Академический Документы

Профессиональный Документы

Культура Документы

3638 - Simba M7 C

Загружено:

heleloy1234Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3638 - Simba M7 C

Загружено:

heleloy1234Авторское право:

Доступные форматы

Atlas Copco Long-hole drilling rigs

Simba M7 C

Technical specification

www.atlascopco.com

M7 C

M7 C

Illustration shows rig with optional equipment mounted.

Long-hole drilling rig with tophammer rock drill. The Rig Control System (RCS) provides efficient and high precision drilling, longer consumable life and an ergonomic working environment. Ring drilling with parallel holes upwards/downwards up to 5.5 m apart. Hole diameter 5189 (102) mm.

Standard features

Rock drill

Atlas Copco COP 1800-series Dual-damping system for shock wave absorption and continuous rock contact for high penetration Lubricated and pressurized mating surfaces providing longer service intervals Shank adapters suitable for the given hole range

Control system

Rig Control System (RCS) Automation level: ABC Basic Angle reading instrument Rotation Pressure Controlled feed (RPCF) Dampening Pressure Controlled Impact (DPCI) Pre-set parameters for different drilling conditions Anti-jamming system

Drilling unit

Mechnized rod handling system Feed with hydraulic two-stage cylinder Front- and rear-mounted stingers Drill steel support for guidance during collaring and rod handling

Carrier

Mine-adapted carrier with articulated steering and four-wheel drive Low-emission, turbo-charged diesel engine

Positioning unit

Boom mounted drilling unit Accurate, smooth and proportional movements Mine-adapted, sturdy components

General

Operator panel mounted under canopy FOPS-approved protective roof Electrical cable reel Working lights under protective roof

Simba M7 C

Specifications

ROCK DRILL

COP 1838ME Shank adapter Hole diameter Impact power Impact rate Hydraulic pressure, max. Rotation motors Rotation speed Lub. air consump. (at 3 bar) Water consumption Weight R32, TC35, T38, T45 (TDS64) 5189 (102) mm 18 kW 54 Hz 250 bar 07/09 0210/0140 rpm 8 l/s 100250 l/min 171 kg

Electrical system

Total installed power ................................................... 118 kW Main motors ..............................................................2x55 kW Voltage ................................................................4001,000 V . Frequency .................................................................5060 Hz Transformer ....................................................................8 kVA Working lights mounted on roof .................... 35W, 24V HID Electronic overload protection for electric motors Digital volt/amperage meter in electric cabinet Phase sequence indicator Earth fault indicator Battery charger Cable reel

FEED

BMH 200-series BMH 214 BMH 215 3,465 mm 1,525 mm 3,670 mm BMH 216 3,770 mm 1,830 mm 3,975 mm

Air system

Screw-compressor ...................................... Atlas Copco GA 5 Capacity at 5400 rpm and 7 bar ......................................20 l/s Hydraulic driven axial piston motor .............................. 10 cc Adjustable flow/pressure Digital air pressure gauge External air supply connection for hole blowing

3,160 mm Total length 1,220 mm Drill rod length Total length with extractor 3,365 mm

Drilling unit

Rod Handling System, RHS 17 .............................. 17+1 rods . Adaptable to R32,TC35, T38, T45 (TDS 64) drill rods Adaptable to 4, 5 and 6 rods Mechanized drilling up to 32 m Rock drill lubrication surveillance system

Water system

Capacity at 15 bar boost ................................... max 250 l/min Minimum water inlet pressure ........................................ 2 bar Hydraulic drive, axial piston motor ............................... 10 cc Hydraulic driven water booster pump Digital water pressure gauge Water flow/pressure guard

Positioning system

Boom BUT 35BS (Ni-CR plated piston rods) Feed extension (with 4 drill steel) ............................. 900 mm Feed extension (with 5and 6 drill steel) ................ 1,200 mm Boom extension ...................................................... 1,600 mm . Rotary acurator BHR 30 for 360 ring drilling Stinger backward on feed .......................................BSJ 8-200 Stinger forward on feed ......................................... BSJ 8-115 . Feed dump, drilling ............. +90 forward and -10 backward Rig alignment laser

Carrier

Engine ..............................................Deutz TCD 2013L04 2V Power rating at 2,300 rpm ............................ 120 kW (163 hp) Tramming speed on flat ground ............................... >15 km/h Tramming speed on incline 1:8 .................................. >5 km/h Gradeability at max load on drive wheels .......................... 1:4 Torque at 1,400 rpm ...................................................572 Nm Hydrodynamic .................................Dana 24000 transmission Articulated steering .................................. 41 steering angle Front axle .............................................DANA Spicer 123/90 Rear axle ......................DANA Spicer 123/90, 8 oscillation . Tyres ........................................................................12.00 R24 Clearence outside axles ...................................................... 15 Hydraulic rear and front jacks ............................................2x2 Emergency and parking brakes .....................................SAHR Fuel tank, volume .............................................................110 l Electric system .................................................................24 V Batteries ........................................................ 2 x 125 Ah, 24V . Tramming lights ..............................................40W, 24V LED Service brakes 2 separate circuits (hydraulically applied, fully enclosed wet disc brakes) Automatic differential lock on front axle, limited slip Swingable seat for tramming/drilling, including safety belt Beacon warning lamp and break lights 12V outlet for communication radio Hydrostatic power steering system FOPS-approved protective roof Illuminated stairs for platform Central lubrication system Catalyser and silencer Four-wheel drive Boot washing kit Fire extinguisher Reverse alarm Warning horn Spirit levels

Control system

Rig Control System (RCS) versatile and upgradeable to a higher degree of automation Exposed components are designed and tested acc. to IP 65 USB-memory stick for transfer of data and storage of drill parameters Control panel mounted under canopy Drill settings for up to five different drill bits Integrated diagnostic system Angle reading instrument

Power pack

System pressure, max .................................................. 250 bar Hydraulic oil tank, volume max/min ....................... 250/200 l Filtration, absolute ........................................................ 16 m . Oil temperature gauge with thermostat Hydraulic pump for rotation, positioning, feed Water cooled oil cooler in stainless steel Low oil level indicator and shut-down Smart oil leakage shut-down system Hydraulic pump for percussion Electric oil filling pump Mineral hydraulic oil Oil filter indicator

Simba M7 C

Specifications

DRILL STEEL

Rock drill Hole diameter, mm Drill rod Shank adapter Guide tubes

COP 1838ME COP 1838ME COP 1838HE COP 2550UX COP 2550UX

5164 6476 7689 89102 89102

R32 Speedrod T38 Speedrod T45 Speedrod T51 TDS 64/TDS 76

R32 T38 T45 T51 ST58

TDS 45 TDS 56/TDS 64 TDS 64/TDS 76 TDS 76 N/A

Optional equipment

Drilling system

Water mist flushing, water oil cooler, external air supply Water mist flushing, air oil cooler, external air supply Hole blowing kit Dry drilling system COP 1838MEX/COP 1838HE/COP 1838HEX, COP 2550UX

Cabin

FOPS-approved cabin: - Mediaplayer with USB port - Boot washing kit - Air conditioning unit without heating Stainless steel cabin Air conditioner with heating Front window, 24 mm Swingable operators seat FOPS-approved grizzly bar for front window Reversing camera with monitor Joystick controlled spotlight

Positioning system

Automatic lubrication for positioning/drilling system Central lubrication for positioning/drilling system Rod handling system RHS 27 on request (up to 51 m) Thread lubrication kit Stinger extension pieces

Carrier

Fire suppression system, manual Fire suppression system, automatic (check-fire) Fire suppression system, full automatic Particle filter UNIKAT Brake lights L-carrier Solid tyres Deutz TCD 2013 L06 2V, 175 kW (238 hp)

Automation

Simba ABC Regular Drill Plan Handling Full Drill Data Handling Rig Remote Access Breakthrough Automatic Stop Text Message System Remote Cradle Control/Remote Feed Control Void Detection Total station navigation

Miscellaneous

Manual rig washing kit Manual lubrication kit Hose and cable guide at water/cable reel Link-one parts book Remote operating kit Additional panel Manual spotlight

Water system

Water hose reel with dual control

Power packs

Heater kit

Electrical system

Soft start for 400700 V Electrical cable on reel, H07RN-F Electrical cable on reel, Buflex Plug PC4 Plug PC5 Socket PC4 Socket PC5 Switch gear Electrical outlet, 16 A Extra transformer, 15 kVA Extra working lights, 2 x 200 W, 24 V (on tripod)

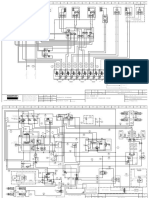

Simba M7 C

Measurements

SIDE vIEw

www.atlascopco.com

2960

M7 C

M7 C

2900

3740 11560

4000

Copyright 2010, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos in this brochure may show equipment with optional extras. Specifications and equipment are subjects to change without notice. Consult your Atlas Copco Customer Center for specific information.

COvERaGE aREa

Dimensions in mm 1200 (900) Feed extension 850 Stinger extension

50 11

16 00

10

7850

90o 45o 360o

25o 35o Dimensions with 45o boom-lift 25o boom-swing

150 3900 1600

2000 Stinger extension

Dimensions with 0o boom-lift 35o boom-swing

TURNING RaDIUS

depending on surface mm Outer Inner 6,250 3,800

wEIGHT

gross weight kg Total Boom side Engine side 17,800 12,300 5,500

DIMENSIONS

mm Width Height tramming Height roof up Height with cabin (option) Length tramming Ground clearance 2,350 2,960 2,960 3,050 9,460 205 400 V 440 V 440 V H07RN-F H07RN-F Buflex H07RN-F Buflex H07RN-F Buflex H07RN-F Buflex Buflex 4G150 4G120 3x150+3G35 4G120 3x150+3G25 4G95 3x120+3G25 4G70 3x95+3G16 3x50+3G10

RECOMMENDED CaBLE SIZE aND LENGTH

voltage Type Dimension, mm2 Diameter, mm 67 60 52 60 52 55 46 49 42 32 Length, m 60 75 100 75 100 90 135 110 155 275

NOISE aND vIBRaTION

Operator sound pressure level in canopy, drilling, free field (ISO 11201) Operator sound pressure level in cabin, drilling, free field (ISO 11201) Operator sound pressure level working close to machine, drilling, free field Sound power level (ISO 3744), drilling, free field Vibration levels seated, drilling (ISO 2631-1) Vibration levels standing, drilling (ISO 2631-1) 106+-6 dB(A) re 20uPa 75+- 3 dB(A) re 20uPa 106+-6 dB(A) re 20uPa 126 dB(A) re 1pW 0.07+- 0.07 m/s^2 0.07+- 0.07 m/s^2

460500 V 460500 V 500550 V 500550 V 660700 V 660700 V 1,000 V

900

6140

Parallell holes with 0o boom-lift 35o boom-swing Coverage area 1100x4690 mm

700

9851 2194 01b

G = Protection yellow/green Recommendations are given for surrounding temperature of 30oC.

11/2010

Вам также может понравиться

- ST2G FolletoДокумент4 страницыST2G Folletomarcelonieto761Оценок пока нет

- 9851 3499 01 - L Feed Beams 6000 BMH6818Документ9 страниц9851 3499 01 - L Feed Beams 6000 BMH6818Zhang JieОценок пока нет

- Boltec M, L and SДокумент3 страницыBoltec M, L and SDamian SaldarriagaОценок пока нет

- 1253 s10 ScalerДокумент5 страниц1253 s10 ScalerpauloОценок пока нет

- TransmisioДокумент34 страницыTransmisioWilliams ArayaОценок пока нет

- Boltec S: Start The EngineДокумент2 страницыBoltec S: Start The EngineerwinОценок пока нет

- Spraymec 6050 WPCДокумент3 страницыSpraymec 6050 WPCPatop CofréОценок пока нет

- Technical Specification Boltec SДокумент4 страницыTechnical Specification Boltec SNoemy Margoth WuОценок пока нет

- Mr-hl500 Data SheetДокумент1 страницаMr-hl500 Data SheetAlmaОценок пока нет

- Th430 Specification Sheet EnglishДокумент8 страницTh430 Specification Sheet EnglishAmanda TaylorОценок пока нет

- 00-01 Boltec S - Course IntroductionДокумент6 страниц00-01 Boltec S - Course IntroductionALVARO ANTONIO SILVA DELGADOОценок пока нет

- Sandvik Lh204 Underground Loader: Technical SpecificationДокумент7 страницSandvik Lh204 Underground Loader: Technical SpecificationRigo McFly Casanova ArmijoОценок пока нет

- DS312 Specification Sheet EnglishДокумент4 страницыDS312 Specification Sheet EnglishAntonio BocanegraОценок пока нет

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaДокумент8 страниц13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Оценок пока нет

- Perforadora Montabert HC 50: ReseminДокумент12 страницPerforadora Montabert HC 50: ReseminAdolfo MarcosОценок пока нет

- Sandvik Dd311 Development Drill: Technical SpecificationДокумент4 страницыSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeОценок пока нет

- 04 Simba E7Документ5 страниц04 Simba E7AlejandoОценок пока нет

- Jumbo Ficha TecnicaДокумент4 страницыJumbo Ficha TecnicaRodrigo FooОценок пока нет

- DD210-V 9604sb PDFДокумент4 страницыDD210-V 9604sb PDFBrandon MoralesОценок пока нет

- Planos Electrcos Ehidraulicos Jumbo s1dДокумент116 страницPlanos Electrcos Ehidraulicos Jumbo s1dseverinoОценок пока нет

- PerforadorasДокумент2 страницыPerforadorasElias Silva100% (1)

- Spec ST3.5 9851 2254 01 G - tcm836-1532853Документ4 страницыSpec ST3.5 9851 2254 01 G - tcm836-1532853IoannisVourdounisОценок пока нет

- Single & Dual Load Sensing, Accumulator Charging ValveДокумент8 страницSingle & Dual Load Sensing, Accumulator Charging Valvetystar_21Оценок пока нет

- 8792869899.1en Easer L OperationДокумент180 страниц8792869899.1en Easer L OperationAngel Bernachea100% (2)

- Taladro Largo Simba s7dДокумент98 страницTaladro Largo Simba s7dJorgeLuisAvalosCaldas100% (1)

- Muki Bolter: Roof Bolter For Small SectionsДокумент4 страницыMuki Bolter: Roof Bolter For Small SectionsJose Antonio Sanchez SegoviaОценок пока нет

- LH201 9900sbДокумент4 страницыLH201 9900sbmarix12Оценок пока нет

- Sandvik Rd525 Rock Drill: Technical SpecificationДокумент2 страницыSandvik Rd525 Rock Drill: Technical SpecificationWaltherEnriqueAlcocerОценок пока нет

- Simba Range SelectionДокумент1 страницаSimba Range SelectionVeronica BeatrizОценок пока нет

- MONTABERT HC112 Tech Spec 1 PDFДокумент1 страницаMONTABERT HC112 Tech Spec 1 PDFSaid TouhamiОценок пока нет

- 8999 5718 00 Diagrams and DrawingsДокумент140 страниц8999 5718 00 Diagrams and DrawingsMicaelОценок пока нет

- Especificaciones DT820Документ5 страницEspecificaciones DT820Jorge Cid BlancoОценок пока нет

- Simba 1354Документ4 страницыSimba 1354Manuel Uturunco AguilarОценок пока нет

- Sandvik TH550 TechspecДокумент3 страницыSandvik TH550 TechspecDaniel LopezОценок пока нет

- Battery To Batter Charger1Документ1 страницаBattery To Batter Charger1Akil ShaikhОценок пока нет

- DD311 Planos HidráulicosДокумент8 страницDD311 Planos HidráulicosBrayan vidal López GuzmánОценок пока нет

- Hydraulic Drifter: Innovative DesignДокумент2 страницыHydraulic Drifter: Innovative DesignEsty50% (2)

- Manuel Partes ElectricoДокумент28 страницManuel Partes ElectricoAndersonОценок пока нет

- 00 RCS Presentation SP3Документ28 страниц00 RCS Presentation SP3yeya1963titoОценок пока нет

- LF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Документ2 страницыLF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Max RojasОценок пока нет

- Boltec 235Документ4 страницыBoltec 235Ronald Osorio100% (1)

- RCS Brochure Tcm533-1172411Документ8 страницRCS Brochure Tcm533-1172411Ronald OsorioОценок пока нет

- 9851 3586 01 COP MD20 BrochureДокумент4 страницы9851 3586 01 COP MD20 BrochureEduardo MassainiОценок пока нет

- Datos Tecnicos LH202Документ8 страницDatos Tecnicos LH202Roel Aroni CuaresmaОценок пока нет

- 3-Gama de Productos - Simbas (Документ31 страница3-Gama de Productos - Simbas (dan roy wouters sarabiaОценок пока нет

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFДокумент4 страницыTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFTamara Monsalve100% (1)

- 9852 2944 01d Settings COP 1838HD+ - VerFДокумент1 страница9852 2944 01d Settings COP 1838HD+ - VerFrodolfoОценок пока нет

- Sistema Hco EJC 145 (Colores)Документ92 страницыSistema Hco EJC 145 (Colores)JorgeОценок пока нет

- Danfoss 520l0954Документ32 страницыDanfoss 520l0954joeccorrrea100% (1)

- Ejc 145 4ydДокумент3 страницыEjc 145 4ydAngel Medina CutiОценок пока нет

- Boomer S 1D PDFДокумент4 страницыBoomer S 1D PDFlorenzo henerОценок пока нет

- Columna DTH Simba M4C ITH - CondestbleДокумент9 страницColumna DTH Simba M4C ITH - CondestbleRonald OsorioОценок пока нет

- Raise Boring Heads: User ManualДокумент40 страницRaise Boring Heads: User ManualMaykol Ken Hasaki MaselОценок пока нет

- Minetruck MT436B 9851 2249 01N tcm833-1540890 PDFДокумент4 страницыMinetruck MT436B 9851 2249 01N tcm833-1540890 PDFLuis Hernández BarrazaОценок пока нет

- Simba Atlas Copco PDFДокумент4 страницыSimba Atlas Copco PDFdiego0% (1)

- Simba M4 C PDFДокумент4 страницыSimba M4 C PDFTamara MonsalveОценок пока нет

- Especificaciones MT-2010Документ4 страницыEspecificaciones MT-2010HEMER LUIS RIVERAОценок пока нет

- Boltec MC - 9851 2202 01fДокумент4 страницыBoltec MC - 9851 2202 01fPablo Luis Pérez PostigoОценок пока нет

- Atlas Copco ST2DДокумент4 страницыAtlas Copco ST2DJohnny ZhangОценок пока нет

- Flyer Dredge enДокумент9 страницFlyer Dredge enheleloy1234Оценок пока нет

- Ayvaz Marine ProductsДокумент55 страницAyvaz Marine Productsheleloy1234Оценок пока нет

- DH DT2 EngДокумент4 страницыDH DT2 Engheleloy1234Оценок пока нет

- Analysis of Support Design Practice at Elmalik Portals of Bolu Tunnel Bolu Tuneli Elmalik Agzinda Tahkimat Tasarimi Uygulamasinin AnaliziДокумент211 страницAnalysis of Support Design Practice at Elmalik Portals of Bolu Tunnel Bolu Tuneli Elmalik Agzinda Tahkimat Tasarimi Uygulamasinin Analiziheleloy1234100% (1)

- KD79K690H01 PDFДокумент27 страницKD79K690H01 PDFjacleeОценок пока нет

- Dry All LiteratureДокумент8 страницDry All LiteraturekrechbaОценок пока нет

- Samsung AS09 12 HPBN Service ManualДокумент54 страницыSamsung AS09 12 HPBN Service ManualMega - Remote Service MrsОценок пока нет

- DUOL Innovative Structure Solutions ENG WEB Katalog 2022 PDFДокумент40 страницDUOL Innovative Structure Solutions ENG WEB Katalog 2022 PDFtrinitron12345Оценок пока нет

- Psa012b821bf EnglishДокумент52 страницыPsa012b821bf EnglishDirt FilterОценок пока нет

- Brochure Air-Conditioners 20180306 enДокумент20 страницBrochure Air-Conditioners 20180306 enalaaОценок пока нет

- LG Air Cooled Screw Chiller (60 HZ, R134a) High Compact - 6CHAC-0Документ129 страницLG Air Cooled Screw Chiller (60 HZ, R134a) High Compact - 6CHAC-0Anonymous ixIhrPM2Оценок пока нет

- Data Center TechnologyДокумент38 страницData Center TechnologyBagus Aj100% (1)

- Elements of Mech Engg-FinalДокумент5 страницElements of Mech Engg-Finalabddul128Оценок пока нет

- How Does Evaporative Cooling WorkДокумент2 страницыHow Does Evaporative Cooling Worksunil kumarОценок пока нет

- Cooling Load CalculationДокумент90 страницCooling Load CalculationmiraqueelaliОценок пока нет

- Whirlpool Error Codes nON 3d CoolДокумент9 страницWhirlpool Error Codes nON 3d CoolNavjot KaurОценок пока нет

- DAIKIN VAM VRV HVE ModelДокумент5 страницDAIKIN VAM VRV HVE ModelPads PrietoОценок пока нет

- High Static Pressure Duct: Specifications 60HzДокумент3 страницыHigh Static Pressure Duct: Specifications 60HzPrimero Valencia LuisОценок пока нет

- Free Energy - Passive Solar CoolingДокумент21 страницаFree Energy - Passive Solar CoolingGiuseppe VaccinaОценок пока нет

- Validation of A Vapour Compression Refrigeration System Design ModelДокумент7 страницValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87Оценок пока нет

- Multiprocess Control SystemДокумент26 страницMultiprocess Control SystemSagar MorjeОценок пока нет

- Everest Air Conditioning CompanyДокумент11 страницEverest Air Conditioning CompanyAdorabel Limpahan Singco LptОценок пока нет

- Air Cooled Chillers 50Hz 20131203Документ39 страницAir Cooled Chillers 50Hz 20131203Dragos PicuОценок пока нет

- تصميم مكثف بنموذجينДокумент10 страницتصميم مكثف بنموذجينAHMAD DiabОценок пока нет

- Ascott Accessories Brochure 2022Документ20 страницAscott Accessories Brochure 2022msinanacikgozОценок пока нет

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaДокумент36 страницCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaОценок пока нет

- Códigos de Avería Genéricos y Específicos. Acceso GratuitoДокумент10 страницCódigos de Avería Genéricos y Específicos. Acceso Gratuitowilson orlando morales ospinaОценок пока нет

- MFL39754859 - Owners Manual 2013 PDFДокумент24 страницыMFL39754859 - Owners Manual 2013 PDFTenali RamanОценок пока нет

- Multi MitsubishiДокумент204 страницыMulti MitsubishiMaleyPedro GonzalesОценок пока нет

- Catalouge kĩ thuật VRVДокумент912 страницCatalouge kĩ thuật VRVHoangNguyen167100% (1)

- Absorption ChillersДокумент49 страницAbsorption ChillersNallasivam Be A BizzaroОценок пока нет

- Section 4 Schedule of Compensation - 200013Документ18 страницSection 4 Schedule of Compensation - 200013Mohammad Amin AliОценок пока нет

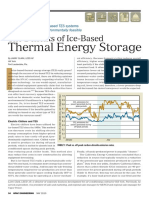

- Thermal Energy Storage: The Benefits of Ice-BasedДокумент4 страницыThermal Energy Storage: The Benefits of Ice-BasedinnuRVОценок пока нет