Академический Документы

Профессиональный Документы

Культура Документы

High-Frequency Induction Heating

Загружено:

agameronИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

High-Frequency Induction Heating

Загружено:

agameronАвторское право:

Доступные форматы

HIGH-FREQUENCY INDUCTION HEATING

High-frequency Induction Heating

BY

FRANK W. CURTYS

Chief Engineer, Van Norman Company

Second Edition

McGRAW-HILL BOOK COMPANY, INC. NEW YORK TORONTO 1950 LONDON

PREFACE TO THE SECOND EDITION

Induction heating has undergone many improvements during the past few years, largely in connection with application techniques. While principles have remained the same, a better knowledge of their use prevails, and today users of high-frequency generators have a broader selection of coils, fixtures and process data to draw form for the solution of heating problems. In this edition a more comprehensive analysis of coil design has been included. A work coil is the basis around which induction heating functions. Therefore, by having a wider variety of designs from which choose, the more efficient can a setup be made. Many new forms of coils are described, together with basic principles with which the user of high-frequency equipment should be familiar. The discussion of fixture designs likewise has been expanded, because, along with coils, they form the most important considerations form successfully processing parts by means of induction heat. Localized hardening and the joining of metal assemblies are the principle uses for induction heating, and the chapters dealing with these two applications include a more comprehensive analysis of production requirements. Types of steels best suited to induction hardening, various means of quenching, soft solders, brazing alloys and fluxes all are treated in greater detail. Users of high-frequency heating equipment invariably seek technical information relating to application problems and it is in response to this need that the second edition has been enlarged.

Frank W. Curtis

PREFACE TO THE FIRST EDITION

The purpose of this book is to offer the user of high-frequency induction-heating equipment basic technical application details that will serve as a ready reference in connection with the heating of metal parts, such as may be required for hardening, heat-treating, brazing, soldering, annealing, stressrelieving, forging, upsetting, or melting. Though the generation of highfrequency current is an electrical function, putting this current to practical use becomes almost entirely mechanical. It is with this thought in mind that the user of induction-heating equipment is more concerned. Therefore, other than brief references to electrical data characteristic to this type of heating, the text is confined to application technique. High-frequency heating has already demonstrated remarkable versatility in many industries and without doubt will exert a marked influence on future product design and manufacturing process-planning. Heating methods have always undergone a transition of one kind or another, and it is logical to assume that induction-heating principles will open an important field of possibilities in economies and production gains. The text includes a broad coverage of heating coils and fixtures as used in hardening and joining operations, since these constitute the main requirements of a successful application. References area made to product design because technically there are advantages in considering the fundamental needs of induction heating when constructional details of a component are originated. In view of the association so often made between induction heating and dielectric heating, a brief chapter has been included on the latter, mainly for the purpose of showing the differences between these two methods of heat transfer. This textbook would not have been possible without the generous assistance of manufacturers and users of high-frequency equipment who have contributed illustrations showing induction-heating illustrations in use. The author takes this opportunity to thank the following manufactures for their valuable assistance: Ajac Electrothermic Corporation; Ecco High Frequency Corporation, Federal Telephone & Radio Corporation; Girdler Corporation; Induction Heating Corporation; Tocco Division; The Ohio Crankshaft Company; and Westinghouse Electric & Manufacturing Company. He thanks also Glen C. Riegel, of the Caterpillar Tractor Company, and Richard F. Harvey, of the Brown & Sharpe Manufacturing Company. Deep appreciation is also extended to the Induction Heating Corporation for its help in making available many case histories an laboratory analyses of inductionheating problems. Frank W. Curtis

CONTENTS

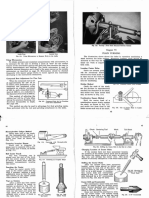

Preface to the second edition Preface to the first edition I. Principles of Induction Heating Diagrams of current paths Basic principles involved Relation of frequency Heating coils used Heating formula Effect of surface heating on metals Induction-heating Equipment Motor-generator sets Vacuum-tube oscillators Selection of equipment Diagram of circuits Miscellaneous units Spark-gap converters Design of Induction-heating Coils Single-turn and multi-turn coils Constructional design details Coil proportions Series-type coils Parallel inductors Miscellaneous coils Mounting of coils Built-up coil design Brazing, Soldering, and Joining Brazing with silver alloys Types of brazed joints Fixtures for production setups Continuous soldering operations Multiple setups Brazing carbide tools Miscellaneous seups

II.

III.

IV.

Вам также может понравиться

- Metallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964От EverandMetallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964W. O. AlexanderОценок пока нет

- Induction Heating PaperДокумент8 страницInduction Heating PaperSyed Salman AliОценок пока нет

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967От EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasРейтинг: 4 из 5 звезд4/5 (1)

- PLL Induction HeaterДокумент86 страницPLL Induction Heaterguzzi1100Оценок пока нет

- Refractory Transition Metal Compounds: High Temperature CermetsОт EverandRefractory Transition Metal Compounds: High Temperature CermetsОценок пока нет

- Induction Heating BasicsДокумент39 страницInduction Heating Basicstastaman123100% (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОценок пока нет

- Design and Simulation of Single Phase Inverter AirconditionerДокумент60 страницDesign and Simulation of Single Phase Inverter AirconditionerAmmar AL IdaneeОценок пока нет

- Laser Beam Welding GuideДокумент7 страницLaser Beam Welding GuideBhargav Srinivas KolliОценок пока нет

- ENGR 3050 Capacitive Displacement Sensor Lab IntroductionДокумент3 страницыENGR 3050 Capacitive Displacement Sensor Lab IntroductionJamesОценок пока нет

- Capacitive SensorДокумент17 страницCapacitive SensorPaul Jazz Lopez100% (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОт EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОценок пока нет

- Induction Heater Tutorial 10kw and 3kw PDFДокумент39 страницInduction Heater Tutorial 10kw and 3kw PDFpichaidv80% (5)

- Plastic Deformation of Materials: Treatise on Materials Science and Technology, Vol. 6От EverandPlastic Deformation of Materials: Treatise on Materials Science and Technology, Vol. 6R. J. ArsenaultОценок пока нет

- Induction HeatingДокумент5 страницInduction HeatingjjzoranОценок пока нет

- A Modular IGBT Converter System For High Frequency Induction Heating ApplicationsДокумент3 страницыA Modular IGBT Converter System For High Frequency Induction Heating Applicationsimosaba322Оценок пока нет

- Crucible Size and Surounding Space Size For Furnace - Home Model Engine MachinistДокумент4 страницыCrucible Size and Surounding Space Size For Furnace - Home Model Engine MachinistKhin Aung ShweОценок пока нет

- Advanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingОт EverandAdvanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingОценок пока нет

- Professor Induction Column on Induction Coil FailuresДокумент6 страницProfessor Induction Column on Induction Coil FailuresajaydevbОценок пока нет

- Induction HeatingДокумент29 страницInduction HeatingwchavezbОценок пока нет

- Welding & Fabrication PDFДокумент96 страницWelding & Fabrication PDFVicente Banda ZuñigaОценок пока нет

- Machinist Course - Precision Measuring and GagingДокумент96 страницMachinist Course - Precision Measuring and Gagingmerlinson1100% (1)

- Induction HeatingДокумент24 страницыInduction HeatingAbir Lovesick100% (5)

- Lapping tapers and seatings to improve fit and finishДокумент1 страницаLapping tapers and seatings to improve fit and finishsyllavethyjimОценок пока нет

- Induction HeatingДокумент40 страницInduction HeatingVijay Khoday100% (1)

- A New Unity Power Factor Quasi-Resonant Induction Heater PDFДокумент225 страницA New Unity Power Factor Quasi-Resonant Induction Heater PDFŽarko Dačević100% (1)

- Electrolytic Nickel Phosphorus PlatingДокумент34 страницыElectrolytic Nickel Phosphorus PlatingKhoa Vũ100% (1)

- 12KW Induction HeaterДокумент8 страниц12KW Induction HeaterEric Driscoll100% (2)

- The Thesis Industrial Electronics Applications (Design and Simulation of Coreless Induction Furnace)Документ87 страницThe Thesis Industrial Electronics Applications (Design and Simulation of Coreless Induction Furnace)Mohammed Afifi100% (2)

- Induction HeatingДокумент7 страницInduction HeatingSaurabh DangariaОценок пока нет

- Proto Type Arc FurnaceДокумент5 страницProto Type Arc FurnaceMoudeh ToumaОценок пока нет

- Grinding MachinesДокумент140 страницGrinding MachinesyowiskieОценок пока нет

- Scientific Calculator Operation Guide PDFДокумент75 страницScientific Calculator Operation Guide PDFArevalo ErolesОценок пока нет

- Induction Heat Treatment TechnologyДокумент6 страницInduction Heat Treatment TechnologyEsmaeil NaОценок пока нет

- High Frequency Induction HeatingДокумент14 страницHigh Frequency Induction HeatingEd Seward100% (3)

- Elementary Machine Shop PracticeДокумент136 страницElementary Machine Shop PracticeTaliaNara88% (8)

- Forging: Shaping Materials Through Compressive ForcesДокумент20 страницForging: Shaping Materials Through Compressive ForcesRam Janm SinghОценок пока нет

- Build a Portable Arc Welding MachineДокумент45 страницBuild a Portable Arc Welding MachineDaniel100% (1)

- How Induction Heating Works PDFДокумент3 страницыHow Induction Heating Works PDFpichaidvОценок пока нет

- EDM ConstructionДокумент8 страницEDM ConstructionNacer Mezghiche100% (1)

- Handbook of Induction HeatingДокумент797 страницHandbook of Induction Heatingaltamiro100% (5)

- Inside Type Outside Type: Fit. 113. Turain! e Steet Shaft Mounted Betw M CeotercДокумент22 страницыInside Type Outside Type: Fit. 113. Turain! e Steet Shaft Mounted Betw M CeotercRick ManОценок пока нет

- Technical Service Manual: Model Number ChartДокумент19 страницTechnical Service Manual: Model Number ChartIván NavarroОценок пока нет

- Permanent Magnet Materials - A N PatelДокумент64 страницыPermanent Magnet Materials - A N PatelRishabhОценок пока нет

- Heat Conduction - Basic ResearchДокумент362 страницыHeat Conduction - Basic ResearchJosé Ramírez100% (1)

- The Degradation of The American MachinistДокумент3 страницыThe Degradation of The American MachinistAlberto CastiñeirasОценок пока нет

- Blocking Oscillator: Resistor Transformer Transistor Duty-Cycle Leds Red-Eye EffectДокумент5 страницBlocking Oscillator: Resistor Transformer Transistor Duty-Cycle Leds Red-Eye EffectArul RajОценок пока нет

- Exp2 Magnetic AmplifierДокумент20 страницExp2 Magnetic AmplifierNikhil Aggarwal50% (2)

- Sheet FormingДокумент4 страницыSheet Formingvenkat_222123Оценок пока нет

- Precision Grinding PDFДокумент16 страницPrecision Grinding PDFErik Green67% (3)

- General geometrical model of scroll compressors based on initial involute anglesДокумент9 страницGeneral geometrical model of scroll compressors based on initial involute anglescswong111100% (1)

- Abrasive Grinding WheelsДокумент136 страницAbrasive Grinding WheelsMartin OngОценок пока нет

- Designing Gear CuttersДокумент3 страницыDesigning Gear CuttersKrishnadev Madhavan NairОценок пока нет

- Soft and Hard Soldering +brazingДокумент28 страницSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Heat Treatmhent 2Документ483 страницыHeat Treatmhent 2Recep VatanseverОценок пока нет

- Hindustan Motors Case StudyДокумент50 страницHindustan Motors Case Studyashitshekhar100% (4)

- Portfolio Artifact Entry Form - Ostp Standard 3Документ1 страницаPortfolio Artifact Entry Form - Ostp Standard 3api-253007574Оценок пока нет

- To Introduce BgjgjgmyselfДокумент2 страницыTo Introduce Bgjgjgmyselflikith333Оценок пока нет

- 621F Ap4405ccgbДокумент8 страниц621F Ap4405ccgbAlwinОценок пока нет

- Quantification of Dell S Competitive AdvantageДокумент3 страницыQuantification of Dell S Competitive AdvantageSandeep Yadav50% (2)

- HCW22 PDFДокумент4 страницыHCW22 PDFJerryPОценок пока нет

- FX15Документ32 страницыFX15Jeferson MarceloОценок пока нет

- Java development user guide eclipse tutorialДокумент322 страницыJava development user guide eclipse tutorialVivek ParmarОценок пока нет

- Estimation of Working CapitalДокумент12 страницEstimation of Working CapitalsnehalgaikwadОценок пока нет

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalДокумент41 страница2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcОценок пока нет

- IДокумент2 страницыIsometoiajeОценок пока нет

- Pita Cyrel R. Activity 7Документ5 страницPita Cyrel R. Activity 7Lucky Lynn AbreraОценок пока нет

- Axe Case Study - Call Me NowДокумент6 страницAxe Case Study - Call Me NowvirgoashishОценок пока нет

- Audit Acq Pay Cycle & InventoryДокумент39 страницAudit Acq Pay Cycle & InventoryVianney Claire RabeОценок пока нет

- ConductorsДокумент4 страницыConductorsJohn Carlo BautistaОценок пока нет

- 4 Wheel ThunderДокумент9 страниц4 Wheel ThunderOlga Lucia Zapata SavaresseОценок пока нет

- Oracle Learning ManagementДокумент168 страницOracle Learning ManagementAbhishek Singh TomarОценок пока нет

- Resume of Deliagonzalez34 - 1Документ2 страницыResume of Deliagonzalez34 - 1api-24443855Оценок пока нет

- Borello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceДокумент10 страницBorello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceaykutОценок пока нет

- ESA Knowlage Sharing - Update (Autosaved)Документ20 страницESA Knowlage Sharing - Update (Autosaved)yared BerhanuОценок пока нет

- Orc & Goblins VII - 2000pts - New ABДокумент1 страницаOrc & Goblins VII - 2000pts - New ABDave KnattОценок пока нет

- Krok2 - Medicine - 2010Документ27 страницKrok2 - Medicine - 2010Badriya YussufОценок пока нет

- RUJUKANДокумент3 страницыRUJUKANMaryTibanОценок пока нет

- 17BCE0552 Java DA1 PDFДокумент10 страниц17BCE0552 Java DA1 PDFABHIMAYU JENAОценок пока нет

- Polyol polyether+NCO Isupur PDFДокумент27 страницPolyol polyether+NCO Isupur PDFswapon kumar shillОценок пока нет

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationДокумент60 страницSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinОценок пока нет

- Assignment 2 - Weather DerivativeДокумент8 страницAssignment 2 - Weather DerivativeBrow SimonОценок пока нет

- Instrumentation Positioner PresentationДокумент43 страницыInstrumentation Positioner PresentationSangram Patnaik100% (1)

- Innovation Through Passion: Waterjet Cutting SystemsДокумент7 страницInnovation Through Passion: Waterjet Cutting SystemsRomly MechОценок пока нет

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressОт EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressРейтинг: 5 из 5 звезд5/5 (1)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)От EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Рейтинг: 5 из 5 звезд5/5 (2)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsОт EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsОценок пока нет

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)От EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Рейтинг: 4.5 из 5 звезд4.5/5 (5)

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.От EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.Оценок пока нет

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersОт EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersОценок пока нет

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsОт EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsРейтинг: 5 из 5 звезд5/5 (1)