Академический Документы

Профессиональный Документы

Культура Документы

Dmta 2

Загружено:

Vaisakh PsИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dmta 2

Загружено:

Vaisakh PsАвторское право:

Доступные форматы

~iomoteriak

0 1996

17 (1996)

1627-1630

ELSEVIER

0142-9612(95)00330-4

Elsevier Science Limited Printed in Great Britain. All rights reserved 0142-9612/96/$X.00

Dynamic mechanical thermal analysis of denture soft lining materials

Mark Waters*, Robert Jagger**, Keith Williams*

*Department

Medicine, Stomatology, University of Zagreb, Zagreb, Croatia

and Vjeko Jerolimov+

of Basic Dental Science, **Department of Restorative Dentistry, University of Wales College of Dental School, Heath Park, Cardiff CF4 4XY, UK; Department of Removable Prosthetics, Faculty of

The purpose denture to sinusoidal temperature materials methods. for each formulation mechanical plasticization Elsevier Keywords: properties

Received

of this study shear range

was to characterize using dynamic at a frequency The technique

the deformation mechanical simulated thermal

properties analysis.

of a range Specimens

of long-term were subjected a

soft lining

materials of 30-70C.

deformation

of 1 Hz and a strain the type more relevant

of 64 microns results

peak to peak over soft lining used obtained indicatwere

and rate of deformation than previously G/G loss tangent materials over (Molloplast

would Shear material.

experience modulus

clinically, G, dissipative

thus producing modulus

G and mechanical the moduli insensitive The silicone

With increasing compliance properties values lowered

temperature generally

of the acrylic to temperature

decreased,

ing an increased

and greater were

deformation.

B) and alternative the range chosen. 0 The suggesting of testing. that the 1996

(Novus) process

loss tangent Limited

of the acrylics the Tg values

fell continuously below

with temperature, temperature

3OC, the lowest

Science Dental

materials,

denture

liners,

dynamic

mechanical

thermal

analysis,

deformation

16 July

1995; accepted

3 November

1995

Of the physical properties of soft lining materials, the resilience and the capacity of a material to absorb energy are of particular importance. Methods previously used to determine deformation characteristics have been static compression set, torsional pendulum and mechanical impedance tests. Compression set measurements invoke measuring the rate of recovery of the material after the application of a given stress. However, this is a static load application technique and does not predict in viva behaviour. Braden and Clarke realized the importance of measuring deformation at rates appropriate to those the experienced in viva. Hence they measured response of the materials to cyclic (sinusoidal) forces using a torsional pendulum, previously described by Braden and Stafford3. However, the technique is insufficient to maintain a constant amplitude over a set temperature range. Mechanical impedance testing4 has limitations in precision of measurement owing to specimen size requirements. Many of the limitations of the above techniques are overcome by the use of the recently developed dynamic mechanical thermal analysis (DMTA). The technique involves the application of a sinusoidally oscillating stress to a material which enables measurement of the strain at a fixed frequency or range of frequencies over a specific temperature range and also isothermally as a function of time5. Correspondence to Mr M.G.J. Waters.

1627

DMTA has been used to evaluate denture-base polymers6, but investigation of resilient liners using this technique has not been reported. The purpose of this investigation was to compare the moduli of selected resilient lining materials using DMTA.

THEORETICAL CONSIDERATIONS When a sinusoidal stress is applied to a perfectly elastic solid the deformation (and hence the strain) occurs exactly in phase with the applied stress, hence the modulus is not time dependent. A completely viscous material will respond with the deformation lagging behind the applied stress (Figure I). When a sinusoidal stress is applied to a viscoelastic material it will behave neither as a perfectly elastic nor as a perfectly viscous body and the resultant strain will lag behind the stress by some angle(s) where 0 = 90 (Figure z). The magnitude of the loss angle is dependent upon the amount of internal motion occurring in the same frequency range as the imposed stress. For a perfectly elastic material deforming in shear, it is possible to write:

y(f) =

Where y(t) is the shear strain, o(t) is the shear stress and

Biomaterials 1996, Vol. 17 No. 16

1628

DMTA of denture

soft liners:

M. Waters

et al.

The stress and strain are therefore 90 out of phase for a sample whose properties are defined by Equation 4. For a viscoelastic material, the strain will lag behind the stress by an amount normally called the loss angle (6). It is normally convenient to separate the viscoelastic response into in phase and out phase components. The in phase stress and strain result in which is completely energy elastically stored recoverable, while the out of phase stress and strain result in the dissipation of energy. The in phase and the out phase shear moduli G and G are: G, = 4 = Amplitude of in phase stress component

Elastic mawrial t T Viscous mawid

i G,,= c

the response materials to of an

Y = Amplitude of out of phase stress component / are similarly:

Figure 1 Schematic perfectly elastic and applied stress.

representation of perfectly viscous

*J The shear compliances

G is the shear modulus and the time dependence oscillation (0). The stress is given by: a(t) = 60 cos wt and the strain as: y(t) = 2 cos wt

of (2)

J=;

and J tan&Cr=_=_=G

(T

Y

y

(3)

For a perfectly viscous rod the deformation behaviour is:

The storage modulus is the elastic response and corresponds to completely recoverable energy, whereas the loss modulus is the viscous response corresponding to energy lost through internal motion. The tangent of this loss angle, tan 6, is dimensionless and is equal to the ratio of energy lost (dissipated as heat) to energy stored per cycle: tan6 = Loss modulus G Storage modulus = ??

The strain rate, d/dt responds linearly to stress for a viscous body with a proportionately constant 7, the viscosity. The rate of strain is a maximum when the stress is a maximum and a minimum when the stress is a minimum. Integrating Equation 4 yields:

MATERIALS AND METHODS

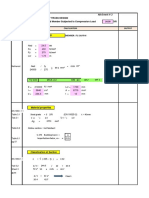

The materials investigated are listed in Table I. Samples were prepared by packing dough into 50%/ 50% stone/plaster moulds that had been prepared by investing acrylic blanks 75 x 25 x 3mm in a conventional dental flashing technique. Mixing, packing and cureing were carried out according to manufacturers instructions. The cured strips of material were then cut to specimen dimensions of 10 mm diameter and 3 mm thick, using an appropriate cutting instrument. Five pairs of specimens were produced for each material and were stored in air at 37C. They were then tested in a dynamic mechanical thermal analyser (DMTA) apparatus (Polymer Laboratories Ltd., Loughborough, UK) model MKII, linked to a Compaq 386 IBM compatible computer. The specimens were subjected to sinusoidal shear deformation at a frequency of 1 Hz and a strain of 64 microns peak to peak (x4) over a temperature range of 30C to 70C. Parameters measured were G, storage modulus (MPa); G, loss modulus (MPa) and tan 6, loss tangents, with readings at 30C, 37C, 50C and 70C.

S1ress t

b

Figure 2 a, Schematic representation of the response of a viscoelastic material to an applied sinusoidal stress. b, Schematic representation of the resolution of the in-andout-of phase stress components.

Biomaterials 1996,

Vol. 17 No. 16

DMTA

of denture

soft liners: M. Waters et al. of materials Type Plasticized acrylic Plasticized acrylic Silicone elastomer Silicone elastomer Copolymer resilient liner Polyphosphazene fluoroelastomer used Manufacturer Coe Laboratories Inc., Chicago, Illinois, USA Dentimex EIV., Zeist, Holland Regneri G-MBH & KG, Karlsruhe, Germany Flexico Developments Ltd., London, UK Weil-Dental G-MBH, Rosbach, Germany Hyginic Corporation, Akron, Ohio, USA

1629

Table 1 Material

Type and manufacturer

Coe Super Soft Vetrex Soft Malloplast B Flexibase RTV Flexor Novus

Table 2 Material

Shear parameters N = 5

measured

at 37C G (MPa) SD 0.055 0.104 0.094 0.117 0.115 0.058 cv 17.6 15.9 21.4 20.0 15.1 16.5 Mean 0.331 0.536 0.029 0.030 0.070 0.041 SD 0.079 0.088 0.008 0.014 0.008 0.003 cv 23.9 16.5 28.9 17.4 11.7 7.7 Tan 6 (G/G) Mean 1.078 0.826 0.066 0.158 0.092 0.117 SD 0.126 0.044 0.015 0.012 0.010 0.014 cv 11.7 5.4 22.7 7.4 11.1 12.3

G (MPa) Mean

Coe Super Soft Vertex Soft Molloplast B Flexibase Flexor Novus

tan cs =

0.311 0.654 0.439 0.509 0.766 0.355

1.078.

0 = 47.

and coefficients of Means, standard deviations variation were calculated for all parameters. Means were tested by Students t-test. Results were tested by one-way ANOVA and multiple comparisons of means, together with p-value calculations.

RESULTS

Table 2 gives the mean, standard deviation, and coefficient of variance at 37C for G, G, and tan 6. The shear storage modulus G plotted against temperature is shown in Figure 3. The acrylic materials Vertex Soft and Coe Super Soft are particularly temperature dependent in this temperature range, while the remaining materials indicate G values which are virtually insensitive to temperature. At 37C, Flexor exhibits the highest modulus value and would be expected to develop the highest energy absorbing capacity, with Coe Super Soft the poorest in this respect. Vertex Soft is within the max-min range of moduli at 37C but falls below the non-acrylic materials above

1 .o

50C, while Coe Super Soft exhibits the lowest G value above 35C. Since all materials where cycled over a strain range of 64 microns this figure would also be expected to indicate the resilience of the respective materials, i.e., Flexor the best and Coe Super Soft the poorest at 37C. A plot of the dissipative modulus G against temperature is shown in Figure 4. The nonacrylic materials show a virtually zero modulus change which is indicative of highly elastic and resilient materials in the temperature and strain amplitude range chosen. Both acrylic G values are particularly temperature dependent and since they fall continuously, suggest a Tg value below 30C. The mechanical loss tangent plotted against temperature (Figure 5) merely confirms the elastic behaviour of the non-acrylic materials.

DISCUSSION A necessary requirement of soft lining materials is their ability to elastically recover following deformation

0.8

r+

. Coe super-soft + Vertex soft * Molloplrst-B

-\

n

0 Flexibasc +\ X Flexor

Coe

super-soft

+ Vertex SOfL * Mollophs~-R

0 x 0 Flcxihase Flexor Novus

n

25 30 35 40 45 C SO 55 60 65 70

25

30

35

40

45

SO

55

60

65

70

C modulus measured over temperaFigure 4 Dissipative range 30-70C. modulus measured over temperature

Figure 3 Shear storage ture range 30-70C.

Biomaterials 1996, Vol. 17 No. 16

1630

DMTA of denture

soft liners:

M. Waters

et al.

I.2 r

l y_

+

n

Coe

super-soft

Vertex soft * Molloplast-R

m 6 -) 0.40.2 *-0 25 30 35 I 40 I 45 OC Figure 5 Mechanical ture range 30-70C. loss tangent measured over temperar 50 I 55 I 60 I 65 r 70

during mastication over reasonably long time periods. This elastic recovery response is normally quoted as resilience, i.e. the materials ability to consistently and immediately return to its original shape following deformation. Unfortunately, polymeric materials tend to exhibit time-dependent behaviour during and following deformations 3 7. Thus it would be expected that materials deforming at temperatures near and above their Tg would demonstrate time-dependent properties which may include viscoelastic behaviour. The greater the degree of elastic response elicited during a deformation event, the greater the chance of success as a soft lining material. Another important property requirement is the elastic modulus, since the lower this value the greater the energy absorbed at a given load during the deforming cycle. This behaviour will help in allowing the point applied loads to be spread over a larger area of the material with lower loads transferred to the underlying tissue. These important parameters can be measured in a number of ways as already outlinedy277. However, an important requirement for time-dependent materials is to simulate masticatory deformation by cycling the materials through a given stress-strain regime at a frequency close to that of chewing. Past methods have generally failed to simulate masticatory deformation with periods of cycling as long as 5 mini. In this work, elastic properties have been measured using a dedicated DMTA testing machine which allows measurement of both the elastic and viscous response of materials at specific testing rates over a series of temperatures. The storage modulus measures the perfectly elastic response of the materials. Thus if resilience is the prime requirement of a soft lining material, then at 37C Flexor would be expected to show ideal properties, with Novus the poorest of the non-acrylic materials at 37C. Since the materials were deformed to a specific strain, this behaviour does not represent the energy-absorbing capacities of these soft liners for a given load. If the capacity to absorb energy is a more realistic requirement particularly in terms of patient comfort, then the ranking of materials shown may not represent the in vivo requirement. Evidently, the behaviour of the acrylic materials is highly temperature sensitive, showing good elastic response at 37C in line with the other candidate

Biomaterials 1996. Vol. 17 No. 16

materials but falling away rapidly with temperature. Since both acrylics demonstrate an element of viscous behaviour as evidenced by the dissipative modulus (G) (Figure 4) and tan 6 (Figure 5) plots, this viscous proportion to the total deformation decreases with temperature. The acrylic materials therefore demonstrate improved elastic cycling response with increasing temperature. The clinical consequences of these temperaturedependent changes are difficult to interpret from one type of test. Certainly, an increased proportion of elastic response is desirable compared with time-dependent recovery events (i.e., viscoelastic and viscous). However, at higher temperatures, the modulus of the acrylics may be too low to sustain a given loading in thicknesses normally applicable to soft lining materials. Thus the deforming force may simply move the material allowing direct loading onto the underlying tissues. The DMTA apparatus did prove to be a rapid and convenient method for determination of the deformation properties of soft lining materials under clinically relevant loading and cycling. Further work will look at methods to determine the exact time/ deformation event which is necessary to further classify viscoelastic and viscous materials at or near body temperature. CONCLUSIONS

(11 The acrylic materials were less resilient than the

other materials.

(2) The acrylic materials were temperature sensitive

(31 (4) (5)

with all values decreasing with increasing temperature, whilst the other materials indicated moduli which were relatively constant over the temperature range. Flexor was the stiffest material at 37C, i.e. highest modulus. Molloplast was the most resilient material. Dynamic mechanical thermal analysis (DMTA) proved to be a rapid, reliable and convenient method for the determination of viscoelastic properties of resilient liners.

REFERENCES

HR. Soft lining materials: Some relevant properties and their determination. 1 Pro&et Dent1969;21:244-250. Braden M, Clarke RL. Visco-elastic properties of soft lining materials. I Dent Res 1972; 51: 1525-1528. Braden M, Stafford GD. Viscoelastic properties of some denture base materials. 1 Dent Res 1968; 47: 519-523. Clarke RL, Braden M. Determination of visco-elastic properties of dental polymers by mechanical impedance measurements. JDent Res 1982; 61: 1245-1249. Wetton RE, Marsh RDL, Wan-De-Velde TG. Theory and application of dynamic mechanical thermal analysis.

Wilson HJ, Tomlin

Thermochim

Acta 1991; 175: 1-11.

Clarke RL. Dynamic mechanical thermal analysis of dental polymers. 1.Heat-cured poly(methy1 methacrylate)-based materials. Biomaterials 1989; 10: 494-498. Wright PS. Soft lining materials: their status and prospects. J Dent 1976; 4: 247-256.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Step by Step Hydraulic CalculationДокумент26 страницStep by Step Hydraulic CalculationKarkare89Оценок пока нет

- Concrete Strength Testing ExplainedДокумент32 страницыConcrete Strength Testing ExplainedMinn LwinОценок пока нет

- Philips Lighting 1Документ45 страницPhilips Lighting 1Manisankar DhabalОценок пока нет

- SFD N004 2013 PDFДокумент21 страницаSFD N004 2013 PDFMohamed Abo-ZaidОценок пока нет

- Electrical legend and layout for bedroomДокумент1 страницаElectrical legend and layout for bedroomPardhan Lakshay PareekОценок пока нет

- BS en 10130 2006Документ16 страницBS en 10130 2006Phong TongОценок пока нет

- 5 6138727946501751075Документ3 страницы5 6138727946501751075Xkarr RastaОценок пока нет

- Compresssive Strength Test Concrete Hollow Block PDFДокумент8 страницCompresssive Strength Test Concrete Hollow Block PDFMohammad Tarequl AlamОценок пока нет

- 01 ElevatorsДокумент14 страниц01 Elevatorsengineer63Оценок пока нет

- Mtech Thesis New (ZnO)Документ59 страницMtech Thesis New (ZnO)Tirthankar MohantyОценок пока нет

- Whats New in ASME B31 3Документ15 страницWhats New in ASME B31 3Anonymous qhVGVpОценок пока нет

- Nano CompositeДокумент26 страницNano Compositenandan akОценок пока нет

- ASME B31.3 Straight PipesДокумент2 страницыASME B31.3 Straight Pipesjame11inОценок пока нет

- ASTM STP538 - Cleaning Stainless SteelДокумент11 страницASTM STP538 - Cleaning Stainless SteelPeter FowlesОценок пока нет

- Carbothane 134 HG PDSДокумент4 страницыCarbothane 134 HG PDSTeknik produksi wikonОценок пока нет

- 1.1 General Background: Seminar Report 2021Документ20 страниц1.1 General Background: Seminar Report 2021Classic PrintersОценок пока нет

- Upright Sprinkler VK300Документ4 страницыUpright Sprinkler VK300james alfarasОценок пока нет

- Causeway BOQДокумент7 страницCauseway BOQSujan GhimireОценок пока нет

- G+12 Raft Foundation ReportДокумент13 страницG+12 Raft Foundation ReportvinujohnpanickerОценок пока нет

- Corrosion-Guide 1 Stainless Steel CategoriesДокумент8 страницCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéОценок пока нет

- GTX BeamДокумент6 страницGTX BeamSanjay SudhakaranОценок пока нет

- What Is A Glass Transition Temperature - Definition From CorrosionpediaДокумент1 страницаWhat Is A Glass Transition Temperature - Definition From CorrosionpediaCTPОценок пока нет

- 2018 Deco Foil LeafletДокумент2 страницы2018 Deco Foil LeafletMahmood MolaeiОценок пока нет

- Annealing (metallurgy) - Heat treatment softens metalsДокумент4 страницыAnnealing (metallurgy) - Heat treatment softens metalsStephen MontelepreОценок пока нет

- Water Treatment DegasifierДокумент6 страницWater Treatment DegasifierEDUARDOОценок пока нет

- 1) Design A Large Building WITHOUT Expansion JointДокумент7 страниц1) Design A Large Building WITHOUT Expansion JointSubinDesarОценок пока нет

- G-R 25Документ27 страницG-R 25Duncan VanderwallОценок пока нет

- QCD Fire Pump Check ListДокумент3 страницыQCD Fire Pump Check ListAnoirОценок пока нет

- Joints in Steel Construction - Simple Connections - Part 22 PDFДокумент1 страницаJoints in Steel Construction - Simple Connections - Part 22 PDFkakem61Оценок пока нет

- MDДокумент18 страницMDTheo AnggaraОценок пока нет