Академический Документы

Профессиональный Документы

Культура Документы

Fisher Deaerator Level Control Solutions Application Brochure

Загружено:

samy7354Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fisher Deaerator Level Control Solutions Application Brochure

Загружено:

samy7354Авторское право:

Доступные форматы

Fisher Deaerator Level Control Solutions

Technology and Innovation in Process Control

Application Discussion

deaerator removes non-condensable gases that can corrode boiler internals. It does so by heating incoming condensate to the saturation point in order to reduce the solubility of any entrained gases.

These are mainly oxygen, carbon dioxide and ammonia that become very corrosive at elevated temperatures. The deaerator level control valve is used to control level in the deaerator to maximize elimination of entrained gases. Because of condensate pump rangeability, the deaerator level control valve has to control a wide range of process conditions. This valve provides startup and regulating functions in one valve eliminating cumbersome cross over points and easing operation. During initial operation, this valve must address the potential for cavitation formation and provide adequate rangeability to address the entire condensate requirements. Turndowns of at least 75:1 are common. The deaerator level control valve has to provide high rangeability and stable throttling control. However, this valve must be designed to handle other conditions such as: n Filling of the deaerator prior to plant startup n Cavitation potential due to high differential pressures at startup n Maintaining deaerator level during all operating conditions n Adequate seat load to prevent leakage while the condensate pump is in recirculation mode n Providing availability for high plant turndown Since the deaerator valve is shut during plant startup, tight shutoff (ANSI Class V or greater) is critical. Any leakage can cause the deaerator level to rise, risking a plant trip during startup along with damaging to the valve. At startup the valve must reduce pressure as high as 600 psig while avoiding cavitation. The cavitation potential in the deaerator level control valve subsides with the decay in condensate pump pressure. As this occurs and as system capacity demands increase, the valve must affect a smooth transition from anti-cavitation protection to that of providing higher flow rates. It also must provide stable control to maintain load and the turndown required (at times, greater than 75:1) during normal plant operation. Emerson offers specific Fisher-engineered solutions for the variations encountered in plant design. These solutions provide protection against cavitation, erosion, plugging and leakage while providing the necessary rangeability. Also, to ensure proper operation after valve installation, a Fisher FIELDVUE Digital Valve Controller can be used to monitor valve performance. The FIELDVUE DVC provides diagnostic reviews that can be conduced without interrupting the process in order to identify potential performance issues. This helps to ensure proper operation and tight shutoff over the normal service life of the valve.

Technology and Innovation in Process Control

Severe Service Control Hierarchy

Deaerator Level Control Valve Solutions

FISHER CUSTOMIZATION Lack of control and recurring cavitation damage were constant problems with a combination rotary valve/attenuator, typically requiring costly trim replacement every year. The Fisher solution was a high capacity globe valve with characterized Cavitrol III, two-stage trim along with the unmatched stem sealing capabilities of ENVIRO-SEAL packing. See www.Fishersevereservice.com for additional details.

FISHER OPTIMIZATION Cavitrol Trim Employs special-shaped orifices and drilled-hole technology in keeping the flowing media above its vapor pressure Used in combination with Fisher high-pressure and high-capacity valve bodies to prevent cavitation, achieve tight shutoff and reduce vibration levels

BASIC TECHNOLOGY Standard trim control valve Hardened trim materials to extend service life

Emerson. Your partner in instrument and valve reliability. The way you manage your key production assets directly affects your plants performance and profitability. Emersons Asset Optimization capabilities deliver world-class services and innovative technologies to increase the availability and performance of mechanical equipment, electrical systems, process equipment, instruments and valves for improved bottom-line results. Asset Optimization helps you improve process availability and attain peak performance, which means wherever you are in your plants life cyclestartup, maximizing operations or life extensionby relying on Emersons Asset Optimization capabilities, youll be on the path to realizing the true potential of your plants instruments and valves. The Next Step Contact your local Emerson Process Management sales office or sales representative location for more information or to make a purchase. For severe service solutions, see us at www.FisherSevereService.com

Fisher Controls International LLC 2006 All Rights Reserved Fisher, FIELDVUE, Cavitrol and Micro-Flat are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their respective owners. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy they are not to be construed as warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice. Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Fisher product remains solely with the purchaser.

NORTH AMERICA Emerson Process Management Marshalltown, Iowa 50158 USA T 1 (641) 754-3011 F 1 (641) 754-2830

www.EmersonProcess.com/Fisher

LATIN AMERICA Emerson Process Management Sorocaba, Sao Paulo 18087 Brazil T +(55)(15)238-3788 F +(55)(15)228-3300

www.EmersonProcess.com/Fisher

EUROPE Emerson Process Management Cernay 68700 France T +(33) (0)3 89 37 64 00 F +(33) (0)3 89 37 65 18

www.EmersonProcess.com/Fisher

MIDDLE EAST & AFRICA Emerson FZE Dubai, United Arab Emirates T +971 4 883 5235 F +971 4 883 5312

www.EmersonProcess.com/Fisher

ASIA PACIFIC Emerson Process Management Singapore 128461 Singapore T +(65) 6777 8211 F +(65) 6777 0947

www.EmersonProcess.com/Fisher

D351244X012 CD140 Printed in U.S.A. / April 2006

Вам также может понравиться

- API 650 Tank Design 1 1Документ5 страницAPI 650 Tank Design 1 1samy7354100% (1)

- Orifice Plate DrawingsДокумент11 страницOrifice Plate Drawingssamy7354Оценок пока нет

- Ds EvmtДокумент107 страницDs Evmtsamy7354Оценок пока нет

- ALCONДокумент5 страницALCONsamy7354Оценок пока нет

- Welding SymbolsДокумент26 страницWelding Symbolssamy7354Оценок пока нет

- A135A135MДокумент9 страницA135A135Msamy7354Оценок пока нет

- Afua Kwatemaa Obeng 11-26-07Документ1 страницаAfua Kwatemaa Obeng 11-26-07samy7354Оценок пока нет

- FGD Bid Preparation and Proposal Review Guideline EPRIДокумент186 страницFGD Bid Preparation and Proposal Review Guideline EPRIivanjankov100% (6)

- Ali Jassim Concrete Firewater Tank For APD 12-15-09Документ1 страницаAli Jassim Concrete Firewater Tank For APD 12-15-09samy7354Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- IMOA Newsletter 2007 07Документ16 страницIMOA Newsletter 2007 07Yudha SatriaОценок пока нет

- Aldehyde and Ketones Tollen TestДокумент9 страницAldehyde and Ketones Tollen TestGule RashОценок пока нет

- Sample Paper For ChemistryДокумент23 страницыSample Paper For ChemistryAmit joshiОценок пока нет

- Gasgroup Data HexeneДокумент28 страницGasgroup Data HexeneTon Blok100% (1)

- Papercrete4 PDFДокумент9 страницPapercrete4 PDFPrasad TekadeОценок пока нет

- Ques Paper 2-XI-ENGДокумент8 страницQues Paper 2-XI-ENGKrish VermaОценок пока нет

- Crystex HD OT 20 PDFДокумент2 страницыCrystex HD OT 20 PDFmeidyОценок пока нет

- Balancing Chemical Equations Guided Inquiry - StudentHandoutДокумент2 страницыBalancing Chemical Equations Guided Inquiry - StudentHandoutamber khasruaОценок пока нет

- Chloride MohrДокумент2 страницыChloride MohrVaibhav KrОценок пока нет

- Type of Evaporator 1pptДокумент12 страницType of Evaporator 1pptgrittyptОценок пока нет

- Rotary Positive Displacement Pumps, Commercial Ships Use: Standard Specification ForДокумент8 страницRotary Positive Displacement Pumps, Commercial Ships Use: Standard Specification ForCHRISTIAN ZAVALAОценок пока нет

- BIO Advancing The Biobased Economy 2016Документ84 страницыBIO Advancing The Biobased Economy 2016unicornmfkОценок пока нет

- Advanced Inorganic Chemistry (CHM4301) : Alkenes and AlkynesДокумент19 страницAdvanced Inorganic Chemistry (CHM4301) : Alkenes and AlkynesAnonymous lClX1bОценок пока нет

- 4CH1 2C Que 20211120Документ24 страницы4CH1 2C Que 20211120Fazal AhmedОценок пока нет

- Royal Ultra 865MДокумент9 страницRoyal Ultra 865Mjuanfdez42368Оценок пока нет

- Light-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorДокумент20 страницLight-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorMahmood KhanОценок пока нет

- Mark Scheme (Results) Summer 2016Документ31 страницаMark Scheme (Results) Summer 2016NaushinОценок пока нет

- MOSFET Round 1 (Done)Документ12 страницMOSFET Round 1 (Done)Inimai SubramanianОценок пока нет

- Development of The Model of The AtomДокумент2 страницыDevelopment of The Model of The AtomshamshadОценок пока нет

- Tugas PPM Deny Saputro Arifin 113170039Документ9 страницTugas PPM Deny Saputro Arifin 113170039Vira IrnandaОценок пока нет

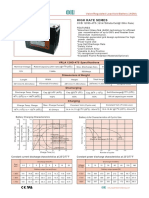

- High Rate Series: CCB 12HD-475Документ1 страницаHigh Rate Series: CCB 12HD-475orunmila123Оценок пока нет

- 26252.9.6. Uniformity of Content of Single-Dose PreparationsДокумент1 страница26252.9.6. Uniformity of Content of Single-Dose PreparationsMiyyada Aichaoui100% (1)

- Plastics PDFДокумент18 страницPlastics PDFV Phanindra BoguОценок пока нет

- Ecotoxicology and Environmental SafetyДокумент10 страницEcotoxicology and Environmental SafetyUlfa Mudia SariОценок пока нет

- Chemistry Sample Syllabus 2 Id 1029717v1Документ13 страницChemistry Sample Syllabus 2 Id 1029717v1Wong Weng SiongОценок пока нет

- The Influence of Methanol Concentration To Biodiesel Yield and QualityДокумент5 страницThe Influence of Methanol Concentration To Biodiesel Yield and QualityOniОценок пока нет

- PROTEINSДокумент5 страницPROTEINSYLADE, ERICCA ANDREAОценок пока нет

- SRMB SteelДокумент31 страницаSRMB SteelAmol Ujawane100% (1)

- Magnetic Terms and UnitsДокумент3 страницыMagnetic Terms and UnitsDeepak Choudhary DCОценок пока нет

- Models For Volcanic-Hosted Epithermal Precious Metal Deposits A ReviewДокумент11 страницModels For Volcanic-Hosted Epithermal Precious Metal Deposits A ReviewOrlando B Santa CruzОценок пока нет