Академический Документы

Профессиональный Документы

Культура Документы

Formulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol Hydrochloride

Загружено:

IOSR Journal of PharmacyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Formulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol Hydrochloride

Загружено:

IOSR Journal of PharmacyАвторское право:

Доступные форматы

IOSR Journal of Parmacy ISSN: 2250-3013, www.iosrphr.org Volume 2 Issue 5 Sep-Oct. 2012 PP.

34-38

Formulation and evaluation of controlled release ocular inserts of betaxolol hydrochloride

Ashture Amar1, Kankudte Ashish2, Patil Ajaykumar1, Joshi Anand1

2

Department of Industrial Pharmacy, Karnataka College of pharmacy, Bidar, Karnataka, India Department of Quality Assurance, SSSs Indira college of Pharmacy, Nanded, Maharashtra, India

AbstractBetaxolol Hydrochloride is a cardio selective 1 adrenergic receptor blocking agent used in the

treatment of chronic open angle glaucoma and ocular hypertension In the present study, an attempt was made to formulate Betaxolol HCl ocular inserts. In matrix type the formulations for Betaxolol containing 10%, 12%, and 14% w/v of Gelatin, 1%, 1.5%, 2%, 2.5% and 3% w/v for Chitosan were prepared by solvent casting method and plasticizer were used in different concentration for smoothing texture of the ocular inserts. The prepared batches of ocular inserts were evaluated for weight variation thickness, drug content uniformity, swelling index. An increase in average weight and thickness is due to increase in polymer concentration. IR spectral studies were performed to confirm the interaction of drug with excipients. All formulations were tested for in vitro drug release (Simulated tear fluid) by vial method. The formulations GH8 and C5 show a maximum cumulative percentage drug release of 98.76% and 97.72% at the end of 12 th hrs, respectively. The drug release in all formulations decreases as the polymer concentration increases. The dissolution data of formulation were subjected to first order, Higuchis, and peppas equations. Drug release from the ocuserts by diffusion controlled mechanism. No significant change in the drug content and physical features was observed during storage at 250C/60% RH and 400C/75% RH for the selected formulation for three months. KeywordsBetaxolol Hydrochloride, Chitosan, Gelatin, Ocular inserts.

I.

INTRODUCTION

Betaxolol, Hydrochloride a cardio selective 1 adrenergic receptor blocking agent used in the treatment of chronic open angle glaucoma and ocular hypertension1. Continuous delivery of drugs to the eye offers major advantages over conventional therapies that involve administration of drug solutions or suspensions as eye drops. Eye drop administration often results in poor bioavailability and therapeutic response due to rapid precorneal elimination of the drug and is also associated with patient compliance problems. The frequent periodic instillation of eye drops becomes necessary to maintain a continuous level of medication. This gives the eye a massive and unpredictable dose of medication. These factors necessitate the formulation of a controlled release ocular drug delivery system which maintains a steady state drug release. Ophthalmic inserts offer many advantages over conventional dosages forms, like increased ocular residence, possibility of releasing drug at a slow and constant rate, accurate dosing, and increased shelf life2. The use of hydrophilic polymer does not ensure the prolonged time of residence of medicament in the eye. The water insoluble polymers have the drawback of causing corneal abrasion, irritation.etc 3.The present study is an attempt to formulate ocular inserts of Betaxolol Hydrochloride using biodegradable polymers like Gelatin and Chitosan.

II.

MATERIALS METHODS

Materials Betaxolol Hydrochloride was obtained as a gift sample from FDC Pharmaceuticals (P) Ltd., Mumbai. Chitosan was obtained as a gift sample from Central Institute of Fisheries Technology, India. Gelatin was purchased from S.D.Fine Chemicals (P) Ltd., Boisar. All other chemicals and solvents used were of analytical reagent grade. Methods Preparation of Ocular Inserts Method used for the preparation of ocular inserts is solvent casting techinique4. Table 1 shows composition of ocular inserts. The required quantity of Polymers and glycerin were weighed and dissolved in purified water for gelatin and in acetic acid (1%v/v) for chitosan ,the mixture was heated at 600C on a water bath until the entire polymer was dissolved. The weighed amount of Betaxolol Hydrochloride (passed through sieve

34

Formulation and evaluation of controlled release ocular inserts of betaxolol hydrochloride

# 400) was added and stirred for 6 h at 400C on magnetic stirrer to get uniform dispersion. After complete mixing the casting solution 15 ml for gelatin and 50 ml for chitosan was poured in clean petridish (Anumbra, area of 63.64 cm2approximately). The petridish was cooled at 100C by placing on ice until the inserts were gelled. The gelled inserts were taken out from ice and allowed to dry at room temperature for 24 h. The dried inserts thus obtained were cut into required size (8mm diameter) by cork borer and wrapped individually in aluminum foil and stored till used for evaluation. Cross linking of the gelatin ocular inserts. The prepared inserts of gelatin were hardened by using 5 ml of 10%w/v solution of glutaraldehyde in isopropyl alcohol for a time period of 30min, the inserts were transferred to an aqueous sodium metabisulfite solution (2%w/v) and then immediately removed and placed in absolute alcohol bath to remove the excess of glutaraldehyde from the inserts. If the excess of glutaraldehyde was not removed from the surface, it may cause irritation to the eye. Evaluation of ocular inserts 6,7. The ocular inserts were evaluated for thickness, weight variation, swelling index and drug content uniformity. The thickness was measured using a dial caliper (Mitutoyo, Japan) at different points and the mean values were calculated. Ocular inserts weights were determined by using electronic balance. To check the uniformity of the drug in the film, three inserts were taken from each batch and individually dissolved or crushed in 5 ml of simulated tear fluid and the resultant solution was filtered. An aliquot of the filtrate was suitably diluted and analyzed spectrophotometrically (Shimadzu -UV1700) for Betaxolol HCl content at 233 nm. The concentration of the drug was determined from the standard curve. Same procedure was adopted for other formulations in triplicate and mean drug content and standard deviations were calculated. Swelling index9 Three inserts were weighed and placed separately in beakers containing 4ml of distilled water. After a period of 5 minutes, the inserts were removed and the excess water on their surface was removed using a filter paper and then again weighed till there was no increase in the weight. The swelling index was then calculated by dividing the increase in weight by the original weight and was expressed as percentage. Drug Excipients compatibility study by IR. The stability of the drug in the formulation was confirmed by IR spectral analysis. IR spectra of pure drug and formulations were determined using Shimadzu FTIR-8400S Spectrophotometer by KBr Disc method. In-vitro Drug Release Studies10 The in vitro drug release from the different ocular inserts was studied using the vial method. Each insert was placed in 10 ml capacity vials containing 5 ml of simulated tear fluid that was previously warmed at 37 10C. These vials were placed over hot plate (maintained at temperature 37 10 C) that was positioned on an electromagnetic sieve shaker (Electrolab-EMS-8). Shaker was kept at minimum shaking speed to simulate the blinking of eye. Aliquots of 1 ml samples at specific interval of time were withdrawn carefully using pipette and equivalent amount of fresh dissolution fluid was replaced. The aliquots withdrawn were suitably diluted with Simulated tear fluid and was analyzed at 233 nm using Shimadzu-UV1700 Spectrophotometer against blank. Accelerated Stability Studies The optimized formulations in its final pack were stored at 250C /60%RH and 400C/75%RH for 3 months in Humidity chamber (Thermolab). The samples were withdrawn at every 10 day time intervals and analyzed for physical appearance and drug content.

III.

RESULTS AND DISCUSSION

The thickness of the formulations containing gelatin varies from0.2810.021 to 0.3640.017mm, for formulation containing gelatin hardened for 30 minutes varies from 0.3030.014 to 0.3850.028 and for formulation containing chitosan variesfrom0.2950.041 to0.3410.029 mm, the results showed that the thickness was uniform. The weight of formulations containing gelatin varies from 16.660.01 to 20.700.01 mg, for formulations containing gelatin hardened for 30 minutes varies from 16.680.01 to 20.830.01 mg and for formulations containing chitosan varies from10.590.01 to 18.530.01 mg, for all formulations, as the polymer concentration increases weight of the inserts increases. The drug content in all formulations were found to contain 91.760.01% to 99.790.01 % of Betaxolol Hydrochloride, which complies with BP. IR spectra analytical reports shown in Fig 1 indicating that there was no interaction between drug and excipients used.

35

Formulation and evaluation of controlled release ocular inserts of betaxolol hydrochloride

The swelling index of all formulations varies from1.710.02 to 2.780.01% shown in the Fig 2. The results showed that swelling index increased as the concentration of gelatin increases, where as hardening of gelatin formulations for 30 minutes with glutaraldehyde decreased the swelling index which may be due to decreased in water permeability, further the swelling index decreased as the concentration of chitosan increases, which may be attributed to its relatively poor water solubility. Increase in the concentration of glycerin in gelatin, hardened gelatin and chitosan formulations increased the swelling index The ocular inserts prepared with gelatin released the drug in 2-3 h. The formulations with gelatin hardened for 30 minutes showed complete release of drug within 8-12 h. The formulation prepared with chitosan showed complete release of drug within 3-12 h. As the concentration of polymer increases, drug release from the formulations decreases. As the concentration of glycerin in formulation is increased drug release was increased, which could be attributed to its high rate and extent of swelling. This finding was also supported by results of swelling studies where the highest swelling index was exhibited by the formulation containing highest concentration of glycerin, indicating that increase in water soluble plasticizer content results in faster swelling and release from ocular inserts. When the formulation containing gelatin was hardened for 30 minutes with glutaraldehyde the drug release decreased. The release of the drug from the ocular inserts containing gelatin and chitosan has followed first order kinetics and fickian diffusion transport whereas the ocular inserts containing gelatin hardened for 30 minutes followed zero order kinetics and non-Fickian diffusion transport. Among all the formulations, the best formulations were GH8containing gelatin 14% w/v hardened for 30 mins with glutaraldehyde and C5containing chitosan 3% w/v, since they showed retarded release of drug up to 12h. The formulations GH8and C5were subjected to stability studies. From the result of accelerated stability studies it was found that the formulations were stable and the drug content was found to be within limits.

IV.

CONCLUSION

From the results it can be concluded that formulations GH8 containing gelatin 14%w/v hardened for 30minutes with glutaraldehyde and C5 containing Chitosan 3% w/v has achieved the objectives of increased contact time, prolonged release, and decreased frequency of administration and thus may improve the patient compliance. V. ACKNOWLEDGEMENTS The authors are thankful to the Principal, Karnataka College of Pharmacy, Bidar for providing the necessary facilities.

REFERENCES

[1]. [2]. [3]. [4]. [5]. [6]. [7]. [8]. [9]. [10]. Swamy SMV et al Development of sustained ocular drug delivery system for betaxolol. Indian j Pharm Educ Res. 2006 July-September; 40(3): 165-68. B. K. Dubey et al, design and characterization of sustained release levofloxacin ocular inserts. International Journal of Biomedical and Advance Research vol 2,NO 11(2011) Narasimha Murthy.S Biodegradable polymer matrix based ocuserts of diclofenac sodium. Indian Drugs.1997; 34(6): 336-338 Manvi FV, et al. Development and evaluation of timolol maleate ocular inserts. Indian Drugs.1997; 34(5):264268. Mundada AS, et al. Design and evaluation of soluble ocular drug inserts for controlled release of ciprofloxacin hydrochloride. Indian J Pharm Sci.2004; 570-577. Mishra D N, et al. Design and Characterization of Bioadhesive in situ gelling Ocular inserts of gatifloxacin sesquihydrate. DARU.2008; 16: Allen DJ, et al. Apparatus and preliminary evaluation. J Pharm Sci. 1972; 61:106. Knaig JL, Goodmann H. J Pharma Sci. 1962; 5:77. Banker GS, et al. Water vapour transmission properties of free polymer films. IBID 1996; 18: 458. Dandagi PM, et al. Development and evaluation of ocular films of cromolyn sodium. Indian J Pharm Sci. 2004; 66(3): 309-312

36

Formulation and evaluation of controlled release ocular inserts of betaxolol hydrochloride

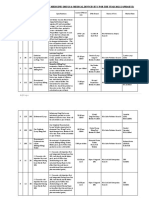

Table1: Composition of Formulations Glycerin Ingredients(%w/v) (%w/w of dry Betaxolol weight of Gelatin Chitosan HCl polymer) 0.33 10 40 0.33 10 50 0.33 10 60 0.33 12 40 0.33 12 50 0.33 12 60 0.33 14 40 0.33 14 50 0.33 14 60 0.1 1.0 20 0.1 1.5 20 0.1 2.0 20 0.1 2.5 20 0.1 3 20 0.1 3 10 0.1 3 30

Formulations G1 G2 G3 G4 G5 G6 G7 G8 G9 C1 C2 C3 C4 C5 C6 C7

Formulations* GH1 GH2 GH3 GH4 GH5 GH6 GH7 GH8 GH9 -

G-Gelatin inserts, GH-Gelatin inserts hardened for 30 minutes, C-Chitosan inserts. In all formulations Benzyl alkonium chloride (0.01%w/v) was used as preservative. *Formulations of gelatin hardened for 30min with glutaraldehyde.

Figure 1: Ftir Spectra Of Betaxolol Hcl (A), Betaxolol Hcl + Gelatin Hardened For 30 Minutes with Glutaraldehyde (B) And Betaxololhcl + Chitosan (C).

37

Formulation and evaluation of controlled release ocular inserts of betaxolol hydrochloride

3

2.5

% Swelling index

1.5

0.5

6 C

Formulations

Figure2: Percentage swelling index of all formulations

100

Cumulative % drug released

90 80 70 60 50 40 30 20 10 0 0 2 4 6 8 10 12 14 Time (h)

GH1 GH2 GH3 GH4 GH5 GH6 GH7 GH8 GH9

Figure 3: In Vitro drug release profiles of formulations containing gelatin ocular inserts hardened for 30 minutes with glutaraldehyde.

100

Cumulative % drug released

90 80 70 60 50 40 30 20 10 0 0 2 4 6 8 10 12 14 Time (h) C1 C2 C3 C4 C5 C6 C7

Figure 4: In Vitro drug release profiles of formulations containing chitosan

38

Вам также может понравиться

- Formulation and Evaluation of Sustained Release Sodium Alginate Microbeads of CarvedilolДокумент8 страницFormulation and Evaluation of Sustained Release Sodium Alginate Microbeads of CarvedilolDelfina HuangОценок пока нет

- Formulation and Evaluation of in Situ Ophthalmic Gels of Diclofenac SodiumДокумент8 страницFormulation and Evaluation of in Situ Ophthalmic Gels of Diclofenac Sodiumsunaina agarwalОценок пока нет

- Captopril FloatingДокумент6 страницCaptopril FloatingMira TjakkuduОценок пока нет

- A Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaДокумент14 страницA Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaSaravanan RamОценок пока нет

- ClarithromycinДокумент6 страницClarithromycinFareeha ZahoorОценок пока нет

- Etoposide JurnalДокумент6 страницEtoposide JurnalShalie VhiantyОценок пока нет

- Aloe Vera GelДокумент8 страницAloe Vera GelUday MahajanОценок пока нет

- Development of New Ophthalmic Suspension Prednisolone AcetateДокумент6 страницDevelopment of New Ophthalmic Suspension Prednisolone AcetaterandatagОценок пока нет

- Formulation and Evaluation of Niosomal in Situ GelДокумент14 страницFormulation and Evaluation of Niosomal in Situ GelrandatagОценок пока нет

- The Effect of Tea Pigment On The Properties of Hydroxypropylmethylcellulose For Curing Artificial Tears of Animal EyeДокумент9 страницThe Effect of Tea Pigment On The Properties of Hydroxypropylmethylcellulose For Curing Artificial Tears of Animal EyeZainab SattarОценок пока нет

- A C A D e M I C S C I e N C e SДокумент7 страницA C A D e M I C S C I e N C e SMSKОценок пока нет

- Experiment No:: Object/AimДокумент9 страницExperiment No:: Object/AimSudeep KothariОценок пока нет

- My Research PaperДокумент10 страницMy Research PaperMamta AroraОценок пока нет

- Salbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesДокумент8 страницSalbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesThiiwiie'thiiwiie PrathiiwiieОценок пока нет

- Formulation and In-Vitro Evaluation of Glibenclamide Dry Emulsion in Vegetarian CapsulesДокумент5 страницFormulation and In-Vitro Evaluation of Glibenclamide Dry Emulsion in Vegetarian CapsulesBaru Chandrasekhar RaoОценок пока нет

- Sajp2 (4) 315 318Документ4 страницыSajp2 (4) 315 318Habibur RahmanОценок пока нет

- Claudio Müller, Gloria Godoy, Marta de Diego.: Chemical Stability of Prednisone Oral Suspension and Drug SubstanceДокумент5 страницClaudio Müller, Gloria Godoy, Marta de Diego.: Chemical Stability of Prednisone Oral Suspension and Drug SubstanceGitanti Rohmanda HolaholaОценок пока нет

- Stability Testing of Beclomethasone Dipropionate NanoemulsionДокумент7 страницStability Testing of Beclomethasone Dipropionate NanoemulsionEdgar Pardo SotoОценок пока нет

- Vol 2 - Cont. J. Pharm SciДокумент48 страницVol 2 - Cont. J. Pharm Sciwilolud9822Оценок пока нет

- Journal 7225Документ5 страницJournal 7225Viena Che Bolu GultomОценок пока нет

- Experiment KumudДокумент8 страницExperiment KumudSudeep KothariОценок пока нет

- Formulation and Evaluation of Herbal Cream Containing Curcuma LongaДокумент7 страницFormulation and Evaluation of Herbal Cream Containing Curcuma LongaAnonymous uDOOlXxOIAОценок пока нет

- Formulasi Sediaan FarmasiДокумент11 страницFormulasi Sediaan FarmasiKukuh PermadiОценок пока нет

- Research PaperДокумент6 страницResearch PaperNitin BansalОценок пока нет

- A A A A C CC C A A A A D D D D Eeee M M M M IIII C CC C S S S S C CC C IIII Eeee N N N N C CC C Eeee S S S SДокумент5 страницA A A A C CC C A A A A D D D D Eeee M M M M IIII C CC C S S S S C CC C IIII Eeee N N N N C CC C Eeee S S S SvouudaosuОценок пока нет

- 5 MargretChandiraДокумент16 страниц5 MargretChandiraFIRMAN MUHARAMОценок пока нет

- Formulation & Evaluation of GelДокумент4 страницыFormulation & Evaluation of GelMeenakshi VermaОценок пока нет

- 566 PDFДокумент6 страниц566 PDFafrilya eka anggraeniОценок пока нет

- Dry Suspension Formulation of Taste Masked Antibiotic Drug For Pediatric UseДокумент6 страницDry Suspension Formulation of Taste Masked Antibiotic Drug For Pediatric UseRani RubiyantiОценок пока нет

- Dry Blend Scale UpДокумент5 страницDry Blend Scale Upzedd06Оценок пока нет

- Article WJPR 1469869485Документ9 страницArticle WJPR 1469869485DewimОценок пока нет

- Preparation and Evaluation of Solid Dispersion of Candesartan CilexetilДокумент5 страницPreparation and Evaluation of Solid Dispersion of Candesartan CilexetilDeepu NaniОценок пока нет

- Research Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneДокумент9 страницResearch Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneMuhamad Nur ArifinОценок пока нет

- Ethanol Content Determination in Medicine Syrups UДокумент8 страницEthanol Content Determination in Medicine Syrups UemilОценок пока нет

- Formulation & Evaluation of Floatable Insitu Gel For Stomach-Specific Drug Delivery of OfloxacinДокумент15 страницFormulation & Evaluation of Floatable Insitu Gel For Stomach-Specific Drug Delivery of OfloxacincpmelankolisОценок пока нет

- Jurnal Transdermal IbuprofenДокумент12 страницJurnal Transdermal IbuprofenRatissa Eka NingtiyasОценок пока нет

- Thermosensitive in Situ Gel For Ocular Delivery of LomefloxacinДокумент6 страницThermosensitive in Situ Gel For Ocular Delivery of LomefloxacinNAVDEEP SINGHОценок пока нет

- Physical and Release Properties of Metronidazole SuppositoriesДокумент10 страницPhysical and Release Properties of Metronidazole SuppositoriesZainab Eassa JassimОценок пока нет

- Project PPT YugeshДокумент57 страницProject PPT Yugeshyugesh shresthaОценок пока нет

- Spectrophotometric Method Development and ValidatiДокумент7 страницSpectrophotometric Method Development and ValidatiEVELYN SOLANHS ACERO RODRIGUEZОценок пока нет

- 03 Ijpscr 2022 0005Документ6 страниц03 Ijpscr 2022 0005BRNSS Publication Hub InfoОценок пока нет

- 1223-Article Text-4692-1-10-20081006 PDFДокумент6 страниц1223-Article Text-4692-1-10-20081006 PDFJosé RojasОценок пока нет

- Microsoft Word - 2 - APP-94-30-12Документ5 страницMicrosoft Word - 2 - APP-94-30-12Ronaldo JemaduОценок пока нет

- JURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19Документ3 страницыJURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19AnditapitalokaОценок пока нет

- Formulation and Evaluation of Thermosensitive Intranasal in Situ Gel of Sumatriptan Succinate by Using A Blend of PolymersДокумент9 страницFormulation and Evaluation of Thermosensitive Intranasal in Situ Gel of Sumatriptan Succinate by Using A Blend of PolymersabikeshОценок пока нет

- Formulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanДокумент8 страницFormulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanDược K45 Trần Dũng TâmОценок пока нет

- Ijipsrmnr 880Документ13 страницIjipsrmnr 880srirampharmОценок пока нет

- Dissolution Rate Enhancement of Aceclofenac by Solid Dispersion TechniqueДокумент5 страницDissolution Rate Enhancement of Aceclofenac by Solid Dispersion TechniqueMuthia ZhafiRaОценок пока нет

- Formulation and Phisical Stability Testing of Chitosan Gel From Vaname Shrimp Shell (Litopenaeus Vannamei) With Carbopol 940 Gelling AgentДокумент1 страницаFormulation and Phisical Stability Testing of Chitosan Gel From Vaname Shrimp Shell (Litopenaeus Vannamei) With Carbopol 940 Gelling AgentWeirdo BlackОценок пока нет

- Formulation and Evaluation of Prednisolone Sodium Phosphate InjectionДокумент8 страницFormulation and Evaluation of Prednisolone Sodium Phosphate InjectionMiranda MileОценок пока нет

- Saquinavir Sodgganga PDFДокумент104 страницыSaquinavir Sodgganga PDFSiva PrasadОценок пока нет

- GSCBPS 2019 0082Документ17 страницGSCBPS 2019 0082mwdhtirahОценок пока нет

- Ebeb PDFДокумент5 страницEbeb PDFAlbert FandohanОценок пока нет

- Spectrometric Dissolution Method For Dabigatran Etexilate Mesylate CapsulesДокумент14 страницSpectrometric Dissolution Method For Dabigatran Etexilate Mesylate CapsulesVinod ChoudharyОценок пока нет

- A Validated RP-HPLC Method For The Determination of Celecoxib in Bulk and Pharmaceutical Dosage FormДокумент5 страницA Validated RP-HPLC Method For The Determination of Celecoxib in Bulk and Pharmaceutical Dosage FormOskar LazaroОценок пока нет

- 4.dileep Clopidogrel Oct 2012Документ11 страниц4.dileep Clopidogrel Oct 2012Suman kamuruОценок пока нет

- Silver Sulfadiazine For Treatment of Burns and Wounds PDFДокумент7 страницSilver Sulfadiazine For Treatment of Burns and Wounds PDFprakas.rao39695Оценок пока нет

- Sajp2 (4) 319 322Документ4 страницыSajp2 (4) 319 322Habibur RahmanОценок пока нет

- Sulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportДокумент3 страницыSulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportIOSR Journal of PharmacyОценок пока нет

- A Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantДокумент5 страницA Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantIOSR Journal of PharmacyОценок пока нет

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- Treatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.Документ3 страницыTreatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.IOSR Journal of Pharmacy100% (1)

- Phytochemical Screening and Antioxidant Activity of Clove Mistletoe Leaf Extracts (Dendrophthoe Pentandra (L.) Miq)Документ6 страницPhytochemical Screening and Antioxidant Activity of Clove Mistletoe Leaf Extracts (Dendrophthoe Pentandra (L.) Miq)IOSR Journal of PharmacyОценок пока нет

- Master Formula CardДокумент7 страницMaster Formula CardTrilochan Ayurveda100% (1)

- Analysis and Critical Review of ICH Q8, Q9 and Q10 From A Generic Pharmaceutical Industry View PointДокумент12 страницAnalysis and Critical Review of ICH Q8, Q9 and Q10 From A Generic Pharmaceutical Industry View PointARMANDO JOSE RIVERO LAVERDEОценок пока нет

- Truth in AdvertisingДокумент3 страницыTruth in AdvertisingClyde TanОценок пока нет

- Capítulo 5 - Micelas Poliméricas para Encapsulación, Vectorización y Cesión de FármacosДокумент37 страницCapítulo 5 - Micelas Poliméricas para Encapsulación, Vectorización y Cesión de FármacosJessica RomeroОценок пока нет

- Financial Report 2013 Ghandhara NissanДокумент123 страницыFinancial Report 2013 Ghandhara NissanSarfraz AliОценок пока нет

- IVMS ID High Yield Microbiology Antimicrobial Pharmacology and IDДокумент58 страницIVMS ID High Yield Microbiology Antimicrobial Pharmacology and IDiahmed3000100% (1)

- Market Survey Medicine Phase II 22-23Документ3 страницыMarket Survey Medicine Phase II 22-23Hajra MirzaОценок пока нет

- Adverse Effects of FluoroquinolonesДокумент10 страницAdverse Effects of FluoroquinolonesAvelox FloxОценок пока нет

- Reflections DR PG RamanДокумент213 страницReflections DR PG RamanAbiola Williams Smith100% (1)

- Nikolas Rose - Neurochemical SelvesДокумент15 страницNikolas Rose - Neurochemical Selveslc49Оценок пока нет

- Konduktometri Jurnal KaiДокумент9 страницKonduktometri Jurnal Kaianggihalfiantara_178Оценок пока нет

- Generic Name Brand Name Dosage Indications Mechanisms of Action Adverse Effects Nursing ResponsibilitiesДокумент10 страницGeneric Name Brand Name Dosage Indications Mechanisms of Action Adverse Effects Nursing ResponsibilitiesJennalyn CasapaoОценок пока нет

- Stok Per 05 Juli 2019Документ34 страницыStok Per 05 Juli 2019Desi SafitriОценок пока нет

- Herbal Property Dictionary SampleДокумент27 страницHerbal Property Dictionary Sampledarkllight100% (3)

- University of San Carlos Department of Business Administration School of Business and EconomicsДокумент4 страницыUniversity of San Carlos Department of Business Administration School of Business and EconomicsDaisy KetchОценок пока нет

- DendrimersДокумент8 страницDendrimersAjaya BhattaraiОценок пока нет

- Medical and Pharmaceutical Commoditi 4 C 8 GRДокумент1 страницаMedical and Pharmaceutical Commoditi 4 C 8 GROksanaОценок пока нет

- Handbook On Herbal Products (Medicines, Cosmetics, Toiletries, Perfumes) 2 Vols. - Chapter 'Herbal Cosmetics'Документ41 страницаHandbook On Herbal Products (Medicines, Cosmetics, Toiletries, Perfumes) 2 Vols. - Chapter 'Herbal Cosmetics'randatagОценок пока нет

- PACOP GREEN QUESTIONS-dispДокумент4 страницыPACOP GREEN QUESTIONS-dispMark Clinton OrigenesОценок пока нет

- Daftar PustakaДокумент2 страницыDaftar Pustakarini dwi wahyuningsihОценок пока нет

- Effective Home Remedies With HerbsДокумент23 страницыEffective Home Remedies With HerbsAlexandru Vasile100% (1)

- CASE STUDY CHAPTER 3 Business EthicsДокумент5 страницCASE STUDY CHAPTER 3 Business EthicsHeidy JosephineОценок пока нет

- ch8 1Документ8 страницch8 1yonggyeОценок пока нет

- CNS StimulantsДокумент18 страницCNS StimulantsMartynas MockusОценок пока нет

- NCK Catalogue 3.1Документ36 страницNCK Catalogue 3.1Rajesh WostiОценок пока нет

- Research PlanДокумент7 страницResearch Planelieza salvadorОценок пока нет

- Mbbs Question PaperДокумент27 страницMbbs Question Paperwaku74Оценок пока нет

- Mumbai ListДокумент2 744 страницыMumbai ListShuBham Is Live100% (1)

- Ayurved Visitation Proforma 2011-12 PDFДокумент41 страницаAyurved Visitation Proforma 2011-12 PDFAlapati Vinod KumarОценок пока нет

- Pharmaceutical Calculation I - Pharmaceutical CalculationДокумент39 страницPharmaceutical Calculation I - Pharmaceutical Calculationlili fitrianiОценок пока нет