Академический Документы

Профессиональный Документы

Культура Документы

Dying Process of Jeans

Загружено:

Ramesh Singh RajpurohitОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dying Process of Jeans

Загружено:

Ramesh Singh RajpurohitАвторское право:

Доступные форматы

Dyeing There are two main types of silk fabrics. 1.

Yarn-dyed or dyed-woven, like taffeta, duchess satin and many pattern-wo ven fabrics. 2. Piece-dyed fabrics, which is carried out after weaving, like crepes, twi lls, etc. The dyeing process gives the silk different shades.

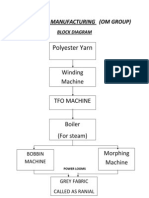

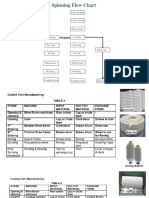

Dyeing department Arvind Mills has a grill section that was loaded with 12 beams of yarn, though l atest machinery could support even 16 of them. They are also known as warping be ams and their design depends upon the texture and construction of fabric e.g. we ight, length etc. Each beam consist of 350-400 ends and 12 such beams are joined together to form one at last with 4000-4800 ends which is used in the weaving process. Four types of dyeing processes are used in Arvind mills namely: 1. Indigo dyeing 2. SBIT-sulphur bottoming indigo topping 3. IBST-indigo bottoming sulphur topping 4. Sulphur dyeing All the above processes differ in the process of loading on the fabric. The dyeing process in a flow chart is explained below.

Pre-wetting PWA | W.B.1 (W.B.-Washing box) | Dye box (6 shades are used) | W.B.2 | Sulphur | W.B.3 | Pre dryer | Saw box (Sizing) | Post dryer | Compromising (speed is increased) | H/S In Dying Process machinery they are used this is a World largest dying machine. This is 50 rope/ball machine, Means one time 50 rope are dying. And other 2nd dying machine are also they have use capacity of this 2nd Dyeing m achine is 10 rope/ball in one operation time. 800 mtr space in this process. 13 workers are work in this process, in this 13, only 1 and 2 are handle the hol e machine and other are work in rope warping purpose. Capacity 110 mtr rope per day. Price of this machine is 19 lacks. In this machine and Dyeing process 19 tanks. Ropes are go to in all the tanks an

d dyeing. 1st tank- in this tank Sulphuring combinations colure are use. And they work in 85o Temperature. 2nd, 3rd and 4th tank they are use only for washing purpose, and in this tank on ly use water. This is a pre-washing process. After this process completion colur e are use and Different-different Dyeing purpose. Tank 5th and 6th are use only for Black Colure Dyeing. This tank are use and Per sonalisation purpose means only for Black colure Dyeing Purpose they are use thi s two tank. Tank 8th is a highest capacity tank in this process. In this tank use 7000 litte r only for Box Dying process. In this tank indigo dyeing are use. 14th tank also use Indigo fix box sulphuring colure. After this tank Dyeing process are complete. And rope are go to the next step fo r washing prupore , means rope are go to the water tanks are extra unuseful dyei ng are remove. In 15th tank they use sulphured so remove the unuseful and unpick Dyeing . 16th, 17th and 18th they use only pour Hot water and washing purpose, this is a port wash process. In 19th tank they use softer, so row from use in indigo, sulphur, they reopen ro pe in strict form. In this running processes under combination of per 15 rope 1 rope is go in to th e under lap spectra photo system machine ( this system used in purpose of the Qu ality checking process , this system connect to the information system departmen t and Quality control department so they easy handle to the any quality related difficulties) in Testing and checking purpose Only one limitation of the machine and the process is this machine only 1 time s top 5 lacks loss only 1 time stops this process. So company panning to handle th is problem they create a plan in related to the power plant and other power rela ted some solution are provided.

Major Brands and Products Fabric Denim Shirtings Khakis Knitwear Voiles Garment Exports Shirts Jeans Arvind Brands (owned) Flying Machine Newport Ruf & Tuf Excalibur Arvind Brands Arrow

Lee Wrangler . Weaving department The weaving department has 203 weaving machines en Toto, of the make ZAX and 209 i, the latter being an older version. The machines are of the company TSUDAKOMA, a Japanese concern as opposed to the spinning department where the machines wer e of German companies. The ZAX machines work at 750 rpm whereas 209i model machi nes work at 650 rpm. Together they churn out a lac m2 of cloth a day. In total t he department has 159 ZAX machines and 44 209i. There happen to be 261 labourers working in 4 shifts in the department with 20 staff members i.e. 5 in each shif t, out of whom there is one supervisor for each shift. A beam card keeps all the records of what is being put on the machine and under whom it is supervised. Inputs used for the weaving departments can vary from: 1. OE- open end 2. ER- even ring 3. UR- uneven ring Lycra is used to increase the elasticity of the fiber. Filament is used in the f iber which is exported to countries where the level of sweating is lower as comp ared to Indian condition where majorly cotton is used for the same reason. The weaving department has the distinction of being the largest at Arvind Mills and exports close to 95% of its manufactured fabric. Discussing the denim fabric , the core competence of AM, original denim is composed of 100% cotton but with a view to bring in variations to the material in consonance with the emerging tr ends in the market, various natural fibers like linen and synthetic fibers like filament, lycra, polyester are added to cotton. While weaving such mixed fabric, the core is made of the addend and original cotton is wound around it. Yarn wov en vertically is called warp while that woven laterally is termed as weft. For w eaving purposes a cotton count ranging from 5 to 20 is generally used.

Вам также может понравиться

- Curtain WallДокумент32 страницыCurtain WallParas Gulia100% (6)

- Manufacture of Narrow Woven Fabrics - Ribbons, Trimmings, Edgings, Etc. - Giving Description of the Various Yarns Used, the Construction of Weaves and Novelties in Fabrics Structures, also Desriptive Matter as to Looms, Etc.От EverandManufacture of Narrow Woven Fabrics - Ribbons, Trimmings, Edgings, Etc. - Giving Description of the Various Yarns Used, the Construction of Weaves and Novelties in Fabrics Structures, also Desriptive Matter as to Looms, Etc.Оценок пока нет

- Jute Spinning ProcessДокумент19 страницJute Spinning ProcessMilon Hossain0% (1)

- PPTДокумент56 страницPPTSomalika Banerjee100% (2)

- Waterproofing SystemsДокумент4 страницыWaterproofing SystemsfairmatechemicalОценок пока нет

- Topic-8 Ceiling EstimatesДокумент8 страницTopic-8 Ceiling EstimatesMyla Riza Sintones NepomucenoОценок пока нет

- Silicone Rubber White PaperДокумент6 страницSilicone Rubber White PaperRahul YadavОценок пока нет

- Material Selection & Corrosion Resistance Alloys For Petroleum IndustryДокумент4 страницыMaterial Selection & Corrosion Resistance Alloys For Petroleum Industryعزت عبد المنعمОценок пока нет

- MYSORE SILK FACTORY Industrial VisitДокумент16 страницMYSORE SILK FACTORY Industrial Visitsingam100% (9)

- SpinningДокумент8 страницSpinningAishee BhowmickОценок пока нет

- Grey Cloth Manufacturing ProcessДокумент8 страницGrey Cloth Manufacturing ProcessPriya JainОценок пока нет

- 1 - The Sewing Needle TrainingДокумент20 страниц1 - The Sewing Needle TrainingLâmViên100% (1)

- Textile Wet Processing UNIT-4Документ6 страницTextile Wet Processing UNIT-4Chaarvi SaranyaОценок пока нет

- Internship of Mehmood Textile MillsДокумент72 страницыInternship of Mehmood Textile MillsDrMuhammed NawazОценок пока нет

- Cement Physical TestingДокумент6 страницCement Physical TestingPradeep SinghОценок пока нет

- Welding and Hot Dip GalvanizingДокумент9 страницWelding and Hot Dip GalvanizingFarid Ma'rufОценок пока нет

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentОт EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentОценок пока нет

- Ductile Cast IronДокумент9 страницDuctile Cast Ironander_sarettaОценок пока нет

- Recent Development in Denim ManufacturingДокумент24 страницыRecent Development in Denim ManufacturingMichael LiuОценок пока нет

- Concrete With Steel Furnace Slag and Fractionated Reclaimed Asphalt PavementДокумент177 страницConcrete With Steel Furnace Slag and Fractionated Reclaimed Asphalt PavementprmraoОценок пока нет

- Assembling Electrical Wiring Support 021Документ4 страницыAssembling Electrical Wiring Support 021goodlife26960% (1)

- Yarn Realisation: DR HRMДокумент31 страницаYarn Realisation: DR HRMnatarajan2006Оценок пока нет

- Vardhman TextilesДокумент216 страницVardhman TextilesKriti Singh100% (2)

- Qasir Spinning ReportДокумент60 страницQasir Spinning ReportRana AtiqueОценок пока нет

- Textiles For Commercial, Industrial, and Domestic Arts Schools; Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesОт EverandTextiles For Commercial, Industrial, and Domestic Arts Schools; Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesРейтинг: 4 из 5 звезд4/5 (1)

- The Textiles Student's Manual - An Outline of All Textile Processes, From the Origin of the Fibre to the Finished ClothОт EverandThe Textiles Student's Manual - An Outline of All Textile Processes, From the Origin of the Fibre to the Finished ClothРейтинг: 4 из 5 звезд4/5 (1)

- About Arvind MillsДокумент9 страницAbout Arvind Millsraviraj0224Оценок пока нет

- Manufacturing Process at RSWMДокумент22 страницыManufacturing Process at RSWMDishant JoshiОценок пока нет

- Isin LankaДокумент8 страницIsin LankaThilinaAbhayarathne100% (1)

- Raymond TextileДокумент8 страницRaymond Textilepgdm1315100% (1)

- Textile InternshipДокумент55 страницTextile InternshipANEESHA PANDAОценок пока нет

- Arvind Textile Internship Report-Final 2015Документ50 страницArvind Textile Internship Report-Final 2015Divyanshu Sagar0% (1)

- ElseДокумент19 страницElsepenihaniОценок пока нет

- Textile Internship Alok IndustriesДокумент31 страницаTextile Internship Alok IndustriesAditya DevОценок пока нет

- Case Study FinalДокумент61 страницаCase Study FinalMahuri Kesharwani100% (1)

- Textile InternshipДокумент54 страницыTextile InternshipANEESHA PANDAОценок пока нет

- Manufacturing ProcessДокумент6 страницManufacturing ProcessKennaa BekeleОценок пока нет

- TT 403 Ginning TechnologyДокумент45 страницTT 403 Ginning Technologymt khan100% (2)

- Textile InternshipДокумент51 страницаTextile InternshipPadmasri JeyakumarОценок пока нет

- Textile Internship Report AlokДокумент39 страницTextile Internship Report AlokRahul TelangОценок пока нет

- Jute ProcessingДокумент7 страницJute Processingtulika_ajwaniОценок пока нет

- Fabric Science II ReportДокумент12 страницFabric Science II ReportShrishti AgarwalОценок пока нет

- Internship Report On Reliance Weaving MillsДокумент49 страницInternship Report On Reliance Weaving MillsAnthony Black75% (4)

- Weaving Process Interlaces The WarpДокумент8 страницWeaving Process Interlaces The WarpChetna SinghОценок пока нет

- Internship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteДокумент30 страницInternship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteAditya RainaОценок пока нет

- Rana Training Report of Nishat #7Документ74 страницыRana Training Report of Nishat #7Rana AtiqueОценок пока нет

- Raymond Visit ReportДокумент12 страницRaymond Visit ReportMandy Terrell100% (1)

- Alkaram Internship ReportДокумент55 страницAlkaram Internship ReportHSОценок пока нет

- Orient Fashion ReportДокумент13 страницOrient Fashion Reportmegha shreeОценок пока нет

- AFTAB IV ReportДокумент14 страницAFTAB IV Reportanjali jhudeleОценок пока нет

- Company ProfileДокумент70 страницCompany ProfileDrMuhammed NawazОценок пока нет

- Mixing:: Basic Tasks of Blow RoomДокумент9 страницMixing:: Basic Tasks of Blow RoommohitОценок пока нет

- Shuttle-Less Looms: S.D.M.M. Premathilake ItumДокумент9 страницShuttle-Less Looms: S.D.M.M. Premathilake ItumDr. J. P. SinghОценок пока нет

- 6 Sem. B.Tech (Fashion & Apparel Technology) : Pcft4303 Garment Processing & FinishingДокумент18 страниц6 Sem. B.Tech (Fashion & Apparel Technology) : Pcft4303 Garment Processing & FinishingDarshan HandeОценок пока нет

- Textile Internship Report, NIFT MumbaiДокумент23 страницыTextile Internship Report, NIFT MumbaiPrerna KhatriОценок пока нет

- Combing Section: Wool ProcesingДокумент6 страницCombing Section: Wool Procesingsagiralam1Оценок пока нет

- Benninger & Wet ProcessingДокумент72 страницыBenninger & Wet ProcessingFary SamiОценок пока нет

- Om FinalДокумент18 страницOm FinalHarleena BhelaОценок пока нет

- 1.1 Introduction of Sri Bhavani Textiles Processor (P) LimitedДокумент35 страниц1.1 Introduction of Sri Bhavani Textiles Processor (P) LimitedrdilipkillerОценок пока нет

- Report Visit To A Yarn Mill KatunayakaДокумент4 страницыReport Visit To A Yarn Mill KatunayakaNikolai QuynОценок пока нет

- Raymond UCO DenimДокумент25 страницRaymond UCO DenimChaitanya Gajbhiye100% (1)

- Popular 2Документ30 страницPopular 2Mujahid MehdiОценок пока нет

- Garments Dyeing For LearnerДокумент5 страницGarments Dyeing For LearnerMohammed Atiqul Hoque ChowdhuryОценок пока нет

- Report Nishat 2Документ62 страницыReport Nishat 2Mukarram Ali KhanОценок пока нет

- Open End Spinning-SkДокумент3 страницыOpen End Spinning-Skshaikat6163Оценок пока нет

- Summer Textile Internship: Technocraft Industries India LimitedДокумент80 страницSummer Textile Internship: Technocraft Industries India LimitedSuraj KediaОценок пока нет

- Weaving OnwardsДокумент37 страницWeaving OnwardsEruОценок пока нет

- Lect2 - Blow Room 1Документ18 страницLect2 - Blow Room 1Mina Samy abd el zaherОценок пока нет

- Advantages of Shuttleless LoomsДокумент8 страницAdvantages of Shuttleless LoomsTanzeel Areeb0% (1)

- Open-End Spinning - Wikipedia PDFДокумент16 страницOpen-End Spinning - Wikipedia PDFK.s. PandianОценок пока нет

- Illustrated Catalogue of Cotton MachineryОт EverandIllustrated Catalogue of Cotton MachineryОценок пока нет

- Webinar-Coating Girth Welds FINAL REV PDFДокумент59 страницWebinar-Coating Girth Welds FINAL REV PDFdakidofdaboomОценок пока нет

- Common Work Results For PlumbingДокумент16 страницCommon Work Results For PlumbingMac ShaikОценок пока нет

- TNB Junction - Box B Weatherproof EДокумент4 страницыTNB Junction - Box B Weatherproof EmubeennavazОценок пока нет

- LemljenjeДокумент2 страницыLemljenjeTolić BrankoОценок пока нет

- How To Select EDM Electrode MaterialsДокумент4 страницыHow To Select EDM Electrode MaterialssrgvnewОценок пока нет

- Nitocote EP415 PDFДокумент4 страницыNitocote EP415 PDFdejanmicic972Оценок пока нет

- Textile Auxiliaries Manufacturers - Transpek SiloxДокумент3 страницыTextile Auxiliaries Manufacturers - Transpek SiloxSatyajitsinh GohilОценок пока нет

- Michem® Emulsion 39235Документ2 страницыMichem® Emulsion 39235dewanibipinОценок пока нет

- OpvДокумент11 страницOpvPankaj KumarОценок пока нет

- Aluminium Composite Panels (ACP)Документ18 страницAluminium Composite Panels (ACP)Nathaniel LimОценок пока нет

- Service Magic Lead CostДокумент9 страницService Magic Lead CostDave ZegersОценок пока нет

- VULCAN Galvanized Tank Liner Data SheetДокумент5 страницVULCAN Galvanized Tank Liner Data Sheettkay58Оценок пока нет

- Final BSR 2016Документ106 страницFinal BSR 2016Asela UdayangaОценок пока нет

- Excel Implementation of Schaeffler and Delong Diagrams PDFДокумент8 страницExcel Implementation of Schaeffler and Delong Diagrams PDFEmad A.AhmadОценок пока нет

- Interior Partition Wire MeshДокумент9 страницInterior Partition Wire MeshKağan ZorluoğluОценок пока нет

- QCS 2010 Section 4 Part 2 General Requirements For Concrete PilesДокумент6 страницQCS 2010 Section 4 Part 2 General Requirements For Concrete Pilesbryanpastor106Оценок пока нет

- Powder Metallurgy Process (E-2 Batch)Документ13 страницPowder Metallurgy Process (E-2 Batch)Manu DubeyОценок пока нет

- Ismanam 2015 Final ProgramДокумент52 страницыIsmanam 2015 Final Programidsaofd0% (1)