Академический Документы

Профессиональный Документы

Культура Документы

Variable Length Induction Tract: Fig. 4.10 An Air Control Valve

Загружено:

stefanovicana1Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Variable Length Induction Tract: Fig. 4.10 An Air Control Valve

Загружено:

stefanovicana1Авторское право:

Доступные форматы

132

A practical approach to motor vehicle engineering and maintenance

Fig. 4.10 An air control valve

advisable to check the tightness of the securing nuts and bolts periodically. These nuts and bolts must be tightened in the proper sequence, shown for a particular engine in Fig. 4.12.

Variable length induction tract

The length of the induction tract (tube) through which the engines air supply is drawn has an effect on the operating efficiency of the engine. For low to medium engine speeds a long induction tract is beneficial whereas a shorter induction tract is beneficial at high engine speed. Figure 4.13(a)

shows a simplified variable length induction system. An electronically controlled valve between the throttle valve and the engine switches air flow between the long and short tracts as required by engine speed. At low to medium engine speed this air valve is closed as shown in Fig. 4.13(b). As the engine speed rises the electronic control unit causes the air valve to open, as shown in Fig. 4.13(c) and the main mass of air enters the engine through by the short route.

Turbo charging

Engines that rely on atmospheric air pressure for their operation are known as naturally aspirated engines. The power output of naturally aspirated engines is limited by the amount of

Fig. 4.11 An air intake manifold

Fig. 4.12 Tightening sequence for exhaust manifold retaining hardware (nuts)

Engine air supply and exhaust systems

Air in Air in Throttle valve Air control valve Throttle valve Air control valve

133

Filter Filter (b) Air in Throttle valve Air control valve

Filter (a) (c)

Fig. 4.13 (a) Variable length induction tract, (b) idling to medium speed, (c) high speed

air that can be induced into the cylinder on each induction stroke. Engine power can be increased by forcing air into the cylinders under pressure. The turbo charger is commonly used on modern engines to boost the pressure of the incoming air. The turbo charger consists of two main units, the turbine and the compressor mounted

on a common shaft. The turbine is driven by exhaust gas and utilises energy that would otherwise be wasted by being expelled through the exhaust system into the atmosphere. The general principle of turbo charging is shown in Fig. 4.14. Exhaust gas energy is directed to the small turbine which is

Exhaust from engine

Air to engine

Wastegate valve

Turbine

Compressor

Air inlet Exhaust outlet

Fig. 4.14 A turbo charger system

134

A practical approach to motor vehicle engineering and maintenance

connected to the shaft that also drives the compressor. After driving the turbine, the exhaust gas travels through the exhaust system and out through the tail pipe. Intake air is drawn into the compressor through the air filter. The compressor raises the pressure to approximately 0.5 bar above atmospheric pressure and the pressure is controlled by the waste gate valve that allows the exhaust gas to by-pass the turbine.

4.2 Exhaust system

A fundamental purpose of the exhaust system is to convey exhaust gas away from the engine and to expel it into the surrounding atmosphere at some point that is convenient to vehicle occupants. On motor cars this usually means through the tail pipe at the rear of the vehicle. On trucks it is often at some other point, often just behind the drivers compartment. Another function of the exhaust system is to deaden the exhaust sound to an acceptable level. This sound level is regulated by law. The exhaust system shown in Fig. 4.15 has a number of sections. Starting at the front of the vehicle the sections are: the down pipe, or front pipe; the unit marked 1, this is the catalytic convertor, an interconnecting pipe to the first silencer (2); a further length of pipe which is curved to take it round other units on the vehicle; this pipe connects to the rear silencer (3); and the gas finally leaves through the tail pipe. The exhaust system is mounted firmly to the exhaust manifold at the front end, but it is flexibly mounted to the underside of the vehicle for the remainder of its length. The flexible mountings are required to allow the system to move independently of the main vehicle structure. This allows for the fact that the engine itself is normally flexibly mounted, and the type of exhaust mountings used prevent noise and vibration being transmitted to the vehicle structure. In order to provide for ease of maintenance and economy when replacing parts, the

Service attention to the air supply system

A normal service requirement is to renew the air filter element at regular intervals. Should the filter element become clogged it will restrict the flow of air to the engine and cause the engine to run rich. This will obviously affect the engine performance and it will also cause the emission control system to malfunction. To guard against problems in this area, all vehicles should be properly serviced before they are tested for compliance with the emissions regulations, for example, a pre-MOT service and check-over. Other items that should receive regular attention include: sensor connections, condition of flexible hoses and tightness of joints and securing brackets. Air flow meters, throttle position sensors, etc. are normally quite reliable. In the event of problems with these items, it will normally be necessary to read out fault codes, either through the on-board diagnostic system or by the use of diagnostic code readers and other tools.

Fig. 4.15 Underside view of an exhaust system

Вам также может понравиться

- Ic Engine Varable Valve Timing and Lift Control System Assignment 1 Bsme0116303 Section BДокумент32 страницыIc Engine Varable Valve Timing and Lift Control System Assignment 1 Bsme0116303 Section BAbdullah Khan100% (1)

- Novel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI EngineДокумент4 страницыNovel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI Engineyash1239Оценок пока нет

- Gas Turbine in Cairo North Power StationДокумент38 страницGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- 1910 OwnersManual PDFДокумент19 страниц1910 OwnersManual PDFrcord0310Оценок пока нет

- Governing of IC Engines: 1. Hit and Miss Governing. in This System of GoverningДокумент7 страницGoverning of IC Engines: 1. Hit and Miss Governing. in This System of GoverningSreejith MaNuОценок пока нет

- 3 Dismble Assemble Oil Bath FilterДокумент2 страницы3 Dismble Assemble Oil Bath Filtermaliksawan376116Оценок пока нет

- Intake Air SystemsДокумент8 страницIntake Air SystemsJosé AntonioОценок пока нет

- Multi Point Fuel Injection SystemДокумент12 страницMulti Point Fuel Injection Systemashwini yewaleОценок пока нет

- Exhaust System and Intake Manifold: Exhaust Ball Joint CouplingДокумент26 страницExhaust System and Intake Manifold: Exhaust Ball Joint CouplingSry SantosОценок пока нет

- Intake Air Management For Diesel EnginesДокумент7 страницIntake Air Management For Diesel EnginesAshokОценок пока нет

- 918 SampleДокумент4 страницы918 Sample128mansouriОценок пока нет

- Air Brake System Using Exhaust Gas PowerPoint PresentationДокумент16 страницAir Brake System Using Exhaust Gas PowerPoint PresentationErole Technologies Pvt ltd Homemade Engineer100% (1)

- All Aircraft Fuel Systems Have Filters and Strainers ToДокумент15 страницAll Aircraft Fuel Systems Have Filters and Strainers ToumeshОценок пока нет

- Design and Optimization of A Throttle Body Assembly by CFD AnalysisДокумент11 страницDesign and Optimization of A Throttle Body Assembly by CFD Analysisbob loblawОценок пока нет

- C94e PDFДокумент11 страницC94e PDFPhotonsmart DxОценок пока нет

- Multipoint Fuel Injection SystemДокумент6 страницMultipoint Fuel Injection Systemalan kurniawanОценок пока нет

- Design and Optmization of A Throttle BodyДокумент11 страницDesign and Optmization of A Throttle BodyRodrigo PassosОценок пока нет

- Air Injection SystemДокумент4 страницыAir Injection Systemankush.ahuja2005Оценок пока нет

- Engineering Letter: Fanperformance-ThesystemeffectДокумент4 страницыEngineering Letter: Fanperformance-ThesystemeffectJuan Pablo ApazaОценок пока нет

- TurbochagingДокумент16 страницTurbochagingbatinoac9973Оценок пока нет

- Air Brake System of LocomotiveДокумент18 страницAir Brake System of LocomotiveArashdeep Singh100% (2)

- 021 11-00-00 Turbine Engines Amend0Документ120 страниц021 11-00-00 Turbine Engines Amend0kashimotocomotuya100% (1)

- Railway BrakingДокумент6 страницRailway BrakingJoshua Bailey100% (1)

- Air Induction SystemДокумент6 страницAir Induction SystemSirleh SalehОценок пока нет

- AENG 413 Induction System Assignment - FrancoДокумент6 страницAENG 413 Induction System Assignment - FrancoDeomary FrancoОценок пока нет

- Pneumatic Systems: 5-1. Schematic Drawing of A Hydraulic Circuit, and Physical Drawing of The Components in The CircuitДокумент8 страницPneumatic Systems: 5-1. Schematic Drawing of A Hydraulic Circuit, and Physical Drawing of The Components in The Circuitmuhd_danialОценок пока нет

- 5.pneumatic Trainer KitДокумент7 страниц5.pneumatic Trainer KitAlmas 1710Оценок пока нет

- Basic Diesel Engines - Jun-17-1Документ124 страницыBasic Diesel Engines - Jun-17-1Moataz NazeemОценок пока нет

- Dsreddy SeminarДокумент23 страницыDsreddy Seminarsarath ChandraОценок пока нет

- The Overall Motronic SystemДокумент12 страницThe Overall Motronic SystemKanagasundram JathursajanОценок пока нет

- On Board DiagnosticsДокумент52 страницыOn Board Diagnosticsjayasundar100% (1)

- Engine Fuel SystemДокумент14 страницEngine Fuel Systemusmankhanakbar100% (2)

- IC Engines ReportДокумент14 страницIC Engines Reportadarsh muraliОценок пока нет

- Active Air Suspension SystemДокумент14 страницActive Air Suspension SystemRoshan SahОценок пока нет

- 1980 Dual Jet E2 MДокумент40 страниц1980 Dual Jet E2 MNestor CastilloОценок пока нет

- PCVДокумент20 страницPCVyared abebeОценок пока нет

- Air Braking System in Indian RailwayДокумент22 страницыAir Braking System in Indian RailwayClassic Printers100% (1)

- Electronic Fuel InjectionДокумент13 страницElectronic Fuel InjectionTerrence JimОценок пока нет

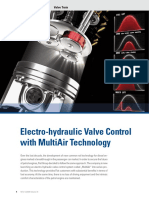

- Electro-Hydraulic Valve Control With Multiair Technology: Cover StoryДокумент8 страницElectro-Hydraulic Valve Control With Multiair Technology: Cover StoryAnonymous i2nXmcJEanОценок пока нет

- Tr7-8fi ManualДокумент82 страницыTr7-8fi ManualClint CooperОценок пока нет

- Air Induction SystemДокумент12 страницAir Induction SystemBegu CataОценок пока нет

- Types of Jet Engines: 6.1 TurbojetДокумент20 страницTypes of Jet Engines: 6.1 Turbojetapi-376777497Оценок пока нет

- C210 WML 204Документ10 страницC210 WML 204Efrén SantínОценок пока нет

- AERO Engine Maintenance AND Repair Notes-1 AERO Engine Maintenance AND Repair Notes-1Документ29 страницAERO Engine Maintenance AND Repair Notes-1 AERO Engine Maintenance AND Repair Notes-1uthira100% (1)

- Commercial Vehicles Air BrakesДокумент50 страницCommercial Vehicles Air BrakesYatna AcharyaОценок пока нет

- Ad Dit LC B Ti E I Advanced Internal Combustion Engines Mae 589V (Spring 2009)Документ15 страницAd Dit LC B Ti E I Advanced Internal Combustion Engines Mae 589V (Spring 2009)snmathad2Оценок пока нет

- A Seminar-Report: Topic Air Brake System of Indian RailwaysДокумент9 страницA Seminar-Report: Topic Air Brake System of Indian RailwaysVineet Yadav100% (1)

- Total 7 Bearings:-2 at Fdgs (1 & 1.5), 1 LP Front 2 LP Aft, 1 HP Front 1 HP Rear. But WillДокумент15 страницTotal 7 Bearings:-2 at Fdgs (1 & 1.5), 1 LP Front 2 LP Aft, 1 HP Front 1 HP Rear. But WillAnurag MishraОценок пока нет

- Unit 1 Automotive SubsystemsДокумент36 страницUnit 1 Automotive SubsystemsArulmuruganОценок пока нет

- Flow Analysis of Upstream Fluid Flow Using Simulation For Different Positions of Optimized Inlet Guide Vane in Centrifugal Air CompressorДокумент9 страницFlow Analysis of Upstream Fluid Flow Using Simulation For Different Positions of Optimized Inlet Guide Vane in Centrifugal Air CompressorAJER JOURNALОценок пока нет

- Air Brake PDFДокумент17 страницAir Brake PDFShubham RanaОценок пока нет

- Pneumatics System: Operation of A Single Acting Cylinder Controlled by 3-Way ValveДокумент14 страницPneumatics System: Operation of A Single Acting Cylinder Controlled by 3-Way ValveMubarak ShehuОценок пока нет

- CFD Analysis of ManifoldДокумент27 страницCFD Analysis of ManifoldsravitejaОценок пока нет

- Air Brake HandbookДокумент59 страницAir Brake HandbookBinny Sharma100% (1)

- Final Edition of Automotive QBДокумент15 страницFinal Edition of Automotive QByoussef faroukОценок пока нет

- Unit 1 Automotive SubsystemsДокумент36 страницUnit 1 Automotive SubsystemsArulmuruganОценок пока нет

- Induction SystemДокумент6 страницInduction SystemDaniel MkandawireОценок пока нет

- Zaude ModrnДокумент47 страницZaude ModrnZewdeneh AsemieОценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Tank ComponentsДокумент12 страницTank Componentsstefanovicana1Оценок пока нет

- A Topology Based Approach For Exploiting Sparsity in Multibody Dynamics in Cartesian FormulationДокумент18 страницA Topology Based Approach For Exploiting Sparsity in Multibody Dynamics in Cartesian Formulationstefanovicana1Оценок пока нет

- Frequently Asked Questions (FAQ) Regarding WP.29: (Updated On May 2005)Документ17 страницFrequently Asked Questions (FAQ) Regarding WP.29: (Updated On May 2005)stefanovicana1Оценок пока нет

- Tank Container Relief Vent Valve RV 30, RV 40 RV 30 RV 40: GestraДокумент2 страницыTank Container Relief Vent Valve RV 30, RV 40 RV 30 RV 40: Gestrastefanovicana1Оценок пока нет

- Text With EEA RelevanceДокумент26 страницText With EEA Relevancestefanovicana1Оценок пока нет

- Volvo Sept 2011 PV776-K-BodyBuilder Kit TOCДокумент1 страницаVolvo Sept 2011 PV776-K-BodyBuilder Kit TOCstefanovicana1Оценок пока нет

- x3 CatalogueДокумент10 страницx3 Cataloguestefanovicana1Оценок пока нет

- 7series Sedan CatalogueДокумент9 страниц7series Sedan Cataloguestefanovicana1Оценок пока нет

- Vehicle Sideslip and Roll Parameter Estimation Using GPSДокумент8 страницVehicle Sideslip and Roll Parameter Estimation Using GPSstefanovicana1Оценок пока нет

- Engine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and ControlДокумент6 страницEngine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and Controlstefanovicana1Оценок пока нет

- Quattro The Evolution of Audi All-Wheel DriveДокумент50 страницQuattro The Evolution of Audi All-Wheel Drivestefanovicana1100% (1)

- BWM 0000004 01Документ54 страницыBWM 0000004 01stefanovicana1Оценок пока нет

- BWM 0000002 01Документ28 страницBWM 0000002 01stefanovicana1Оценок пока нет

- Adjoint Sensitivity Analysis For Differential-Algebraic Equations: The Adjoint Dae System and Its Numerical SolutionДокумент14 страницAdjoint Sensitivity Analysis For Differential-Algebraic Equations: The Adjoint Dae System and Its Numerical Solutionstefanovicana1Оценок пока нет

- GX630 GX660 GX690: Technical ManualДокумент36 страницGX630 GX660 GX690: Technical ManualDiego Leandro Garcia HernandezОценок пока нет

- Interactive Panel Display: Kia Soul: Engine Control Module (ECM) - Schematic DiagramsДокумент6 страницInteractive Panel Display: Kia Soul: Engine Control Module (ECM) - Schematic DiagramsGaragem Officina MechanicaОценок пока нет

- Ic Engine Interview QuestionsДокумент3 страницыIc Engine Interview QuestionsMayur Panchal100% (1)

- Internal Combustion Engines - Saleel and Sivakumar PDFДокумент86 страницInternal Combustion Engines - Saleel and Sivakumar PDFRam NareshОценок пока нет

- Modern Diesel TechnologyДокумент666 страницModern Diesel TechnologytpmuhammadtpОценок пока нет

- BAIC X25 Engine-EN PDFДокумент449 страницBAIC X25 Engine-EN PDFFrank Paredes100% (5)

- Service Manual Diesel Engine DB33AДокумент78 страницService Manual Diesel Engine DB33ADVHHTC100% (4)

- Nset 4b3.9-g1 CumminsДокумент7 страницNset 4b3.9-g1 CumminsBarbaraОценок пока нет

- 3.internal Combustion Engine-21-30Документ10 страниц3.internal Combustion Engine-21-30Aqsa KanwalОценок пока нет

- 7.1. Emission Control SystemДокумент18 страниц7.1. Emission Control SystemChristian Icaza SamaniegoОценок пока нет

- Engine Mechanical: SectionДокумент136 страницEngine Mechanical: SectioncbОценок пока нет

- 202-F200betu Fl200betu 2019Документ99 страниц202-F200betu Fl200betu 2019URIEL CABALLEROОценок пока нет

- Actual Fuel-Air Cycles PDFДокумент28 страницActual Fuel-Air Cycles PDFanup chauhanОценок пока нет

- Table For Piping Manhour Estimative CalculationДокумент20 страницTable For Piping Manhour Estimative CalculationdanieltraduОценок пока нет

- 1104A-44TG2 ElectropaK PN1784 PDFДокумент2 страницы1104A-44TG2 ElectropaK PN1784 PDFSamir Yahia Kamal100% (2)

- Mikuni BS34 Idle Circuit TuningДокумент7 страницMikuni BS34 Idle Circuit TuningGuilhermeZikanОценок пока нет

- Volkswagen Engine and Transmission Codes: DTC DescriptionДокумент28 страницVolkswagen Engine and Transmission Codes: DTC DescriptionDanyBob100% (1)

- 3013C Pistons and Connecting Rods - Install - PDF Version 1 PDFДокумент4 страницы3013C Pistons and Connecting Rods - Install - PDF Version 1 PDFJaime Herrera LaraОценок пока нет

- Caterpillar MotorДокумент40 страницCaterpillar MotorSorin Iordache100% (2)

- Engine Data Sensors - Throttle and Brake ControlДокумент1 страницаEngine Data Sensors - Throttle and Brake ControlMisa GamezОценок пока нет

- BS 6 EmissionsДокумент32 страницыBS 6 EmissionsKawaljeet SinghОценок пока нет

- 4e Fe Toyota Pin OutДокумент3 страницы4e Fe Toyota Pin OutCristiam Aguilar100% (3)

- Types of Turbine EnginesДокумент11 страницTypes of Turbine EnginesLander MontojoОценок пока нет

- 2002 RSX - Intake Manifold Removal and Installation: Removal - K20A3 EngineДокумент8 страниц2002 RSX - Intake Manifold Removal and Installation: Removal - K20A3 Enginekel4n4Оценок пока нет

- WD615 Workshop Manual 20140Документ134 страницыWD615 Workshop Manual 20140George Jhonson84% (51)

- Otto CycleДокумент4 страницыOtto CycleRaven MercadoОценок пока нет

- Dash (Oct, 2015) EURO III VXДокумент147 страницDash (Oct, 2015) EURO III VXKishonkumar KishonОценок пока нет

- 2001 RacingДокумент224 страницы2001 RacingdensrxОценок пока нет

- Snowmobile Two Stroke 2005 Service ManualДокумент300 страницSnowmobile Two Stroke 2005 Service ManualАртёмОценок пока нет

- 3516 Top End OverhaulДокумент4 страницы3516 Top End OverhaulRosendo Maiga B50% (2)