Академический Документы

Профессиональный Документы

Культура Документы

Sealing Problems

Загружено:

Akshay SetlurИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sealing Problems

Загружено:

Akshay SetlurАвторское право:

Доступные форматы

feature multiphase pumps

Mechanical sealing technology used in multiphase pumping the benefits

Nikolaus Necker from Burgmann Industries GmbH & CoKG describes the advantages you can gain when using mechanical sealing technology in multiphase pumping.

mongst the technologies developed for oil and gas production in the last 20 years, multiphase pumping is one of the most promising. The significant reduction of capital investment either on or offshore together with an increased production rate has led to a growing demand for pumping systems to be installed. The biggest challenge to be overcome by a piece of rotating equipment in multiphase service is the variation in the process fluid from 100% liquid to

100% gas. This creates very difficult operating conditions for the pump and even more difficult conditions for its mechanical seals, which are a critical part of any pump. Mechanical seals are readily available for liquid or gas phase applications. However, in a multi-phase pump the mechanical seals will see transient conditions. The transient nature of the wellhead stream creates pressure surges, slugs of liquid and gas locks. A multiphase pump and its mechanical seals must be able to

withstand all these rather harsh operating conditions. Consequently special mechanical seals have to be developed.

Types of pump

Multiphase pumps can be subdivided into two groups, each with benefits and limitations. These are rotordynamic and positive displacement pumps. Rotordynamic pumps rely on the concept of helico-axial hydraulics. A

Figure 1. Pressurized dual mechanical seal (API 610, plan 53 or 54), type SH, for multiphase pumping.

20 WORLD PUMPS August 2005

www.worldpumps.com

feature multiphase pumps

multistage pump can have up to 15 compression cells on a single shaft. Each compression cell comprises a rotating helicoaxial flow impeller and a stationary diffuser. The produced effluent can thus be boosted over long distances without the need for prior separation and with no limitation regarding gas volume fractions. This type of pump is compact, offers mechanical simplicity and reliability, is tolerant of solids and produces high flow rates. Positive displacement pumps, or twin screw pumps as they are also known can already handle gas volume fractions up to 70%. In this respect only some minor improvements have to be made to existing pump design. The twin rotor screw pump consists of two contrarotating screws. A certain amount of liquid is needed to seal the gaps between the screws and the liner. This kind of pump has true dry running characteristics, thus can handle an extreme range of specific gravity and gas volume fraction. They have proven their reliability in several real multiphase boosting applications.

Figure 3. The Twin Rotor Screw Pump consists of two contra-rotating screws.

Chemical parameters

The chemical analysis of the process medium differs, depending on the oil field and/or the location. This means that the crude oil may contain: wax salt water sour gas (H2S) and / or carbon dioxide (CO2) cracked hydrocarbons solids. All this affects the operating performance of the seal and results in erosion or corrosion of the mechanical seal components.

face. The friction at the seal face results in a temperature increase in the fluid at the seal face. The decrease in pressure and the simultaneous temperature increase of the fluid at the seal face results in the vaporisation of the volatile elements within the sealed fluid.

Figure 2. Rotordynamic Pumps rely on the concept of helico-axial hydraulics.

Sealing principle

The fluid being sealed decreases in pressure across the width of the seal

The problem task

Unlike sealing systems, which are exclusively and specifically applied in liquid or gaseous media, mech-anical seals for multiphase pumps operate with continually chaning gas and liquid flow rates. Thus the mechanical seal has to cope with the following conditions: unpredictable process medium composition density and viscosity variations temperature variations erosion effects, mainly by sand high and low operating pressures insufficient lubrication and cooling of the seal faces.

Figure 4. A typical dual high pressure seal in a face-toface arrangement.

WORLD PUMPS August 2005

www.worldpumps.com 21

feature multiphase pumps

This can result in insufficient lubrication and cooling of the seal faces. The gas content in a multi phase process medium creates an additional risk of insufficient seal face lubrication which may result in the failure of the seal faces. In an optimum parallel gap the axial opening and closing forces are balanced. In this case the contact force (Fc) is evenly distributed across the width of the seal face. The pressure gradient of the sealed fluid (Fs) is linear. Depending on the mechanical seal face stiffness, two other gap formations can occur. In an A-gap situation a high contact force at the outside diameter is created. The pressure gradient steepens. This results in an unstable running condition of the seal. In a V-gap situation, a low contact force is created at the inner diameter of the seal face, the pressure gradient shallows, the mechanical seal runs in a stable condition. Two examples of rotating sealing solutions follow.

Single mechanical seal (API 610, plan 32)

Single mechanical seals can be used in twin screw pumps for multiphase applications. Single seals are lubricated and cooled by a flush from an external source (API610-plan 32). The flush has to be continuous and reliable even during start-up and shut-down of the pump. A close clearance throttle bushing in front of the seal controls the rate of flow of the flush medium into the pump, thus isolating the seal from the process fluid.

This mechanical seal is a special design employed for high duty sealing applications. The seal faces are double balanced; in the event of barrier fluid pressure loss or a high pressure transient in the seal chamber the seal remains closed allowing pump rundown with little risk of face damage or product contamination to the atmospheric side. The identical stationary seal face assemblies give optimum running characteristics under changing operating conditions. The seal is designed as a cartridge unit, thus is compact, robust and easy to maintain. Corrosion and erosion is avoided by choosing appropriate seal face and constructional materials. Silicon carbide is typically used for the seal faces as it has high hardness and excellent heat transfer properties. Duplex and Super duplex stainless steels are used for the metal parts.

Pressurised dual mechanical seal (API 610, plan 53 or 54)

Engineered pressurised dual seals are predominantly used in multiphase pumps. The example shows a typical dual high pressure seal in a face-to-face arrangement. This type of seal is commonly used in areas where the practicality of using a single seal with plan 32 external (continuous loss) flush is limited. Dual seals are lubricated by an external closed loop supply system.

Conclusion

Mechanical seals have proven their ability to seal multiphase mixtures over a wide range of operating conditions in hundreds of applications in extremely harsh environments around the world. The mechanical seal types and sliding materials available today are capable of meeting any technical demand defined by multiphase pumping services. In order to assimilate the sealing systems with the specific operating conditions close cooperation between seal manufacturer, pump manufacturer and end user is a basic precondition. Correct application, installation and operation are the key factors for a long meantime-between failure. s CONTACT

Nikolaus Necker Burgmann Industries GmbH & Co. KG Aeussere Sauerlacher Str. 6-10 82515 Wolfratshausen Germany Phone +49 8171 23 1200 Fax: +49 8171 23 1214 E-mail:necker@burgmann.com Website: www.burgmann.com

Figure 5. Mechanical steel gap stiffness.

gap and contact force parallelgap FS FC

k1 = 0,5

unstable indifferent

A-gap

0 < k1< 0,5

V-gap

0,5 < k1< 1

stable

pa > pi

22

www.worldpumps.com

WORLD PUMPS August 2005

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Sturctural Report Cold StorageДокумент35 страницSturctural Report Cold StorageSaugat Thapa0% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Sample CSHP (Safety&Health D.O.13 DOLE)Документ1 страницаSample CSHP (Safety&Health D.O.13 DOLE)Jemsel D. Valdez, Sr.Оценок пока нет

- Se Sovent Design Manual 101o New011007Документ24 страницыSe Sovent Design Manual 101o New011007jomy_pj8106Оценок пока нет

- Friendship CenterДокумент22 страницыFriendship CenterJazz100% (2)

- Day in The Life of A Proactive Maint PlannerДокумент6 страницDay in The Life of A Proactive Maint PlannerAkshay SetlurОценок пока нет

- Equipment - Risk and ReliabilityДокумент28 страницEquipment - Risk and ReliabilityAkshay SetlurОценок пока нет

- Reliability Growth Cause Analysis TutorialДокумент12 страницReliability Growth Cause Analysis TutorialAkshay SetlurОценок пока нет

- Series 44 Self-Operated Pressure Regulators Type 44-7 Excess Pressure Valve Type 44-8 Safety Excess Pressure Valve (SEV)Документ4 страницыSeries 44 Self-Operated Pressure Regulators Type 44-7 Excess Pressure Valve Type 44-8 Safety Excess Pressure Valve (SEV)Akshay SetlurОценок пока нет

- Operating Instructions Gas Valve Block For Fuel According DVGW Approval Project A51GДокумент1 страницаOperating Instructions Gas Valve Block For Fuel According DVGW Approval Project A51GAkshay SetlurОценок пока нет

- Before You Edit This Template, So Much The Better If There Is A Free FontДокумент2 страницыBefore You Edit This Template, So Much The Better If There Is A Free FontAkshay SetlurОценок пока нет

- Capsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Документ4 страницыCapsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Akshay SetlurОценок пока нет

- Reduction of Chemical Effects of Swelling and ShrinkageДокумент22 страницыReduction of Chemical Effects of Swelling and ShrinkageAkshay SetlurОценок пока нет

- Steam Table PDFДокумент1 страницаSteam Table PDFAkshay SetlurОценок пока нет

- Skills Matrix TemplateДокумент6 страницSkills Matrix TemplateAkshay SetlurОценок пока нет

- Shrink and SwellДокумент3 страницыShrink and SwellAkshay SetlurОценок пока нет

- Establishing Proper Pressure Drop For Feedwater Flow Control ValvesДокумент5 страницEstablishing Proper Pressure Drop For Feedwater Flow Control ValvesAkshay SetlurОценок пока нет

- Before You Edit This Template, So Much The Better If There Is A Free FontДокумент2 страницыBefore You Edit This Template, So Much The Better If There Is A Free FontAkshay SetlurОценок пока нет

- How To Create Infographics in PowerPoint by HubSpotДокумент10 страницHow To Create Infographics in PowerPoint by HubSpotAkshay SetlurОценок пока нет

- Kaizen Event 5S Radar ChartДокумент8 страницKaizen Event 5S Radar ChartAkshay SetlurОценок пока нет

- Element % by Mass Calorific Value KJ/KGДокумент2 страницыElement % by Mass Calorific Value KJ/KGAkshay SetlurОценок пока нет

- Primary SchoolДокумент57 страницPrimary SchoolMUUTHUKRISHNAN100% (1)

- University Forum: Item Description Qty Unit Rate (AED) Amount (AED) Drainage InstallationДокумент5 страницUniversity Forum: Item Description Qty Unit Rate (AED) Amount (AED) Drainage InstallationMohammed AzharОценок пока нет

- Quality PlanДокумент23 страницыQuality PlanArun Kumar88% (8)

- Police Office Station - BOQ - UNOPS - AfghanistanДокумент6 страницPolice Office Station - BOQ - UNOPS - AfghanistanHimdad TahirОценок пока нет

- BS en 206Документ7 страницBS en 206amit_halcrow100% (1)

- Glycodur Cat enДокумент52 страницыGlycodur Cat enjhhvgОценок пока нет

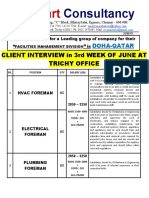

- MBA Qatar Company InterviewДокумент2 страницыMBA Qatar Company InterviewTradiyo ForexОценок пока нет

- A23b - Chalenges For Underwater Concrete Repair in Deep WaterДокумент12 страницA23b - Chalenges For Underwater Concrete Repair in Deep WaterJoão Carlos Protz ProtzОценок пока нет

- Design of Concrete Structures - I Question PaperДокумент3 страницыDesign of Concrete Structures - I Question PaperSourav Sil50% (2)

- Structural Design of Sump WallДокумент9 страницStructural Design of Sump WallOjeleke OluwadareОценок пока нет

- EC-EMX-instruction-inflatable Spider TentДокумент2 страницыEC-EMX-instruction-inflatable Spider TentSerena WangОценок пока нет

- HVAC Technician Sample ResumeДокумент2 страницыHVAC Technician Sample ResumeRommel MartinezОценок пока нет

- Compressed Air: Stäubli Invents Active SafetyДокумент12 страницCompressed Air: Stäubli Invents Active SafetyAlper SakalsizОценок пока нет

- Conceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Документ16 страницConceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dawit SolomonОценок пока нет

- SP-008 Doors and WindowsДокумент100 страницSP-008 Doors and WindowsmcbluedОценок пока нет

- Concrete Mix Design As Per Indian Standard CodeДокумент4 страницыConcrete Mix Design As Per Indian Standard CodesemakambaОценок пока нет

- SANS1655ED1 1 - 04-10-22 - WP - TMДокумент15 страницSANS1655ED1 1 - 04-10-22 - WP - TMjohndupОценок пока нет

- The Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisДокумент23 страницыThe Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisSaurav ShresthaОценок пока нет

- Ground Floor Plan Second Floor PlanДокумент5 страницGround Floor Plan Second Floor PlanElzie BarbosaОценок пока нет

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsДокумент1 страница4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksОценок пока нет

- Toughness Problems in Steel Welded Joints During Fabrication and Service For Thick ComponentsДокумент6 страницToughness Problems in Steel Welded Joints During Fabrication and Service For Thick Componentsandreahank100% (1)

- Storage Tank Design Calculation - Api 650Документ21 страницаStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Armor-X 600v (4) SouthwireДокумент3 страницыArmor-X 600v (4) SouthwireLuis RamirezОценок пока нет

- SamsdataДокумент296 страницSamsdataSamuel AugustineОценок пока нет

- PR170 Vietnam Bach Dang BridgeДокумент2 страницыPR170 Vietnam Bach Dang BridgeWang MaxОценок пока нет

- 1KS 34075 en PDFДокумент1 страница1KS 34075 en PDFbebeОценок пока нет