Академический Документы

Профессиональный Документы

Культура Документы

Understanding Water Activity

Загружено:

AnikИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Understanding Water Activity

Загружено:

AnikАвторское право:

Доступные форматы

FEATURE

Understanding the Importance of Water Activity in Food

A. J. F ONTANA , J R .

Decagon Devices, Inc. Pullman, WA

nderstanding the role of water activity in food is important for food quality, stability, and safety. Water activity is an important property that can be used to predict food stability and safety with respect to microbial growth, rates of deteriorative reactions, and physical properties. Throughout history the importance of controlling water in food to preserve and control food quality by drying, freezing, or adding sugar or salt has been recognized. Water activity is a measure of the energy status of the water in a system (or the degree to which water is bound) and, hence, its availability to act as a solvent and participate in chemical and biochemical reactions and growth of microorganisms. The concept of water activity has been incorporated by various regulatory agencies in defining safety regulations regarding growth of undesirable microorganisms, definitions of potentially hazardous foods, critical control points, standards for several preserved foods, and packaging requirements. Two basic properties of water can be measured. First, water content describes the total amount of water present in a food system. Second, water activity (a w ) describes the energy status or escaping tendency of the water in a product. The water activity of a product is equal to the relative humidity of the air in equilibrium with the product in a sealed measurement chamber. Both the water content and activity of a product must be specified to fully describe its water status. However, water activity is the property most important in food quality and safety issues.

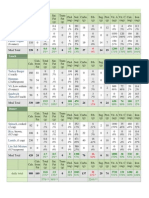

Figure 1 shows food stability in terms of rates of degradative reactions as a function of water activity (1). Water activity predicts food safety and stability with respect to microbial growth, chemical and biochemical reaction rates, and physical properties. By measuring and controlling water activity in foodstuffs, it is possible to 1) predict which microorganisms will be potential sources of spoilage and infection, 2) maintain the chemical stability of foods, 3) minimize nonenzymatic browning reactions and spontaneous autocatalytic lipid oxidation reactions, 4) prolong the desired activity of enzymes and vitamins in food, and 5) optimize the physical properties of foods, such as texture and shelf life. Each of these areas will be discussed in detail. Microbial Safety One purpose of food safety is to prevent growth of and toxin production by harmful microorganisms. According to the 1995 trends shown in a U.S. survey, American consumers confidence in the safety of its food supply has increased. In fact, 77% of shoppers are now completely or mostly satisfied that supermarket foods are safe (2). However, spoilage and bacterial contamination were identified as concerns. Scott (3) showed that microorganisms have a limiting water-activity level below which they will not grow. Water activity (a w ), not water content, determines the lower limit of available water for microbial growth. The lowest a w levels at which the vast majority of food-spoiling bacteria will

grow is 0.90. Staphylococcus aureus under anaerobic conditions is inhibited at an a w of 0.91, but under aerobic conditions the inhibitory a w level is 0.86. The a w limit for mold and yeast growth is 0.61, whereas mycotoxigenic molds have a lower limit for growth at an a w of 0.78 (4). Table I lists the water activity limits for growth of microorganisms significant to public health and examples of foods that generally contain microorganism levels within these ranges. In addition to the relationship between microbial growth and water activity, a number of other aspects of food microbiology are influenced by water activity. The effect of a w on sporulation, germination, and mycotoxin production of microorganisms is complex (5). Generally for yeast, a higher a w level is required for sporulation than for spore germination. The minimum aw level for toxin production is generally higher than the minimum a w level necessary for growth. Chemical and Biochemical Reactivity Water activity influences not only microbial spoilage but also chemical and enzymatic reactions. Water may act as a solvent or reactant or change the mobility of the reactants by affecting the viscosity of the food system (6). Water activity influences the rate and extent of nonenzymatic browning, lipid oxidation, degradation of vitamins,

CEREAL FOODS WORLD / 7

Publication no. W-1999-1214-01F. 2000 American Association of Cereal Chemists, Inc.

enzymatic reactions, protein denaturation, starch gelatinization, and starch retrogradation. The rate of nonenzymatic browning increases with increasing aw, reaching a maximum at aw ranging from 0.6 to 0.7 (Fig. 1). Lipid oxidation rate is at its minimum when aw has an intermediate range and increases at both high and low aw levels, although due to different mechanisms. These

reactions result in the formation of highly objectionable flavors and odors. Watersoluble vitamin degradation in food systems increases with increasing aw levels (7). Enzyme and protein stability is influenced significantly by water activity due to their relatively fragile natures. Most enzymes and proteins must maintain conformation to remain active. Maintaining critical aw levels to prevent or entice conforma-

tional changes is important to food quality. Most enzymatic reactions are slowed at water activities below 0.8, but some reactions occur even at very low aw levels, such as 0.20.3. Water activity also influences the gelatinization temperature and retrogradation rate of starch. Physical Properties In addition to predicting the rates of various chemical and enzymatic reactions, water activity effects the textural properties of foods. Foods with high aw have a texture that is described as moist, juicy, tender, and chewy (8). When the water activity of these products is lowered, undesirable texture attributes, such as hard, dry, stale, and tough are used. Foods with normally low aw have texture attributes described as crisp and crunchy, whereas higher aw levels may change the texture to soggy. Dry, cereal-based foods and starch-based snack products, such as crackers, potato chips, puffed corn curls, and popcorn, lose their sensory crispness with increasing water activity. The crispness intensity and overall hedonic texture of dry snack food products are a function of aw (9). Critical water activities are found when products become unacceptable from a sensory standpoint, falling into the aw range where amorphous to crystalline transformations occur in simple-sugar food systems and mobilization of soluble food constituents begins. Excessive and rapid drying or moisture reabsorption by glassy materials can cause undesirable consequences, such as product loss due to cracking and excessive breakage. Water activity is an important parameter in controlling water migration of multicomponent products. Some foods contain components at different water activity levels, such as cream-filled snack cakes or cereals with dried fruits. Moisture will migrate from a region of high aw to a region of lower aw; the rate of migration depends on many factors. Undesirable texture changes can result from moisture migration in multicomponent foods. For example, moisture migrating from the higher aw of dried fruit to the lower aw of cereal causes the fruit to become hard and dry, while the cereal becomes soggy (10). Water activity also is an important factor affecting the stability of powders and dehydrated products during storage. Controlling water activity in a powder product maintains proper product structure, texture, stability, density, and rehydration properties. Knowledge of the water activity of powders as a function of moisture content and temperature is essential during processing, handling, packaging, and storage to prevent the deleterious phenomena of caking, clumping, collapse, and stickiness. Caking is water activity, time- and temperature-dependent and is related to the collapse phenomena of the powder under gravitational force (11).

Ionic

Covalent

Solute & Capillary

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Fig. 1. Water ActivityStability Map (adapted from Labuza [1]). Table I. Water Activity and Growth of Microorganisms in Fooda Range of aw 1.000.95 Microorganisms Generally Inhibited by Lowest aw in This Range Pseudomonas, Escherichia, Proteus, Shigella, Klebsiella, Bacillus, Clostridium perfringens, some yeasts Salmonella, Vibrio parahaemolyticus, Clostridium botulinum, Serratia, Lactobacillus, Pediococcus, some molds and yeasts Many yeasts, Micrococcus Foods Generally in This Range Highly perishable (fresh) foods and canned fruits, vegetables, meat, fish, and milk; foods containing up to 40% (w/w) sucrose or 7% sodium chloride Some cheeses (cheddar, swiss, muenster, provolone); cured meats; some fruit juice concentrates; foods containing 55% (w/w) sucrose or 12% sodium chloride Fermented sausages; sponge cakes; dry cheeses; margarine; foods containing 65% (w/w) sucrose (saturated) or 15% sodium chloride Most fruit juice concentrates; sweetened condensed milk; flour; rice; pulses containing 1517% moisture Jam; marmalade Rolled oats containing 10% moisture; fudge; marshmallows; jelly; some dried fruits; nuts Dried fruits containing 1520% moisture; honey Pasta containing 12% moisture; spices containing 10% moisture Whole egg powder containing 5% moisture Cookies, crackers, bread crusts, etc. containing 35% moisture Whole milk powder containing 23% moisture; dried vegetables containing 5% moisture; corn flakes containing 5% moisture

0.950.91

0.910.87

0.870.80 0.800.75 0.750.65 0.650.60 0.50 0.40 0.30 0.20

Most molds, Staphylococcus aureus, most Saccharomyces (bailii) spp., Debaryomyces Most halophilic bacteria, mycotoxigenic aspergilli Xerophilic molds, Saccharomyces bisporus Osmophilic yeasts, few molds No microbial proliferation No microbial proliferation No microbial proliferation No microbial proliferation

Adapted from Beuchat (4).

8 / JANUARY 2000, VOL. 45, NO. 1

Shelf Life and Packaging Water activity also determines the shelf life of products. Critical upper and lower water activity levels can be established with respect to microbial, texture, flavor, appearance, aroma, nutritional, and cooking qualities of food products. Rates of moisture exchange through the package and the rate of change in aw of the food toward a critical limit determines the shelf life of a product. Knowledge of the temperature, ambient relative humidity, and critical aw levels can aid in selection of a package with the correct barrier properties to optimize quality and shelf life. Government Regulations The U.S. FDAs Good Manufacturing Practice (GMP) regulations (12) incorporate water activity guidelines in defining food safety regulations. The purpose of GMP regulations is to detail the specific requirements and practices to be followed by the industry to ensure foods are produced under sanitary conditions and are pure, wholesome, and safe to eat (13). However, neither GMP regulations nor regulatory agency activities alone can guarantee a completely safe food supply (14). A science-based system, such as hazard analysis and critical control points (HACCP), can improve food safety and reduce the incidence of foodborne illnesses. HACCP programs are mandatory for some segments of the food industry. HACCP is based on the idea that food safety problems can be controlled or prevented by controlling the production process from beginning to end, rather than relying on detection of problems in the finished product. HACCP identifies where potential hazards may occur in the food production process and determines critical control points for preventing problems. For example, a target water activity must be established to prevent hazardous organisms from growing. By controlling major food risks, such as microbiological, chemical, and physical contaminants, the food industry can better ensure the safety of its products. Water Activity Measurements In the past, measuring the water activity of foodstuffs was a time-consuming and difficult process. Methods of determining water activity are detailed in the Official Methods of Analysis of AOAC International (15). New instrument technologies have vastly improved the speed, accuracy, and reliability of measurements. Reliable laboratory instrumentation is required to guarantee the safety of food products and enforce government regulations. Two types of water activity instruments are available commercially. One uses chilled-mirror dewpoint technology, whereas the other measures relative humidity with sensors that detect changes in electrical resistance or capacitance. Each has advantages and disadvantages and varies in accuracy, repeat-

ability, speed of measurement, stability of calibration, linearity, and convenience. Dew point is a primary measurement of vapor pressure that has been used for decades (16). Dew-point instruments are accurate, fast, simple to use, and precise. (1720). The aw measurement range of commercially available dew-point meters is 0.030 to 1.000, with a resolution of 0.001 and accuracy of 0.003. Measurement time is typically less than 5 min. The basic principle involved in dew-point determination of vapor pressure in air is that air may be cooled without changes in water content until the air saturates. The

dew-point temperature is the temperature at which the air reaches saturation. It is determined by measuring the temperature of a chilled mirror when condensation begins. The water activity of the sample is the ratio of the saturation vapor pressure at the dew-point temperature to the saturation vapor pressure at the product temperature. In an instrument (AquaLab) dew point, the sample is equilibrated within the headspace of a sealed chamber containing a mirror, optical sensor, internal fan, and infrared temperature sensor. At equilibrium, the relative humidity of the air in the chamber is the same as the water activity of the

An advertisement appeared here in the printed version of the journal

CEREAL FOODS WORLD / 9

sample. A thermoelectric cooler precisely controls the mirror temperature. An optical reflectance sensor detects the exact point at which condensation first appears. A beam of infrared light is directed onto the mirror and reflected back to a photodetector that detects the change in reflectance when condensation occurs on the mirror. A thermocouple attached to the mirror accurately measures the dew-point temperature. The internal fan circulates the air, which reduces vapor equilibrium time and controls the boundary layer conductance of the mirror surface (21). Additionally, an infrared thermometer measures the sample-surface temperature. Both the dew-point and sample temperatures are used to determine water activity. When measuring water activity, the dew-point temperature is repeatedly determined until vapor equilibrium is reached. Because the measurement is based on temperature determination, calibration is unnecessary, but a standard salt solution can be run to check the proper functioning of the instrument. If there is a problem, the mirror is easily accessible and can be cleaned in a few minutes. Other instruments for measuring aw use resistance or capacitance sensors to measure relative humidity. These sensors are made from a hygroscopic polymer and associated circuitry that produces a signal relative to the equilibrium relative humidity (ERH). Commercially available instruments measure the entire aw range with an accuracy of 0.015. Because these instruments relate an electrical signal to relative humidity, the sensor must be calibrated with a minimum of five known salt standards. The ERH is equal to the water activity of the sample only as long as the sample and sensor temperatures are the same. Capacitive sensors typically require 30 to 90 min to reach complete temperature and vapor equilibrium. Accurate measurements require good temperature control. The advantages of capacitance sensors include simple design and inexpensive implementation. Conclusion For many foods, water activity is an important property in food quality and safety. It predicts food safety and stability with respect to microbial growth, chemical and biochemical reaction rates, and physical properties. The need to measure water activity in foods is illustrated by the FDAs incorporation of the water activity principle

A. J. Fontana, Jr. Anthony J. Fontana, Jr., Ph.D., is an applications engineer at Decagon Devices, Inc. He provides scientific and technical customer support and makes presentations of products, technologies, techniques, and applications to customers. In addition, he assists in product/technology development and testing. Prior to his work at Decagon, he managed a quality-control laboratory for a large cheese, whey protein concentrated, alcohol, and animal feed mix manufacturer. Dr. Fontana received his B.Sc. degree in Biochemistry from University of California, Riverside, in 1985, and his Ph.D. degree in Agricultural and Environmental Chemistry from University of California, Davis, in 1994.

into the Code of Federal Regulations. New instrument technologies have vastly improved speed, accuracy, and reliability of aw measurements. References

1. Labuza, T. P. Properties of water as related to the keeping quality of foods. Proc. 3rd Int. Congr. Food Sci. & Technol. IFT, Chicago 1970. 2. Sloan, A. E. Feeling safe about food safety. Food Technol. 49(6):21, 1995. 3. Scott, W. J. Water relations of food spoilage microorganisms. Adv. Food Res. 7:83, 1957. 4. Beuchat, L. R. Microbial stability as affected by water activity. Cereal Foods World. 26: 345, 1981. 5. Beuchat, L. R. Influence of water activity on growth, metabolic activities, and survival of yeasts and molds. J. Food Prot. 46:135, 1983. 6. Leung, H. K. Influence of water activity on chemical reactivity. Page 27 in: Water Activity: Theory and Applications to Food. L. B. Rockland and L. R. Beuchat, eds. Marcel Dekker, New York, 1987. 7. Kirk, J. R. Influence of water activity on stability of vitamins in dehydrated foods. Page 631 in: Water Activity: Influences on Food Quality. L. B. Rockland and G. F. Stewart, eds. Academic Press, New York, 1981. 8. Bourne, M. C. Effects of water activity on textural properties of food. Page 75 in: Water Activity: Theory and Applications to Food. L. B. Rockland and L. R. Beuchat, eds. Marcel Dekker, New York, 1987. 9. Katz, E. E., and Labuza, T. P. Effect of water activity on the sensory crispness and mechanical deformation of snack food products. J. Food Sci. 46:403, 1981. 10. Brandt, L. Bound for success: Controlling water activity gives technologists the edge

11.

12.

13.

14. 15. 16. 17.

18.

19. 20.

21.

in developing safe, shelf-stable foods. Food Formulating Sep.:41, 1996. Chuy, L. E., and Labuza, T. P. Caking and stickiness of dairy-based food powders as related to glass transition. J. Food Sci. 59: 43, 1994. Johnston, M. R., and Lin, R. C. FDA views on the importance of aw in good manufacturing practice. Page 287 in: Water Activity: Theory and Applications to Food. L. B. Rockland and L. R. Beuchat, eds. Marcel Dekker, New York, 1987. U.S. Food and Drug Administration. Title 21, Code of Federal Regulations, Parts 108, 110, 113, and 114, U.S. Government Printing Office, Washington DC, 1998. Vetter, J. L. Food Law and Regulations. American Institute of Baking, Manhattan, KS, 1996. AOAC. Official Methods of Analysis of AOAC International, 16th ed. AOAC International, Arlington, VA, 1995, p. 42-1. Harris, G. A. Food Water Relations. Food Tech Eur. Dec. 95/Jan. 96, 1995. Richard, J., and Labuza, T. P. Rapid determination of the water activity of some reference solutions, culture media and cheese using a new dew point apparatus. Sci. Aliments. 10:57, 1990. Roa, V., and Tapia de Daza, M. S. Evaluation of water activity measurements with a dew point electronic humidity meter. Lebensm.-Wiss. & Technol. 24:208, 1991. Voysey, P. An evaluation of the AquaLab CX-2 system for measuring water activity. Dig. Microbiol. Sect. 124, 1993. Snavely, M. J., Price, J. C., and Jun, H. W. A comparison of three equilibrium relative humidity measuring devices. Drug Dev. Ind. Pharm. 16:1399, 1990. Campbell, G. S., and Lewis, D. P. Water activity and dew point temperature measuring apparatus and method. U.S. Patent 5,816,704.

10 / JANUARY 2000, VOL. 45, NO. 1

Вам также может понравиться

- Supercharging Autophagy - Based On The Teachings Of Dr. Eric Berg: Unleashing Its Full PotentialОт EverandSupercharging Autophagy - Based On The Teachings Of Dr. Eric Berg: Unleashing Its Full PotentialОценок пока нет

- Aw Food SafetyДокумент9 страницAw Food SafetyBiodiesel Pala FredricksenОценок пока нет

- Aquaponics Algae: How to Control, Combat and Get Rid of Algae in Aquaponics SystemОт EverandAquaponics Algae: How to Control, Combat and Get Rid of Algae in Aquaponics SystemРейтинг: 5 из 5 звезд5/5 (2)

- Food Preservation Involves The Action Taken To Maintain The Desired Properties or Nature of FoodsДокумент2 страницыFood Preservation Involves The Action Taken To Maintain The Desired Properties or Nature of FoodsSuraj KamathОценок пока нет

- Fundamentals of Water ActivityДокумент0 страницFundamentals of Water Activityharish_srinivasan_11Оценок пока нет

- Water Activity ConfectioneryДокумент11 страницWater Activity ConfectioneryMarita Cruz MedinaОценок пока нет

- Doc1 Water ActivityДокумент23 страницыDoc1 Water ActivityArchana Ganesan Archana GanesanОценок пока нет

- The Relationship Between Water Activity and Fish Spoilage During Cold Storage: A ReviewДокумент6 страницThe Relationship Between Water Activity and Fish Spoilage During Cold Storage: A Reviewcorteztrixie205Оценок пока нет

- Food Science Lab Report 2Документ6 страницFood Science Lab Report 2Hazim Hs100% (1)

- The Relationship Between Water Activity and Fish Spoilage During Cold Storage: A ReviewДокумент6 страницThe Relationship Between Water Activity and Fish Spoilage During Cold Storage: A ReviewMoch GaluhОценок пока нет

- Lecture 1-Role of Water and Water Activity in FoodsДокумент9 страницLecture 1-Role of Water and Water Activity in Foodsheartwin150% (2)

- Food Product Shelf Life: Analytical ProgressДокумент10 страницFood Product Shelf Life: Analytical ProgressNasir MahmudОценок пока нет

- Factors Affecting Growth and SurvivalДокумент26 страницFactors Affecting Growth and Survivalurmila choudharyОценок пока нет

- Water ActivityДокумент19 страницWater ActivitySiri NalОценок пока нет

- Food Shelf LifeДокумент10 страницFood Shelf LifeRao JeetuОценок пока нет

- Food SpoilageДокумент5 страницFood SpoilageRajaDeepak VermaОценок пока нет

- Presentation 18Документ22 страницыPresentation 18Sagar KrupaОценок пока нет

- AKM - The Effect of Water Activity On Shelf Life of Food ReportДокумент16 страницAKM - The Effect of Water Activity On Shelf Life of Food ReportSyahirah YusriОценок пока нет

- Water Activity and SpicesДокумент2 страницыWater Activity and SpicesEser GülОценок пока нет

- Lab 1-Water ActivityДокумент2 страницыLab 1-Water ActivityMOOОценок пока нет

- Water 2Документ10 страницWater 2saadОценок пока нет

- Factors Affecting Growth And: Survival of Microorganisms in FoodДокумент7 страницFactors Affecting Growth And: Survival of Microorganisms in FoodAchuthanand MukundanОценок пока нет

- How Water Activity and PH Work Together To Control Microbial GrowthДокумент10 страницHow Water Activity and PH Work Together To Control Microbial GrowthIsisОценок пока нет

- Water Activity and Intermediate FoodsДокумент2 страницыWater Activity and Intermediate Foodsmenyaemma8214100% (1)

- Evaluation and Definition of Potentially Hazardous FoodsДокумент23 страницыEvaluation and Definition of Potentially Hazardous FoodsAlan Emmanuel Guevara CervantesОценок пока нет

- Effect of Water On Quality and Preservation of FoodДокумент10 страницEffect of Water On Quality and Preservation of FoodrupinisinnanОценок пока нет

- Exercise 1: Microbial Growth in Relation To Water ActivityДокумент2 страницыExercise 1: Microbial Growth in Relation To Water ActivityErena Iyra ChiocoОценок пока нет

- Lab 1 - Water ActivityДокумент7 страницLab 1 - Water ActivityLian WidawatiОценок пока нет

- Blessing SeminarДокумент48 страницBlessing SeminarTemidayoОценок пока нет

- Water Activity and Food StabilityДокумент15 страницWater Activity and Food Stabilityanur3a31Оценок пока нет

- Lecture 2mcb 316Документ8 страницLecture 2mcb 316Patricia AdeyemoОценок пока нет

- 4.factors Affecting Growth and Survival of Microorganisms in Foods PDFДокумент17 страниц4.factors Affecting Growth and Survival of Microorganisms in Foods PDFKumkum CrОценок пока нет

- Unesco - Eolss Sample Chapters: Quality Control of Raw MaterialsДокумент9 страницUnesco - Eolss Sample Chapters: Quality Control of Raw MaterialsAchal BishtОценок пока нет

- 8 - Mass Transfer Mechanisms During Dehydration of Vegetable FoodДокумент51 страница8 - Mass Transfer Mechanisms During Dehydration of Vegetable FoodHouse DoctorОценок пока нет

- Food Dehydration: Viollaz, P.E. and Alzamora, S.MДокумент9 страницFood Dehydration: Viollaz, P.E. and Alzamora, S.MErrol Giggs SamusamuОценок пока нет

- Water Quality in Poultry ProductionДокумент9 страницWater Quality in Poultry Productionumer farooqОценок пока нет

- Application of Water Activity in Tomato Sauce ProcessingДокумент7 страницApplication of Water Activity in Tomato Sauce ProcessingFréÿ ChîkãlîpöОценок пока нет

- NT10102 Fundamentals of Food Science & NutritionДокумент24 страницыNT10102 Fundamentals of Food Science & NutritionStefanus Owen KikiОценок пока нет

- Torres - FoodChem Week 11 To 13Документ1 страницаTorres - FoodChem Week 11 To 13john buenafeОценок пока нет

- Experiment 1 - Moisture Content & AwДокумент3 страницыExperiment 1 - Moisture Content & AwAmirah Syakira40% (5)

- Section 1: Overview of MicrobiologyДокумент8 страницSection 1: Overview of MicrobiologyJuan Carlos RodriguezОценок пока нет

- Water Activity 1Документ50 страницWater Activity 1aoauaz2000Оценок пока нет

- FF - Water Activity in CoffeeДокумент2 страницыFF - Water Activity in CoffeeGambia TostadoresОценок пока нет

- Food MCB II NotesДокумент73 страницыFood MCB II NotesRichard Simon KisituОценок пока нет

- Application of Chemistry in Food ProcessingДокумент24 страницыApplication of Chemistry in Food ProcessingAkinola AyomideОценок пока нет

- Animals 11 01865Документ15 страницAnimals 11 01865Erwin Luis KleinОценок пока нет

- Antimicrobial Activity of Foods With Different Physio Chemical CharacteristicsДокумент12 страницAntimicrobial Activity of Foods With Different Physio Chemical CharacteristicsrajaОценок пока нет

- Lecture 1 - Water: Direct Reactant in Hydrolytic ProcessДокумент14 страницLecture 1 - Water: Direct Reactant in Hydrolytic ProcessYee KatherineОценок пока нет

- Cuases of Food DeteriorationДокумент7 страницCuases of Food DeteriorationJyoti JhaОценок пока нет

- Gut Health in 4 (Easy) StepsДокумент2 страницыGut Health in 4 (Easy) StepsInternational Aquafeed magazineОценок пока нет

- Basic Principles of FermentationДокумент20 страницBasic Principles of FermentationAriiezma Selaludhamay D'hatiОценок пока нет

- Spoilage and Preservation of FoodДокумент6 страницSpoilage and Preservation of FoodOkwukwe Dan-WachukuОценок пока нет

- 5.0 Water in FoodДокумент42 страницы5.0 Water in FoodAfiqah OsmeraОценок пока нет

- Addressing Technical and Environmental Obstacles in Livestock Management For Enhanced Drinking Water AQualityДокумент5 страницAddressing Technical and Environmental Obstacles in Livestock Management For Enhanced Drinking Water AQualityKIU PUBLICATION AND EXTENSIONОценок пока нет

- Food Chemistry Is The Study Of: That Occur During The Manufacture, Handling, and Storage of Foods"Документ2 страницыFood Chemistry Is The Study Of: That Occur During The Manufacture, Handling, and Storage of Foods"Cha RamirezОценок пока нет

- Moisture DeterminationДокумент14 страницMoisture DeterminationAppleDashingОценок пока нет

- ERHДокумент8 страницERHJai MurugeshОценок пока нет

- Water Activity PDFДокумент9 страницWater Activity PDFlalitk02Оценок пока нет

- Acidos Organicos Mecanismo SiiiiiiiiiiiДокумент58 страницAcidos Organicos Mecanismo SiiiiiiiiiiiEunice VegaОценок пока нет

- Catatan Penting BrandДокумент4 страницыCatatan Penting BrandAnikОценок пока нет

- Anik 8Документ11 страницAnik 8AnikОценок пока нет

- Example For Fashion Products: Select The Main Category From The Dropdown Select The Sub Category From The DropdownДокумент8 страницExample For Fashion Products: Select The Main Category From The Dropdown Select The Sub Category From The DropdownAnikОценок пока нет

- Anik 6Документ7 страницAnik 6AnikОценок пока нет

- Fields and Description: Warna / ColorДокумент6 страницFields and Description: Warna / ColorAnikОценок пока нет

- Example For Fashion Products: Select The Main Category From The Dropdown Select The Sub Category From The DropdownДокумент8 страницExample For Fashion Products: Select The Main Category From The Dropdown Select The Sub Category From The DropdownAnikОценок пока нет

- This Spreadsheet Only Works With Macros Enabled. Please Enable Them To ProceedДокумент2 страницыThis Spreadsheet Only Works With Macros Enabled. Please Enable Them To ProceedAnikОценок пока нет

- How To Mass Upload The Products Using This TemplateДокумент34 страницыHow To Mass Upload The Products Using This TemplateAnikОценок пока нет

- (Not) A Perfect Life PDFДокумент447 страниц(Not) A Perfect Life PDFAnikОценок пока нет

- Bri OnesДокумент12 страницBri OnesOlan MalazzabОценок пока нет

- Food Fortification in The Philippines: M ' " ": - T P, - TДокумент4 страницыFood Fortification in The Philippines: M ' " ": - T P, - ThoneylettuceОценок пока нет

- Webinar Orientation On School-Based Feeding Program ImplementationДокумент2 страницыWebinar Orientation On School-Based Feeding Program ImplementationGraciella Fae PuyaoanОценок пока нет

- CPR List - FDA PhilippinesДокумент2 страницыCPR List - FDA PhilippinesMiguel Pillas100% (6)

- "©daffodil International University" IДокумент29 страниц"©daffodil International University" IOnly LaptopОценок пока нет

- Quail Farming & Quail Parasites. By: Basit Sohail (2019-Ag-397)Документ7 страницQuail Farming & Quail Parasites. By: Basit Sohail (2019-Ag-397)Zohaib Saeed AhmadОценок пока нет

- 1 Pick Out Malunggay Leaves From TheДокумент9 страниц1 Pick Out Malunggay Leaves From TheShiela Marie VergaraОценок пока нет

- Escaping Hunger, Escaping ExcessДокумент13 страницEscaping Hunger, Escaping ExcessDaisy100% (1)

- Salting Curing MixturesДокумент2 страницыSalting Curing MixturesAsia VelascoОценок пока нет

- Chapter 2 and Synthesis MatrixДокумент20 страницChapter 2 and Synthesis Matrixhibiscus-eurie montillanaОценок пока нет

- PD GRINDAMYL SUREBake 900Документ2 страницыPD GRINDAMYL SUREBake 900Toni AcoskiОценок пока нет

- Nutrient ManagementДокумент8 страницNutrient ManagementJerome EnriquezОценок пока нет

- Lesson Plan in Epp 6 (Crop Production)Документ8 страницLesson Plan in Epp 6 (Crop Production)Jackaii Waniwan IIОценок пока нет

- Keto DietДокумент2 страницыKeto Dietroi guzmanОценок пока нет

- Unit 4 - B2 - Key - Supplementary ExercisesДокумент6 страницUnit 4 - B2 - Key - Supplementary ExercisesrilitoОценок пока нет

- Soal Pas Inggris Kelas 9 Semester 1 2020Документ7 страницSoal Pas Inggris Kelas 9 Semester 1 2020LALA RUSLANIОценок пока нет

- Proposal Business PlanДокумент13 страницProposal Business PlanM Yusuf MaulanaОценок пока нет

- Basic Food I ReviewerДокумент27 страницBasic Food I ReviewerMaria Celina DumagcoОценок пока нет

- Do You Like It?Документ2 страницыDo You Like It?Rafa100% (2)

- Labelling Legislation Study Food Info Vs Cons Decision 2014Документ317 страницLabelling Legislation Study Food Info Vs Cons Decision 2014WMOSОценок пока нет

- Food Beverages ReportДокумент14 страницFood Beverages ReportIp AdrrОценок пока нет

- Boar's Head Brands Recipe BookДокумент27 страницBoar's Head Brands Recipe BookJo DaleyОценок пока нет

- NutriMirror 1000calДокумент2 страницыNutriMirror 1000caljruiz08Оценок пока нет

- Beveragedistributors Usa - UPDATEDДокумент62 страницыBeveragedistributors Usa - UPDATEDAtlas SОценок пока нет

- GoldilocksДокумент2 страницыGoldilocksRegine ManaloОценок пока нет

- Green White Modern Weekly PlannerДокумент4 страницыGreen White Modern Weekly PlannerLeonard SalvacionОценок пока нет

- Quarterly Report Bottled Water Quality (April-June, 2021)Документ30 страницQuarterly Report Bottled Water Quality (April-June, 2021)Junaid AhmedОценок пока нет

- List of Low Cholesterol Foods For AggrekoДокумент5 страницList of Low Cholesterol Foods For AggrekoIan AriОценок пока нет

- Grain Vs Silage CornДокумент4 страницыGrain Vs Silage CornPrima HerdiantoОценок пока нет

- Famous Caterers in KolkataДокумент15 страницFamous Caterers in KolkataKoushik MondalОценок пока нет

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldОт EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldРейтинг: 3.5 из 5 звезд3.5/5 (5)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterОт EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterРейтинг: 3.5 из 5 звезд3.5/5 (487)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookОт EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyОт EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyРейтинг: 4 из 5 звезд4/5 (11)

- The Obesity Code: Unlocking the Secrets of Weight LossОт EverandThe Obesity Code: Unlocking the Secrets of Weight LossРейтинг: 4 из 5 звезд4/5 (6)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideОт EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideРейтинг: 4 из 5 звезд4/5 (6)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingОт EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingРейтинг: 4 из 5 звезд4/5 (3)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayОт EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayРейтинг: 4 из 5 звезд4/5 (4)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingОт EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingРейтинг: 4 из 5 звезд4/5 (9)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomОт EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomРейтинг: 4 из 5 звезд4/5 (1)

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsОт EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsОценок пока нет

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingОт EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingОценок пока нет

- Keto Friendly Recipes: Easy Keto For Busy PeopleОт EverandKeto Friendly Recipes: Easy Keto For Busy PeopleРейтинг: 3.5 из 5 звезд3.5/5 (2)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОт EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОценок пока нет

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayОт EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayРейтинг: 4 из 5 звезд4/5 (10)

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthОт EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthРейтинг: 2 из 5 звезд2/5 (1)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyОт EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyРейтинг: 4 из 5 звезд4/5 (1)

- Binging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsОт EverandBinging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsОценок пока нет

- The Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesОт EverandThe Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesОценок пока нет