Академический Документы

Профессиональный Документы

Культура Документы

Alumina

Загружено:

ehsannasiri100%(1)100% нашли этот документ полезным (1 голос)

116 просмотров5 страницAlumina is the most widely used oxide ceramic material. Its applications include spark plugs, tap washers, pump seals, electronic substrates, grinding media, abrasion resistant tiles, cutting tools and bioceramics. It is also used mixed with other materials such as flake graphite.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAlumina is the most widely used oxide ceramic material. Its applications include spark plugs, tap washers, pump seals, electronic substrates, grinding media, abrasion resistant tiles, cutting tools and bioceramics. It is also used mixed with other materials such as flake graphite.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

116 просмотров5 страницAlumina

Загружено:

ehsannasiriAlumina is the most widely used oxide ceramic material. Its applications include spark plugs, tap washers, pump seals, electronic substrates, grinding media, abrasion resistant tiles, cutting tools and bioceramics. It is also used mixed with other materials such as flake graphite.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Alumina (Aluminium Oxide) - The Different Types of

Commercially Available Grades

Background

Alumina is the most widely used oxide ceramic material. Its applications are

widespread, and include spark plugs, tap washers, pump seals, electronic

substrates, grinding media, abrasion resistant tiles, cutting tools, bioceramics,

(hip-joints), body armour, laboratory ware and wear parts for the textile and

paper industries. Very large tonnages are also used in the manufacture of

monolithic and brick refractories. It is also used mixed with other materials

such as flake graphite where even more severe applications are envisaged,

such as pouring spouts and sliding gate valves.

Key Properties

The characteristics which alumina has and which are important for these

applications are shown below.

High compression strength

High hardness

Resistant to abrasion

Resistant to chemical attack by a wide range of chemicals even at

elevated temperatures

High thermal conductivity

Resistant to thermal shock

High degree of refractoriness

High dielectric strength

High electrical resistivity even at elevated temperatures

Transparent to microwave radio frequencies

Low neutron cross section capture area

Raw material readily available and price not subject to violent

fluctuation

Annual Production

Annual production of alumina is some 45 million tonnes, of which 90% is used

in the manufacture of aluminium metal by electrolysis.

Where Does Alumina Come From?

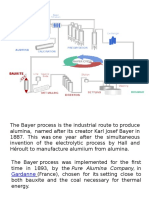

Most of the aluminium oxide produced commercially is obtained by the

calcination of aluminium hydroxide (frequently termed alumina trihydrate or

ATH). The aluminium hydroxide is virtually all made by the Bayer Process. This

involves the digestion of bauxite in caustic soda and the subsequent

precipitation of aluminium hydroxide by the addition of fine seed crystals of

aluminium hydroxide.

Phases of Alumina

Aluminium oxide exists in many forms, o, _, q, o, k, u, , ; these arise during the

heat treatment of aluminium hydroxide or aluminium oxy hydroxide. The most

thermodynamically stable form is a-aluminium oxide.

Aluminium Hydroxides

Aluminium forms a range of hydroxides; some of these are well characterised

crystalline compounds, whilst others are ill-defined amorphous compounds.

The most common trihydroxides are gibbsite, bayerite and nordstrandite,

whilst the more common oxide hydroxide forms are boehmite and diaspore.

Commercially the most important form is gibbsite, although bayerite and

boehmite are also manufactured on an industrial scale.

Aluminium hydroxide has a wide range of uses, such as flame retardants in

plastics and rubber, paper fillers and extenders, toothpaste filler, antacids,

titania coating and as a feedstock for the manufacture of aluminium chemicals,

e.g. aluminium sulfate, aluminium chlorides, poly aluminium chloride,

aluminium nitrate.

Commercial Grades of Alumina

Smelter Grade Alumina

Smelter or metallurgical grade alumina is the name given to alumina utilised in

the manufacture of aluminium metal. Historically it was manufactured from

aluminium hydroxide using rotary kilns but is now generally produced in fluid

bed or fluid flash calciners. In the fluid flash processes the aluminium

hydroxide is fed into a counter-current stream of hot air obtained by burning

fuel oil or gas. The first effect is that of removing the free water and this is

followed by removal of the chemically combined water; this occurs over a

range of temperatures between 180-600C. The dehydrated alumina is

principally in the form of activated alumina and the surface area gradually

decreases as the temperature rises towards 1000C. Further calcination at

temperatures > 1000C converts this to the more stable a-form. The

conversion to the a-form is typically of the order of 25% and the specific

surface area is relatively high at >50m/g due to the presence of transition

aluminas.

Calcined Alumina

If aluminium hydroxide is heated to a temperature in excess of 1100C, then it

passes through the transition phases of alumina referred to above.

The final product, if a high enough temperature is used, is a-alumina. The

manufacturing process is commercially undertaken in long rotary kilns.

Mineralisers are frequently added to catalyse the reaction and bring down the

temperature at which the a-alumina phase forms; fluoride salts are the most

commonly used mineralisers.

These calcined alumina products are used in a wide range of ceramic and

refractory applications. The main impurity present is sodium oxide. Various

grades are produced which differ in crystallite size, morphology and chemical

impurities.

The calcined grades are often sub-divided into ordinary soda, medium soda

(soda level 0.15-0.25% wt%) and low soda alumina.

Low Soda Alumina

Many applications, particularly in the electrical/electronic areas, require a low

level of soda to be present in the alumina. A low soda alumina is generally

defined as an alumina with soda content of <0.1% by weight. This can be

manufactured by many different routes including acid washing, chlorine

addition, boron addition, and utilisation of soda adsorbing compounds.

Reactive Alumina

Reactive alumina is the terms normally given to a relatively high purity and

small crystal size (<1 m) alumina which sinters to a fully dense body at lower

temperatures than low soda, medium-soda or ordinary-soda aluminas. These

powders are normally supplied after intensive ball-milling which breaks up the

agglomerates produced after calcination. They are utilised where exceptional

strength, wear resistance, temperature resistance, surface finish or chemical

inertness are required.

Tabular Alumina

Tabular alumina is recrystallised or sintered o-alumina, so called because its morphology

consists of large, 50-500 m, flat tablet-shaped crystals of corundum. It is produced by

pelletising, extruding, or pressing calcined alumina into shapes and then heating these shapes

to a temperature just under their fusion point, 1700-1850C in shaft kilns.

After calcination, the spheres of shapes of sintered alumina can be used as they are for some

applications, e.g. catalyst beds, or they can be crushed, screened and ground to produce a

wide range of sizes. As the material has been sintered it has an especially low porosity, high

density, low permeability, good chemical inertness, high refractoriness and is especially

suitable for refractory applications.

Fused Alumina

Fused alumina is made in electric arc furnaces by passing a current between vertical carbon

electrodes. The heat generated melts the alumina. The furnace consists of a water cooled

steel shell and 3-20 tonne batches of material are fused at any one time. The fused alumina

has a high density, low porosity, low permeability and high refractoriness. As a result these

characteristics, it is used in the manufacture of abrasives and refractories.

High Purity Aluminas

High purity aluminas are normally classified as those with a purity of 99.99% and can be

manufactured by routes starting from Bayer hydrate using successive activations and

washings, or via a chloride to achieve the necessary degree of purity. Even higher purities

are manufactured by calcining ammonium aluminium sulfate or from aluminium metal. In

the case of the route via ammonium aluminium sulfate, the necessary degree of purity is

obtained by successive recrystallisations. Especially high purities can be made from

aluminium by reacting the metal with an alcohol, purifying the aluminium alkoxide by

distillation, hydrolysing and the calcination. A minor route involves subjecting super purity

aluminium metal pellets under distilled water to a spark discharge.

Applications include the manufacture of synthetic gem stones such as rubies and yttrium

aluminium garnets for lasers, and sapphires for instrument windows and lasers.

:

http://www.azom.com/article.aspx?ArticleID=1389#_Aluminium_Hydroxides

Вам также может понравиться

- High Purity AluminaДокумент13 страницHigh Purity AluminaNilay JoshiОценок пока нет

- AluminaДокумент5 страницAluminaSiddhartha PachisiaОценок пока нет

- Feralco Liquid Aluminium Sulphate BrochureДокумент5 страницFeralco Liquid Aluminium Sulphate BrochurenoelhalloranОценок пока нет

- Polyaluminumchlorideproduction PDFДокумент7 страницPolyaluminumchlorideproduction PDFDũng LêОценок пока нет

- III Sem ICTДокумент56 страницIII Sem ICToctoviancletusОценок пока нет

- Silica Removal During Lime Softening in Water Treatment PlantДокумент10 страницSilica Removal During Lime Softening in Water Treatment PlantLouay MansourОценок пока нет

- OM For MES Sulfonation Plant Rev 0Документ184 страницыOM For MES Sulfonation Plant Rev 0Harits Eka FebriyantoОценок пока нет

- Project Report On Aluminium Chloride SolutionДокумент9 страницProject Report On Aluminium Chloride SolutionEIRI Board of Consultants and PublishersОценок пока нет

- Water Resin 1Документ57 страницWater Resin 1Kuntal SatpathiОценок пока нет

- Product Description (KNO3)Документ2 страницыProduct Description (KNO3)Vanjared OcampoОценок пока нет

- FuMATech AcidMembranes EinzelДокумент6 страницFuMATech AcidMembranes Einzeldow2008Оценок пока нет

- Water TreatmentДокумент10 страницWater TreatmentchristopherОценок пока нет

- Activated Alumina OverviewДокумент6 страницActivated Alumina OverviewIka Silvia AnggraeniОценок пока нет

- Introduction To Ion ExchangeДокумент40 страницIntroduction To Ion ExchangeMasood AhmedОценок пока нет

- Design of A Defluoridizing UnitДокумент11 страницDesign of A Defluoridizing UnitRatnakaram Venkata NadhОценок пока нет

- Coagulant (Pac) and Flocculant (Pam)Документ2 страницыCoagulant (Pac) and Flocculant (Pam)udit singhОценок пока нет

- CORROSION RATE ANALYSIS ,, Assignment 1Документ4 страницыCORROSION RATE ANALYSIS ,, Assignment 1Muhammad MustafaОценок пока нет

- ION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFДокумент40 страницION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFRahul Khandelwal100% (2)

- 10-Ion Exchange F11Документ11 страниц10-Ion Exchange F11Fitra Isni Rosita100% (2)

- Koagulasi Dan Flokulasi PrinsipДокумент129 страницKoagulasi Dan Flokulasi PrinsipAndreaHalim0% (1)

- 0304 SilicaДокумент3 страницы0304 SilicamrinalbhadurioОценок пока нет

- Bauxite To Alumina Book 2018Документ33 страницыBauxite To Alumina Book 2018Amogh VaishnavОценок пока нет

- Alumina RefiningДокумент9 страницAlumina RefiningAtik Faysal AyonОценок пока нет

- QuickLime MSDS (2012)Документ2 страницыQuickLime MSDS (2012)chinck83Оценок пока нет

- Pictorial Diagram of The Bayer Process 2Документ6 страницPictorial Diagram of The Bayer Process 2natsmdОценок пока нет

- WWTP ChemicalsДокумент34 страницыWWTP ChemicalsHRK65Оценок пока нет

- Cooling Tower Water Treatment MIOX Superior DisinfectionДокумент21 страницаCooling Tower Water Treatment MIOX Superior Disinfectioncarlos0% (1)

- Pde ReportДокумент10 страницPde ReportChellam Siva Chellam SivaОценок пока нет

- Activated Alumina F220 Data SheetДокумент2 страницыActivated Alumina F220 Data SheetRawlinsonОценок пока нет

- PAC Vs ALUMДокумент6 страницPAC Vs ALUMKristofer WeeksОценок пока нет

- Coagulation and FlocculationДокумент33 страницыCoagulation and FlocculationAndy Eka SaputraОценок пока нет

- Crystallization EquipmentsДокумент1 страницаCrystallization EquipmentsKumar AmitОценок пока нет

- Name: Raheel Anjum Roll #: B0533027Документ8 страницName: Raheel Anjum Roll #: B0533027api-26797747Оценок пока нет

- Alumina ProcessДокумент16 страницAlumina Processashwini_kumar1984Оценок пока нет

- Coloida Silica RemovalДокумент9 страницColoida Silica RemovalAnthony LimОценок пока нет

- Water Treatment ChemicalsДокумент9 страницWater Treatment Chemicalsjidi125737Оценок пока нет

- Silica Scaling in Water TreatmentДокумент5 страницSilica Scaling in Water TreatmentRais Nur FuadiОценок пока нет

- EXTRACTIVEДокумент34 страницыEXTRACTIVEraj mehra100% (1)

- PAC Proses PDFДокумент100 страницPAC Proses PDFAdnan FirdausОценок пока нет

- FlotationДокумент7 страницFlotationArif HışırОценок пока нет

- Materials of ConstructionДокумент3 страницыMaterials of ConstructionMary Antonette M. TingalОценок пока нет

- Membrane Assisted CrystallizationДокумент12 страницMembrane Assisted Crystallizationup4allОценок пока нет

- 97-01 Nafion General InfoДокумент8 страниц97-01 Nafion General InfoprimekronosОценок пока нет

- 4-MCran Membrane CleaningДокумент41 страница4-MCran Membrane CleaningKhalid AbdelRahimОценок пока нет

- IR 3x3 350 P Maintenance ManualДокумент12 страницIR 3x3 350 P Maintenance ManualAngelОценок пока нет

- Ammonium SulfateДокумент3 страницыAmmonium SulfateXiwen Huang100% (1)

- Ceramic Membrane FiltrationДокумент4 страницыCeramic Membrane FiltrationPermionics IndiaОценок пока нет

- Guidelines For Treatment of Galvanized Cooling Towers To Prevent White RustДокумент8 страницGuidelines For Treatment of Galvanized Cooling Towers To Prevent White RustSivakumar Selvaraj100% (1)

- Industry & The Environment: AluminiumДокумент33 страницыIndustry & The Environment: AluminiumJaleel ForbesОценок пока нет

- Aluminum Smelting and RefiningДокумент4 страницыAluminum Smelting and Refininggullipalli srinivasa raoОценок пока нет

- Metallurgy of AluminiumДокумент9 страницMetallurgy of Aluminiumhassan materialsОценок пока нет

- Aluminium SmeltingДокумент41 страницаAluminium SmeltingVanamali Krish100% (1)

- Aluminum - Production and Transformation: From BauxiteДокумент5 страницAluminum - Production and Transformation: From Bauxitelamia97Оценок пока нет

- Aluminium As Building MaterialДокумент10 страницAluminium As Building MaterialKŕishňã AgârwaĺОценок пока нет

- Properties Processing and Application ofДокумент20 страницProperties Processing and Application ofTushar AneyraoОценок пока нет

- History:: General Information For Manufacture of AluminiumДокумент5 страницHistory:: General Information For Manufacture of AluminiumSenthilkumar PragasamОценок пока нет

- How Aluminium Is ProducedДокумент3 страницыHow Aluminium Is ProducedHtet Arkar KyawОценок пока нет

- 5 Aluminium RecyclingДокумент4 страницы5 Aluminium Recyclinggosaye desalegn50% (2)

- Aluminum Manufacturing ReportДокумент30 страницAluminum Manufacturing ReportmalynОценок пока нет

- D1072 (Total Sulfur in Fuel Gases by Combustion and Barium)Документ6 страницD1072 (Total Sulfur in Fuel Gases by Combustion and Barium)Ale Hurtado MartinezОценок пока нет

- Polythionic Acid Stress Corrosion CrackingДокумент4 страницыPolythionic Acid Stress Corrosion CrackingpmkarОценок пока нет

- CH 12Документ66 страницCH 12PushkalОценок пока нет

- As PDFДокумент4 страницыAs PDFShikha AgrawalОценок пока нет

- Surface Engineering Part 1Документ71 страницаSurface Engineering Part 1Prasanth M Cool100% (1)

- Mass Spectroscopy InterpretationДокумент44 страницыMass Spectroscopy InterpretationRenjitha J RОценок пока нет

- Acids, Base & SaltsДокумент5 страницAcids, Base & SaltsAbhinav SharmaОценок пока нет

- Periodic TableДокумент8 страницPeriodic TableKhairiyah AbdullahОценок пока нет

- Document Title Sheet: Revision Originator Release Date Description of Functional Change Updates To Smelter ListДокумент174 страницыDocument Title Sheet: Revision Originator Release Date Description of Functional Change Updates To Smelter ListMaddison1005Оценок пока нет

- Ch4 Watertreatment DisinfectionДокумент30 страницCh4 Watertreatment DisinfectionSUBHAM KumarОценок пока нет

- M Kumar Ci (Em) /Irimee/JmpДокумент51 страницаM Kumar Ci (Em) /Irimee/JmpSaptarshi PalОценок пока нет

- Stoichiometric Calculations Worksheet KEYДокумент4 страницыStoichiometric Calculations Worksheet KEYGabby Lisowicz100% (1)

- Answers KISS Metals WorksheetsДокумент6 страницAnswers KISS Metals WorksheetsDannyn ChenОценок пока нет

- Best Welding Practices (Pernis) : Doel / ScopeДокумент91 страницаBest Welding Practices (Pernis) : Doel / Scopechompink6900100% (1)

- Reaction Notes-ChemistryДокумент19 страницReaction Notes-ChemistrySirupyEwe GamerОценок пока нет

- JS893 Reclaimed Domestic Wastewater 2006 ArДокумент20 страницJS893 Reclaimed Domestic Wastewater 2006 Arرائحه المسكОценок пока нет

- Galvanising of Hot Rolled Strip91 - 1Документ8 страницGalvanising of Hot Rolled Strip91 - 1Suvro ChakrabortyОценок пока нет

- Jfe - Japanese Steel ClassificationДокумент24 страницыJfe - Japanese Steel ClassificationEsteban TraveltoUsa100% (1)

- 03c EIL MR 3002 dd1059Документ146 страниц03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- Welding Manual Nov 2010Документ187 страницWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Cherry Bomb Lip Tint in OilДокумент2 страницыCherry Bomb Lip Tint in Oilazarine wahanaОценок пока нет

- IGCSE Chemistry-Mole ConceptДокумент8 страницIGCSE Chemistry-Mole ConceptmarkusОценок пока нет

- Atoms, Elements, and Compounds Crossword - WordMintДокумент1 страницаAtoms, Elements, and Compounds Crossword - WordMintMohammed BashirОценок пока нет

- Bioinorganic Introduction - 11Документ28 страницBioinorganic Introduction - 11harjitkaurОценок пока нет

- Metallic Bonding Exam Style QuestionДокумент3 страницыMetallic Bonding Exam Style QuestionCheezy NachosОценок пока нет

- CLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 9Документ20 страницCLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 9Aakash PatilОценок пока нет

- Over-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDДокумент29 страницOver-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDSarahОценок пока нет

- WOR8294 Assaying and Refining of GoldДокумент28 страницWOR8294 Assaying and Refining of GoldRehan Sheikh100% (2)

- Homework-5 2Документ3 страницыHomework-5 2Dorothy CastilloОценок пока нет

- DisinfectantsДокумент4 страницыDisinfectantsPhu NguyenОценок пока нет