Академический Документы

Профессиональный Документы

Культура Документы

Apricot

Загружено:

postman1294Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Apricot

Загружено:

postman1294Авторское право:

Доступные форматы

Available online at www.sciencedirect.

com

Food Chemistry

Food Chemistry 108 (2008) 334340 www.elsevier.com/locate/foodchem

Analytical Methods

Characterisation of Italian commercial apricot juices by high-performance liquid chromatography analysis and multivariate analysis

Andrea Versari *, Giuseppina P. Parpinello, Alessia U. Mattioli, Sergio Galassi

` Dipartimento di Scienze degli Alimenti, Universita di Bologna, P.zza Goidanich 60, Cesena (FC) 47023, Italy Received 14 June 2007; received in revised form 18 August 2007; accepted 11 October 2007

Abstract The modern fruit juice industry needs their products to be characterized by high-quality attributes to meet consumers expectation. In this view, the composition of 26 Italian commercial apricot juices obtained from organic, integrated and conventional agriculture was analysed for carbohydrates, organic acids, amino acids, phenolic compounds and furanic compounds by high-performance liquid chromatography (HPLC). The content of 5-hydroxymethylfurfural in apricot juices (range 0.118 mg/l) was within the regulatory limit of 20 mg/l. The lack of furanic compounds in apricot fresh fruits conrmed their importance as quality markers of heating condition during processing and storage of fruit juices. Univariate analysis disclosed some signicant dierences among the composition of the apricot juices in terms of glucose, fructose, malic acid, glycine, chlorogenic acid, rutin, and a*-parameter (redness). Principal component analysis on chemical composition of apricot juices resulted in two principal components (PCs) that accounted for 66% of the total variance. Organic apricot juices showed some separation from the other juices, whereas a lack of distinction between integrated and conventional juices appeared. 2007 Elsevier Ltd. All rights reserved.

Keywords: Apricot juice; Compositional data; HPLC; Organic foods; PCA

1. Introduction Apricot is the third most widely grown stone fruit crop with a world production of ca. 2.8 Mt in 2005. The production is mainly located in the Mediterranean countries which collectively account for 40% of global production. Italy is the third largest apricot producing country in the world with about 180.000 tons/year, and around 40% of the Italian production is located in the EmiliaRomagna region, north of Italy (Mennone, Mattatelli, & Pirazzini, 2005). Moreover, fruit juices constitute an important sector of the local food industry and several major fruit processing companies are located in this region as well (Lunati, 2005). The modern apricot industry needs commercial juices characterized by high-quality juice attributes to meet consumers expectation and for regulatory purposes.

*

Corresponding author. Tel.: +39 0547 338118; fax: +39 0547 382348. E-mail address: andrea.versari@unibo.it (A. Versari).

The common concern of consumers about food quality and nutrition has led to an increasing attention in the market of foods with natural ingredients, including food products from organic and integrated agriculture. Organic agriculture diers from the conventional type by its avoidance of synthetic chemicals for soil preparation, fertilization and pest control (Council Regulation ECC No. 2092/91). Integrated agriculture allows production methods in between the organic and the conventional types. Numerous claims are made about the benets of organic foods, in order to justify the premium price that consumers have to pay. Although products from organic origin are believed to be nutritionally superior, healthier, and also tastier than the corresponding conventional foods, a clear evidence supporting this assumption requires further and specic research (Brandt & Mlgaard, 2001; Fillion & Arazi, 2002; Woese, Lange, Boess, & Bogl, 1997). With regard to fruits and juices, it is well known that varietal, geographical, seasonal and maturity dierences, as well

0308-8146/$ - see front matter 2007 Elsevier Ltd. All rights reserved. doi:10.1016/j.foodchem.2007.10.053

A. Versari et al. / Food Chemistry 108 (2008) 334340

335

as processing conditions generally aect their composition. Carbohydrates, organic acids (Bartolozzi, Bertazza, Bassi, & Cristoferi, 1997; Gurrieri, Audergon, Albagnac, & Reich, 2001; Wills, Scriven, & Greeneld, 1983), amino acids (Katona, Sass, & Molnar-Perl, 1999) and phenolic com pounds (Fernandez de Simon, Perez-Ilzarbe, Hernandez, Gomez-Cordoves, & Estrella, 1992; Garcia-Viguera, Bridle, ` Ferreres, & Tomas-Barberan, 1994; Triro, Risi, Cocconi, & Bolzoni, 2006) are among the major constituents of apricot fruits and juices. These compounds are useful to monitor the quality of fruits during ripening, processing and storage, and they contribute to the nutritional and sensory attributes of both fresh fruits and juices. Carbohydrates are the main source of energy for humans, being highest for glucose, followed by sucrose and fructose (Miller, Colagiuri, & Brand, 1986). Fructose has been reported to be 1.8 times sweeter than sucrose (Doty, 1976), whilst glucose is less sweet than sucrose (Pangborn, 1963). The content of organic acids in fruit juices not only inuences their avour but also their stability, nutrition, acceptability and keeping quality. In particular, malic and citric acids are correlated to the perception of sourness in peach juices (Esti et al., 1997) and a sensory contribution is expected to occur in apricot juices also (CoSeteng, McLellan, & Downing, 1989; Noble, Philbrick, & Boulton, 1986). Phenolic compounds may have potential health benets due to their antioxidant properties (Clydesdale, Kolasa, & Ikeda, 1995; Johnson, Williamson, & Musk, 1994; Rice-Evans, Miller, & Paganga, 1996), thus fruit juices with a high content of bioactive compounds may represent a specialty products/ingredients in the design of functional juices. Furanic compounds have been identied as degradation products associated with non-enzymatic browning in model solution and fruit juices, and are considered as markers for heat abuse during processing and storage of fruit juices (Lee & Nagy, 1996). The amino acid proline is considered a marker for the authenticity of apricot juices (RSK-value, 1987). While data on the composition of apricot fruit cultivars grown in Italy are available, information on commercial apricot juices is limited. The aim of this work was to analyse the composition of carbohydrates, organic acids, amino acids, phenolic compounds and furanic compounds by high-performance liquid chromatography (HPLC) of 26 commercial apricot juices produced in Italy. This work focused on apricot juice from organic, integrated and conventional agriculture due to the economic interest importance of this product in Italy. 2. Materials and methods 2.1. Samples Twenty-six commercial apricot juices were purchased from local markets and stored at room temperature before analysis. Samples were representative of the major Italian fruit juice companies and consisted of ve organic (ORG), ve integrated (INT), and 16 conventional (CON) juices.

Juices were diluted at a xed soluble solid content of 10Brix (digital refractometer PR-101, Atago, Tokyo, Japan), centrifuged at 3000g 15 min at 4 C and ltered through a 0.45 lm cellulose-acetate membrane (Orange Scientic, Dasit, Milano, Italy) before HPLC analysis. To verify the origin of the furanic compounds, fully ripe apricot fruits were sampled, freshly squeezed, then analysed by HPLC and the result compared with commercial juices. 2.2. Standards Furanic compounds: 5-Hydroxymethylfurfural (HMF), 3hydroxy-2-pyrone (HPYR), furfural (FUR), 2,5-dimethyl4-hydroxy-3(2H)-furanone (DMHF) and 2-acetylfuran (AcFUR); Carbohydrates: Glucose, fructose, sucrose, and sorbitol; Organic acids: Malic acid, citric acid and ascorbic acid; Amino acids: Arginine, aspartic acid, asparagine, glutamic acid, threonine, alanine, proline, tyrosine, c-aminobutyric acid, valine, phenylalanine, isoleucine, methionine, leucine and hystidine; Phenolic compounds: Catechin, chlorogenic acid and rutin were from commercial source (Sigma, Milano, Italy). 2.3. Chromatographic apparatus A HPLC system (Jasco, Tokyo, Japan) equipped with a pump system (PU980), a refractive index detector (RI830) for carbohydrate analysis, and a diode array detector (MD1510) monitored at 210 nm, 263 nm, 280 nm and 350 nm, for the analysis of organic acids, amino acids, furanic compounds and phenolic compounds, respectively. Data were acquired and processed using Borwin-PDA version 1.50 software (JMBS Developments, Grenoble, France). Juices were injected with a 20 ll loop using a 7125 valve (Rheodyne, Cotati, CA). 2.4. Analysis of carbohydrates Carbohydrates were simultaneously analysed onto an Aminex HPX-87Ca column (300 7.8 mm) protected with a pre-column (30 4.6 mm) lled with the same stationary phase (Bio-Rad) and kept at 80 C. The analytical conditions used were as follows: Flow 0.6 ml/min, eluent 0.045 N H2SO4 with 6% acetonitrile (v/v). 2.5. Analysis of organic acids Malic and citric acid were simultaneously analysed onto an Aminex HPX-87H column (300 7.8 mm) protected with a pre-column (30 4.6 mm) lled with the same stationary phase (Bio-Rad) and kept at 45 C. The analytical conditions used were as follows: ow 0.5 ml/min, eluent 0.045 N H2SO4 with 6% acetonitrile (v/v) (Castellari, Versari, Spinabelli, Galassi, & Amati, 2000). Ascorbic acid was analysed by capillary electrophoresis according to a method previously described (Versari, Mattioli, Parpinello, & Galassi, 2004).

336

A. Versari et al. / Food Chemistry 108 (2008) 334340

2.6. Analysis of amino acids Amino acids were analysed according to the methods previously described in details (Fabiani, Versari, Parpinello, Castellari, & Galassi, 2002). Briey, Amino acids were derivatized (FMOCAA) at room temperature using a precolumn procedure. An aliquot of 300 ll of fruit juice (or a standard solution of amino acids) was added with 600 ll of 200 mM borate buer (pH 10.0). Then, 600 ll of 15 mM FMOC-Cl (in acetonitrile) was added to the fruit juice and the derivatization occurred. After 5-min, the reaction was stopped by the addition of 600 ll of 300 mM ADAM (wateracetonitrile, 1:1, v/v), and the reaction lasted for 1-min to form the FMOCADAM complex. Then, the sample was ltered and analysed by HPLC using a Purospher RP-18 column (250 4-mm) protected with a guard column of the same material (Merck, Darmstad, Germany). The column operated at 25 C with a ow rate of 1.0 ml/min using 50 mM acetate buer (pH 4.2) as eluent A and acetonitrile as eluent B. Amino acids were separated with the following linear gradient elution conditions (min/A%): 0/72, 3/72, 27/55, 32/0, 37/0, 39/72, 47/72. 2.7. Analysis of phenolic compounds A method for the analysis of phenolic compounds in apricot was developed using an Inertisil ODS2 RP-column (250 4 mm) kept at 25 C. The analytical conditions used were as follows: ow 0.4 ml/min, eluent (A) H2O/ CH3COOH (98/2, v/v), eluent (B) H2O/CH3COOH/ CH3OH (34/1/60, v/v/v), with a simple gradient elution (min/A%): 0/100; 50/20; 60/20; 65/100; 75/100. 2.8. Analysis of furanic compounds The separation of furanic compounds was performed with an Aminex HPX-87H column (300 7.8 mm) protected with a pre-column (30 4.6 mm) lled with the same stationary phase (Bio-Rad Laboratories, Hercules, CA). Column and precolumn were thermostated at 45 C by a heater (Jones Chromatography, Mid Glamorgan, UK). The isocratic elution was run with a ow rate of 0.5 ml/ min, using 0.01 N H2SO4 with acetonitrile (810:190, v/v) as mobile phase. The UV spectra (200350 nm) of each compounds was recorded on-line with a resolution of 4 nm. Precision (CV%) was calculated by four repeated analysis of a sample containing DMHF (CV = 5.7%), HMF (0.4%), and FUR (0.7%). Accuracy (recovery%) was evaluated in triplicate using the apricot juices spiked with a known amount of HMF (9498%), and FUR (95101%). 2.9. Peak identication and quantication Peak identication was based on the retention times (tR), spiking technique and spectral overlay, whereas peak quantication was based on the external standard calibration method using linear regression analysis (r > 0.999)

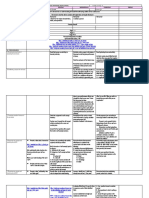

(Statistica 5.0, StatSoft, Tulsa, OK). The quantication of selected compounds in commercial Italian apricot juices was carried out in duplicate. 2.10. Color measurement The CIEL*a*b* color parameters were measured in the reectance mode with D65 illuminant and 2 observer angle (Chroma Meter CR-300, Minolta, Ramsey, NJ). Samples were measured against a white ceramic reference plate (L* = 97.43, a* = 0.13, b* = +1.68). 2.11. Statistical analysis The range, mean and standard deviation (mean SD) of the three types of apricot juices (organic, integrated, and conventional) were calculated. Analysis of variance (ANOVA) and mean comparisons by Tukey Honest Significant dierence (HSD) test for unequal number of samples at 5% level was performed using Statistica 5.1 (StatSoft, Tulsa, OK). To gain insight the data structure a multivariate analysis called principal component analysis (PCA), a pure display method, was performed to detect the most important factors of variability and to describe the relationship between variables and observations (Lewi, 1992). 3. Results and discussion 3.1. Analysis and composition of fruit juices There is an ongoing interest in developing a reliable and rapid methods to asses the quality of foods for nutritional and regulatory purposes. Fig. 1 shows a typical chromatographic pattern of carbohydrates (A), organic acids (B), furanic compounds (C), phenolic compounds (D) and amino acids (E) found in commercial apricot juices. HPLC analysis of apricot fruit juices was satisfactory in terms of main peak separation and identication. Besides the identied compounds, the chromatographic proles showed further information due to the presence of minor non-identied peaks. The diode array detector has led to considerable improvements in the HPLC analysis, as not only the retention time but also the UV spectrum can be used for routine identication purposes. In this view, commercial apricot juices showed the presence of HMF (tR = 22.1 min), FUR (tR = 31.6 min), together with an unknown peak (tR = 23.2 min) (Fig. 1C). Additional information can be derived from the UV absorption spectra of HMF [kmax = (228), 284 nm], FUR [kmax = (228), 276 nm], HPYR [kmax = (231), 294 nm], and the unknown peak eluting at tR = 23.2 min [kmax = (232), 292 nm] which clearly resembled that one of HPYR. The denitive identication of the peak eluting at tR = 23.2 min requires further investigation. Table 1 summarizes the composition of the apricot juices. The mean values for glucose, fructose, malic acid, glycine, chlorogenic acid, rutin and a*-parameter showed a signicant dierence among apricot juices, being always

A. Versari et al. / Food Chemistry 108 (2008) 334340

337

Fig. 1. HPLC chromatogram of commercial apricot juices. Legend: carbohydrates (A), organic acids (B), furanic compounds (C), phenolic compounds (D) and amino acids (E). For analytical conditions see Section 2. Legend A. Peaks: 1. Sucrose; 2. Glucose; 3. Fructose; 4. Sorbitol. Legend B. Peaks: 1. Citric acid; 2. Malic acid. Legend C. Peaks: 1. HMF; 2. Unknown; 3. FUR. In the window, UV spectra of Furfural (FUR-blu); 5-Hydroxymethylfurfural (HMF-red); 3-Hydroxy-2-pyrone (HPYR-green); and unknown peak at tR = 23.2 min ( ). Legend D. Peaks: 1. Chlorogenic acid derivative; 2. Rutin derivative; 3. Chlorogenic acid; 4. Rutin. Legend E. Peaks: 1. Asparagine; 2. Serine; 3. Aspartic acid; 4. Glutamic acid; 5. Threonine; 6. Glycine; 7. Alanine; 8. Tyrosine; 9. Proline; 10. fmoc (derivatization reagent); 11. Methionine + NH4OH; 12. Valine.

higher in organic juices except for the glycine content. The general composition of apricot juices was consistent with data from the literature (Bartolozzi et al., 1997; Fernandez de Simon et al., 1992; Garcia-Viguera et al., 1994; Gurrieri ` et al., 2001; Katona et al., 1999; Triro et al., 2006), whereas a lack of information on furanic compounds in apricot juices occurred. Thus, to verify the origin of the furanic compounds, fully ripe apricot fruits were sampled, then analysed by HPLC and the result compared with commercial juices. A lack of HMF, FUR and the unknown peak was found in apricot fruits, thus conrming the importance of the furanic compounds as markers of heating condition during processing and storage of apricot juices. Although the organic juices showed a high content of both HMF (range 118 mg/l) and FUR (0.12.3 mg/l) (Table 1), the overall level of HMF in apricot juices was lower than the regulatory limit of 20 mg/l (A.I.J.N., 1996). Based on this result, a lack of sensory contribution of the furanic compounds in apricot juices is expected, taking into account the taste thresholds reported in the litera-

ture for HPYR, FUR and HMF in orange juice, being 30 mg/l, 80 mg/l, and >200 mg/l, respectively (Shaw, Tatum, Kew, Wagner, & Berry, 1970). The analysis of carbohydrates and amino acids of apricot juices provided additional information related to the occurrence of furanic compounds. A high correlation between HMF with the a*-parameter (r = 0.75) and fructose (r = 0.72) was found. The color variables are commonly used to predict both chemical and sensory changes in food products. On peach juice the a*-value (redness) increases by increasing heating time and temperature (Garza, Ibarz, Pagan, & Giner, 1999). These ndings suggest that fructose play a major role in HMF formation. Apricot juice is characterized by a similar content of fructose (range 933 g/l) and glucose (range 1331 g/l). Both sugars may contribute to the browning of juice depending on the pH value. At the pH value of apricot juices (range 3.123.60) fructose degrades more rapidly than glucose (Shallenberger & Mattick, 1983). Asparagine was the main amino acid found in apricot juice (range 8201570 mg/l), representing

338

A. Versari et al. / Food Chemistry 108 (2008) 334340

Table 1 Composition of Italian commercial apricot juices and signicance level for statistical evaluation Compounds Apricot juicesa (mean SD) ORG (n = 5)b Glucose (g/l) Fructose (g/l) Sucrose (g/l) Sorbitol (g/l) Malic acid (g/l) Citric acid (g/l) Ascorbic acid (mg/l) Asparagine (g/l) Proline (mg/l) Glycine (mg/l) Chlorogenic acid (mg/l) Rutin (mg/l) HMFd (mg/l) Peak tR = 23.2 mine (mg/l) FURf (mg/l) pH a* value

a b

INT (n = 5) 18 3 14 3B 24 6 21 1.8 0.4B 1.4 0.3 187 183 1.1 0.2 50 14 31 5B 18 4B 9 1B 31 41 0.7 0.3 3.24 0.09 14.0 1.3B

B

CON (n = 16) 19 3 14 3B 25 7 32 2.0 0.4B 1.4 0.3 215 104 1.0 0.3 52 23 25 5A 18 4B 9 1B 21 62 1.2 0.5 3.29 0.03 11.8 0.2A

B

p-Levelc 0.0410 0.0006 n.s. n.s. 0.0001 n.s. n.s. n.s. n.s. 0.0038 0.0011 0.0008 n.s. n.s. n.s. 3.30 0.11 12.9 0.6A

Overall (n = 26) 19 4 16 5 24 9 32 2.20.7 1.5 0.4 194 116 1.1 0.3 53 24 25 6 20 6 91 33 62 1.1 0.5 n.s. 0.0211

23 5 22 8A 21 17 44 3.2 0.7A 1.8 0.8 138 61 1.1 0.3 61 35 20 6A 26 10A 10 2A 67 73 1.2 0.8

Fruit from: organic (ORG), integrated (INT), and conventional (CON) agriculture. Number of samples. c ANOVA and mean comparisons by Tukey HSD test for unequal number of samples at 5% level. d Hydroxymethylfurfural (HMF). e Peak tR = 23.2 min (unknown) quanticated as 3-Hydroxy-2-pyrone derivative. f Furfural (FUR). AB Means within rows with changed letter are signicantly dierent according to the Tukey HSD test (P 6 0.05).

up to 78% of the total amino acid content (Fig. 1E). Amino acids did not appear to have a strong relationship with the accumulation of the furanic compounds in commercial apricot juices (r 6 0.47). Among the dierent amino acids, asparagine, the main amino acid of apricot juice, is considered to produce only an intermediate extent of browning, whereas the most reactive amino acids are lysine, glycine, tryptophan and tyrosine (Kaaname & Labuza, 1989). The chemical reactions responsible for non-enzymatic browning in foodstus are complex. Sometimes the main reactants are aldoses and amino acids, but in fruit juices fructose and organic acids are also involved. In system containing low ascorbic acid content, e.g. apricot juice, the formation of non-enzymatic browning is mainly due to the acid-catalyzed dehydration of sugars (Burdurlu, Koca, & Karadeniz, 2006; Roig, Bello, Rivera, & Kennedy, 1999). Sorbitol is an important index for detection of adulteration of apricot juice with sweeteners. The analysed apricot juices showed a range between 0.8 and 11 g/l, with one sample (0.8 g/l) falling outside the RSK guide values range of 1.514 g/kg. 3.2. Principal components analysis PCA was used as unsupervised method to examine the similarity among the three types of apricot juices. PCA on chemical composition of apricot juices resulted in two principal components (PCs) with eigenvalues >1 (PC1 = 4.9; PC2 = 1.7) that accounted for 66% of the total variance (Fig. 2). The PC1 (49%) was associated with HMF, fructose, malic acid, chlorogenic acid, and a*-parameter. The PC2

Fig. 2. Positions of the PC scores on the rst two PC axes for the apricot juices from organic ( ), integrated ( ), and conventional agriculture ().

(17%) was associated with asparagine and threonine. A clustering of apricot juices partially occurred. In fact, organic apricot juices showed some separation along the rst factor (positive half), whereas a lack of distinction between integrated and conventional juices appeared. The organic apricot juices were separated on the PC1 axis because of their high fructose, malic acid, chlorogenic acid, HMF content and a*-parameter, while the dispersion of conventional apricot juices along the PC2 axis was a function of asparagine and threonine content. Integrated juices were located close to the centre of the plot and did not appear to be dominated by any of the parameters.

A. Versari et al. / Food Chemistry 108 (2008) 334340

339

In conclusion, the modern fruit juice industry needs their products to be characterized by high-quality attributes to meet consumer expectations. In this view, the analytical control of fruit juice composition is becoming an important issue, and HPLC provides an important tool for research as well as for routine analysis. The commercial apricot juices showed some dierence in their composition especially in terms of glucose, fructose, malic acid, glycine, chlorogenic acid, rutin and a*-parameter. These compositional data are helpful in the development of future commercial juices to target specic consumer requirements. A further long-term study is required to set up a reliable authentic database to be used to analyse unknown test samples. In this view, it is important to get more insight the interaction between the genetic and the environmental variability, the growing condition and the processing on the composition of apricot fruits and juices. References

A.I.J.N. (1996). Code of Practice for Evaluation of Fruit and Vegetable Juices. Association of the Industry of Juices and Nectars from Fruits and Vegetables of the European Economic Community, Bruxelles. Bartolozzi, F., Bertazza, G., Bassi, D., & Cristoferi, G. (1997). Simultaneous determination of soluble sugars and organic acids as their trimethylsilyl derivatives in apricot fruits by gasliquid chromatography. Journal of Chromatography A, 758, 99107. Brandt, K., & Mlgaard, J. P. (2001). Organic agriculture: Does it enhance or reduce the nutritional value of plant foods? Journal of the Science of Food and Agriculture, 81, 924931. Burdurlu, H. S., Koca, N., & Karadeniz, F. (2006). Degradation of vitamin C in citrus juice concentrates during storage. Journal of Food Engineering, 74, 211216. Castellari, M., Versari, A., Spinabelli, U., Galassi, S., & Amati, A. (2000). An improved HPLC method for the analysis of organic acids, carbohydrates and alcohols in grape musts and wines. Journal of Liquid Chromatography & Related Technologies, 23, 20472056. Clydesdale, F. M., Kolasa, K. M., & Ikeda, J. P. (1995). All you want to know about fruit juice. Nutrition Today, 3(4), 1428. CoSeteng, M. Y., McLellan, M. R., & Downing, D. L. (1989). Inuence of titratable acidity and pH on intensity of sourness of citric, malic, tartaric, lactic and acetic acid solutions and on the overall acceptability of imitation apple juice. Canadian Institute of Food Science and Technology Journal, 22, 4651. Council Regulation (EEC) No. 2092/91 of 24 June 1991 on organic production of agricultural products and indications referring there to on agricultural products and foodstus with amendments. Ocial Journal of the European Communities, L198, 1991, 115. Doty, T. E. (1976). Fructose sweetness: A new dimension. Cereal Foods World, 21, 6263. Esti, M., Messia, M. C., Sinesio, F., Nicotra, A., Conte, L., La Notte, E., & Palleschi, G. (1997). Quality evaluation of peaches and nectarines by electrochemical and multivariate analyses: relationship between analytical measurements and sensory attributes. Food Chemistry, 60, 659666. Fabiani, A., Versari, A., Parpinello, G. P., Castellari, M., & Galassi, S. (2002). High performance liquid chromatographic analysis of free amino acids in fruit juices using derivatization with 9-uorenylmethylchloroformate. Journal of Chromatographic Science, 1, 1418. Fernandez de Simon, B., Perez-Ilzarbe, J., Hernandez, T., Gomez Cordoves, C., & Estrella, I. (1992). Importance of phenolic compounds for the characterization of fruit juices. Journal of Agricultural and Food Chemistry, 40, 15311535.

Fillion, L., & Arazi, S. (2002). Does organic food taste better? A claim substantiation approach. Nutrition and Food Science, 32, 153157. Garcia-Viguera, C., Bridle, P., Ferreres, F., & Tomas-Barberan, F. A. (1994). Inuence of variety, maturity and processing on phenolics compounds of apricot juices and jams. Zeitschrift fur Lebensmittel Unterschung und Forschung, 199, 433436. Garza, S., Ibarz, A., Pagan, J., & Giner, J. (1999). Non-enzymatic browning in peach puree during heating. Food Research International, 32, 335343. Gurrieri, F., Audergon, J.-M., Albagnac, G., & Reich, M. (2001). Soluble sugars and carboxylic acids in ripe apricot fruit as parameters for distinguishing dierent cultivars. Use of principal component analysis to characterize apricot fruit quality. Euphytica, 117, 183189. Johnson, I. T., Williamson, G., & Musk, S. R. R. (1994). Anticarcinogenic factors in plant foods: a new class of nutrients? Nutrition Research Review, 7, 175204. Kaaname, A., & Labuza, T. P. (1989). The Maillard reaction in foods. In J. W. Baynes & V. M. Monnier (Eds.), The Maillard Reaction in Aging, Diabetes, and Nutrition (pp. 301327). New York, NY: A.R. Liss, Inc. Publ.. Katona, Zs. F., Sass, P., & Molnar-Perl, I. (1999). Simultaneous determination of sugars, sugar alcohols, acids and amino acids in apricot by gas chromatographymass spectrometry. Journal of Chromatography A, 847, 91102. Lee, H. S., & Nagy, S. (1996). Chemical degradative indicators to monitor the quality of processed and stored citrus products. In Chemical Markers for Processed and Stored Foods. In T.-C. Lee & H.-J. Kim (Eds.). American Chemical Society, Symposium Series (vol. 631, pp. 86106). Washington, DC: American Chemical Society. Lewi, P. J. (1992). Multivariate data display. In R. G. Brereton (Ed.), Multivariate Pattern Recognition in Chemometrics (pp. 4370). London, UK: Elsevier. Lunati, F. (2005). La frutta biologica per la surgelazione e la produzione di succhi. Italus Hortus, 12, 1718. Mennone, C., Mattatelli, B., & Pirazzini, P. (2005). Evoluzione e prospettive della coltura dellalbicocco in Italia. Frutticoltura, 23, 1418. Miller, J. J., Colagiuri, S., & Brand, J. C. (1986). The diabetic diet: Information and implications for the food industry. Food Technology Australia, 38, 155160. Noble, A. C., Philbrick, K. C., & Boulton, R. B. (1986). Comparison of sourness of organic acid anions at equal pH and equal titratable acidity. Journal of Sensory Studies, 1, 18. Pangborn, R. M. (1963). Relative taste intensities of selected sugars and organic acids. Journal of Food Science, 28, 726733. Rice-Evans, C., Miller, N. J., & Paganga, G. (1996). Structureantioxidant activity relationship of avonoids and phenolic acids. Free Radical Biology and Medicine, 20, 933956. Roig, M. G., Bello, J. F., Rivera, Z. S., & Kennedy, J. F. (1999). Studies on the occurrence of non-enzymatic browning during storage of citrus juice. Food Research International, 32, 609619. RSK-value (1987). The Complete Manual. Guide Values and Range of Specic Numbers for Fruit Juices and Nectars. Including the Revised Methods of Analysis. Schonborn, Germany: Association of the German Fruit Juice Industry Verlag Flussiges Obst GmbH. Shallenberger, R. S., & Mattick, L. R. (1983). Relative stability of glucose and fructose at dierent acid pH. Food Chemistry, 12, 159165. Shaw, P. E., Tatum, J. H., Kew, T. J., Wagner, C. J., & Berry, R. E. (1970). Taste evaluation of nonenzymic browning compounds from orange powder and use of inhibitors. Journal of Agricultural and Food Chemistry, 18, 343345. ` Triro, A., Risi, P., Cocconi, E., & Bolzoni, L. (2006). Polyphenol content in pear, peach and apricot purees and nectars. Industria delle Conserve (Italy), 81, 269280. Versari, A., Mattioli, A., Parpinello, G. P., & Galassi, S. (2004). Rapid analysis of ascorbic and isoascorbic acids in fruit juice by capillary electrophoresis. Food Control, 15, 355358.

340

A. Versari et al. / Food Chemistry 108 (2008) 334340 Woese, K., Lange, D., Boess, C., & Bogl, W. K. (1997). A comparison of organically and conventionally grown foods Results of a review of the relevant literature. Journal of the Science of Food and Agriculture, 74, 281293.

Wills, R. B. H., Scriven, F. M., & Greeneld, H. (1983). Nutrient composition of stone fruit (Prunus spp.) cultivars: apricot, cherry, nectarine, peach and plum. Journal of the Science of Food and Agriculture, 34, 13831389.

Вам также может понравиться

- African Traditional Medicine A PrimerДокумент5 страницAfrican Traditional Medicine A PrimerEditor IJTSRDОценок пока нет

- Daily Lesson Log Personal Dev TДокумент34 страницыDaily Lesson Log Personal Dev TRicky Canico ArotОценок пока нет

- Fruit Juicing Lab ReportДокумент21 страницаFruit Juicing Lab ReportMarilyn Kwarteng100% (1)

- Decommissioning HSE PDFДокумент105 страницDecommissioning HSE PDFRafael Rocha100% (1)

- Determination of the Total Phenolic Contents of Essential Oil Obtained From Cymbopogon Citratus (Lemongrass) and Persea Americana Mill (Avocado Pear Seed) and Its Bioactive Component Using Gc-Ms AnalysisДокумент12 страницDetermination of the Total Phenolic Contents of Essential Oil Obtained From Cymbopogon Citratus (Lemongrass) and Persea Americana Mill (Avocado Pear Seed) and Its Bioactive Component Using Gc-Ms AnalysisInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Innovative Technologies in Beverage ProcessingОт EverandInnovative Technologies in Beverage ProcessingIngrid Aguilo-AguayoОценок пока нет

- Bar Exam Questions Week 1Документ30 страницBar Exam Questions Week 1Mark Bantigue100% (1)

- Recovery of Phenolic Antioxidants and Functional Compounds From Coffee Industry By-ProductsДокумент8 страницRecovery of Phenolic Antioxidants and Functional Compounds From Coffee Industry By-ProductsLaraib ShahidОценок пока нет

- Vi NagreДокумент11 страницVi Nagreivan estevesОценок пока нет

- Antioxidant Activity and Physico ChemicaДокумент9 страницAntioxidant Activity and Physico ChemicaParamita GhoshОценок пока нет

- Characterization of Polyphenols and Evaluation of Antioxidant Capacity in Grape Pomace of The Cv. MalbecДокумент7 страницCharacterization of Polyphenols and Evaluation of Antioxidant Capacity in Grape Pomace of The Cv. MalbecMOSTAPHA MOUTAOIKILОценок пока нет

- Effects of Apple Storage PeriДокумент10 страницEffects of Apple Storage PeriRyan RetortaОценок пока нет

- Journal of Food Engineering: G. Ferrari, P. Maresca, R. CiccaroneДокумент9 страницJournal of Food Engineering: G. Ferrari, P. Maresca, R. Ciccaronejoel tuanama salasОценок пока нет

- Analyses of Fresh and Dried Maqui Berries and Juice, J.E. Brauch - 2015Документ9 страницAnalyses of Fresh and Dried Maqui Berries and Juice, J.E. Brauch - 2015Ludwing BurgosОценок пока нет

- Food Chemistry: Theodora-Ioanna Lafka, Vassilia Sinanoglou, Evangelos S. LazosДокумент9 страницFood Chemistry: Theodora-Ioanna Lafka, Vassilia Sinanoglou, Evangelos S. LazosjeinerОценок пока нет

- Rodrigues 2021Документ11 страницRodrigues 2021Julieth Orduña OrtegaОценок пока нет

- 1 s2.0 S2665927121000332 MainДокумент10 страниц1 s2.0 S2665927121000332 MainLaires AraujoОценок пока нет

- Effect of Fruit Ripening On Bioactive Compounds AnДокумент7 страницEffect of Fruit Ripening On Bioactive Compounds AnIsabella Martins AndersenОценок пока нет

- Phytochemical Analysis and Antioxidant Activity of The Hydroethanolic Extract of Passiflora Edulis F. Flavicarpa ResiduesДокумент10 страницPhytochemical Analysis and Antioxidant Activity of The Hydroethanolic Extract of Passiflora Edulis F. Flavicarpa ResiduesJulianAndresSanchezRodriguezОценок пока нет

- A Novel Beverage Rich in Antioxidant Phenolics - Maqui Berry (Aristotelia Chilensis) and Lemon JuiceДокумент8 страницA Novel Beverage Rich in Antioxidant Phenolics - Maqui Berry (Aristotelia Chilensis) and Lemon JuiceRodrigo Alejandro Romo MuñozОценок пока нет

- Food Chemistry: Concepcio N Sa Nchez-Moreno, Lucı A Plaza, Begon A de Ancos, M. Pilar CanoДокумент8 страницFood Chemistry: Concepcio N Sa Nchez-Moreno, Lucı A Plaza, Begon A de Ancos, M. Pilar CanoJaderОценок пока нет

- Analisis Sensorial DescriptivoДокумент7 страницAnalisis Sensorial DescriptivoManuel VelezОценок пока нет

- Nutritional Quality and Bioactive Compounds of SOme Fruit JuiceДокумент8 страницNutritional Quality and Bioactive Compounds of SOme Fruit JuiceLSPRO LAMPUNGОценок пока нет

- Effect of Coating and Wrapping Materials On The Shelf Life of Apple Malus Domestica CV BorkhДокумент11 страницEffect of Coating and Wrapping Materials On The Shelf Life of Apple Malus Domestica CV BorkhNadia Aprili PutriОценок пока нет

- Res7 PDFДокумент12 страницRes7 PDFdon.meОценок пока нет

- Luo - 2019 - Rosemary VacuumДокумент13 страницLuo - 2019 - Rosemary VacuumMaja PezeljОценок пока нет

- ZJAR - Volume 46 - Issue 6 - Pages 1995-2008Документ14 страницZJAR - Volume 46 - Issue 6 - Pages 1995-2008phamgiang29032002Оценок пока нет

- Quitosano + Aceit Limon en FresonesДокумент28 страницQuitosano + Aceit Limon en FresonesMAX ALEJANDRO ACOSTA MONTALBÁNОценок пока нет

- Food Chemistry: M. Morales-De La Peña, L. Salvia-Trujillo, M.A. Rojas-Graü, O. Martín-BellosoДокумент9 страницFood Chemistry: M. Morales-De La Peña, L. Salvia-Trujillo, M.A. Rojas-Graü, O. Martín-BellosoChau PhanОценок пока нет

- Foods-02-00018 - Phenolic Extracts From Wild Olive Leaves and Their Potential As Edible Oils AntioxidantsДокумент14 страницFoods-02-00018 - Phenolic Extracts From Wild Olive Leaves and Their Potential As Edible Oils AntioxidantsDiego MattarocciОценок пока нет

- WineДокумент7 страницWinePorfirio JacobОценок пока нет

- Bodoira Et Al-2019-Journal of Food Science PDFДокумент8 страницBodoira Et Al-2019-Journal of Food Science PDFAnonymous YJLJ3g2Оценок пока нет

- The Influence of Cultivar and Enzyme Treatment On The Aroma Complex of Apple JuiceДокумент10 страницThe Influence of Cultivar and Enzyme Treatment On The Aroma Complex of Apple JuiceSemira ČanićОценок пока нет

- Gomez Et Al., 2019Документ43 страницыGomez Et Al., 2019Karla Alessandra Miranda VargasОценок пока нет

- HS-SPME-CG-EM Jugos y NéctaresДокумент11 страницHS-SPME-CG-EM Jugos y NéctarescarlosОценок пока нет

- Food Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberДокумент8 страницFood Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberMaria MihaelaОценок пока нет

- Analysis of Phenolic Compounds in Different Parts of Pomegranate Fruit by HPLC-PDA-ESI-MS and Evaluation of Their Antioxidant Activity - Application To Different Italian VarietiesДокумент14 страницAnalysis of Phenolic Compounds in Different Parts of Pomegranate Fruit by HPLC-PDA-ESI-MS and Evaluation of Their Antioxidant Activity - Application To Different Italian VarietiesAndré Gomes MesquitaОценок пока нет

- Journal of Food EngineeringДокумент9 страницJournal of Food EngineeringterОценок пока нет

- 4 - 2011 - Phenolic Compounds Content and Antioxidant Activity in Pomace From Selected Red Grapes Widely Produced in BraziliДокумент6 страниц4 - 2011 - Phenolic Compounds Content and Antioxidant Activity in Pomace From Selected Red Grapes Widely Produced in BraziliLIBIO FIDEL ESPINOZA MEZAОценок пока нет

- Blueberry Pomace, Valorization of An Industry By-Product Source of Fibre With Antioxidant CapacityДокумент8 страницBlueberry Pomace, Valorization of An Industry By-Product Source of Fibre With Antioxidant CapacityGRACIELAОценок пока нет

- The Antioxidative PotentialДокумент6 страницThe Antioxidative Potentialdiego16Оценок пока нет

- Effect of The Addition of Plant Extracts On The Microbiota of Minimally Processed Strawberry Jam and Its Physicochemical and Sensorial PropertiesДокумент9 страницEffect of The Addition of Plant Extracts On The Microbiota of Minimally Processed Strawberry Jam and Its Physicochemical and Sensorial PropertiesCosette VargasОценок пока нет

- Deoliveira 2009Документ7 страницDeoliveira 2009ChristopherОценок пока нет

- Food Chemistry: Pronprapa Wongfhun, Michael H. Gordon, Arunee ApichartsrangkoonДокумент6 страницFood Chemistry: Pronprapa Wongfhun, Michael H. Gordon, Arunee ApichartsrangkoonSaif EvonyОценок пока нет

- Research Journal JodieДокумент10 страницResearch Journal JodiesmileyjotvОценок пока нет

- Food Chemistry: Merve Tomas, Jules Beekwilder, Robert D. Hall, Osman Sagdic, Dilek Boyacioglu, Esra CapanogluДокумент8 страницFood Chemistry: Merve Tomas, Jules Beekwilder, Robert D. Hall, Osman Sagdic, Dilek Boyacioglu, Esra CapanogluDiego AiresОценок пока нет

- Juices Enriched With Phenolic Extracts From Grapes: Corresponding Author: Jana - Kulichova@mendelu - CZДокумент7 страницJuices Enriched With Phenolic Extracts From Grapes: Corresponding Author: Jana - Kulichova@mendelu - CZbnechitaОценок пока нет

- Robert 2010Документ9 страницRobert 2010Adhwa AlifahОценок пока нет

- 2021 - Bioactive Compounds Ant Antioxidant Capacity of Grape Pomance FlourДокумент8 страниц2021 - Bioactive Compounds Ant Antioxidant Capacity of Grape Pomance FlourLIBIO FIDEL ESPINOZA MEZAОценок пока нет

- Solvent Free Microwave-Assisted Extraction of Antioxidants From Sea Buckthorn (Hippophae Rhamnoides) Food By-ProductsДокумент9 страницSolvent Free Microwave-Assisted Extraction of Antioxidants From Sea Buckthorn (Hippophae Rhamnoides) Food By-ProductsBubuizan Valentina-IoanaОценок пока нет

- Valeriaceci 35 Mehmood 6357Документ10 страницValeriaceci 35 Mehmood 6357Manu ValluОценок пока нет

- 1 - Cao 2012Документ10 страниц1 - Cao 2012Fernando MendozaОценок пока нет

- Effect of Storage On Anthocyanin Degradation in Black Mulberry Juice and ConcentratesДокумент9 страницEffect of Storage On Anthocyanin Degradation in Black Mulberry Juice and ConcentratesMoh EfendiОценок пока нет

- Effect of Food Additives On The Antioxidant Properties andДокумент9 страницEffect of Food Additives On The Antioxidant Properties andRizki IchiОценок пока нет

- Valorización Del Orujo de Uva. Extracción de Compuestos Fenólicos Bioactivos Con Propiedades AntioxidantesДокумент10 страницValorización Del Orujo de Uva. Extracción de Compuestos Fenólicos Bioactivos Con Propiedades AntioxidantesGINA MENDOZA APAZAОценок пока нет

- Fortification of Yogurts With Different Antioxidant Preservatives A Comparative Study Between Natural and Synthetic AdditivesДокумент26 страницFortification of Yogurts With Different Antioxidant Preservatives A Comparative Study Between Natural and Synthetic AdditivesYans PangerunganОценок пока нет

- By-Products From Di Erent Citrus Processes As A Source of Customized Functional FibresДокумент6 страницBy-Products From Di Erent Citrus Processes As A Source of Customized Functional FibresdanielОценок пока нет

- Main Organic Acid Distribution of Authentic Citrus Juices in Turkey (#138557) - 119982Документ5 страницMain Organic Acid Distribution of Authentic Citrus Juices in Turkey (#138557) - 119982Ben WunderОценок пока нет

- OrangeДокумент16 страницOrangesankalp agarwalОценок пока нет

- Aop Cta 5947Документ8 страницAop Cta 5947Winda Uli AsifaОценок пока нет

- Food Chemistry: Antonella Bosso, Massimo Guaita, Maurizio PetrozzielloДокумент8 страницFood Chemistry: Antonella Bosso, Massimo Guaita, Maurizio PetrozzielloDaniela SolarteОценок пока нет

- Food Chemistry: Shixin Deng, Brett J. West, C. Jarakae JensenДокумент4 страницыFood Chemistry: Shixin Deng, Brett J. West, C. Jarakae JensenPetra GarcíaОценок пока нет

- On The Extraction and Antioxidant Activity of PhenДокумент10 страницOn The Extraction and Antioxidant Activity of PhenXimena CáceresОценок пока нет

- Phytochemical Composition and Antioxidant Activity of Fresh and Dried Grape (Vitis Vinifera) Fruit ProportionsДокумент6 страницPhytochemical Composition and Antioxidant Activity of Fresh and Dried Grape (Vitis Vinifera) Fruit ProportionsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- D435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureДокумент73 страницыD435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureD YasIr MussaОценок пока нет

- Life Everlasting 2021001Документ11 страницLife Everlasting 2021001realangelinemylee2020721001Оценок пока нет

- AJINOMOTO 2013 Ideal Amino Acid Profile For PigletsДокумент28 страницAJINOMOTO 2013 Ideal Amino Acid Profile For PigletsFreddy Alexander Horna Morillo100% (1)

- Research Paper CalamansiДокумент7 страницResearch Paper Calamansih040pass100% (1)

- Case StudyДокумент3 страницыCase StudyMarlon MagtibayОценок пока нет

- Showalter Female MaladyДокумент13 страницShowalter Female MaladyKevin Sebastian Patarroyo GalindoОценок пока нет

- Competency Competency Multiple Choice Multiple Choice ComputationДокумент4 страницыCompetency Competency Multiple Choice Multiple Choice ComputationAaron James LicoОценок пока нет

- Medical Devices Industry in IndiaДокумент6 страницMedical Devices Industry in IndiaMurali Krishna Reddy100% (1)

- Importance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyДокумент8 страницImportance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyilgarОценок пока нет

- Turbo Lab 1Документ10 страницTurbo Lab 1Seng SoonОценок пока нет

- A Sound of Thunder - Ray BradburyДокумент9 страницA Sound of Thunder - Ray BradburyBrenden CheeОценок пока нет

- (R#1) XQ-450 - 600-800VДокумент121 страница(R#1) XQ-450 - 600-800VFrancisco PestañoОценок пока нет

- Manufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Документ2 страницыManufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Official Feby AfriwanОценок пока нет

- A Research Presented ToДокумент28 страницA Research Presented ToAngeliePanerioGonzagaОценок пока нет

- Burns Plastic Reconstructive Surgery MSCДокумент4 страницыBurns Plastic Reconstructive Surgery MSCCareer VoyageОценок пока нет

- Standard Practice For Magnetic Particle Testing For AerospaceДокумент16 страницStandard Practice For Magnetic Particle Testing For AerospaceSaul RuizОценок пока нет

- Nutritional Classification of BacteriaДокумент7 страницNutritional Classification of BacteriaRalphpinno SanchezОценок пока нет

- Ocean StarДокумент36 страницOcean Starrobertshepard1967Оценок пока нет

- Brief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsДокумент9 страницBrief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsFELIPE ROJAS TRAVERSOОценок пока нет

- FPGA-based System For Heart Rate Monitoring PDFДокумент12 страницFPGA-based System For Heart Rate Monitoring PDFkishorechiyaОценок пока нет

- TAXATIONДокумент18 страницTAXATIONNadine LumanogОценок пока нет

- Mary Kay FinalДокумент17 страницMary Kay Finalharsh0695Оценок пока нет

- TMP DEDAДокумент8 страницTMP DEDAFrontiersОценок пока нет

- Imperial SpeechДокумент2 страницыImperial SpeechROJE DANNELL GALVANОценок пока нет

- Department of Education: Republic of The PhilippinesДокумент1 страницаDepartment of Education: Republic of The PhilippinesAre Em GeeОценок пока нет

- اطلع علي زتونة 3 ع مراجعة الترم الثاني 2024Документ60 страницاطلع علي زتونة 3 ع مراجعة الترم الثاني 2024ahmad sholokОценок пока нет