Академический Документы

Профессиональный Документы

Культура Документы

Structural Calculation of I.O.C.L Water Reserver at Chaitnyapur 08.10.2012

Загружено:

Anonymous OuLOmbИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Structural Calculation of I.O.C.L Water Reserver at Chaitnyapur 08.10.2012

Загружено:

Anonymous OuLOmbАвторское право:

Доступные форматы

Structural Design Calculation of Walls of Under Ground Water Reservoir, Sump and Pump Room at Chaitanyapur of I.O.C.

L under Haldia Development Authority, Haldia.

Dealt By

ARKHTON

Wall of CWR:

Under Ground Water Reservoir, HDA 08/10/2012 1

Design on R.C. tank of internal dimensions 56.3 m x 45.6 m x 3.6 m. The tank is t be provided underground. The soil surround the tank is likely to get wet. Adopting suitable working stresses. Soil weights 1.97 ton /metre3. Using M 25 concrete and Fe 500 steel.

Solution. The following cases arise: Case 1. Tank is full and the surrounding soil is dry. Case 2. Tank is empty and the surrounding soil is water-logged. Case 3. Tank is full and the surrounding soil is water-logged. Case 4. Tank is empty and the surrounding soil is dry. Of these, the first two cases are the extreme cases and the tank should be designed for these cases. Case 1. Tank is full and surrounding soil is dry.

= 19700 x 1.5 x (1 sin 30)/(1 + sin 30) N/metre2 = 9850 N/meter2 Maximum water pressure = 9810 x 3.0 N/meter2 = 29430 N/metre2 Net pressure at the bottom of wall = 29430 9850 N/metre2 = 19580 N/metre2 Consider one metre run of the wall. Maximum bending moment producing tension away from the water face = ph2/33.5 = (19580 x 3.02)/33.5 = 5260.29 Nm. 5260 Nm Maximum bending moment producing tension near the water face = ph2/15 = (19580 x 3.02)/15 = 11748 Nm. 11748 Nm Maximum soil pressure

Case 2. Tank is empty and the surrounding soil is water-logged. Pressure intensity exerted by wet earth at bottom of the wall = wh (1 sin 6)/(1 + sin 6) = 19700 x 1.5 x (1 sin 6)/(1 + sin 6) N/m2 = 23956.99 N/m2 23957 N/m2 Consider one metre run of the wall. Maximum bending moment producing tension near water face = ph2/33.5 = (23957 x1.52)/33.5 Nm = 1609.05 Nm. 1609 Nm Maximum bending moment producing tension away from the water face = ph2/15 = (23957 x 1.52)/15 Nm = 3593.55 Nm. 3594 Nm

Under Ground Water Reservoir, HDA 08/10/2012 2

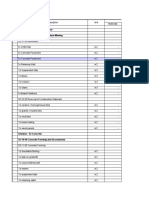

The bending moments computed above are tabulated below: Case B.M. producing Tension near B.M. producing Tension away from Water face (Nm) Water face (Nm) Case 1 11748 5260 Case 2 1609 3594 On no crack basis T = (11748 x 6)/1.8 = 197.88 mm [Permissible tensile stress (bending) 1.80 N/mm2 for M25 concrete] Let the effective cover to the reinforcement be 40 mm. Assuming 300 mm depth Effective depth = 300 (40+6)= 254 mm. Steel for a bending moment of 11748 Nm = (11748 x 1000)/(205 x 0.905 x 254) = 249.30 mm2 250 mm2 Spacing of 12 mm diameter bars = (113 x 1000)/250 = 452 mm But provide 12 mm diameter bars at 185 mm c/c (610 mm2) So Pt = 0.02% and d= 254/300D = 0.847D From Table 0.002 0.9D 0.176 0.8D 0.172 0.847D 0.17388 So, t = (11748 X 1000)/(0.17388 X 1.8 X 1000) = 193.74 mm < 300 mm Hence O.K. Steel for a bending moment of 5260 Nm = (5260 X 6)/ 1.8 = 92.37 mm < 300 mm Hence O.K. Spacing of 12 mm diameter bars = (113 x 1000)/610 = 185 mm 12 mm diameter bars at 185 mm centres (610 mm2 < 600 mm2 i.e. 0.2%)

Distribution Steel 0.2% i.e. 0.2/100 X300X1000 = 600 mm2 (12mm @188.33C/C)

Under Ground Water Reservoir, HDA 08/10/2012 3

Providing 12 mm dia @ 185 mm C/C for Both the faces.

Design of the bottom slab of CWR

Assuming 300 mm depth Effective depth = 300 (40+6) = 254 mm. Distribution Steel 0.2% i.e. 0.2/100 X300X1000 = 600 mm2 (12mm @188.33C/C) Providing 12 mm dia @ 185 mm C/C for Both the faces.

Wall of Sump:

Case 1. Sump is full and surrounding soil is dry. = 19700 x 4.45 x (1 sin 30)/(1 + sin 30) N/metre2 = 29222 N/meter2 Maximum water pressure = 9810 x 5.95 N/meter2 = 58370N/metre2 Net pressure at the bottom of wall = 58370 29222 N/metre2 = 29150 N/metre2 Consider one metre run of the wall. Maximum bending moment producing tension away from the water face = ph2/33.5 = (29150 x 5.952)/33.5 = 30805.45 Nm. 30805 Nm Maximum bending moment producing tension near the water face = ph2/15 = (29150 x 5.952)/15 = 68798.85 Nm. 68799 Nm Maximum soil pressure

Case 2. Sump is empty and the surrounding soil is water-logged. Pressure intensity exerted by wet earth at bottom of the wall = wh (1 sin 6)/(1 + sin 6) = 19700 x 4.45 x (1 sin 6)/(1 + sin 6) N/m2 = 71072.42 N/m2 71072 N/m2 Consider one metre run of the wall. Maximum bending moment producing tension near water face = ph2/33.5 = (71072 x4.452)/33.5 Nm = 42012.03 Nm. 42012 Nm Maximum bending moment producing tension away from the water face = ph2/15 = (71072 x 4.452)/15 Nm = 93826.88 Nm. 93827 Nm

Under Ground Water Reservoir, HDA

08/10/2012

The bending moments computed above are tabulated below: Case B.M. producing Tension near B.M. producing Tension away from Water face (Nm) Water face (Nm) Case 1 30805 68799 Case 2 42012 93827

On no crack basis T = (93827 x 6)/1.8 = 559.24 mm [Permissible tensile stress (bending) 1.80 N/mm2 for M25 concrete] Let the effective cover to the reinforcement be 40 mm. Assuming 600 mm depth Effective depth = 600 (30+8)= 562 mm. Steel for a bending moment of 93827 Nm = (93827 x 1000)/(205 x 0.905 x 562) = 899.88 mm2 900 mm2 Spacing of 12 mm diameter bars = (201 x 1000)/900= 223.33 mm But provide 16 mm diameter bars at 165mm c/c (1218 mm2)

So Pt = 0.3%

Distribution Steel 0.2% i.e. 0.2/100 X600X1000 = 1200 mm2 (16mm @167.5C/C) Providing 16 mm dia @ 165 mm C/C for Both the faces.

Design of the bottom slab of Sump

Assuming 300 mm depth Effective depth = 300 (40+6) = 254 mm. Distribution Steel 0.2% i.e. 0.2/100 X300X1000 = 600 mm2 (12mm @188.33C/C) Providing 12 mm dia @ 185 mm C/C for Both the faces.

Under Ground Water Reservoir, HDA

08/10/2012

Wall of Pump Room:

Pump Room is empty and the surrounding soil is water-logged. Pressure intensity exerted by wet earth at bottom of the wall = wh (1 sin 6)/(1 + sin 6) = 19700 x 3.40 x (1 sin 6)/(1 + sin 6) N/m2 = 54302.52 N/m2 54303 N/m2 Consider one metre run of the wall. Maximum bending moment producing tension near water face = ph2/33.5 = (54303 x3.402)/33.5 Nm = 18738.58 Nm. 18739 Nm Maximum bending moment producing tension away from the water face = ph2/15 = (54303x 3.402)/15 Nm = 41849.51 Nm. 41850 Nm

The bending moments computed above are tabulated below: B.M. producing Tension near B.M. producing Tension away from Water face (Nm) Water face (Nm) 18739 41850 On no crack basis T = (41850 x 6)/1.8 = 373.49 mm [Permissible tensile stress (bending) 1.80 N/mm2 for M25 concrete] Let the effective cover to the reinforcement be 40 mm. Assuming 400 mm depth Effective depth = 410 (30+6) = 474 mm. Steel for a bending moment of 41850 Nm = (41850 x 1000)/ (205 x 0.905 x 374) = 603.14 mm2 603 mm2 Spacing of 12 mm diameter bars = (113 x 1000)/603= 187.39 mm But provide 12 mm diameter bars at 135mm c/c (837 mm2)

So Pt = 0.2%

Distribution Steel 0.2% i.e. 0.2/100 X410X1000 = 1200 mm2 (12mm @135C/C) Providing 12 mm dia @ 135 mm C/C for Both the faces.

Design of the bottom slab of Pump Room

Assuming 300 mm depth Effective depth = 300 (40+6) = 254 mm. Distribution Steel 0.2% i.e. 0.2/100 X300X1000 = 600 mm2 (12mm @188.33C/C) Providing 12 mm dia @ 185 mm C/C for Both the faces.

Under Ground Water Reservoir, HDA 08/10/2012 6

Вам также может понравиться

- English Words That Only Indians Use - Hey Loons PDFДокумент3 страницыEnglish Words That Only Indians Use - Hey Loons PDFAnonymous OuLOmbОценок пока нет

- 18 - Model Crematoria DesignsДокумент83 страницы18 - Model Crematoria DesignsAnonymous OuLOmbОценок пока нет

- Balanced Sections, Under Reinforced Section and Over Reinforced SectionДокумент3 страницыBalanced Sections, Under Reinforced Section and Over Reinforced SectionAnonymous OuLOmbОценок пока нет

- Rain Water HarvestingДокумент32 страницыRain Water HarvestingAnonymous OuLOmb100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Concrete Recycling - Research and PracticeДокумент659 страницConcrete Recycling - Research and Practicekarim hassanОценок пока нет

- Tunneling Problems For 1020 MW Tala Hydroelectric Project in Bhutan HimalayasДокумент10 страницTunneling Problems For 1020 MW Tala Hydroelectric Project in Bhutan HimalayasHarold TaylorОценок пока нет

- Cement Chemistry L1Документ23 страницыCement Chemistry L1Bharat Singh100% (2)

- Unit Rates and Cost Per ItemДокумент213 страницUnit Rates and Cost Per ItemDesiree Vera GrauelОценок пока нет

- Applications of Self Compacting ConcreteДокумент9 страницApplications of Self Compacting ConcreteMohamedRaahimОценок пока нет

- Floating Precast Concrete Docks - tcm77-1305758Документ3 страницыFloating Precast Concrete Docks - tcm77-1305758Ahmad BalahОценок пока нет

- Civil Engg. (BE) - Project Topics For StudentsДокумент38 страницCivil Engg. (BE) - Project Topics For StudentsSantosh Kumar50% (2)

- Construction and Building Materials: Yao Ding, Jian-Guo Dai, Cai-Jun ShiДокумент12 страницConstruction and Building Materials: Yao Ding, Jian-Guo Dai, Cai-Jun ShivikasОценок пока нет

- Complete Bar Bending Schedule For Different Structure (Free E-Book)Документ20 страницComplete Bar Bending Schedule For Different Structure (Free E-Book)Prakhar PatidarОценок пока нет

- History of ConcreteДокумент20 страницHistory of Concreteapi-3766593100% (2)

- What Are Stiffness Modifiers in EtabsДокумент35 страницWhat Are Stiffness Modifiers in EtabsHiren Desai50% (2)

- Division 4 MasonryДокумент39 страницDivision 4 MasonryLynette CabantingОценок пока нет

- Katalog SealentДокумент15 страницKatalog SealentWulan EgidiaОценок пока нет

- Sikaplan BrochureДокумент24 страницыSikaplan Brochurejdonosov1579Оценок пока нет

- The Effect of The Using Waste Marble Dust As Fine Sand On The Mechanical Properties of The ConcreteДокумент9 страницThe Effect of The Using Waste Marble Dust As Fine Sand On The Mechanical Properties of The ConcreteYu Paing HanОценок пока нет

- ASTM C535 - 16 Resistencia A La Degradacion de Agregado Gruedo - Maquina de Los AngelesДокумент3 страницыASTM C535 - 16 Resistencia A La Degradacion de Agregado Gruedo - Maquina de Los AngelesFrancisco QuiñonezОценок пока нет

- Vivens 1Документ27 страницVivens 1Dushimiyimana jean EudeОценок пока нет

- Component Catalog Tree ViewДокумент10 страницComponent Catalog Tree Viewlkjhgfdsazxcvbnm89Оценок пока нет

- Fiber Reinforced ConcreteДокумент16 страницFiber Reinforced ConcreteNaviya K NaviyaОценок пока нет

- TECHNICAL INSTRUCTION 1D-2013-MAy PDFДокумент65 страницTECHNICAL INSTRUCTION 1D-2013-MAy PDFStelian ConstantinescuОценок пока нет

- Anchor Watch 02Документ7 страницAnchor Watch 02Janaka KarunarathnaОценок пока нет

- 5 Factors To Consider in Foundation DesignДокумент25 страниц5 Factors To Consider in Foundation DesignMotamed Ben TaherОценок пока нет

- Building Design-PWD GuidelinesДокумент71 страницаBuilding Design-PWD GuidelinesPrayas SubediОценок пока нет

- Precast ConcreteДокумент6 страницPrecast ConcreteRaja Sekhar Reddy KasuОценок пока нет

- 3.articulated Tower PlatformsДокумент2 страницы3.articulated Tower PlatformsAman SinghalОценок пока нет

- Sika WT-200 P - Brochure PDFДокумент4 страницыSika WT-200 P - Brochure PDFΜιχάλης ΧατζημιχαήλОценок пока нет

- Norma AREMA para Ensayo A FlexionДокумент11 страницNorma AREMA para Ensayo A FlexionDiego CBОценок пока нет

- FRC PDFДокумент9 страницFRC PDFHammad SalahuddinОценок пока нет

- Guid LinesДокумент26 страницGuid LinesZurc RamcivОценок пока нет

- ACI 116R Admixture Effects Setting TimeДокумент3 страницыACI 116R Admixture Effects Setting TimeRavi Ayyavu100% (1)