Академический Документы

Профессиональный Документы

Культура Документы

GLOBAL Spectrophotometric Range of Levis

Загружено:

Rafiqul AlamАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GLOBAL Spectrophotometric Range of Levis

Загружено:

Rafiqul AlamАвторское право:

Доступные форматы

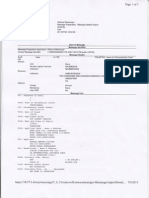

LS&CO.

Denim Shade Standards & Shipment Assembly Procedures

Denim Shade Standards

1.0 LS&CO. Product Integrity will assign a Shade Standard according to Finish Category to a fabric at adoption - in some regions (LSA), assignment will be according to actual finish - in other regions (LSE), assignment may be based on a "best fit" for multiple finishes on the same fabric 2.0 Mills will screen rolls for shipping using the shade blanket procedures and applying the appropriate shade limit standards for the wash recipe 3.0 Mills will sort the rolls into to a cutting order sequence either by Minimum Path Tapering (best practice) or Manual Tapering using the guidelines below. 4.0 LS&CO. reserves the right to tighten requirements for individual fabrics as market needs require. This will be negotiated with the supplier at the outset of a program.

Shade Standard Limits by Wash Recipe Finish Category A B C D E F G Finish Rigid One Wash / Rinse Light Stone Medium Stone Heavy Stone H.Stone Bleach/Peroxide/Distressed Super Stone Bleach dL +/1.50 1.00 1.25 1.50 1.75 2.00 2.25 da +/0.4 0.4 0.4 0.4 0.4 0.4 0.4 db +/1.0 0.6 0.8 0.8 0.8 0.8 0.8

Maximum Shade Variation within a Shipment: 1.0 DEcmc Master Wash Reproducibility (against Mill Reference): L = +/- 1.0

LS&CO. Best Practice Minimum Path Tapering

Hunterlab ColorQuest 0/45 or LabScan XE w/Shelyn software (recommended equipment)

Average Standard Roll Range Taper method

Standard Tolerances 1.8 DEcmc 1.8 DEcmc 0.5 DEcmc Not Applicable to Minimum Path Minimum path, clustered into 1 group LS&CO. Accepted Practice Manual Tapering Standard Tolerances 1.0 dL

Light to Dark within a shipment

LS&CO. Product Integrity

Page 1 of 2

Effective: 1 February 2008 Revised: 5 March 2008

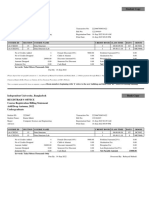

LS&CO. Denim Shade Standards & Shipment Assembly Procedures

Shade Blanket Construction

Front <---------------- 24" ---------------------> Back

Standard Swatch

8"

8"

8"

8"

<----------

2" Border made from natural/undyed fabric or same style as the swatches.

<---------------------- 28" ------------------------>

Shipment Assembly Procedures 1.0 From each roll in the shipment, cut individual swatches measuring 9" X 9", to finish 8" X 8" when sewn in the shade blanket. 2.0 Sew a maximum 9 swatches per side and trim with a 2" border on all sides made from a natural/undyed fabric or the same fabric style as the swatches. Sew front and back sides back to back to create one shade blanket. Blankets with fewer swatches are acceptable, but no more than 9 per side. 3.0 Include one Standard Swatch from the master roll in the blanket. If multiple blankets are washed at the same time, we recommend that a minimum of 3 blankets include the standard swatch. 4.0 Wash shade blankets in a finish that most closely replicates the intended garment finish. In order to calibrate the consistency of the washloads, the washed Standard Swatches must be compared to a mill reference standard prior to assembling the cutting order sequence. If the washed Standard Swatches exceed a dL reading of +/- 1.0 from the mill reference, a new blanket must be reconstructed and washed. Rewashing of the same blanket is not permitted. 5.0 Cut swatches apart and create a cutting order sequence for the rolls in the shipment using either Minimum Path Tapering (best practice) or Manual Tapering guidelines. Only swatches washed together in the same load can be assembled into a cutting order sequence. If more than one washload is necessary based on the yardage & roll size requirements, separate cutting order sequences must be created for the shipment.

LS&CO. Product Integrity

Page 2 of 2

Effective: 1 February 2008 Revised: 5 March 2008

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- International Certificate in WealthДокумент388 страницInternational Certificate in Wealthabhishek210585100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 08 Sepam - Understand Sepam Control LogicДокумент20 страниц08 Sepam - Understand Sepam Control LogicThức Võ100% (1)

- RACI Matrix: Phase 1 - Initiaton/Set UpДокумент3 страницыRACI Matrix: Phase 1 - Initiaton/Set UpHarshpreet BhatiaОценок пока нет

- Books of AccountsДокумент18 страницBooks of AccountsFrances Marie TemporalОценок пока нет

- DYSTARДокумент3 страницыDYSTARRafiqul AlamОценок пока нет

- Insider Threat ManagementДокумент48 страницInsider Threat ManagementPatricia LehmanОценок пока нет

- SizingДокумент54 страницыSizingRafiqul Alam100% (1)

- IoT BASED HEALTH MONITORING SYSTEMДокумент18 страницIoT BASED HEALTH MONITORING SYSTEMArunkumar Kuti100% (2)

- Chemical Purchase PolicyДокумент2 страницыChemical Purchase PolicyRafiqul Alam100% (3)

- Chemical Purchase PolicyДокумент2 страницыChemical Purchase PolicyRafiqul Alam100% (3)

- Postgraduate Notes in OrthodonticsДокумент257 страницPostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- SeraWetC As eДокумент2 страницыSeraWetC As eRafiqul AlamОценок пока нет

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Документ23 страницыGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongОценок пока нет

- Pf032200 - 00 Idropol MRC Tds Ing 10.09Документ1 страницаPf032200 - 00 Idropol MRC Tds Ing 10.09Rafiqul AlamОценок пока нет

- Sera Merc C-MNFДокумент9 страницSera Merc C-MNFRafiqul AlamОценок пока нет

- Borbelyne - 15 Tencell PDFДокумент8 страницBorbelyne - 15 Tencell PDFRafiqul AlamОценок пока нет

- Sodium Polysulfides Na2snДокумент2 страницыSodium Polysulfides Na2snRafiqul AlamОценок пока нет

- RgbtocieДокумент262 страницыRgbtocieRafiqul AlamОценок пока нет

- Woven Fabric CalculationДокумент4 страницыWoven Fabric CalculationRafiqul AlamОценок пока нет

- User - Manual - 3 Brinkmann Probe ColorimeterДокумент4 страницыUser - Manual - 3 Brinkmann Probe ColorimeterRafiqul AlamОценок пока нет

- Tencel LiteratureДокумент9 страницTencel LiteratureRafiqul AlamОценок пока нет

- AN - 915 - 1 Uv Visible Atr SpectrosДокумент7 страницAN - 915 - 1 Uv Visible Atr SpectrosRafiqul AlamОценок пока нет

- UV/VIS & NIR Measurements with Immersion Probes Benefits and ApplicationsДокумент1 страницаUV/VIS & NIR Measurements with Immersion Probes Benefits and ApplicationsRafiqul AlamОценок пока нет

- Spectro Guide PrincipleДокумент1 страницаSpectro Guide PrincipleRafiqul AlamОценок пока нет

- Albafix ECO MsdsДокумент5 страницAlbafix ECO MsdsRafiqul AlamОценок пока нет

- Statical DataДокумент15 страницStatical DataRafiqul AlamОценок пока нет

- RotaViscometer ColeparmerДокумент4 страницыRotaViscometer ColeparmerRafiqul AlamОценок пока нет

- Gomplast RollerДокумент4 страницыGomplast RollerRafiqul AlamОценок пока нет

- APEO Free Declaration 2013 Dystar Liquid IndigoДокумент10 страницAPEO Free Declaration 2013 Dystar Liquid IndigoRafiqul AlamОценок пока нет

- Clark DietrichДокумент110 страницClark Dietrichikirby77Оценок пока нет

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Документ19 страницMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldОценок пока нет

- Difference Between Mark Up and MarginДокумент2 страницыDifference Between Mark Up and MarginIan VinoyaОценок пока нет

- FX15Документ32 страницыFX15Jeferson MarceloОценок пока нет

- KPMG Inpection ReportДокумент11 страницKPMG Inpection ReportMacharia NgunjiriОценок пока нет

- Break Even AnalysisДокумент4 страницыBreak Even Analysiscyper zoonОценок пока нет

- Steam Turbine Theory and Practice by Kearton PDF 35Документ4 страницыSteam Turbine Theory and Practice by Kearton PDF 35KKDhОценок пока нет

- Report Emerging TechnologiesДокумент97 страницReport Emerging Technologiesa10b11Оценок пока нет

- DNA Gel Electrophoresis Lab Solves MysteryДокумент8 страницDNA Gel Electrophoresis Lab Solves MysteryAmit KumarОценок пока нет

- En dx300lc 5 Brochure PDFДокумент24 страницыEn dx300lc 5 Brochure PDFsaroniОценок пока нет

- Mission Ac Saad Test - 01 QP FinalДокумент12 страницMission Ac Saad Test - 01 QP FinalarunОценок пока нет

- Write UpДокумент5 страницWrite Upmourad baОценок пока нет

- Panel Data Econometrics: Manuel ArellanoДокумент5 страницPanel Data Econometrics: Manuel Arellanoeliasem2014Оценок пока нет

- #### # ## E232 0010 Qba - 0Документ9 страниц#### # ## E232 0010 Qba - 0MARCOОценок пока нет

- Numerical Methods Chapter 10 SummaryДокумент8 страницNumerical Methods Chapter 10 SummarynedumpillilОценок пока нет

- Reg FeeДокумент1 страницаReg FeeSikder MizanОценок пока нет

- Chennai Metro Rail BoQ for Tunnel WorksДокумент6 страницChennai Metro Rail BoQ for Tunnel WorksDEBASIS BARMANОценок пока нет

- SD8B 3 Part3Документ159 страницSD8B 3 Part3dan1_sbОценок пока нет

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFДокумент3 страницыEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezОценок пока нет

- Hindustan Motors Case StudyДокумент50 страницHindustan Motors Case Studyashitshekhar100% (4)

- Fernandez ArmestoДокумент10 страницFernandez Armestosrodriguezlorenzo3288Оценок пока нет

- DIN Flange Dimensions PDFДокумент1 страницаDIN Flange Dimensions PDFrasel.sheikh5000158Оценок пока нет