Академический Документы

Профессиональный Документы

Культура Документы

PETRO Banlaw Refuelling

Загружено:

paulm3565Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PETRO Banlaw Refuelling

Загружено:

paulm3565Авторское право:

Доступные форматы

www.banlaw.

com

ReFuelling Nozzles

The Worlds Toughest and Safest Nozzles

Toughest

BANLAW prides our services on how well our nozzles perform in some of the harshest working environments in the world. From the frozen conditions of Antarctica to the deserts of Africa and Australia, you can depend on BANLAW products to do the job.

Cleaner Environment

The BANLAW Dry Break automatic cut-off system reduces the risk of fuel spills during the refuel process. This results in a refuelling area free from fuel related safety slip hazards. Fitting over load arms, nozzle holsters and nozzle anchors also eliminates trip hazards from ground stored hoses.

Safest

BANLAW nozzles have a proven safety record as our dependable ball locking mechanism ensures the nozzle cannot fly off, risking the safety of the refuelling operator. BANLAW nozzles are designed with the operator of the field task in mind. Our products are easy to carry and manouver, yet robust and reliable. When refuelling at ground level, an automatic cut-off means the BANLAW nozzle is easier to use and the refuelling operators dont risk climbing onto vehicles, thus reducing the chance of worker injury and compensation.

Increased Productivity

With a 2 bore, BANLAW nozzles have the highest industry flow rate capability, reducing refuelling times. The choice of 5 shut-off pressure settings allow through faster refuelling times flexible solutions to the most complex refuelling problems.

The Best Investment

The BANLAW nozzle is repairable, not disposable, they are robust and last considerably longer in the field and can reduce refuelling times. Basically, it costs less in the long run and is built to last.

w wp t idcm w .er n . o o

YOUR INVESTMENT IS MAXIMISED BY CHOOSING BANLAW

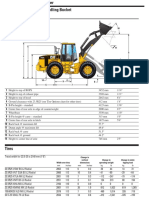

800 Series Nozzles

w wp t idcm w .er n . o o

FLOW RATE 170 - 800 LPM / 45-211GPM

Mining

800 Series Nozzle

BRM23 Receiver

AUS25A Vent with AUS25AA-1 Coupling

Rail

BNR800 Nozzle

AUS23R Receiver

AUS25R Vent with AUS25AA-1 Coupling

Hydraulic

BPH800 Nozzle

AUS23B Receiver

AUS25A Vent with AUS25AA-1 Coupling

FillSafe FuelTrack LubeCentral ReFuelling

www.banlaw.com

1000 Series Nozzles

w wp t idcm w .er n . o o

FLOW RATE 400 - 1000 LPM / 106-264GPM

1000LPM

2 Vents required

1000 Series Nozzle

BRM43 Receiver

AUS25A Vents with AUS25AA-1 Coupling

Accessories

Operation Sign AUSOPSIGN-2

CARRY HANDLE

ACTUATOR

ON TRIGGER

AUS23C-R Cap

OPERATING HANDLE

AUS23C Cap

Breakaway Valve

OFF

STEP 1

1.1 REMOVE RECEIVER CAP. 1.2 REMOVE NOZZLE FROM ANCHOR OR PLUG FROM FRONT OF NOZZLE. 1.3 ENSURE MATING SURFACES OF RECEIVER AND NOZZLE ARE CLEAN AND UNDAMAGED.

STEP 2

2.1 ENSURE OPERATING HANDLE IS LOCKED IN THE OFF POSITION. 2.2 RETRACT ACTUATOR AND PUSH NOZZLE FIRMLY ONTO THE RECEIVER. 2.3 RELEASE ACTUATOR AND PUSH NOZZLE FIRMLY ONTO RECEIVER. 2.4 REPEAT STEPS 2.2 AND 2.3 UNTIL NOZZLE IS SECURELY CONNECTED.

STEP 3

3.1 RELEASE CATCH USING TRIGGER AND ROTATE HANDLE INTO ON POSITION. 3.2 NOZZLE WILL AUTOMATICALLY TURN OFF AFTER TANK VENT HAS CLOSED. 3.3 DO NOT MANUALLY HOLD NOZZLE IN THE ON POSITION DURING REFUELLING OR AFTER TANK VENT HAS CLOSED.

STEP 4

4.1 ENSURE OPERATING HANDLE IS LOCKED IN THE OFF POSITION. 4.2 RETRACT ACTUATOR AND REMOVER NOZZLE FROM RECEIVER. 4.3 RETURN NOZZLE TO ANCHOR OR REPLACE NOZZLE PLUG. 4.4 REPLACE RECEIVER CAP.

PROMPTLY REPORT ANY PROBLEMS TO YOUR SUPERVISORS "The Refuelling Specialists" www.banlaw.com

Nozzle Holster BFTNH203A

800 Anchor BP800049

1000 Anchor AUS22049

Zinc Plated Steel Swivels various sizes available AUS10 Shown

Anodized Aluminium Swivels various sizes available AUS50 & AUS52 Shown

AUS24A Shell Receiver & Cap

Receiver Socket (AUS23SOCKET)

Receiver Socket (AUS-RSOCKET)

ReFuelling Nozzles

www.banlaw.com

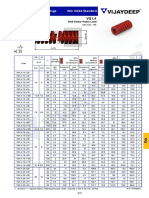

Legend

L (Light), ML (Medium/Light), M (Medium) MH (Medium/Heavy), H (Heavy)

Head loss curves

show pressure drop across nozzle & Banlaw Receiver when used with diesel.

Setting curves

Automatic shut-off of nozzle is initiated by a limiting static pressure measured at the 2 nozzle inlet. Nozzle spring setting is determined by flow rate and head pressure of refuelling application. Actual inlet static pressure must be less than that shown for spring setting. e.g. For 800 series: 150kPa @ 450 l/min, require minimum of M spring setting

Recommended Operating Conditions

Maximum Static Head Pressure: 2.5 MPa (363 psi)

Flowrate Range Diesel

1000 Nozzle 400-1000 l/min. (106-264 gals/min.) 800 Nozzle 170-800 l/min. (45-211 gals/min.)

Spring Settings

L, ML, & M spring P/N. BP800029 MH & H spring P/N. BP800027 Nozzle setting denoted by letters L, M, etc. after nozzle model No. e.g. BPM800M, BAM1000ML

Physical Properties

Mass (with plug) 1000 Series Nozzle 4.3 kgs. (9.5 lbs.) 800 Series Nozzle 3.4 kgs. (7.5 lbs.)

Constituent Materials

Aluminium, zinc plated mild steel, stainless steel, polyurethane, VITON seals.

Please Note: Use only Banlaw factory replacement parts. Failure to do so may cause equipment failure or malfunction, vehicle damage and invalidate factory warranty.

ReFuelling Nozzles

8519 09/10

w wp t idcm w .er n . o o

Вам также может понравиться

- Control Valves: Slaney Direct LTDДокумент15 страницControl Valves: Slaney Direct LTDParis AnabelОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Catalog Mud Pump 25864Документ24 страницыCatalog Mud Pump 25864agus100% (1)

- Compsim PDFДокумент40 страницCompsim PDFciucalata88Оценок пока нет

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- 3-6 Quad BopДокумент29 страниц3-6 Quad Bopsambhaji100% (1)

- Yawmc 0414 Us Yarway ArcvДокумент12 страницYawmc 0414 Us Yarway ArcvCecep AtmegaОценок пока нет

- NOV 2019 - Price ListДокумент3 734 страницыNOV 2019 - Price ListFARIZA FAHMIОценок пока нет

- EspeyДокумент20 страницEspeyGuillermo Esteban Diaz QuezadaОценок пока нет

- Accuseal Plug ValveДокумент20 страницAccuseal Plug ValveTendai Felex Maduke100% (2)

- BAHCO 01.10.2012 CenovnikДокумент432 страницыBAHCO 01.10.2012 CenovnikAleksandar LekicОценок пока нет

- Industrial Gas Generator Illustrated Parts CatalogueДокумент23 страницыIndustrial Gas Generator Illustrated Parts CataloguejuanaОценок пока нет

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Документ16 страницTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanОценок пока нет

- Re91401 A2foДокумент20 страницRe91401 A2foTaz Juan GОценок пока нет

- Gorter r200Документ6 страницGorter r200Manish SaraswatОценок пока нет

- 85 8500 Series Shipping FlyerДокумент2 страницы85 8500 Series Shipping Flyerx6pq7dcbmvОценок пока нет

- Power Steering System ComponentsДокумент10 страницPower Steering System ComponentsAbraham PejovésОценок пока нет

- Banlaw TankVentsДокумент6 страницBanlaw TankVentsPriyogo SutantiyoОценок пока нет

- Man B&W WarningДокумент284 страницыMan B&W WarningMarcin SrokaОценок пока нет

- BT Series Owners Manual - CombinedДокумент142 страницыBT Series Owners Manual - Combinedalejandro777_eОценок пока нет

- 9100 Flanged BrochureДокумент16 страниц9100 Flanged Brochureanugrah_dimas5441Оценок пока нет

- Yawmc 0414 UsДокумент12 страницYawmc 0414 UsNaser JahangiriОценок пока нет

- Cat Acvbr9000Документ16 страницCat Acvbr9000gazwang478Оценок пока нет

- Winch K5ur100mlДокумент88 страницWinch K5ur100mlArleyTrujillo1224Оценок пока нет

- Deareator TankДокумент36 страницDeareator TankAgustin AquinoОценок пока нет

- ACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceДокумент2 страницыACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceDeyokeОценок пока нет

- 876c Data Sheet Revb Mar-2016Документ2 страницы876c Data Sheet Revb Mar-2016Mahmoud AbuzaidОценок пока нет

- 9100 Series Econ D Shipping FlyerДокумент2 страницы9100 Series Econ D Shipping Flyerx6pq7dcbmvОценок пока нет

- Series: Direct Solenoid and Solenoid Pilot Operated ValvesДокумент14 страницSeries: Direct Solenoid and Solenoid Pilot Operated ValvesricardoriveroОценок пока нет

- Blowers TS R: Everest Twin Lobe Rotary Air BlowersДокумент1 страницаBlowers TS R: Everest Twin Lobe Rotary Air Blowersankitsaxena123Оценок пока нет

- Padlock - Anchor Lås 2017Документ41 страницаPadlock - Anchor Lås 2017Peter Davidson100% (1)

- Bomba de Engranajes Catalogo JOYANGДокумент8 страницBomba de Engranajes Catalogo JOYANGlizbethdiosesОценок пока нет

- Atomac BrochureДокумент28 страницAtomac BrochureManish TulaskarОценок пока нет

- 1000series - Hyd. WinchДокумент7 страниц1000series - Hyd. Winchadrianram1Оценок пока нет

- Svedala RV Eng GerardДокумент6 страницSvedala RV Eng GerardPaseandoPorlaVidaОценок пока нет

- Vibratory Feeders and Conveyors PDFДокумент14 страницVibratory Feeders and Conveyors PDFArnaldo BenitezОценок пока нет

- P6 Limit SwitchДокумент3 страницыP6 Limit SwitchABCdude1Оценок пока нет

- Poulan Poulan Pro Chain Saw Service Repair Manual 1900 1950 2050 2055 2075 2150 2175 2375 Wild Thing 2250 2450 2550 220 221 221le 260 260leДокумент31 страницаPoulan Poulan Pro Chain Saw Service Repair Manual 1900 1950 2050 2055 2075 2150 2175 2375 Wild Thing 2250 2450 2550 220 221 221le 260 260leJoãoBapt100% (4)

- Mercer Valve 9100 Relief Valve Flanged AEДокумент16 страницMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaОценок пока нет

- X Series PumpsДокумент8 страницX Series PumpsJorge GalarceОценок пока нет

- Storage Tank Safety and Emissions ManagementДокумент96 страницStorage Tank Safety and Emissions ManagementenggmohanОценок пока нет

- Chapter 1-8: Industrial Gas Generator Illustrated Parts CatalogueДокумент18 страницChapter 1-8: Industrial Gas Generator Illustrated Parts CataloguejuanaОценок пока нет

- Bombas de Pistones Serie PREMIER DenisonДокумент40 страницBombas de Pistones Serie PREMIER DenisonOscar JavierОценок пока нет

- Mercer Valve 9100 Relief Valve Threaded AEДокумент16 страницMercer Valve 9100 Relief Valve Threaded AEdoens JKTОценок пока нет

- Chrysler 300, 300C, 300 Touring Sedans and Dodge Magnum Body Repair ManualДокумент11 страницChrysler 300, 300C, 300 Touring Sedans and Dodge Magnum Body Repair ManualAyman RiyadhОценок пока нет

- 2005 Dodge Magnum LX Body Repair ManualДокумент405 страниц2005 Dodge Magnum LX Body Repair Manualbrharrill185100% (1)

- LIT2299 Rev 10 PD12C Parts ListДокумент28 страницLIT2299 Rev 10 PD12C Parts ListYuliana Andrea Zapata RubioОценок пока нет

- Only Reference 2023Документ32 страницыOnly Reference 2023Luis miguel SanchezОценок пока нет

- Rotary Feeder 1Документ6 страницRotary Feeder 1elangorengaОценок пока нет

- Tandem Booster m100Документ12 страницTandem Booster m100Leonardo Alvarez100% (1)

- Williams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600Документ28 страницWilliams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600espanolasaОценок пока нет

- ASV 10 20 BrochureДокумент8 страницASV 10 20 BrochureThomas Duane DavidsonОценок пока нет

- BPM800 BPM Vs BAM - Rev 1Документ3 страницыBPM800 BPM Vs BAM - Rev 1api-3752216Оценок пока нет

- RAJAMANE Full - Catalog - 09 PDFДокумент25 страницRAJAMANE Full - Catalog - 09 PDFchidambaram kasi100% (1)

- APV Plug Valve CatalogueДокумент40 страницAPV Plug Valve CatalogueVeerapandianОценок пока нет

- Catalogue Armacon-Valve 20190522Документ26 страницCatalogue Armacon-Valve 20190522Scipp ZengОценок пока нет

- PETRO HT Series T110 GA DrawingДокумент2 страницыPETRO HT Series T110 GA Drawingpaulm3565Оценок пока нет

- PETRO Meters TCS 3000 Electronic RegisterДокумент1 страницаPETRO Meters TCS 3000 Electronic Registerpaulm3565Оценок пока нет

- PETRO HT Series T110 GA DrawingДокумент2 страницыPETRO HT Series T110 GA Drawingpaulm3565Оценок пока нет

- PETRO TCS Ops Manual 700-30 35Документ56 страницPETRO TCS Ops Manual 700-30 35paulm3565Оценок пока нет

- PETRO TCS Ops Manual 700-40 45Документ52 страницыPETRO TCS Ops Manual 700-40 45paulm3565Оценок пока нет

- PETRO TCS Engineering Manual 682Документ44 страницыPETRO TCS Engineering Manual 682paulm3565Оценок пока нет

- PETRO TCS Engineering Manual 700Документ48 страницPETRO TCS Engineering Manual 700paulm3565Оценок пока нет

- PETRO PIUSI Meter k700Документ2 страницыPETRO PIUSI Meter k700paulm3565Оценок пока нет

- PETRO TCS 682 Series Piston Meter Operations ManualДокумент42 страницыPETRO TCS 682 Series Piston Meter Operations Manualpaulm3565Оценок пока нет

- PETRO FILL-RITE 800 Series Meter Owner ManualДокумент12 страницPETRO FILL-RITE 800 Series Meter Owner Manualpaulm3565Оценок пока нет

- Liquitainer T80 GaДокумент2 страницыLiquitainer T80 Gapaulm3565Оценок пока нет

- PETRO FILL-RITE 900 Series Meter Owner ManualДокумент4 страницыPETRO FILL-RITE 900 Series Meter Owner Manualpaulm3565Оценок пока нет

- PETRO TANK T Series T12 GAДокумент1 страницаPETRO TANK T Series T12 GApaulm3565Оценок пока нет

- LIQUITAINER MC Tank Typical GaДокумент2 страницыLIQUITAINER MC Tank Typical Gapaulm3565Оценок пока нет

- PETRO LIQUITAINER Self Bunded TanksДокумент5 страницPETRO LIQUITAINER Self Bunded Tankspaulm3565100% (1)

- LIQUITAINER Operations ManualДокумент17 страницLIQUITAINER Operations Manualpaulm3565Оценок пока нет

- Petro Cube 4500L GaДокумент4 страницыPetro Cube 4500L Gapaulm3565Оценок пока нет

- LIQUITAINER Paint SpecificationДокумент28 страницLIQUITAINER Paint Specificationpaulm3565Оценок пока нет

- PETRO Cube BrochureДокумент13 страницPETRO Cube Brochurepaulm3565Оценок пока нет

- Genesis and Development of The Network Arch Consept - NYДокумент15 страницGenesis and Development of The Network Arch Consept - NYVu Phi LongОценок пока нет

- Taller Sobre Preposiciones y Vocabulario - Exhibición Comercial SergioДокумент5 страницTaller Sobre Preposiciones y Vocabulario - Exhibición Comercial SergioYovanny Peña Pinzon100% (2)

- Too Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPДокумент48 страницToo Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPLiam FabelaОценок пока нет

- COMPLAINT - THE STAN J. CATERBONE 42 U.S.C. 14141 "POLICE MISCONDUCT PROVISION" COMPLAINT TO U.S. DEPARTMENT OF JUSTICE August 24, 2017Документ435 страницCOMPLAINT - THE STAN J. CATERBONE 42 U.S.C. 14141 "POLICE MISCONDUCT PROVISION" COMPLAINT TO U.S. DEPARTMENT OF JUSTICE August 24, 2017Stan J. CaterboneОценок пока нет

- CH7Документ34 страницыCH7Abdul AzizОценок пока нет

- Cyber Cafe Audience Profiling Nielsen 2009Документ17 страницCyber Cafe Audience Profiling Nielsen 2009mahi46452Оценок пока нет

- 1 48 Volt Parallel Battery System PSS-SOC - Step-By-Step VolvoДокумент11 страниц1 48 Volt Parallel Battery System PSS-SOC - Step-By-Step VolvoEyosyas NathanОценок пока нет

- Mss 202 Practice 19-20Документ2 страницыMss 202 Practice 19-20fayinminu oluwaniyiОценок пока нет

- Valery 1178Документ22 страницыValery 1178valerybikobo588Оценок пока нет

- Low Cost CompaniesДокумент9 страницLow Cost CompaniesIvan RodriguezОценок пока нет

- Virtual Machine Functionalism (VMF)Документ52 страницыVirtual Machine Functionalism (VMF)Cássia SiqueiraОценок пока нет

- LOVДокумент43 страницыLOVMei FadillahОценок пока нет

- Cat It62hДокумент4 страницыCat It62hMarceloОценок пока нет

- Telemeter-Electronic Brochure Flexible Heaters WebДокумент12 страницTelemeter-Electronic Brochure Flexible Heaters WebXavierОценок пока нет

- Blockchain Unit Wise Question BankДокумент3 страницыBlockchain Unit Wise Question BankMeghana50% (4)

- SecureCore Datasheet V2Документ2 страницыSecureCore Datasheet V2chepogaviriaf83Оценок пока нет

- Network Protection Automation Guide Areva 1 PDFДокумент500 страницNetwork Protection Automation Guide Areva 1 PDFEmeka N Obikwelu75% (4)

- Media and Information Literacy Quarter 3 Module 1Документ67 страницMedia and Information Literacy Quarter 3 Module 1Joshua Catequesta100% (1)

- In Coming MailДокумент4 страницыIn Coming Mailpoetoet100% (1)

- 4439 Chap01Документ28 страниц4439 Chap01bouthaina otОценок пока нет

- Part List SR-DVM70AG, SR-DVM70EUДокумент28 страницPart List SR-DVM70AG, SR-DVM70EUAndrea BarbadoroОценок пока нет

- Introduction and Instructions: ForewordДокумент20 страницIntroduction and Instructions: ForewordDanang WidoyokoОценок пока нет

- Hydraulic Breakers in Mining ApplicationДокумент28 страницHydraulic Breakers in Mining ApplicationdrmassterОценок пока нет

- Exchange Rates JBДокумент9 страницExchange Rates JBboss9921Оценок пока нет

- Braided Composites ModellingДокумент33 страницыBraided Composites ModellingaamirmubОценок пока нет

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadДокумент3 страницыRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaОценок пока нет

- Tarlac - San Antonio - Business Permit - NewДокумент2 страницыTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- Fabric Technologist RoleДокумент3 страницыFabric Technologist RoleAnup Kumar DeyОценок пока нет

- 6398 14990 1 PBДокумент8 страниц6398 14990 1 PBKent Ky GillaОценок пока нет

- Advanced Machining User Guide PDFДокумент250 страницAdvanced Machining User Guide PDFDaniel González JuárezОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)