Академический Документы

Профессиональный Документы

Культура Документы

Bonpet Zlozenka Eng

Загружено:

cchristt2584Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bonpet Zlozenka Eng

Загружено:

cchristt2584Авторское право:

Доступные форматы

The plant supervising devices The designing of the stationary extinguishing plant depends on the built in mechanical components

which enable the good performance of the plant at all times and which will signal the errors in the system. The built in components for protection and supervision are: the preparation group (pressure regulator) for the spraying gas, the closing valves, the safety valves, manometers and pressure switches. The pressure switches supervise the pressure of the spraying gas in the pressure container with the extinguishing liquid BONPET and the pressure of the compressed air which serves to open the automatic ball valve. Should a lower working pressure than the one originally set in be detected, a signal will be sent to the control centre which will then Dispositivos de supervisin del sistema Bonpet require the inspection of the plant. El diseo del sistema fijo de extincion bonpet depende de incorporartank with The automatic ball valves are equipped with an additional los elementos mecanicos que permitan un buen desempeo del sistema enthe liqcompressed air which enables repeated opening of valves to let todo momento. Los componentes claveseven la proteccion y supervision son: el uid into the extinguishing zone para if the compressed air may tempogrupo de preparacion (regulador de presion) para el gas presurizado, las valvulas rarily not be available. de cierre, las valvulas de seguridad, manometros y switches de presion. Los operation stages of the stationary extinguishing plant The de operacion del sistema fijo extincion Bonpet Etapas La planta operar en dos in two regimes: The plantoperar en dosetapas: La planta will operate etapas: a) modo espera a) stand espera a) modo by **Los dispositivos manuales yyautomticos de sealizacin, swicthes de presin The automatic and manual signalling devices, pressure switches are Los dispositivos manuales automticos de sealizacin, swicthes de presin son supervisados por elV panelde control de incendios con 24v. supervised with 24 voltage control de incendios centre. son supervisados por elpanel de fire fighting controlcon 24v. If the pressure of the spraying gas in pressure container with BONPET *Si lathe pressure of thecon Bonpet oolaair whichdeaire caen con la apertura de or presin del cilindro compressed presin opens the con la apertura *Si lapresin del cilindro con Bonpet lapresin de aire caenball valve drop, la the pressure switch de presin manda una una sealfire extinguishing vlvula bola, el switch will signal the trouble to the panel de control de la vlvula bola, el switch de presin manda seal panel de control de de incendios. centre. control incendios. b) Extintor de incendios b) fire extinguishing * La deteccin de incendios (La sealizacin, as como la extincin del The fire detection (the signalling of the fire as well as the fire incendio sern activados manualmente o podra activarse the fire will be detected by extinguishing will be activated manually or mediante un sistema de deteccin automtico). the automatic fire detection). * El suministro elctrico The alarm goes off en la zona deteccin del incendio ser desconectado. * La seal ser comunicada al panel de control y la brigada de incendios. The electric supply in the zone of fire detection will be disconnected * La extincin en la zona afectada, se dar con la apertura de la vlvula The signal will be communicated to the control centre and to the fire automtica. brigade * Las alarmas se desactivaran automticamente. The extinguishing with the signal opening the automatic ball valve in the defined zone

The procedures for manufacturing and erection of the stationary extinguishing plant These include: Design The client preparing the place for the cabinet with the components of the stationary extinguishing plant and a free route for the pipeline to the zones of extinguishing the fire, the connection to the compressed air to the cabinet with the elements of the stationary fire extinguishing plant Erection of the plant Pressure testing of the plant Filling in with the fire extinguishing liquid BONPET Inspection of the plant by a company authorised to inspect the systems af active fire protection Training of staff who will operate the stationary extinguishing plant (to be appointed by the client) Certificate of acceptance of the plant by the Client .

BONPET SYSTEMS - MISSION We provide people with the best top-level quality technology BONPET products are easy to use, and increase the level of their safety, or protection of their property against fire. We, the employees, are the holders of our success, as together we create a dynamic and professional working environment that stimulates team work and the exchange of knowledge at the national and international level. We are committed to quality and reliability. We always put the satisfaction and safety of our users and their property at the centre of all our activities. BONPET SYSTEMS - VALUES A. TOP-LEVEL QUALITY TECHNOLOGY OF BONPET PRODUCTS Buyers, their safety and satisfaction with our products that is the centre of our operation. B. SPEED AND FLEXIBILITY Through speedy response and ability of adapting we can master all hurdles that are imposed on us by different marketing and legislative requirements. We can handle any challenge no matter the size of the occurring problem. With knowledge, innovations and flexible solutions we know how to fulfil expectations our partners have, no matter how impossible some expectations might seem. C. PARTNERSHIP AND TRUST We work on building good relationships with our partners and employees. These are the foundations of a good relation towards our partners, buyers, suppliers and everyone we live with. Only with good and open human relationships is it possible to incorporate the success of the business into our primary mission. BONPET SYSTEMS - VISION We wish to, at the national and worldwide markets, establish ourselves as a well known, successful and reputable enterprise that constantly strives towards greater success and effectiveness.

Inspection of stationary fire fighting plant The inspections of the plant for active fire protection shall be carried out in accordance with the valid regulations and the instructions for maintenance of the plant The daily visual inspections will be carried out by means of manometers and monthly inspections by the client in accordance with the procedures stipulated by the manufacturer. Every six months the inspection will be carried out by the manufacturer of the stationary fire extinguishing plant. The inspections and the eventual trouble shooting on the stationary fire extinguishing plant will be logged in a diary. The equipment life expectancy The plant is designed to serve for minimum ten years. This period may be extended by means of regular check ups and the necessary maintenance. The fire extinguishing liquid BONPET in the pressure container will be exchanged every five years, Should the liquid be consumed for putting out the fire the pipeline and the nozzles need to be replaced too. The warranty period of the active fire extinguishing plant is one (1) year if used according to instructions of the manufacturer.

BONPET SYSTEMS D.O.O. Obrtnika cesta 30 1420 Trbovlje Slovenia

Business premises: Gabrsko 11a 1420 Trbovlje Slovenia

Tel: +386/356-14-720 Fax:+386/3 56-14-722 E-mail: info@bonpet.si www.bonpet.si

BONPET FIRE EXTINGUISHING AMPOULE FIXED BONPET FIRE SAFETY SYTEMS

BONPET FIRE EXTINGUISHING AMPOULE

We would like to introduce our automatic Bonpet extinguishing ampoule that, because of its method of operation, enables you to assure fire protection of potential fire sources even on locations that so far have not, due to economic reasons, had the possibility of having an appropriate and needed fire protection with the installation of large fixed fire safety systems. it is the only fire extinguisher in the whole world that is not affected by any human or technological factor (it has an aesthetic look which reminds us of a lamp); no additional damage is caused by the extinguishing, as the liquid that stays on the surface is simply wiped up; it is environment friendly (safe for people and environment); it has a long lifetime of 10 years; no maintenance is needed (one should only keep an eye on the glass so it does not get damaged); it is easy to assemble and, in case of removal to another premises, easy to dismantle as well. In Slovenia the ampoule has been tested at the Slovenian National Building and Civil Engineering Institute in Ljubljana (P 653/99-530-2: extinguishing of kitchen fire, P 651/99-530-1: extinguishing of flammable liquids). On the basis of Technical Agreement (URSZR GS 01 02 01 00), issued by the Slovene Ministry of Defence in 2001, Protection and Rescue government, conformity declaration accompanies these ampoules. Dimensions, Weight, Colours Each ampoule contains 600 millimetres of liquid extinguishing product in a closed glass ampoule. Dimensions: 300 mm x 90 mm x 60mm Weight: 1030 g Examples of installing ampoules in housekeeping: Kitchen: above the kitchen-range Boiler room: above the oil burners or when using solid fuel above the stove Examples of installing ampoules in enterprises: Kitchens: tea kitchens above the kitchen-range, in restaurant kitchens near the kitchen-ranges, grill plates, Computers in constant running: above the computers in the cabinet they are in, or if not in a cabinet, onto the wall above the computers, Electrical gadgets and machines in areas where constant human pres ence is not assured, Electro and compensative cabinets: in the upper parts of the cabinets, Boiler rooms: above the burners, Laboratory glass cases, Lacquering workrooms, Installation shafts, Smaller and handy storehouses used for storing flammable liquids, Lift engine rooms, Substitutive electrical generator set, Archives, Holiday cottages (kitchen, boiler rooms, steam accumulation stoves, etc.), Application with the method of throwing: security staff members or duty staff members, fire fighters, and locations where fire risk is much higher and human presence is constant..

FIXED BONPET FIRE SAFETY SYTEMS

Considerable damages in textile and paper industry caused by fires forced the man even at the beginning of the industrial age to search for a way of protecting the property against fire. In 1874 already this search led to the invention of an extinguishing plant consisting of pipelines with spraying nozzles which turned out to be the first automatic sprinkler using water as extinguishing substance. The system has basically remained the same until today. Only the extinguishing substances have been changed in order to improve the efficiency of extinguishing and thereby reducing the damages which may occur in such fires. Stationary low pressure fire extinguisher Our basic purpose is to protect the property by a stationary fire extinguisher especially in large open areas threatened by fires. It is particularly suited to extinguish fires of class A (solid substances) and class B (inflammable liquids). This appliance uses the extinguishing liquid BONPET which is classified among special extinguishing substances. The stationary extinguisher is classified among drenching systems though it does not actually operate as drenching system (system of immersing or flooding). Due to the extraordinary capabilities of extinguishing fires there is a surprisingly small quantity of liquid BONPET in the pressure container. The appliance is classified among the low pressure systems operating at the pressure of up to 5 bar. Advantages of the fire extinguishing plant with a special extinguishing substance Bonpet: Efficient putting out of fires with comparatively small quantity of BONPET liquid The BONPET liquid dinsintegrates biologically; there is no pollution caused by fire extinguishing. The plant is acceptable in terms of price levels (Material requires low 7,5 bar test pressures) The fire extinguishing is carried out without sealing of the rooms (as opposed to the extinguishing with CO2) The beginning of the extinguishing process is not subject to prior evacuation of staff The surfaces get covered with a protective film preventing re-ignition. Technically not demanding and cost effective maintenance Efficiency proved also by test extinguishing of fires in varnishing chambers, fires on inflammable liquids, on transformers The extinguishing liquid BONPET is not hazardous to human health or Designing of a stationary extinguishing plant Based on the inspection of the building and of the drawings of the rooms with technological equipment the designs shall be elaborated with taking into account the valid rules regulating the field of active fire protection. The determining of the number of fire extinguishing zones which in turn depends on the lay-out of plant and equipment or material in the rooms shall constitute the basis for elaboration of the designs. Based on the thus defined zones the necessary quantity of BONPET liquid shall be stipulated. The largest quantity stipulated per each container determines the size of the pressure container. The components of the fire extinguishing plant The stationary fire extinguishing plant is composed of electrical and mechanical components. The mechanical components are: Hot enamelled pressure container, exterior of the container anti corro sion protected Cylinder with pressure gas (nitrogen) Pressure regulation group Connecting material for pipes (reducing coupler, pipe clips, T- joints, stoppers) Zinc coated pipes of various sizes Nozzles Closing valves Pressure valves Safety valves Manometers Automated ball valves with compressed air tank Module for erection of the plant components The electrical components are: Automatic fire signalling Manual signalling of fire and activators of extinguishing Stop button to suppress the extinguishing Fire alarm Connecting electrical conduits Fire fighting control centre Operating of the stationary fire extinguishing plant The main criteria for choosing the stationary extinguishing plant operation mode is the simplicity and a non demanding mode of operating and maintenance. The extinguishing liquid BONPET is placed in a pressure container. The operation pressure is maintained by means of reduction valves on the nitrogen cylinder. In the zones defined for extinguishing there are automatic and manual fire signalling devices which are supervised by the fire fighting control centre. The fire extinguishing liquid flow into the pipeline is suppressed with automated ball valves which are opened by a signal from the fire fighting control centre and thereby enable the flow of liquid to the nozzles in the fire extinguishing zones. GRAJENA GASILNA NAPRAVA NA GASILNO SREDSTVO BONPET DELOVANJE

SIGNAL TO THE SURVEILANCE CENTRE OR FIRE DEPARTMENT

Fixed fire safety system scheme:

POWER SWITCH

9 6

3 3

7 13 12 8 10 11 11 12

15 14 13 15 14 10 13 65

ZONE 1

13

ZONE 2

17

2 1

13

13 17

16

The intended use of Bonpet ampoule: Bonpet extinguishing ampoules are intended for the use of automatic extinguishing of initial fires in small enclosed areas where potential fire sources are normally present - usually such fire sources are electrical installations in continuous operation. Constant presence of human control is not assured. They are required at all the areas where human access to the area is difficult and where opening would accelerate the progress of fire in the area. Installation of the ampoule is recommended due to its following characteristics: automatic operation, which means that extinguishing of all starting fires is effective and lives are protected (in houses, companies, nauti cal science etc.); there are no false alarms, because the ampoule activates only with the rise of temperature; the ampoule can also be used by throwing it directly into the centre of fire source; it is easy to use and human panic and confusion factors are therefore not present; it is installed close to the security guards, next to potentially dangerous fire sources;

COMPRIMISED AIR 5 bar

18

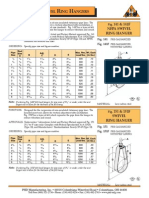

Legend of the individual items components of the stationary extinguishing plant - drawing setting out the composition of the plant in one zone: 1. The nitrogen cylinder 2. Nitrogen reduction valve 3. Manual valve gas 4. Return gas valve 5. Manometer 6. Pressure switch to be set with signalling to fire extinguishing plant control centre 7. Safety valve 8. Pressure container for BONPET liquid 9. Outlet valve 10. Automated ball valve with electrical activating (the valve opens at the control voltage 24 V and remains open; the valve is shut manually. 11. Pipeline 12. Nozzles 13. Automatic signalling notifying of the fire 14. Manual signalling notifying of the fire 15. Alarm 16. Fire extinguishing control centre

Examples of installing ampoules in nautical science: Engine rooms, Kitchen. Criteria for installation of Bonpet fire extinguishing ampoule: A class fire: 8m3 of volume or 4m2 surface of the closed area B class fire: 44x44 cm of flammable liquid burning area The ampoule is stuck into a pylon that is previously screwed on above the area of a potential fire source, on the wall and ceiling, a computer cabinet, electro cabinet with the main safety fuses, as well as compensative cabinets. This way of placing the ampoule enables the liquid in the ampoule to reach the activation temperature as quickly as possible. Professional advice: Our professionals who have been learning about ampoules through carrying out different tests of extinguishing fires of different materials are always at hand to advise you when deciding on the location of installing Bonpet fire extinguishing ampoules and, if requested, carry out training. They can also provide you with a professional installation of the ampoules.

Colours: there are eight different colour versions of the ampoule (as demonstrated), but when ordering large quantities of the product, other colour versions are possible as well. Additional alternatives: an additional switch, used for informing the fire station in case of acti vation of extinguishing, can be added to the ampoule, Bonpet ampoule can be protected with a protective net which prevents damage to the glass, a shoulder bag used by the security guard if he needs to carry the ampoule with him when going on long rounds.

Вам также может понравиться

- Gas detection and safety systems overviewДокумент4 страницыGas detection and safety systems overviewinfo5922Оценок пока нет

- Procedures For Inspection, Testing & Commisionning of Fire Extinguisher SystemДокумент29 страницProcedures For Inspection, Testing & Commisionning of Fire Extinguisher Systemfazrenkamarudin100% (1)

- Training ManualДокумент15 страницTraining Manualrajeshrahul321Оценок пока нет

- Fire Protection Manual GuideДокумент16 страницFire Protection Manual GuideSadiq Basha100% (3)

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingДокумент18 страницIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaОценок пока нет

- Bonpet System - Fire DefenderДокумент3 страницыBonpet System - Fire DefenderDevadoss DossОценок пока нет

- Evolution-Advanced: Analogue Addressable Heat Sensor Instruction ManualДокумент8 страницEvolution-Advanced: Analogue Addressable Heat Sensor Instruction Manualzoran_stevОценок пока нет

- Maintenance ManualДокумент16 страницMaintenance ManualAbdul HakkimОценок пока нет

- Maintenance SheetДокумент2 страницыMaintenance Sheetnauman18Оценок пока нет

- Mosquito Magnet Defender InstructionsДокумент18 страницMosquito Magnet Defender InstructionsMrFixit1328Оценок пока нет

- Buderus Logamax - GB142 - Service Instructions - en - 2-2010Документ132 страницыBuderus Logamax - GB142 - Service Instructions - en - 2-2010Vasiliu Alex50% (2)

- FgsДокумент6 страницFgs312818203016 KAMARAJ J III CMEОценок пока нет

- Procon Boiler Leak DetectionДокумент7 страницProcon Boiler Leak DetectionJans FernandezОценок пока нет

- Conventional FireДокумент5 страницConventional FiremohammadОценок пока нет

- 23BTVEДокумент36 страниц23BTVECsaba SzalaiОценок пока нет

- VSP-6.3-GS-M-7 Internal AuditДокумент18 страницVSP-6.3-GS-M-7 Internal AuditPavan Sameer Kumar CОценок пока нет

- Gas Detection SystemДокумент20 страницGas Detection SystemMikhail BagliukОценок пока нет

- Kitchen Ventilation UV-C WarningДокумент22 страницыKitchen Ventilation UV-C Warningmalekrifai0% (1)

- Manuais - Autoclave 12L - 300051308 Rev 02Документ24 страницыManuais - Autoclave 12L - 300051308 Rev 02Arif HidayatОценок пока нет

- Baxi Luna Comfort ManualДокумент290 страницBaxi Luna Comfort ManualYannis GlombОценок пока нет

- Fire Protection MaintenanceДокумент4 страницыFire Protection MaintenanceFridaytenAprilSalinasОценок пока нет

- Fire Safety Logbook: Greater Manchester Fire and Rescue ServiceДокумент18 страницFire Safety Logbook: Greater Manchester Fire and Rescue ServiceSisayDesalegnОценок пока нет

- Fire Protection and Suppression SystemДокумент4 страницыFire Protection and Suppression Systemamrit90320Оценок пока нет

- Automatic Fire Sprinkler SystemsДокумент3 страницыAutomatic Fire Sprinkler SystemsNiong DavidОценок пока нет

- User Manual and Installation Instructions: Riva Compact HeДокумент44 страницыUser Manual and Installation Instructions: Riva Compact Hecaffran44Оценок пока нет

- Detect tube leaks earlyДокумент4 страницыDetect tube leaks earlyViV CroneОценок пока нет

- Tech Spec of Nitrogen InjectionДокумент5 страницTech Spec of Nitrogen InjectionJustin MyersОценок пока нет

- Fire Fighting Guide (Compatibility Mode)Документ10 страницFire Fighting Guide (Compatibility Mode)waikin118Оценок пока нет

- OMC 1108 ManualДокумент8 страницOMC 1108 ManualmrkbsmОценок пока нет

- Model AV-1-300 Alarm Check Valve CareДокумент7 страницModel AV-1-300 Alarm Check Valve CareNursyafika JasmiОценок пока нет

- Procon Boiler Leak Detection Ask Rev 2012Документ7 страницProcon Boiler Leak Detection Ask Rev 2012Vic BaltОценок пока нет

- Stack Monitoring KitДокумент53 страницыStack Monitoring KitknbiolabsОценок пока нет

- IQ8 Integrated Specs Fire and Voice AlarmДокумент23 страницыIQ8 Integrated Specs Fire and Voice AlarmRa ArОценок пока нет

- Fire DBRДокумент10 страницFire DBRD.SathyanarayananОценок пока нет

- Sense Point Technical HandbookДокумент45 страницSense Point Technical HandbookMaricruz RodríguezОценок пока нет

- Nittan EV-PH Sensor ManualДокумент8 страницNittan EV-PH Sensor Manualzoran_stevОценок пока нет

- Install & Maintain Alarm Valve ComboДокумент32 страницыInstall & Maintain Alarm Valve ComboMSSОценок пока нет

- Inergen System AnsulДокумент2 страницыInergen System AnsulJayFouresОценок пока нет

- Installation and Maintenance Manual: Inverter-DrivenДокумент46 страницInstallation and Maintenance Manual: Inverter-DrivenJose CuevasОценок пока нет

- Ifw15 Flame Relay InstallДокумент10 страницIfw15 Flame Relay InstallDaniel PradoОценок пока нет

- T & C MOS - FF SystemДокумент3 страницыT & C MOS - FF SystemAzharОценок пока нет

- IPL ListДокумент41 страницаIPL Listkapare1209Оценок пока нет

- RT Fire Alarm Systems Care and Maintenance PDFДокумент6 страницRT Fire Alarm Systems Care and Maintenance PDFAndres RamirezОценок пока нет

- 780HT - Catalytic Gas Detector PDFДокумент48 страниц780HT - Catalytic Gas Detector PDFinelecstarОценок пока нет

- General Firefighting Wet Systems Method Statement For Testing & CommissioningДокумент11 страницGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- PiFLOW OS PreppedДокумент4 страницыPiFLOW OS PreppedPauline HölblingОценок пока нет

- S503-Functional SHE Standard - Fire Tube-Shell Boilers - Version - 04 (24198)Документ7 страницS503-Functional SHE Standard - Fire Tube-Shell Boilers - Version - 04 (24198)martin cuadrantiОценок пока нет

- Quemador TBG 210 MEДокумент104 страницыQuemador TBG 210 MEalex roОценок пока нет

- Fire Alarm Installation MethodДокумент7 страницFire Alarm Installation MethodAleen Gamal Al-Dinji100% (1)

- Installation and user manual for Parva Models M90.24S M90.28S M90.24SRДокумент44 страницыInstallation and user manual for Parva Models M90.24S M90.28S M90.24SRZena PopaОценок пока нет

- Nittan EV-P Smoke Sensor ManualДокумент7 страницNittan EV-P Smoke Sensor Manualzoran_stevОценок пока нет

- Buckling Pin BrochureДокумент12 страницBuckling Pin Brochureharry_chemОценок пока нет

- Fire Alarm System DBRДокумент19 страницFire Alarm System DBRKirty VardhanОценок пока нет

- Extinguisher's Manual MARINE - OrFEOДокумент5 страницExtinguisher's Manual MARINE - OrFEOswiezaplesnОценок пока нет

- John Zink - ATTACH H VCU Catalogs Leaflets (Brochure)Документ8 страницJohn Zink - ATTACH H VCU Catalogs Leaflets (Brochure)Pedro Ferrugem KaiserОценок пока нет

- E-COMFORT PLUS Manual de UtilizareДокумент12 страницE-COMFORT PLUS Manual de UtilizareMonica GrecuОценок пока нет

- User Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi TubesДокумент12 страницUser Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi Tubesxaaabbb_550464353100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОт EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОценок пока нет

- TI Nspire Program IntroДокумент8 страницTI Nspire Program IntroHasan128Оценок пока нет

- Documents - MX Grinnellfirepanel PDFДокумент8 страницDocuments - MX Grinnellfirepanel PDFcchristt2584Оценок пока нет

- Documents - MX Grinnellfirepanel PDFДокумент8 страницDocuments - MX Grinnellfirepanel PDFcchristt2584Оценок пока нет

- Autodesk educational product schematic diagramДокумент1 страницаAutodesk educational product schematic diagramcchristt2584Оценок пока нет

- AG Piping Specification SPEL en M SG 12 002 Rev0Документ31 страницаAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584Оценок пока нет

- Tyco Nozzle D-3Документ6 страницTyco Nozzle D-3Rowsedk MoleroОценок пока нет

- 89manuale Calcusus Plus - EngДокумент40 страниц89manuale Calcusus Plus - EngsardockanОценок пока нет

- Technical Specification For Field Erected Fuel Oil Storage TanksДокумент19 страницTechnical Specification For Field Erected Fuel Oil Storage Tankscchristt2584100% (1)

- DEUTZ DFP4 2012 C10 EPA Tier 1 Technical DataДокумент2 страницыDEUTZ DFP4 2012 C10 EPA Tier 1 Technical Datacchristt2584Оценок пока нет

- FMM-7045 Series Multiplex Addressable Manual StationsДокумент2 страницыFMM-7045 Series Multiplex Addressable Manual Stationscchristt2584Оценок пока нет

- FMM-100 Series Die-Cast Metal Fire Alarm Manual StationsДокумент2 страницыFMM-100 Series Die-Cast Metal Fire Alarm Manual Stationscchristt2584Оценок пока нет

- MA3000 Installation ManualДокумент48 страницMA3000 Installation Manualcchristt2584Оценок пока нет

- Battery Calc v1 - 04 111810Документ18 страницBattery Calc v1 - 04 111810cchristt2584Оценок пока нет

- 83V 1ceng0000Документ2 страницы83V 1ceng0000cchristt2584Оценок пока нет

- HOJA TECNICA Modulo D7039 PDFДокумент8 страницHOJA TECNICA Modulo D7039 PDFcchristt2584Оценок пока нет

- PHD - Modelo 141 Colgador Gota PDFДокумент5 страницPHD - Modelo 141 Colgador Gota PDFcchristt2584Оценок пока нет

- Model A240 Indicator PostДокумент5 страницModel A240 Indicator Postcchristt2584Оценок пока нет

- 4090 9001+Supervised+IAM+Installation+Manual+Rev+EДокумент2 страницы4090 9001+Supervised+IAM+Installation+Manual+Rev+Ecchristt2584Оценок пока нет

- Station Manual An-SgxseriesДокумент2 страницыStation Manual An-Sgxseriescchristt2584Оценок пока нет

- D7030X Series LED AnnunciatorsДокумент1 страницаD7030X Series LED Annunciatorscchristt2584Оценок пока нет

- Gaitronics gtc980500Документ8 страницGaitronics gtc980500cchristt2584Оценок пока нет

- Flujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231Документ124 страницыFlujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231cchristt2584Оценок пока нет

- 34XRAДокумент73 страницы34XRAArquimedes PaschoalОценок пока нет

- "DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%Документ1 страница"DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%cchristt2584Оценок пока нет

- d2300cps - SiemensДокумент2 страницыd2300cps - Siemenscchristt2584Оценок пока нет

- OMRON MK-I-S RelayДокумент13 страницOMRON MK-I-S Relaycchristt2584Оценок пока нет

- ReD AlertДокумент1 страницаReD Alertcchristt2584Оценок пока нет

- Call Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace TechnologyДокумент9 страницCall Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace Technologycchristt2584Оценок пока нет

- Válvula Compuerta NRS P-2360Документ1 страницаVálvula Compuerta NRS P-2360cchristt2584Оценок пока нет

- Yard Cat130 WebДокумент180 страницYard Cat130 WebFabricio MatiasОценок пока нет

- Understanding Oracle Bill of MaterialsДокумент15 страницUnderstanding Oracle Bill of MaterialsRamesh GarikapatiОценок пока нет

- CCDP ArchДокумент941 страницаCCDP Archloopback test100% (2)

- Cad vs. Gis - Cad - Vs - GisДокумент5 страницCad vs. Gis - Cad - Vs - GissgrrscОценок пока нет

- Quality ESP InsulatorsДокумент4 страницыQuality ESP InsulatorsAnonymous p4GdtQpОценок пока нет

- 4 Associated Communications & Wireless Services-United Broadcasting Networks v. NTC, 397 SCRA 574Документ18 страниц4 Associated Communications & Wireless Services-United Broadcasting Networks v. NTC, 397 SCRA 574LegaspiCabatchaОценок пока нет

- SAP Interview QuestionsДокумент34 страницыSAP Interview Questionsmahesh16ad4uОценок пока нет

- Ure, Andrew. Philosophy of ManufacturesДокумент243 страницыUre, Andrew. Philosophy of ManufacturesAka_AlvaОценок пока нет

- 1410080-5 HP Floating AeratorДокумент12 страниц1410080-5 HP Floating AeratorAbhinav SrivastavaОценок пока нет

- Q2TD-Shoplot & Apartments Introduction-Last LaunchДокумент61 страницаQ2TD-Shoplot & Apartments Introduction-Last LaunchDuyen HuynhОценок пока нет

- Chapter 5 (AC Three Phase)Документ46 страницChapter 5 (AC Three Phase)Chua Wei CongОценок пока нет

- Pt. Bubu Kreasi Perdana: Performance Review & Development FormДокумент7 страницPt. Bubu Kreasi Perdana: Performance Review & Development FormAgungBolaangОценок пока нет

- IECEx KIWA 17.0011X 1Документ5 страницIECEx KIWA 17.0011X 1antxonmpОценок пока нет

- Gary Huber's Complete Resume, Cover Letter, Summary of Talents, Work HistoryДокумент8 страницGary Huber's Complete Resume, Cover Letter, Summary of Talents, Work HistoryTweetelectricОценок пока нет

- Lathe MachineДокумент9 страницLathe MachineSteven Josh bernalОценок пока нет

- 2008 - Laundry 2008 Disaster Plan - DMCOMMENTS-1-1Документ6 страниц2008 - Laundry 2008 Disaster Plan - DMCOMMENTS-1-1anon-315689100% (2)

- Off Highway VehiclesДокумент2 013 страницOff Highway VehiclesTan JaiОценок пока нет

- The Unreserved Ticketing System of Indian RailwaysДокумент15 страницThe Unreserved Ticketing System of Indian RailwaysGAUTI2212Оценок пока нет

- Inside Dynamics AX 2012 Performance - A1214Документ22 страницыInside Dynamics AX 2012 Performance - A1214BlueGrssОценок пока нет

- IChemE - Courses Catalogue 2013 PDFДокумент40 страницIChemE - Courses Catalogue 2013 PDFkanakarao1Оценок пока нет

- Air Archive Book 1Документ98 страницAir Archive Book 1Cesar Elaskar88% (17)

- Omega Integration Agenda: Quality, Clients & ProjectsДокумент66 страницOmega Integration Agenda: Quality, Clients & ProjectsEric PhamОценок пока нет

- AAHS v56n1 B-58 Story v2Документ10 страницAAHS v56n1 B-58 Story v2flyingmanu100% (5)

- Yasda MachineДокумент2 страницыYasda MachineKrupa GajjarОценок пока нет

- Payroll Costing - Troubleshooting TechniquesДокумент67 страницPayroll Costing - Troubleshooting TechniquesMohamed ShanabОценок пока нет

- Brief History of Aeronautics and AstronauticsДокумент8 страницBrief History of Aeronautics and AstronauticsCatherine MerillenoОценок пока нет

- Top 5 Career Paths For Electronics Engineering StudentsДокумент3 страницыTop 5 Career Paths For Electronics Engineering StudentsAnkitha goriОценок пока нет

- PC-12 Series 10 - CH1 Aircraft GeneralДокумент36 страницPC-12 Series 10 - CH1 Aircraft GeneralBjorn Dahlen100% (1)

- Rosinav - Bussines of The FutureДокумент8 страницRosinav - Bussines of The FutureDragos JohnОценок пока нет

- DCPL Work PermitДокумент1 страницаDCPL Work PermitRajat SonkarОценок пока нет