Академический Документы

Профессиональный Документы

Культура Документы

Consumption of Fossil Fuels Varies by Region and by Country

Загружено:

Lokesh AgrawalИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Consumption of Fossil Fuels Varies by Region and by Country

Загружено:

Lokesh AgrawalАвторское право:

Доступные форматы

Consumption of fossil fuels varies by region and by country.

The biggest consumers are the United States, China, and the European Union, accounting for more than half of all fossil fuel consumption (see below). Coal, which is not easily transported long distances, accounts for a large percentage of consumption where it is locally available, while oil and natural gas can be consumed far from their source of extractionin 2004, trade in fuels totaled US$715 billion worldwide (World Bank, World Development Indicators 2006).

how to make biodiesel fuel - an overview

From the What is Biodiesel section we know that the process of making biodiesel is known as transesterification and is achieved by adding methanol to vegetable oil. The process requires a catalyst to increase the rate of the chemical reaction between the methanol and vegetable oil. The catalyst used in the creation of biodiesel is an alkaline one, either Sodium Hydroxide or Potassium Hydroxide.

When the process is complete the catalyst can be recovered unaffected by the chemical reaction that it accelerated, along with the glycerol separated from the vegetable oil.

If waste vegetable oil is used then we have another situation to deal with. Waste vegetable oil will have been been reheated several times during the course of its usage. The reheating will cause some of the fatty acids bonded to the glycerol to break away and float freely in the vegetable oil - hence the name Free Fatty Acid (FFA). There are two ways of dealing with free fatty acids: 1. Esterify the FFAs creating methyl esters then proceeding with the transesterification. 2. Increase the amount of catalyst in the single transesterifaction process so that the additional catalyst neutralises the FFAs creating soap as an additional by-product. Option 1 is used in the commercial production of biodiesel, but for smaller scale production option 2 is favoured as it reduces the complexity of the process. Following option 2, we would have to perform a titration on a sample of the waste vegetable oil in order to calculate the amount of additional catalyst required to neutralise the FFAs.

The additional catalyst would then react with the FFAs creating soap in the process.

Transesterification is a reversible reaction. This means that the process is working both ways simultaneously until a balance between the vegetable oil and biodiesel is reached. Consequently we need to ensure that the process continues the creation of biodiesel rather than stall once it reaches this point of equilibrium. In commercial production we would tap off the output as it is created thus ensuring that there is a greater quantity of input vegetable oil to keep the reaction producing the biodiesel. For smaller scale production, however, it is more practical to use an increased volume of methanol to ensure that the reaction continues in the direction of producing biodiesel.

Like the catalyst, this excess methanol will be left over after completion of the reaction.

step by step from the top

The commencement of the production process depends upon the type of oil employed, and whether it is fresh oil or used oils from the catering industry. In the case of the latter, a titration process takes place, the result of which determines the proportions of methanol to sodium hydroxide used in the preparation of the reaction catalyst. (Inadequate or omitted titration on used vegetable oil is the single biggest cause of fatty deposits in fuel filters). There are then the following steps in the process of producing the biodiesel: 1. Filtration of inbound waste oil 2. Drying the fuel (i.e. removing water content, especially in the case of used oils) 3. Transesterification (specifically, the separation of the methyl esters from the glycerol) 4. Settling period 5. Separation of the biodiesel fuel from the glycerine layer [containing glycerol, catalyst, soap and methanol] 6. Washing the biodiesel fuel 7. Filtration to 5 microns 8. Drying the fuel again

9. Final products of biodiesel fuel and the by-products If you want to learn how to make biodiesel we can help guide you in the right direction and avoid the costly mistakes!For a pictorial overview of the process of making biodiesel, this is definitely worth looking at...

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 10 Science Notes 04 Carbon and Its Compound 1 PDFДокумент13 страниц10 Science Notes 04 Carbon and Its Compound 1 PDFkunalОценок пока нет

- Chapter 7 AlcoholsДокумент94 страницыChapter 7 Alcoholspammi.radhakrishna.0743Оценок пока нет

- EsterificationДокумент3 страницыEsterificationKhris Sy-HandumonОценок пока нет

- KOH synthetic routesДокумент6 страницKOH synthetic routesCin D NgОценок пока нет

- Julius Caesar Essay QuestionsДокумент8 страницJulius Caesar Essay Questionswwpadwwhd100% (2)

- Aucet 2017 BrochureДокумент18 страницAucet 2017 BrochureNEELIMAОценок пока нет

- Biosynthesis of FlavoursДокумент9 страницBiosynthesis of FlavoursDatta JoshiОценок пока нет

- Analytical Chemistry - Infrared SpectrosДокумент1 страницаAnalytical Chemistry - Infrared SpectrosCamii VelosoОценок пока нет

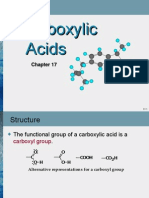

- Chapter 17Документ35 страницChapter 17Mohammed FarhanОценок пока нет

- Carbon and Its CompoundsДокумент65 страницCarbon and Its CompoundsankurОценок пока нет

- Infrared Spectroscopy:: Fundamentals and Interpretation of Organic CompoundsДокумент75 страницInfrared Spectroscopy:: Fundamentals and Interpretation of Organic CompoundsRajkishor YadavОценок пока нет

- Protection Against Stress by Natural Triterpene Esters - AAK PDFДокумент4 страницыProtection Against Stress by Natural Triterpene Esters - AAK PDFjaggampudi. rajasekharОценок пока нет

- Chapter 14 Carboxylic Ester Amides PDFДокумент22 страницыChapter 14 Carboxylic Ester Amides PDFMADANОценок пока нет

- Lehman OOC4e Experiment CorrelationsДокумент7 страницLehman OOC4e Experiment CorrelationsPreeti Gunthey DiwanОценок пока нет

- TMP Trioleate ApplicationДокумент9 страницTMP Trioleate ApplicationLim Chee SiangОценок пока нет

- IIT JEE Advanced Syllabus 2018 For Chemistry - TopperlearningДокумент4 страницыIIT JEE Advanced Syllabus 2018 For Chemistry - Topperlearningzeeshan khanОценок пока нет

- Functional Groups 1Документ39 страницFunctional Groups 1ceffffОценок пока нет

- CH 17Документ18 страницCH 17MirjanaОценок пока нет

- OrganicДокумент8 страницOrganicI am madОценок пока нет

- Multiple-choice Questions on Organic Chemistry ConceptsДокумент37 страницMultiple-choice Questions on Organic Chemistry ConceptsTheo CaldasОценок пока нет

- Bpo C Chapter 23Документ72 страницыBpo C Chapter 23Josiah JohnsonОценок пока нет

- A2 Level Chemistry: Answer All Questions Max 47 MarksДокумент9 страницA2 Level Chemistry: Answer All Questions Max 47 Marksanggi_indragumilarОценок пока нет

- Unit 4 Chemistry A2 NotesДокумент37 страницUnit 4 Chemistry A2 NotesminayokiОценок пока нет

- Sizing AgentДокумент25 страницSizing AgentMd.Amir hossain khanОценок пока нет

- Organic 2 Chapter 1&2Документ94 страницыOrganic 2 Chapter 1&2bahru demekeОценок пока нет

- Organic Functional Groups WorksheetДокумент4 страницыOrganic Functional Groups WorksheetCorey Becker33% (6)

- Chemical Nfpa CodesДокумент930 страницChemical Nfpa CodesCarlos Daniel Cuba Jara0% (1)

- Tempo Reagent MechanismДокумент27 страницTempo Reagent MechanismMd Abdullah Al NomanОценок пока нет

- ORGANIC REAGENTS CHEAT SHEETДокумент15 страницORGANIC REAGENTS CHEAT SHEETApoorv Tandon100% (2)

- Essential Oil Composition From The Flowers of Alstonia Scholaris of BangladeshДокумент4 страницыEssential Oil Composition From The Flowers of Alstonia Scholaris of BangladeshFaridul IslamОценок пока нет