Академический Документы

Профессиональный Документы

Культура Документы

CFD Simulation of Flow-Induced PDF

Загружено:

Zylyn KuaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CFD Simulation of Flow-Induced PDF

Загружено:

Zylyn KuaАвторское право:

Доступные форматы

CFD Simulation of Flow-Induced Motions of a Multi-Column Floating Platform

Recent improvements in capabilities of both hardware and software allow solving the coupled rigid body motions for the floating platform together with the fluid transport equations. This makes CFD a possible alternative or complement to model tests for predicting VIM performance. In addition, CFD allows simulating certain factors which cannot be addressed in scale model tests, and the two methods can ideally serve as cross- validation tools to verify the remaining uncertainties. Previous applications of CFD to Spar VIM predictions have shown promising results. Building on this, flow-induced motion simulations of multi-column floating platforms are being carried out using CFD as part of the R&D effort within Technip. The purpose of this paper is to present the results of two separate preliminary simulations applied to the prediction of vortex-induced motions of a TLP design and compare to the model test results.

T E C H N O L O G Y

Floating Production

n offshore platform is a complex system including hull, mooring, risers, drilling and production equipment. The platform design must take account of local regional metocean criteria and infrastructure for fabrication, installation and operations, [1]. In particular, deepwater Southeast Asia has a characteristic operating environment with unique features that affect the design including: Strong and persistent currents with small to moderate waves A strong preference for dry trees completions, to allow multiple well interventions Use of Tender Assist Drilling Vessel (TAD), which is economical, but imposes tight operational constraints Improved understanding of performance is required to assure both safe, efficient operations, as well as cost-effective design of hull, station-keeping system and risers. Two key areas have been identified for focus Vortex-Induced Motions (VIM) of a TLP Two-body wave/wake interactions

The first of these is addressed here using CFD and the second will be addressed in future undertakings. Published model test data for simplified spar models [2, 3] and for multi-column floating platforms [4, 5, 10] show that the maximum platforminduced VIM response amplitude can reach slightly more than half the column diameter in both cases. The column diameter of a typical column stabilized platform or TLP is about half that of a typical Spars hard tank diameter. So, the multi-column floater will generally experience platform-induced VIM about half as large as a Spar for similar reduced velocity. Spars, TLPs, deep draft SEMIs and other multi-column floating platform designs in deepwater, have similar calm water sway natural periods on the order of 120 seconds. Therefore, due to smaller column diameter, D, the reduced velocity Ur=UT/D, where U is the current speed and T is the natural sway period, reaches the lock-in range 4<U r<8 at lower current speeds for a multi-column floater than for a Spar, potentially leading to more persistent lock-in. In addition, multi-column floaters also

44

JANUARY/ FEBRUARY 2012

Visit our website at www.safan.com

have the potential for flow-induced yaw over a somewhat different range of current speeds, depending on the yaw natural period. Depending on the riser attachment point, or hang-off location, both sway and yaw will induce tension fluctuations in the SCRs. Thus, the potential for fatigue damage of risers on multi-column floaters warrants investigation c.f., [11]. Furthermore, drag augmentation due to VIM may increase platform offsets in current-driven environments. Finally, a variety of floating platform concepts such as proprietary TLP configurations, deep draft semis and novel concepts targeted towards deepwater developments have been proposed and deployed in current-prone regions. Given the potential for persistent lock-in over a realistic range of current speeds, investigation of vortex-induced motions of multi-column platforms is needed. VIM tests have typically been performed in a towing tank, rather than an offshore basin because the tow tank provides smooth flow inlet conditions, and avoids the uncertain impact of inlet current turbulence. However, TLP tests in a limited depth tow tank require a special set-up to obtain the correct mass ratio and correct ratio of natural periods in sway and yaw [4, 6]. In the present case, the model is freely floating and restrained using a set of horizontal springs. Thus, the mass ratio is unity, which is slightly more than the prototype (typically 0.7-0.8). The calculations are carried out by modeling the tested setup. Future tests are planned with an improved set-up. See Ref. [8]). In this paper, the VIM model test presented in [6] has been simulated by CFD tools. Two different CFD model have been used and results are compared with model test. In the first approach, a simplified VIM simulation using a commercial CFD code AcuSolve has been used. Free-surface motion is ignored and only surge and sway of TLP motion is allowed to simplify mesh generation and minimize computational time. In the second approach, CFD simulation with full consideration of free-surface effect and 6 d.o.f motion have been made using a CDF code Star CCM+.

Model Test

The TLP model was constructed based on Technips internal TLP design development for the Southeast Asian region. The scale of the model is 1:70. The TLP model has four square columns connected by four square pontoons. A piece of plywood is fastened to the top of the TLP to act as a deck to mount the test instruments. Details such as corner fillets are included in the TLP model since the near-wall behavior of the fluid flow is not to be neglected in this study. The corner radius on each column should match the corresponding prototype features since the sharp/ round corners of cylinders were found to have a significant impact on the behavior of lift and drag forces due to vortex shedding on fixed cylinders [6, 7]. However, since the flow is expected to separate near the column corners, appurtenances are not being modeled. Actual roughness over the model surface was estimated to be approximately 0.3 mm. The University Teknologi Malaysia (UTM) towing tank, located in Johor Bahru at the southern tip of the Malaysian mainland, has dimensions 120m long x 4m wide x 2.5m deep and is equipped with a movable carriage that runs on the rails along the top of the tank side walls, refer to Figure 2. The tank is equipped with a wavemaker at one end and a perforated steel beach at the other to absorb the wave energy generated. Useful towing length is approximately 90m. Depending on the tow speed, different numbers of oscillations were obtained. At least 30 oscillations were measured for each case. More details of model test set up can be found in [6].

Figure 1. Test model attached to towing carriage.

JANUARY/ FEBRUARY 2012

45

Figure 2. Schematic of TLP model test set up

Preliminary Calculations Using AcuSolve

AcuSolve is a finite-element code to solve incompressible fluid motion, based on the Galerkin/ Least-Squares formulation. AcuSolve is capable of simulating free-surface effects due to 6 d.o.f. motion of floating bodies using Arbitrary Lagrangian Eulerian (ALE) mesh [8]. In this study, free-surface motion is ignored because of low

Figure 3. TLP Dimensions in Full Scale (units: meter)

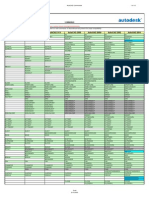

Froude number of the tested cases ( F n< 0.1). Freesurface boundary is fixed on mean water level and free-slip condition is applied on the flat boundary [9]. TLP motion other than surge and sway motion has also been ignored. Because of these simplifications, a simpler moving mesh scheme without using ALE scheme has been used. The whole mesh is horizontally moving following the horizontal motion of TLP. Capability to include yaw is available in AcuSolve but was not attempted here due to time constraints. In the discussion below, all values are given in fullscale unless otherwise noted. Fig. 3 shows dimensions of the under-water part of TLP modeled. Large computational domain with size 700 m x 800 m x 115 m has been used, as shown in Fig. 4. Fig. 5 shows mesh used for the AcuSolve simulation. Four-node tetrahedral elements have been used except at the boundary layer zone on the TLP surface, where six-node prism elements have been used. Different mesh sizes depending on the required resolution at different locations have been used. A coarse mesh size of 40 m has been used in the domain far away from the TLP. In the wake zone trailing the TLP, a finer mesh size of 4 m has been used. A finer mesh size of 2 m has been used in the near field where the interaction between generated vortices occurs. Finally, a boundary mesh size of approximately 0.01 m in the normal direction and 1 m tangentially has been used in the boundary-layer zone near the TLP surface. The complete mesh contains 171,690 nodes and 743,090 cells. Table 1 shows the test matrix that has been simulated. Current speeds are given at full scale. For full-scale Reynolds number, direct eddy simulation (DES) turbulent model has been used. For model-scale Reynolds number, both laminar and turbulent (DES) models have been applied since the boundary layer will be laminar, but the wake will be turbulent. The mesh was similar at model scale. The Froude number is given in the table to show that it remains low for all cases. Thus, neglecting wave effects should generally not cause large errors in the solution.

Visit our website at www.safan.com

Floating Production

46

JANUARY/ FEBRUARY 2012

Before carrying out the VIM simulations, a sway free decay test has been simulated. The TLP is initially displaced by 5 m fullscale, and released to freely oscillate. Fig. 6 shows the comparison with the test results. At the initial stage, the model test shows faster decay than simulation. The discrepancy at the initial stage is presumably due to the transient free surface effect that has been ignored in the numerical modeling. After t = 250 s, the simulation and test results show good agreement. This may indicate that once the motion is established, free surface damping remains low for such long periods. Fig. 7 shows time history of sway motion for U = 1.0 m/s, which corresponds to Ur = 9.6. Simulation with full-scale Reynolds number shows slightly smaller sway motion. At model scale, laminar analysis model produces slightly higher motion. Comparing to the model test results, which are shown in Fig. 8, the simulated results show less modulation. Fig. 9 compares sway amplitude in terms of maximum A/D, which is defined by { Max (Sway) Min (Sway) } / 2D, and nominal A/D, which is defined by times of standard deviation of sway motion. CFD results with model-scale Reynolds number agrees well with the model test data when maximum amplitudes are compared. CFD predicts nominal ampli-

Figure 5. Mesh Sizes for AcuSolve Simulation Table 1. Test Matrix for AcuSolve Simulation

Figure 4. Computational Domain Size in Full Scale (meters)

JANUARY/ FEBRUARY 2012

47

Figure 6. Sway Free Decay Test presented at fullscale.

tude, or standard deviation, higher than model test values, which is consistent with the sway time history showing less modulation than model test results. The peak of A/D curve from CFD results with full-scale Reynolds number is shifted towards lower reduced velocity compared with modelscale simulation and test results. A simulation with finer mesh is needed to confirm the reduced velocity shift of the peak VIM response.

Preliminary Calculations Using Star-CCM+

Figure 7. Sway time history from simulation), U = 1.0 m/s. Black dotted curve: Laminar at model scale; Blue thin curve: DES at model scale; Red curve: DES at full scale

Figure 8. Sway time history from model test, U = 1.0 m/s.

In addition to the calculations reported above using AcuSolve, further calculations have been carried out using the commercial CFD software Star-CCM+, to simulate the VIM performance of the same multicolumn floating platform. The calculations were performed by Technip Malaysia using a much smaller computer with 32 CPU cores in a 4-node cluster running Microsoft HPC operating system. The following are details of the calculations: Physics model: Incompressible Navier-Stokes (Air/water Volume of Fluid with free surface) Turbulence models: RANS and Spalart-Almaras /Detached Eddy Simulation (SA/DES) Eulerian, body-fixed grid Domain size: 4m x 4m x 6m (Width x Depth x Length) Calculations performed at model scale (1:70) Mesh: Approx. 500,000 hexahedral cells (trimmer mesh) Max cell size: 0.5m Min cell size: 0.0025m Target cell size on TLP: 0.0125m No. of prism boundary layers: 4 Total thickness of prism layer: 0.015m Time step: 0.01s, Implicit, 2nd order accuracy 5 sub-iterations per timestep The model is the same reference design as used above for a conventional Tension Leg Platform (TLP) with four square columns with two rounded corners and two sharp corners each. The platform has four rectangular pontoons with sharp corners. Surface roughness was not modeled specifically, since the flow is expected to separate at the corners, but a sensitivity case including estimated roughness was run as discussed below. The ratio of (twice the)

Floating Production

Figure 9. Maximum and RMS A/D Curve

48

JANUARY/ FEBRUARY 2012

Visit our website at www.safan.com

column height/diameter ratio is approximately 2L/ D=3. (D is the square column width=12.8m fullscale) and the measured sway and yaw natural periods of the model were, Tsway=123s, Tyaw=76s respectively. The model tests and calculations were carried out at 1:70 scale but the results are presented as fullscale values, assuming Froude scaling, unless otherwise noted. The tank domain corresponds to the actual width and depth, but using a much shorter length. A portion of the mesh near the body is shown in Figure 10. Increased mesh density around the free surface is obtained using a volumetric control with cell size 0.125m in X and Y and 0.0075m in Z for -0.1m to +0.1m vertical range from free surface (model scale). The model was balanced and floating in calm water at its initial condition. The current was simulated using VOF method by applying the current velocity to the lower (underwater portion) of the domain. The entire domain boundary is assumed to be the velocity inlet (by specifying the normal velocity) and the TLP surface is a nonslip wall. The initial current velocity was applied everywhere in the fluid using a short ramp time at the beginning the calculations. The model was restrained for the initial few timesteps, then released and the 6-dof rigid body equations of motion were solved together with the fluid equations. Standard software settings for numerical schemes were applied throughout. Figure 11 and Figure 12 shows the motions as a function of time for one case using RANS and SpalartAlmaras//DES models, respectively for a reduced velocity Ur~8, close to the peak sway response. Corresponding experimental cases are presented in [6]. Results are shown for the case of the deeper draft at 45 heading. At least 2500 seconds fullscale (~20 sway oscillation cycles) were calculated for each speed. At least 2500 seconds fullscale (~20 sway oscillation cycles) were calculated for each speed. The RANS steady state appears stable, whereas the SA/DES analysis shows more randomness in the response, which more closely resembles the responses observed in experiments. Interestingly, both methods show similar nominal responses for this case. The nominal response amplitude is defined as A = Motion standard devia-

tion*(2). For a sinusoidal response, a Nominal Response= 1.0 implies a sinusoidal motion with amplitude A=1.0. The nominal responses are obtained from the motion time series using the last

Figure 10. Horizontal and vertical mesh slices showing the distribution of elements near the TLP model.

Figure 11. Sway(A/D) and Yaw(deg) vs Time(sec) from CFD analysis using RANS approximation, U r(sway)~8, Ur (yaw)~5, 45 heading, heavy draft case (2L/D=3) 4-Column TLP model from Ref [6].

JANUARY/ FEBRUARY 2012

49

Figure 12. Sway(A/D) and Yaw(deg) vs Time(sec) from CFD analysis using SA/DES approximation, Ur (sway)~8, Ur (yaw)~5, 45 heading, heavy draft case (2L/D=3) 4-Column TLP model from Ref [6].

Figure 14. Nominal response curves of CFD compared to model test results from Ref. [6].

Figure 13. Nominal sway response of CFD compared to model test results from Ref. [6].

few cycles in the simulations. The nominal response is considered a more robust measure of comparison than the maximum amplitude, since the actual response typically shows an unsteady character with some amplitude variation over time. Fig. 13 and 14 show the nominal responses for sway and yaw versus reduced velocity for the TLP hull as tested in [6]. For the higher reduced velocities, the RANS simulation did not yield good agreement with the test nominal responses for higher reduced velocities. However, it is not clear yet whether this is due to the inherent approximations in this method or whether it is also related to the limited mesh resolution discussed below or both. For the case shown in Fig. 11 and 12, good

agreement with experiments was obtained. However, for the higher reduced velocities, the calculation results do not agree well with experiments and both approximations (RANS and DES) predict smaller responses compared to experiments, as shown in Fig. 13 and 14. A reduction in response above Ur=8 was also observed in the previous set of calculations. The reasons are not clear, but we suspect may be due to insufficient mesh resolution which results in too much damping at higher flow velocities. To check on this, the distribution of wall y+ values on the TLP surface at one typical time step near the end of the solution time is shown in Fig. 15. For the majority of the underwater portion, the wall y+ values range from about 1 to around 12, except in a very small range around the waterline where they are locally higher, indicating sufficient resolution in the near boundary layer. Fig. 16 shows the distribution of vorticity along a cut plane near the mid column depth. Typical vortex patterns are seen behind the columns as the flow separates near the corners. However, it appears that the vortices damp out quickly, and a finer mesh discretization is probably needed. The calculations required about 13 seconds (elapsed time) per timestep, so the total calculations run time was about 4.5 days on the 32-core cluster. Further refinement will require more powerful computer facilities. The discrepancy between tests and CFD results may also be related to the change in the period of

Floating Production

50

JANUARY/ FEBRUARY 2012

Visit our website at www.safan.com

Figure 15. Distribution of Wall y+ values on the surface of the TLP, solution time t=300s, modelscale.

roughness, and using sharp corners instead of the slightly rounded corners. Some increase in the response is seen as a result of these factors, which improves agreement for this case. Also, the use of a constant number of sub-iterations may not be most appropriate in the numerical scheme. The graph shows how the calculations behave for one case when a convergence criteria was set to continue inner iterations until the lateral force coefficient (C y) converged within 5% before proceeding to the next timestep. In this case, the criteria caused the sway response to decrease, increasing the difference compared to experiments, although the yaw increased, so the improvement was not significant. Another factor may be the domain size, which may need to be increased beyond the size of the physical tow tank to reduce sidewall effects.

Conclusions

Two sets of preliminary calculations have been compared with model test data for a multi-column floating platform. The agreement between model tests results and CFD calculations is encouraging, especially at lower reduced velocities. The meshes used are relatively coarse, so better results might be obtained through mesh refinement, especially for higher reduced velocities and Reynolds numbers. For the Star CCM+ calculations carried out in Malaysia, further refinement will require more powerful computer facilities. For maximum sway amplitude, the AcuSolve results agree very well with experiments. For RMS or Standard Deviation, the AcuSolve results are somewhat higher than the test data. However, the results can be considered adequate for initial design as they are close to or slightly conservative, compared to the test results. An extension of the existing method to include yaw should be considered to determine if the increased realism leads to further improvements in the comparisons. Given the potential of VOF methods to handle free surface flows with waves and our interest in cases where waves, wakes and currents are all

Figure 16. Distribution of vorticity on a horizontal plane near mid column.

the response that was noted in Ref. [6] and which may indicate a corresponding change in vortex shedding pattern. In case the vortex shedding pattern changes, the mesh resolution which is sufficient to resolve the responses at Ur 8 is not necessarily sufficient at higher reduced velocities. Note that few previous CFD results have been presented at high reduced velocities, even for Spars. Possible effects of physics models were also considered by running a few sensitivity cases using the SA/DES model to see if any improvements could be found in the comparisons for the higher speed case. Fig. 13 and 14 include a few data points showing the effects of considering

JANUARY/ FEBRUARY 2012

51

potentially important, we feel that the preliminary results using Star CCM+ for a multi-column floating body in current are also very encouraging. More experience is needed in working with the many options available in the software and in understanding the mesh parameters required to provide reliable CFD solutions for this challenging application involving VIM of a multi-column floating platform.

Acknowledgements

The authors wish to thank Technip for permission to publish this paper, as well as Shell Deepwater Malaysia and Technip for permission to use the model test results. Also, Jaime Tan HuiChoo deserves credit for carrying out the Star CCM+ calculations.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Barras, S., Sablok, A., Magee, A., Yeoh, K.H.G., 2010, Regional Considerations in the Design and Delivery of Dry Tree Floating Platforms, Offshore Asia 2010 Conference, Kuala Lumpur. van Dijk, R., Magee, A., Perryman, S., Gebara, J., 2003, Model Test Experience on Vortex Induced Vibrations of Truss Spars, OTC 15242. Roddier, D., Finnigan, T., Liapis, S., 2009, Influence of the Reynolds Number on Spar Vortex Induced Motions (VIM): Multiple Scale Model Test Comparisons, OMAE2009-79991. Waals, O., Phadke, A., Bultema, S., 2007, Flow Induced Motions of Multi Column Floaters, OMAE2007-29539. Rijken, O., Leverette, S., Davies, K., 2004, Vortex Induced Motions of Semi Submersible with Four Square Columns, DOT2004paper 12-1. Magee, A., Sheikh, R., Yeoh, K.H.G., Tan, J.H.C., Adi, M.A.M, Pauzi, M.A.G., Abyn, H., 2010, Model Tests for VIM of multicolumn Floating Platforms OMAE201149151. Ng, J.K.T., Halkyard, J., Chan, E.S., Statis-

tical Characteristics of Flow in the Wake Region of a Vertical Bluff Cylinder in Waves, Currents and Combined Wave-Current Flows, OMAE2010-21181. [8] Holmes, S., Gebara, J. and Magee, A, 2008, Centerwell Water Motions and Hydrodynamic Loading Using Viscous Flow Calculations, OMAE2008-57882 [9] Atluri, S., Halkyard, J. and Sirnivas, S. CFD Simulation of Truss Spar Vortex Induced Motion, OMAE2006-92400. [10] Rijken, O. and Leverette, S., 2008, Experimental Study Into Vortex Induced Motion Response of Semi-Submersibles with Square Columns, OMAE2008-57396. [11] Xiang, S., Cao, P., Rijken, O., Ma, J., Chen, Y., 2010, Riser VIM Fatigue Design Induced by Deep Drat Semi-Submersible, OMAE201020339 [12] Magee, A., Abdul Ghani, M.P., Sheikh, R., Yeoh, K.H.G., Tan, J.H.C., Abyn, H., 2010, Model Testing of Floating Platforms at Universiti Teknologi Malaysia, Asia-Pacific Offshore Conference APOC 2010, Kuala PET Lumpur.

This publication thanks Mr. Jang-Whan Kim of Technip, Mr. Allan Magee of Technip, and Mr. Kenneth Yeoh Hock Guan of Technip for providing this paper.

ENQUIRY NUMBER:

01/02-02

Have you read our other magazine?

see us on the web at http://www.safan.com

Floating Production

52

JANUARY/ FEBRUARY 2012

Visit our website at www.safan.com

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Inverter - English 2022Документ17 страницInverter - English 2022Dudes and ToolsОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- An Extended Tension Leg Platform Design PDFДокумент7 страницAn Extended Tension Leg Platform Design PDFZylyn KuaОценок пока нет

- Zombie RPGДокумент30 страницZombie RPGBo100% (3)

- Soil Interaction Effects On Simple Catenary PDFДокумент25 страницSoil Interaction Effects On Simple Catenary PDFZylyn KuaОценок пока нет

- Update On The Design of Steel Catenary Riser Systems PDFДокумент12 страницUpdate On The Design of Steel Catenary Riser Systems PDFZylyn KuaОценок пока нет

- Summer Report On WEB DevelopmentДокумент30 страницSummer Report On WEB DevelopmentADITYA25% (4)

- True Astrology SoftwareДокумент2 страницыTrue Astrology Softwarekarunakaran09Оценок пока нет

- Domino's PizzaДокумент37 страницDomino's PizzaAristianto Pradana0% (3)

- B0193AV P IA Series Integrated Control Configurator PDFДокумент136 страницB0193AV P IA Series Integrated Control Configurator PDFJuan Rivera50% (2)

- Hydrodynamics in Deepwater TLP Tendon Design PDFДокумент8 страницHydrodynamics in Deepwater TLP Tendon Design PDFZylyn KuaОценок пока нет

- Variability of TLP Motion Analysis Against Various Design Methodologies - Parameters PDFДокумент7 страницVariability of TLP Motion Analysis Against Various Design Methodologies - Parameters PDFZylyn KuaОценок пока нет

- TLP Hull - Tendon - Riser Coupled Dynamic Analysis in Deepwater PDFДокумент7 страницTLP Hull - Tendon - Riser Coupled Dynamic Analysis in Deepwater PDFZylyn KuaОценок пока нет

- The Complexities of Fatigue Analysis For Deepwater PDFДокумент13 страницThe Complexities of Fatigue Analysis For Deepwater PDFZylyn KuaОценок пока нет

- Choosing The Most Appropriate Rigid Catenary Riser PDFДокумент8 страницChoosing The Most Appropriate Rigid Catenary Riser PDFZylyn KuaОценок пока нет

- Lecture01 Introduction To Measurement and Instrumentation Compatibility ModeДокумент24 страницыLecture01 Introduction To Measurement and Instrumentation Compatibility ModeZylyn KuaОценок пока нет

- Test1 06-07Документ1 страницаTest1 06-07Zylyn KuaОценок пока нет

- Body PlanДокумент1 страницаBody PlanZylyn KuaОценок пока нет

- India International Centre India International Centre QuarterlyДокумент15 страницIndia International Centre India International Centre QuarterlySruti UОценок пока нет

- Ls Pu BackgroundДокумент5 страницLs Pu BackgroundRolando Cruzada Jr.Оценок пока нет

- Thesis Process MiningДокумент98 страницThesis Process MiningRamyapremnathОценок пока нет

- PSA Referee SystemДокумент4 страницыPSA Referee SystemRamon JimenezОценок пока нет

- 12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)Документ4 страницы12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)DAVID ORLANDO MURCIA BARRERAОценок пока нет

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Документ12 страницAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Оценок пока нет

- GPRS Session 4 Power Control Twn01Q4Документ18 страницGPRS Session 4 Power Control Twn01Q4Nguyen LeОценок пока нет

- BC-5800 Liquid SystemДокумент114 страницBC-5800 Liquid SystemДмитрийОценок пока нет

- 12 Smart Steps To Building A New HatcheryДокумент2 страницы12 Smart Steps To Building A New HatcherytayyababОценок пока нет

- Assignment (Module 1) IntroductionДокумент3 страницыAssignment (Module 1) Introductionkunal kumar100% (1)

- DC DC CONVERT DS en 12Документ2 страницыDC DC CONVERT DS en 12carlos G7Оценок пока нет

- Neon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationДокумент24 страницыNeon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationJimi CohenОценок пока нет

- E-Content #03 (RSR) Thesis and Research Paper Writing - A BriefДокумент2 страницыE-Content #03 (RSR) Thesis and Research Paper Writing - A Briefaravind mouryaОценок пока нет

- Peach TreeДокумент36 страницPeach TreeSana MeerОценок пока нет

- Best Practices For CNIP IndustriesДокумент42 страницыBest Practices For CNIP IndustriesSaurabhDubeyОценок пока нет

- Pet CRD CRPDN Adc MBBL MДокумент125 страницPet CRD CRPDN Adc MBBL MpmellaОценок пока нет

- Logitech Mouse M505 ManualДокумент2 страницыLogitech Mouse M505 ManualbmmanualsОценок пока нет

- 2009-07-04 170949 Mazda TimingДокумент8 страниц2009-07-04 170949 Mazda TimingSuksan SananmuangОценок пока нет

- Tesco Shop On The GoДокумент3 страницыTesco Shop On The GoIkram KhokharОценок пока нет

- Apache Derby DatabaseДокумент4 страницыApache Derby DatabaseJohn KrcmarikОценок пока нет

- Fire Hydrant - WikipediaДокумент9 страницFire Hydrant - WikipediaVaibhav SawantОценок пока нет

- Water Jug & MissionariesДокумент52 страницыWater Jug & MissionariesAdmire ChaniwaОценок пока нет

- Topic 1 Valve and Instrumentation SymbolsДокумент8 страницTopic 1 Valve and Instrumentation SymbolshatiniОценок пока нет

- RF Power Meter v2: Preliminary Operator's ManualДокумент10 страницRF Power Meter v2: Preliminary Operator's Manualsalvatore dalessandroОценок пока нет