Академический Документы

Профессиональный Документы

Культура Документы

Solar-Field AL310 en

Загружено:

Jaime Manuel CavazosОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solar-Field AL310 en

Загружено:

Jaime Manuel CavazosАвторское право:

Доступные форматы

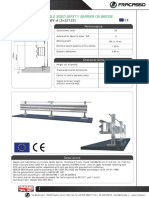

Solar-field AL310

Technical manual for aluminium support structure for photovoltaic free-fields/ flat roofs

1. Aluminium system for free-fields

1.1 GENERAL The aluminium support system for free-fields is made entirely from aluminium alloy EN AW 6060. All of the steel accessories (bolts, nuts, etc...) are made from stainless steel A2. The system is available in 2 versions, 2 portrait & 3 landscape with angles of 25,30,35. The system offers a choice of heavy and light constructions, with the difference being the span between the girders (3,1m & 2,5m accordingly). The mounting of the system requires a reinforced concrete foundation.

Typology

Purlin P80 P80 P105 P105 P80 P80 P105 P105 P80 P80 P105 P105

PV panel layout Portrait Landscape Portrait Landscape Portrait Landscape Portrait Landscape Portrait Landscape Portrait Landscape

Code A80P-25 A80L-25 A105P-25 A105L-25 A80P-30 A80L-30 A105P-30 A105L-30 A80P-35 A80L-35 A105P-35 A105L-35

Aluminium 25

Aluminium 30

Aluminium 35

2. Assembly for trianlges (free-fields)

The individual parts for assembling the trianlges are provided with the necessary machining for easier and faster installation.

2.1 FIXING TO THE FOUNDATION The floor bracket is fastened to the concrete with concrete anchor bolts (FBN II M12). Attention: Isolating material must be placed between the floor bracket and the concrete foundation in order to protect the floor bracket and fasteners from corrosion.

Anchor Bolts Floor Bracket Isolating Material Concrete Foundation

Rear floor bracket

The rear floor bracket is placed 2 meters from the front floor bracket on center.

2,0 m

Front floor bracket

The oval holes in the floor bracket provide the necessary adjustments (left and right) in order to bring the front and rear floor brackets in correct alignment.

2.2 INSTALLING THE FRONT AND REAR LEGS The legs are placed in the floor brackets and are fastened with a hexagon head bolt M12x80 and a safety nut M12. The washer with ribs is used to adjust the height of the leg and then the hexagon head bolt is tightened.

Rear leg Front leg

Safety nut 12 Hexagon head bolt 12x80 Washer with ribs for adjusting the hieght

2.3 INSTALLING THE DIAGONAL BRACING The diagonal bracing is placed between the two legs in order to stabilize the construction The brace is fastened to the legs with a hexagon head bolt M12x60 and a safety nut M12.

Diagonal bracing

Safety nut 12

Hexagon head bolt 12x60

2.4 INSTALLING THE GIRDER CONNECTOR First the girder connector is fastened to the girder at a specific position according to the typology and construction documentation provided for the specific project. Hammer head screws are placed inside the groove under the girder and are fastened to the girder connector with safety nuts.

Hammer head screw 8x20

Girder connector

Safety nut 8

Girder

2.5 INSTALLING THE GIRDER The girder with the girder connector fastened in the correct position is placed over the front and back legs and fastened with a hexagon head bolt M12x80 and a safety nut M12. The girder connector can be adjusted to insure that the correct height of the girder after tightening the hexagon head bolts. Afterwards the end covers are placed on both ends of the girder.

Girder connector

Washer with ribs for adjusting the Safety nut

Hexagon head bolt 12x80

Girder

End cover for girder

3. Installing and aligning the triangles (free-fields).

After repeating the previous steps, the triangles are placed in rows according the the project specifications. The largest span that can be used between girders is 3,1m If needed the triangles can be adjusted in order to insure the correct alignment.

2,0

3.1 ADJUSTMENTS

5) 10 ) (P 80 1m (P 3, 5m 2,

5) 10 0) (P 8 ,1m m (P 3 ,5 2

The legs can be adjusted in height by using the adjustability of the floor bracket.

The girder can be adjusted in length by loosening the hammer head bolts, which will free the girder to move both left and right. Also the girder connector can be used to adjust the height of the girder up and down.

Hammer head bolt 8x20

3.2 INSTALLING DIAGONAL BRACING Diagonal bracing is placed at the beginning and the end of a set of triangles and every third span.

Diagonal bracing

3.3 TABLE FOR FASTENER TORQUE

Drawing

Description

Torque According to specifications 56 Nm

Anchor bolt

Bolt 12x80

Bolt 12x60

32 Nm

Hammer head bolt 8x20

32 Nm

4. Aluminium systems for flat roofs

4.1 GENERAL The aluminium support system for flat roofs is made entirely from aluminium alloy EN AW 6060. All of the fasteners and accessories (bolts, nuts, etc...) are made from stainless steel A2. The system is available in 2 basic versions, 2 portrait & 3 landscape with angles 2530. The fixation to the flat roof is made with the appropriate chemical anchor bolts (FIS EM & FIS HB) that are tested and certified for weather sealing.

Typology Aluminium flat roof 25 Aluminium flat roof 30

Purlin P80 P80 P80 P80

PV panel layout Portrait Landscape Portrait Landscape

Code AL80P-25 AL80L-25 AL80P-30 AL80L-30

5. Assembly for trianlges (Flat roofs).

The individual parts for assembling the trianlges are provided with the necessary machining for easier and faster installation.

5.1 FIXING TO THE FLAT ROOF The floor bracket is fastened to the concrete with chemical anchor bolts. The appropriate types of chemical anchors are the FIS HB (when the support is fastened directly to the concrete slab or with a thin insulating pad) and the FIS EM (for fastening over thick plates of insulation). The insulation can be asphalt, cement, polystyrene plates, etc. The rods M12 are recommended to be at least A2 quality and the nominal depth of the anchor is provided in the technical manuals of fischer. Attention: Isolating material must be placed between the floor bracket and the concrete foundation in order to protect the floor bracket and fasteners from corrosion.

Rear Floor Bracket Anchor Bolt Floor Bracket Isolation Material Flat roof

Front Floor Bracket

The rear floor bracket is placed 2,62 meters from the front floor bracket on center.

2,6

2m

The oval holes in the floor bracket provide the necessary adjustments (left and right) in order to bring the front and rear floor brackets in correct alignment.

10

5.2 INSTALLING THE FRONT AND REAR LEGS The legs are placed in the floor brackets and are fastened with a hexagon head bolt M12x80 and a safety nut M12. The washer with ribs is used to adjust the height of the leg and then the hexagon head bolt is tightened.

Rear Leg

Rear Floor Bracket Washer with ribs for adjusting the hieght Hexagon Head Bolt 12x80

Safety Nut 12 Washer with ribs for adjusting the hieght

5.3 INSTALLING THE GIRDER CONNECTOR First the girder connector is fastened to the girder at a specific position according to the typology and construction documentation provided for the specific project. Hammer head screws are placed inside the groove under the girder and are fastened to the girder connector with safety nuts. Afterwards the end covers are placed on both ends of the girder.

Hammer Head Bolt 8x20

Girder Connector

Girder Safety Nut 8 End Cover for Girder

11

5.4 INSTALLING THE GIRDER The girder with the girder connector fastened in the correct position is placed over the back leg and fastened with a hexagon head bolt M12x80 and a safety nut M12. The girder connector can be adjusted to insure that the correct height of the girder after tightening the hexagon head bolts.

Girder Girder Connector Washer with ribs for adjusting the hieght Bolt 12x80 Safety Nut Washer with ribs for adjusting the hieght

Girder

Safety Nut

Floor Bracket Bolt 12x80

2.3 INSTALLING DIAGONAL BRACING The diagonal bracing is placed between the back leg and the girder in order to stabilize the construction The brace is fastened to the legs with a hexagon head bolt M12x60 and a safety nut M12.

Diagonal Brace

Safety Nut 12

Girder Hexagon head bolt 12x60

12

6. Installing and aligning the triangles (Flat roofs).

After repeating the previous steps, the triangles are placed in rows according the the project specifications. The largest span that can be used between girders is 2,5m If needed the triangles can be adjusted in order to insure the correct alignment.

m 2,5

2,6 2m

m 2,5

6.1 ADJUSTMENTS

The legs can be adjusted in height by using the adjustability of the floor brackets.

Also the girder connector can be used to adjust the height of the girder up and down.

13

6.2 INSTALLING DIAGONAL BRACING Diagonal bracing is placed at the beginning and the end of a set of triangles and every third span.

Diagonal Bracing

6.3 TABLE FOR FASTENER TORQUE

Drawing

Description

Torque According to specifications 56 Nm

Anchor Bolt

Bolt 12x80

Bolt 12x60

32 Nm

Hammer head bolt 8x20

32 Nm

14

7. Installing purlins

The purlins are installed over the girders with a special corner clamp connector. The hammer head nut is inserted into the channel of the girder and is locked into posistion with a clock-wise turning motion. The corner clamp is inserted into the side channel of the purlin and is fastened to the hammer head nut with an allen screw M8.

Hammer head nut

Allen screw

Corner clamp connector

7.1 PURLIN CONNECTOR When the purlin is used continuously to span over several girders, then a special purlin connector is used to fasten the two purlins together. The purlin connector is inserted into the chamber of the purlin and fastened with self-tapping stainless steel screws.

Screw St4,2x13 Purlin Purlin Connector

15

8. Installing the panels

The panels are fixed to the purlins with special clamps. There are end clamps that are used to fix the panels at the beginning and the end of a series, and there are middle clamps that are used between two panels. The clamps are available pre-assembled (with allen screw, spring, plastic grip, hammerhead nut) and are availble for every panel thickness.

Allen screw

The hammer head nut is inserted into the channel of the purlin and turned to lock into the desired position. Then the clamp is fastened into place with the allen screw.

Clamp

Hammer head nut

16

9. Technical data sheets

1- point load F

SolarFine 150

Height Width Perimeter Ix Iy Wx Wy Radii(x) Radii(y) Area Weight 150 mm 41 mm 522,34 mm 229,10 cm4 4 25,71 cm 29,68 cm3 12,54 cm3 5,06 cm 1,70 cm 2 894,02 mm 2413,85 gr/m

L/2 L 2- point load F L/3 L/3 L 2 supports - Uniformly load q F

L 3 supports - Uniformly load qL qL

F (N) 20000 19000 18000 17000 16000 15000 14000 13000 12000 11000 10000 9000 8000 7000 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3

SolarFine 150

3-supports 2-supports 1 point load 2 point load

3,5

4,5

5,5

6 L (m)

17

1- point load F

SolarFine 100

Height Width Perimeter Ix Iy Wx Wy Radii(x) Radii(y) Area Weight L/2 100 mm 41 mm 422,34 mm 78,53 cm4 L/3 L/3 L 14,87 cm3 2 supports - Uniformly load q 2- point load F 18,79 cm4 F L

9,17 cm3 3,32 cm 1,62 cm 714,02 mm2 1927,85 gr/m

L 3 supports - Uniformly load qL qL

L

F (N) 15000 14000 13000 12000 11000 10000 3-supports 9000 8000 7000 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 2-supports 1 point load 2 point load

SolarFine 100

18

SolarPrime 105

Height Width Perimeter Ix Iy Wx Wy Radii(x) Radii(y) Area Weight 1- point load F L/2 L

F (N) 15000 14000 13000 12000 11000 10000 9000 8000 1 point load 7000 2 point load 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 3-supports 2-supports

105 mm 77,8 mm 490,32 mm 107,81 cm4 39,11 cm4 18,24 cm3 10,05 cm3 3,75 cm 2,26 cm 768,05 mm2 2073,72 gr/m 3 supports Uniformly load qL qL

2- point load F L/3 L/3 L F

2 supports Uniformly load q

L

SolarPrime 105

19

SolarPrime 80

Height Width Perimeter Ix Iy Wx Wy Radii(x) Radii(y) Area Weight 1- point load F L/2 L

F (N) 15000 14000 13000 12000 11000 10000 2-supports 9000 3-supports 8000 7000 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 1 point load 2 point load

80 mm 77,8 mm 440,32 mm 53,90 cm4 34,43 cm4 12,00 cm3 8,85 cm3 2,80 cm 2,24 cm 688,05 mm2 1857,72 gr/m 3 supports Uniformly load qL qL

2- point load F L/3 L/3 L

SolarPrime 80

2 supports Uniformly load q

20

10. Structural design loads of brackets

Load 1: Vertical compression (15kN) Load 2: Horizontal forces

15kN 6,5kN

(6,5kN)

Load 1: Vertical compression (10kN) Load 2: Horizontal forces (10kN)

Load 3: Vertical tensile forces (10kN)

10kN

10kN

10kN

1958, the beginning. 2012, world-wide.

Chemical Fixings

High Performance Steel Anchors

General Fixings

Cavity Fixings

Photovoltaic Mounting Structures

Drills and Bits

Samontec - MEP Installation Fixings

Screws

Foams, Sealants

E.W.I. / ETICS

fischer Hellas Emporiki EPE National Road Athens-Lamia (17th) & 6 Roupel str. GR - 14564 Kifissia, Athens Greece Tel.: +30 210 28 38 167, Fax: +30 210 28 38 169 info@fischer.gr

www.fischer.gr

The contents of this manual are subject to change without prior notice. Fischer Hellas Emporiki EPE is not responsible for typographical errors. PLS012 05/2012

Founded in 1958, the fischer brand is synonymous for safe, innovative and sophisticated technical solutions which set new standards in fixing engineering. The products and applications are unique fixing systems that are invented and produced by fischer. That is the reason that there exist unlimited solutions and a large range of applications, and today is recognised as the leader in the market of fixing systems.

Вам также может понравиться

- 8ft Antenna (HTT81.221-10)Документ15 страниц8ft Antenna (HTT81.221-10)guns1976Оценок пока нет

- RFS 1.8mДокумент13 страницRFS 1.8mMarius Tresor EdiboussieОценок пока нет

- Workshop DIY PROJECTSДокумент75 страницWorkshop DIY PROJECTSEmijo.A100% (1)

- Hopergy Roof Mounting System Installation Manual V2.2Документ24 страницыHopergy Roof Mounting System Installation Manual V2.2Jason HallОценок пока нет

- Apm30h&Tmc11h&Ibbs200d&Ibbs200t (Ver.b) Installation GuideДокумент39 страницApm30h&Tmc11h&Ibbs200d&Ibbs200t (Ver.b) Installation GuideLeonardo FertmaneОценок пока нет

- 4ft Antenna SB4 Reflector Installation (NMT480-08)Документ11 страниц4ft Antenna SB4 Reflector Installation (NMT480-08)guns1976Оценок пока нет

- Install Manual Solarfloating SystemДокумент11 страницInstall Manual Solarfloating SystemvasilecmirceaОценок пока нет

- Modu Tek CatalogДокумент184 страницыModu Tek Catalogiskierdo10Оценок пока нет

- Solar-Field SP300: Technical Manual For Photovoltaic Free-Fields With Single Pile FoundationsДокумент16 страницSolar-Field SP300: Technical Manual For Photovoltaic Free-Fields With Single Pile Foundationsfischer Italia s.r.l.Оценок пока нет

- APM30H&TMC11H&IBBS200D&IBBS200T (Ver.B) Installation GuideДокумент39 страницAPM30H&TMC11H&IBBS200D&IBBS200T (Ver.B) Installation GuideJoe LopezОценок пока нет

- Masonry SuДокумент32 страницыMasonry SuÔzØnè BęržëŕkОценок пока нет

- 4ft Antenna SB4-142 Reflector Installation (NMT564-01)Документ11 страниц4ft Antenna SB4-142 Reflector Installation (NMT564-01)guns1976Оценок пока нет

- Steel Ground Mount Structure Installation ManualДокумент11 страницSteel Ground Mount Structure Installation ManualDiego CernaОценок пока нет

- Uni Span FormworkДокумент30 страницUni Span FormworkHans JonesОценок пока нет

- Oga 9.6 Installation Manual For KCNДокумент20 страницOga 9.6 Installation Manual For KCNNgadiyantoОценок пока нет

- 4ft Antenna SB4 With Wind Kit 250kmh Reflector Installation (NMT560-03)Документ11 страниц4ft Antenna SB4 With Wind Kit 250kmh Reflector Installation (NMT560-03)guns1976Оценок пока нет

- Installation Manual for Rockfall Barrier RB 1500Документ40 страницInstallation Manual for Rockfall Barrier RB 1500John Lak0% (1)

- BTS3902E WCDMA Quick Installation Guide (01) (PDF) - enДокумент16 страницBTS3902E WCDMA Quick Installation Guide (01) (PDF) - enhungpn84100% (1)

- MSE 210 On-Roof en LOW KEY PDFДокумент6 страницMSE 210 On-Roof en LOW KEY PDFJesus de NazarethОценок пока нет

- Installation Instructions - Model 10 SignalДокумент63 страницыInstallation Instructions - Model 10 SignalChristian CristãoОценок пока нет

- Shelter Assembly Manual: Model # 203012PДокумент12 страницShelter Assembly Manual: Model # 203012PWayne Lund100% (2)

- New Installation ManualДокумент30 страницNew Installation ManualNgadi YantoОценок пока нет

- Shield Assembly GuideДокумент20 страницShield Assembly GuideBrett DarbyОценок пока нет

- Metal Perforated CeilingДокумент6 страницMetal Perforated CeilingkripeshdubeyОценок пока нет

- 4safebarriera ENG H2 W4 A BP - 3n32122Документ6 страниц4safebarriera ENG H2 W4 A BP - 3n32122TBPОценок пока нет

- NS114 Appendix E - Installation ManualДокумент32 страницыNS114 Appendix E - Installation Manualpwills1234Оценок пока нет

- Introduction - Metallic Expansion Joint PDFДокумент16 страницIntroduction - Metallic Expansion Joint PDFsdmel100% (2)

- Ivc Single Faced Sluice Gate Valve Valvula de CompuertaДокумент14 страницIvc Single Faced Sluice Gate Valve Valvula de CompuertaSurendra ReddyОценок пока нет

- XR3C 6 Element Triband Yagi 20-15-10MДокумент18 страницXR3C 6 Element Triband Yagi 20-15-10Msboonuy331Оценок пока нет

- Assembly Instructions For Bondstrand Fiberglass FlangesДокумент8 страницAssembly Instructions For Bondstrand Fiberglass FlangesHoang CongОценок пока нет

- Jordahl Jva enДокумент48 страницJordahl Jva engasparОценок пока нет

- Masonry Su PDFДокумент32 страницыMasonry Su PDFDanusha EgodawatteОценок пока нет

- DPWH Standard Specifications for Non-Structural Metal FramingДокумент8 страницDPWH Standard Specifications for Non-Structural Metal FramingleovorigОценок пока нет

- Script Bus Duct ScribdДокумент1 страницаScript Bus Duct Scribdshashank_3110Оценок пока нет

- Method Statement FOR Acoustic Ceiling TilesДокумент12 страницMethod Statement FOR Acoustic Ceiling Tilesraks07010% (1)

- Shelter Quick Installation Guide For HuaweiДокумент25 страницShelter Quick Installation Guide For HuaweiFrancisco Salvador MondlaneОценок пока нет

- Construction of Post Tension Slab System.: MaterialsДокумент13 страницConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- Deda Instruction BookletДокумент6 страницDeda Instruction BookletPaulo RodriguesОценок пока нет

- Installation Manual RMC050A - Rev.5Документ42 страницыInstallation Manual RMC050A - Rev.5John LakОценок пока нет

- Chain Link Fencing Guide: Specs, Installation & MoreДокумент3 страницыChain Link Fencing Guide: Specs, Installation & MorevanmurthyОценок пока нет

- Ancoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebДокумент48 страницAncoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebIulia PetrescuОценок пока нет

- Thermal testing of sandwich panelsДокумент13 страницThermal testing of sandwich panelsBurak ErkanОценок пока нет

- Fixings Breifing2021-01-25t151713Документ3 страницыFixings Breifing2021-01-25t151713ckirkcaldy73Оценок пока нет

- Page 2 Trickle VentsДокумент1 страницаPage 2 Trickle Ventstrade2homeОценок пока нет

- Steel FrameДокумент16 страницSteel FrameFernando DomeniconiОценок пока нет

- Installation Procedures for Doors, Windows and GlassДокумент4 страницыInstallation Procedures for Doors, Windows and GlassmustafaОценок пока нет

- 9449 Macalloy Tension StructuresДокумент16 страниц9449 Macalloy Tension StructuresYam BalaoingОценок пока нет

- Bts3902e Quick GuideДокумент20 страницBts3902e Quick GuideAlexander TyshchenkoОценок пока нет

- VARIO GT 24 Standard PanelsДокумент57 страницVARIO GT 24 Standard PanelsdonnyervinОценок пока нет

- Method Statement For False Ceiling Works Gypsum Board, Beam Grid, Ceiling Tiles & BafflesДокумент9 страницMethod Statement For False Ceiling Works Gypsum Board, Beam Grid, Ceiling Tiles & BafflesAddis MekuriaОценок пока нет

- ManualДокумент9 страницManualbheigh5054100% (1)

- Mounting Hyport series ceiling supply pendant base rackДокумент5 страницMounting Hyport series ceiling supply pendant base rackgenjunkОценок пока нет

- Ancon Kwika StripДокумент12 страницAncon Kwika StripplatanospanosОценок пока нет

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideОт EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideОценок пока нет

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingОт EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Fischer VL-Line English VersionДокумент2 страницыFischer VL-Line English Versionfischer Italia s.r.l.Оценок пока нет

- Fischer Solar-Fix Main CatalogueДокумент146 страницFischer Solar-Fix Main Cataloguefischer Italia s.r.l.Оценок пока нет

- Fischer Solar Wind (Lingua Inglese)Документ4 страницыFischer Solar Wind (Lingua Inglese)fischer Italia s.r.l.Оценок пока нет

- Solar-Field DP325 enДокумент15 страницSolar-Field DP325 enJaime Manuel CavazosОценок пока нет

- Fischer Solar-FixДокумент28 страницFischer Solar-Fixfischer Italia s.r.l.Оценок пока нет

- Solar-Field SP300: Technical Manual For Photovoltaic Free-Fields With Single Pile FoundationsДокумент16 страницSolar-Field SP300: Technical Manual For Photovoltaic Free-Fields With Single Pile Foundationsfischer Italia s.r.l.Оценок пока нет