.1 All materials and products must be identified (i.e. raw materials, supplies, finished products) by applicable documentation (specifications, product identifier numbers, packaging, shipping documents) during all stages from receiving raw material to product delivery as follows: Receiving & Incoming Inspection: All purchased products pass through the AP&C receiving department, where they are received as per AP&C internal procedure-QMSP-740. The products are inspected for quantity damage and dimensional inspection when applicable prior to be processed. Any nonconforming product should be processed regarding QMSP-830 procedure. 5.3 Release of Job The Production and/or Quality Department prepare the internal work orders (IWO) and traveller which is reviewed and released by Quality Department and/or Production Manager. A traveller number is issued for each job.

5.2

Revision No.: 5

Prepared by: S.O.

Approved by: F. H.

Date: February 10th 2011

This Quality Assurance procedure is proprietary and must not be reproduced without the written consent of the Quality Assurance Manager of AP&C

Quality Management System Procedure

.

QMSP-753

5.4

IDENTIFICATION & TRACEABILITY

Production

Page 2 of 2

5.4.1 Before processing any spool of wire the operator has to keep a sample from each one for further investigations or tests in case of a problem. 5.4.2 The traveller always identifies the product. Traveller includes the customer name, customer PO number, powder and description when applicable, which are taken directly from the customer Purchase order and/or Internal Work order. The traveller must also include any special customer requirements. AP&C maintains the identification of the configuration of the product in order to meet customer requirements. When processes are completed, the operations on the traveller are signed off by personnel responsible for them. 5.5 Final Inspection & Test Personnel verify the product, release all conforming lots and sign the travel card. 5.6 Shipping Personnel pack and ship the product as AP&C-QMSP-755 or customer supplied procedure. 5.7 5.8 All the documents are kept on file regarding procedure QMSP-423 FIFO A First-In, First Out procedure is applicable in production.

6.0

REFERENCES 6.1 6.2 6.3 6.4 6.5 QMSP-830 QMSP-740 QMSP-423 QMSP-755 Control of Nonconforming Product Receiving Inspection Control of Documents Handling, Storage and Shipping

Quality Manual QM-0501 Section 7.5.3

7.0

ATTACHMENTS 7.1 7.2 7.3 7.4 QMSP-753-F2 QMSP-753-F3 QMSP-753-F4 SOP-09-21-F1 Powder preparation Traceability log - Lots Traceability log - IPN Powder production

Prepared by: S.O. Approved by: F. H. Date: February 10th 2011

Revision No.: 5

This Quality Assurance procedure is proprietary and must not be reproduced without the written consent of the Quality Assurance Manager of AP&C

Вам также может понравиться

- OBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Документ4 страницыOBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Andy RojasОценок пока нет

- Vallourec Drilling Oil Equipment Validation ProcessesДокумент4 страницыVallourec Drilling Oil Equipment Validation ProcessesLora Jackson100% (1)

- EMC-MTP-01: Material Traceability ProcedureДокумент9 страницEMC-MTP-01: Material Traceability Procedurekingofpenetration100% (3)

- Identification and TraceabilityДокумент6 страницIdentification and Traceabilityandruta1978Оценок пока нет

- Material Traceability Procedure EMC-MTP-01Документ9 страницMaterial Traceability Procedure EMC-MTP-01Roshan Aravinth100% (2)

- Procedure For Product IdentificationДокумент5 страницProcedure For Product IdentificationAjay RanganathanОценок пока нет

- Products Traceability and Identification ProcedureДокумент9 страницProducts Traceability and Identification ProcedureWendimagen Meshesha Fanta100% (2)

- Supplier Quality QuestionnaireДокумент4 страницыSupplier Quality QuestionnairesutharitesshОценок пока нет

- COMPANY X SOP for Corrective and Preventive ActionДокумент5 страницCOMPANY X SOP for Corrective and Preventive Actionchemist_tmaОценок пока нет

- SOP 9 IDENTIFICATION AND TRACEABILITYДокумент3 страницыSOP 9 IDENTIFICATION AND TRACEABILITYvaishnavi100% (5)

- Procedure For Control of RecordsДокумент3 страницыProcedure For Control of Recordsmatrixmaze50% (2)

- Sta-P08-02 Non Conforming ProductДокумент6 страницSta-P08-02 Non Conforming ProductAnonymous B7pghhОценок пока нет

- Quality Control ManualДокумент3 страницыQuality Control ManualSaad ZiaОценок пока нет

- 11.1.0 Traceability ProcedureДокумент5 страниц11.1.0 Traceability ProcedureZed100% (1)

- Procedure For Material Identification & Traceability (Rev.0)Документ27 страницProcedure For Material Identification & Traceability (Rev.0)jishnunelliparambil100% (3)

- Non Conformance Control ProcedureДокумент12 страницNon Conformance Control ProcedurePanneer Bala100% (9)

- QMS 075 Procedure For Product Identification and Traceability SampleДокумент2 страницыQMS 075 Procedure For Product Identification and Traceability SampleAli Saifullizan Ismail100% (1)

- Control Non-ConformancesДокумент6 страницControl Non-ConformancesSandraОценок пока нет

- SOP-0012 Control of Non-Conforming Product & MaterialsДокумент1 страницаSOP-0012 Control of Non-Conforming Product & MaterialsMichael TayactacОценок пока нет

- Supplier Evaluation and Approval - Disapproval PGP2001AДокумент6 страницSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasОценок пока нет

- 8.5.2 Identification and TraceabilityДокумент5 страниц8.5.2 Identification and Traceabilitymedtaher missaoui0% (1)

- Nonconformance Control ProcedureДокумент5 страницNonconformance Control ProcedureAlex Dcosta50% (2)

- Procedure For Control of Non-Conforming ProductsДокумент4 страницыProcedure For Control of Non-Conforming Productsmatrixmaze100% (3)

- Receiving InspectionДокумент5 страницReceiving InspectionUmair AwanОценок пока нет

- ISO - Control of Non-Conforming ProductsДокумент5 страницISO - Control of Non-Conforming ProductsAlmario SagunОценок пока нет

- Quality Assurance Incoming Raw Materials Inspection PlanДокумент2 страницыQuality Assurance Incoming Raw Materials Inspection PlanAlvin NodaОценок пока нет

- SOP 006 Rev - NC Calibration & Verification of EquipmentДокумент5 страницSOP 006 Rev - NC Calibration & Verification of EquipmentmeongОценок пока нет

- Procedures Manual 8-31-07Документ36 страницProcedures Manual 8-31-07vabimhahОценок пока нет

- PRODUCT IDENTIFICATION AND TRACEABILITY PROCEDUREДокумент6 страницPRODUCT IDENTIFICATION AND TRACEABILITY PROCEDUREMangBedjoОценок пока нет

- Incoming Inspection-Qmp-Qc-01Документ2 страницыIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaОценок пока нет

- Quality System Procedure Identification & TraceabilityДокумент3 страницыQuality System Procedure Identification & TraceabilityMohammed ZubairОценок пока нет

- Control of Non-ConformityДокумент8 страницControl of Non-ConformitynorlieОценок пока нет

- Automotive Quality Management System Identification and TraceabilityДокумент6 страницAutomotive Quality Management System Identification and Traceabilityom cncОценок пока нет

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureДокумент2 страницыQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Оценок пока нет

- Sampling plan for elastomer parts inspectionДокумент1 страницаSampling plan for elastomer parts inspectionLOGANATHAN V100% (1)

- Materials Receipt and InspectionДокумент6 страницMaterials Receipt and InspectionMj AndresОценок пока нет

- SOP-10 Final Inspection ProcedureДокумент3 страницыSOP-10 Final Inspection ProceduretriveshОценок пока нет

- SHEWS Non-Conformance ReportingДокумент2 страницыSHEWS Non-Conformance ReportingHaroonAbdulRahim0% (1)

- Sample Shipping SOP SummaryДокумент6 страницSample Shipping SOP SummaryMahayudin SaadОценок пока нет

- Supplier EvaluationДокумент4 страницыSupplier EvaluationAmi Kar100% (1)

- Incoming VTM Material Inspection Procedure - RevisedДокумент6 страницIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- Material Receiving ProcedureДокумент7 страницMaterial Receiving ProcedureRomi Abdul Rahman100% (3)

- List of External DocsДокумент2 страницыList of External DocsSyed Mujtaba Ali Bukhari100% (1)

- Material Handling and Preservation ProcedureДокумент2 страницыMaterial Handling and Preservation ProcedureIman ZОценок пока нет

- F Control of Non - Conforming Product ProcedureДокумент3 страницыF Control of Non - Conforming Product ProcedureNgonidzashe Zvarevashe100% (1)

- CLAUSE 8.5 Production and Service ProvisionДокумент10 страницCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneОценок пока нет

- SOP For Training Procedure For Quality Control - Pharmaceutical GuidelinesДокумент2 страницыSOP For Training Procedure For Quality Control - Pharmaceutical Guidelinesnbpgr gmoОценок пока нет

- QMS Inspection ProcedureДокумент5 страницQMS Inspection ProcedureSang Hà100% (1)

- Calibration Procedure PDFДокумент17 страницCalibration Procedure PDFsyedfahadraza627100% (1)

- OBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Документ4 страницыOBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Andy RojasОценок пока нет

- Raw Material Inspection ProcedureДокумент5 страницRaw Material Inspection ProcedureAli RazuОценок пока нет

- Material Handling Control ProcedureДокумент9 страницMaterial Handling Control ProcedureBhisamS Salleh100% (2)

- Control of Non-Conforming Products ProcedureДокумент4 страницыControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- Procedure For Selection and Supplier DevelopmentДокумент5 страницProcedure For Selection and Supplier DevelopmentQuality Unit 1 Ajay Pandey100% (3)

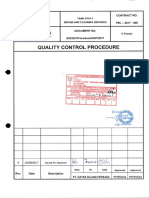

- CONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREДокумент6 страницCONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREAndreas Schlager100% (3)

- Control of Production and Service OperationsДокумент3 страницыControl of Production and Service Operationskashifbutty2kОценок пока нет

- Quality Record Procedure Rev-JДокумент4 страницыQuality Record Procedure Rev-JherminОценок пока нет

- Receiving Material ProcedureДокумент5 страницReceiving Material Proceduregst ajah100% (1)

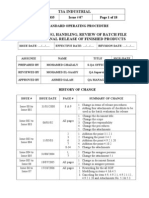

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Документ18 страницIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaОценок пока нет

- Master Validation of All Equipment in ProductionДокумент5 страницMaster Validation of All Equipment in ProductionNaci TürüközüОценок пока нет

- Case Study KarimRamziДокумент10 страницCase Study KarimRamziToufik Akhdari0% (1)

- Silicon Valley Community Foundation 2008 990Документ481 страницаSilicon Valley Community Foundation 2008 990TheSceneOfTheCrimeОценок пока нет

- Greek Labour LawДокумент3 страницыGreek Labour LawSerban MihaelaОценок пока нет

- QTC Cert Module 2 CPQДокумент41 страницаQTC Cert Module 2 CPQjalaj01Оценок пока нет

- How Interest Rates Are DeterminedДокумент23 страницыHow Interest Rates Are DeterminedZackyОценок пока нет

- Promo Pricing Strategies Reduce Prices Attract CustomersДокумент20 страницPromo Pricing Strategies Reduce Prices Attract CustomersMarkDePazDiazОценок пока нет

- Merritt's BakeryДокумент1 страницаMerritt's BakeryNardine Farag0% (1)

- CE Project Costs and FeesДокумент5 страницCE Project Costs and FeesJerichoRoiEspirituTabangОценок пока нет

- Chapter 5 Questions V1Документ6 страницChapter 5 Questions V1prashantgargindia_930% (1)

- Pump and Dump - Print 1Документ7 страницPump and Dump - Print 1Zahid FaridОценок пока нет

- Enterpreneurship mgt401cДокумент3 страницыEnterpreneurship mgt401cArpit GaurОценок пока нет

- Unincorporated Business TrustДокумент9 страницUnincorporated Business TrustSpencerRyanOneal98% (42)

- Cheniere Energy Valuation ModelДокумент11 страницCheniere Energy Valuation Modelngarritson1520100% (1)

- MKT 412 Lecture 12 - Crafting The Service EnvironmentДокумент34 страницыMKT 412 Lecture 12 - Crafting The Service EnvironmentEhsan Karim100% (1)

- Condition Classification For New GST ConditionsДокумент3 страницыCondition Classification For New GST ConditionsVenugopal PОценок пока нет

- 0 - 265454387 The Bank of Punjab Internship ReportДокумент51 страница0 - 265454387 The Bank of Punjab Internship Reportفیضان علیОценок пока нет

- NFJPIA Mock Board 2016 - AuditingДокумент8 страницNFJPIA Mock Board 2016 - AuditingClareng Anne100% (1)

- Basc Risk Assessment Form: Start of SeasonДокумент2 страницыBasc Risk Assessment Form: Start of SeasonhunstreteОценок пока нет

- Cambridge, 2nd Ed. - Depreciation and DisposalДокумент3 страницыCambridge, 2nd Ed. - Depreciation and DisposalShannen LyeОценок пока нет

- O-1 Visa Lawyer in San JoseДокумент2 страницыO-1 Visa Lawyer in San JoseAlison YewОценок пока нет

- All About Msmed Act 2006: CA. Manish ChowdhuryДокумент4 страницыAll About Msmed Act 2006: CA. Manish ChowdhurySUNIL PUJARIОценок пока нет

- Tour Packaging & Sales StrategyДокумент20 страницTour Packaging & Sales StrategyWhena RiosОценок пока нет

- Valliammai Engineering College Question Bank on International Business ManagementДокумент11 страницValliammai Engineering College Question Bank on International Business ManagementKamalesh SriramОценок пока нет

- Oranjolt - Rasn-WPS OfficeДокумент3 страницыOranjolt - Rasn-WPS OfficeKaviya SkОценок пока нет

- Template) PfmeaДокумент1 страницаTemplate) PfmeaPatrick170780Оценок пока нет

- Strengthen PECs in DressmakingДокумент1 страницаStrengthen PECs in DressmakingLeticia AgustinОценок пока нет

- Magnum 3904 DatasheetДокумент3 страницыMagnum 3904 DatasheetbobОценок пока нет

- Partnership Accounting BreakdownДокумент13 страницPartnership Accounting BreakdownHoneylyne PlazaОценок пока нет

- Carriage and Insurance Paid To CIPДокумент16 страницCarriage and Insurance Paid To CIParun arunОценок пока нет

- PPE PPT - Ch10Документ81 страницаPPE PPT - Ch10ssreya80Оценок пока нет