Академический Документы

Профессиональный Документы

Культура Документы

Dosage - Chapter 7

Загружено:

kaukau4everИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dosage - Chapter 7

Загружено:

kaukau4everАвторское право:

Доступные форматы

Aira Jhamaica DImacale Pharmaceutical Dosage Chapter 7: Capsules Capsules and Tablets Preferred when administered orally by adults:

s: conveniently carried, readily identified, easily taken Variety of dosage strengths, providing: Flexibility to the prescriber Accurate individualized dosage for the patient Packaged and shipped by manufacturers at lower cost and with less breakage than comparable liquid forms More stable and have a longer shelf life

Sublingual or buccal tablets To dissolve under the tongue or in the mouth

Alternative Products if Patients cannot Swallow an Intact Solid Dosage Form Chewable tablet Instant dissolving tablet Oral liquid Oral or nasal inhalation solution Suppository Injection

Characteristics May be swallowed whole by patient May be inserted into the rectum for drug release and absorption from site The content may be removed from the gelatin shell and employed as pre measured medicinal powder, the capsule shell being use to contain a dose of the medicinal substance. Ex: Theo-dur Sprinkle Elegance Ease of use Portability Tasteless shell to mask the unpleasant taste/ odor Permits physician to prescribe the exact medication needed buy the patient Conveniently carried Readily identified Easily taken Tasteless when swallowed Commonly embossed or imprinted on their surface the manufacturers name and product code readily identified Available in variety of dosage strength Provide flexibility to the prescriber and accurate individualized dosage for the patient Packaged and shipped by manufacturers at lower cost, less breakage than liquid forms More stable and longer shelf life

Pharmaceutical Standpoints Solid dosage forms: Manufactured efficiently and productively Packaged and shipped at lower cost and with less breakage More stable Have longer shelf life than liquids

Disadvantages of Tablets and Capsules Swallowing Formulation difficulties Some have poor bioavailability or poor water solubility Some have irritant effect on the GIT when taken orally

Key Features of a Good Tablet or Capsule Stability of the active drug Accurate dose Uniformity (weight, amount of active ingredient, coating thickness, etc) Consistent performance (manufacturing parameters, pharmacokinetics) Appropriate disintegration and dissolution Can withstand packaging, shipping, handling without breakage Masking of taste and odor Pharmaceutically elegant Production economically sound

Hard Gelatin Capsules Also referred to as DFC Dry Filled Capsule, manufactured into two sections, the capsule body and a shorter cap Manufacture most of the commercially available medicated capsules Employed in clinical drug trials For extemporaneous compounding of prescriptions Contains 13% to 16% moisture Manufactured form: Gelatin Titanium dioxide (opacifying agent) 0.15% SO2 (prevents decomposition of gelatin) Colorants

Overview of Capsules Capsules Medicinal agents and/or inert substances enclosed in a small shell of gelatin Swallowed wholly Open capsule or crushed tablets Mixed with food or drink (children or patients who are unable to swallow solid dosage forms)

Solid Dosage Forms that must be Left Intact Empty Capsule Shells Enteric coated tablets To pass through the stomach for drug release and absorption in the intestine Extended-release dosage forms Provide prolonged release of the medication Made of gelatin, sugar and water Hard or soft Softened (made elastic or plasticized) by adding glycerin or polyhydric alcohol like sorbitol)

Can be: clear, colorless, tasteless Colored with various FD&C and D&C dyes Made opaque by adding agents like titanium oxide

Gelatin Obtained by partial hydrolysis of collagen from the skin, white connective tissue and bones of animals Properties: Stable in air (dry) Subject to microbial decompositions when moistened Insoluble in cold water, softens through absorption of up to 10 times its weight of water Soluble in hot water and in warm gastric fluid A protein, digested by proteolytic enzymes and absorbed High humidity: additional moisture is absorbed Becomes distorted and lose their rigid shape Remedy: use desiccant material (silica gel, slay, or activated charcoal) Extreme dryness: moisture is lost Becomes brittle and crumble when handled

Pregelatinized starch Croscarmellose Sodium starch glycolate Lubricant or glidant Enhances flow properties Silicon dioxide Magnesium stearate Stearic acid or talc (about 0.25-1%) Surface active agent (surfactant) To facilitate wetting by GI fluids Sodium lauryl sulfate

Fixed or Volatile Oils Do not interfere with stability of the gelatin shells

Eutectic Mixture of Drugs Mixtures of agents that have a propensity to liquefy when admixed

Methods to Track the Passage of Capsules and Tablets through the GIT to Map their Transit Time and Drug Release Patterns Gamma scintigraphy Gamma ray emitting radiotracer incorporated into the formulation with gamma camera coupled to a data recording system Pharmacoscintographic evaluation IVIVC for bioavailability of immediate release products Combination of scintigraphy and pharmacokinetic studies Assesses integrity and transit of time of enteric coated tablets through the stomach to the intestines Drug and dosage form evaluation in new product development Heidelberg capsule (No. 0 gelatin capsule) pH sensitive (non indigestible radio telemetric device) A non-radioactive means to measure solid dosage forms (fasting and non fasting human subjects) Gastric pH, gastric emptying time, gastric residence time

Gelatin Capsule Dissolves and exposes its contents Unsuitable for aqueous liquids (softens gelatin and distorted, resulting in leakage of contents)

Additives Desiccant To protect against the absorption of atmospheric moisture Dried silica gel Clay Activated charcoal Diluents or filter To produce the proper capsules fill volume Provide cohesion to the powders For the transfer of the powder blend into the capsule shells Lactose Microcrystalline cellulose Starch

Manufacture of Hard Gelatin Capsule Shells Manufactured in 2 sections: Capsule body Shorter cap

Drug Absorption Depends on a Number of Factors Excipients Added for Capsule Fill Wetting agents (Li2CO3) Added to capsule formulation to enhance drug dissolution Absorbent Separates interacting agents Absorbs any liquefied material that may form Magnesium carbonate Kaolin or light MgO Disintegrants To assist the break up and disintegration of the capsules contents in the stomach Solubility of the drug Type of product formulation (immediate release, modified enteric) Gastrointestinal contents Physiologic character and response

Innovations to Provide Distinctions (Distinctive Looking Capsules) Pulvules End of the body-producing peg is tapered while leaving the cap-making peg rounded Spansule capsules

Capsules with the ends of both the bodies and caps highly tapered

Dry Formulations Blended thoroughly (active and inactive components) to ensure uniformity of powder mix for the fill

Innovations in Capsule Shell Designs Snap-fit Two halves of capsule shells positively joined through locking grooves in the shell walls Ensure reliable closing of the filled capsule Coni-snap Rim of the capsule body is tapered slightly, not straight Reduces the risk of the capsule rims touching or joining Eliminates splitting (telescoping) and/or denting of capsule shell Coni-snap supro Rim is tapered, upper capsule part extends (rounded edge of lower surface is visible) Opening is difficult, lower surface less gripping to pull 2 halves apart Increases security of contents and integrity of the capsule Eliminates splitting (telescoping) and/or denting of capsule shell

Care in Blending Lack of homogeneity for low dose drugs Results in significant therapeutic consequences

Preformulation Studies Determine whether all of the formulations bulk powders Effectively blended together Require reduction of particle size Other processes to achieve homogeneity

Methods in Reducing Particle Size Milling Particles ranging from 50-1000 micrometer Micronization Drugs of lower dose or when smaller particles are required Particles ranging from 1-20 micrometer

Filling Hard Capsule Shells ***Check the book: coni-snap capsule parts, coni-snap and coni-snap supro capsule sizes (as in actual size of capsule in relation to a quart) Capsule Sizes 000 00 0 1 2 3 4 5 15 grains 10 grains 7.5 grains 5 grains 4 grains 3 grains 2 grains 1 grain 972mg (largest) 648mg 486mg 324mg 259mg 194mg 130mg 64.8mg (smallest) Use punch method Steps: Count the capsules Powder encapsulated placed on a sheet of clean paper or a glass or porcelain plate Powder mixed formed into a cake depth of approximately to 1/3 the length of the capsule body Empty capsule punched vertically into the powder cake until filled

Process of Capsule Filling Milling or sieving of all ingredients Blending Powder blender or empty capsules Capsule filler Capsule deduster or cleaner Capsule injection screen Capsule check-weighing system or reject Finished capsules Packaging

Preparation of Filled Hard Gelatin Capsules Formulation development and preparation and selection of capsule size Filling the capsule shells Capsule sealing (optional) Cleaning and polishing of filled capsules

Examples of Fill in Hard Gelatin Capsules ***Check book: profill system Powder or granulate Pellet mixture Paste Capsule Tablet Capsule Sealing For the manufacturers: Sealing the joint between the 2 capsule parts using: Colored band of gelatin (KAPSEALS, Parker Davis) Heat welding process o Fuses the capsule cap to the body through the double wall thickness at their juncture (distinctive ring around the capsule)

Developing the Formulation and Selection of Capsule Size Goals in preparing a capsule: Accurate dosage Good availability Ease of filling and production Stability Elegance

Liquid wetting agent (liquid sealingwater and ethanol sprayed around the seam area), followed by thermal bonding Extemporaneously o Warm gelatin solution, lightly coating the inner surface of the cap prior to placement on the filled capsule body

Cleaning and Polishing Capsules Small scale By rubbing with a clean gauze or cloth Large scale Cleaning vacuum affixed to the capsule-filling machines (removes any extraneous material) using Accela-Cota apparatus

Water-immiscible volatile and nonvolatile liquids Vegetable and aromatic oils, aromatic and aliphatic hydrocarbons, chlorinated hydrocarbons, ethers, esters, alcohols and organic acids Water-miscible nonvolatile liquids Polyethylene glycols and nonionic surface active agents as polysorbate 80 Water-miscible and relatively nonvolatile compounds Propylene glycol and isopropyl alcohol (depending on factors as concentration used and packaging conditions)

Soft Medications Commercially Prepared into Soft Gelatin Capsules Acetazolamide: Diamox sequels: Carbonic anhydrase inhibitor Cyclosporine: Sandimmune, Neoral: Immunosuppressive Ethosuximide: Zarontin: Anticonvulsant Ranitidine HCl: Zantac Geldose: Histamine H2 receptor inhibitor

Some Medications Commercially Prepared into Soft Gelatin Capsules Acetazolamide: Diamox: Carbonic anhydrase inhibitor Cyclosporine: Sandimmune: Immunosuppressive Cyclosporine: Neoral: Immunosuppressive Digoxin: Lanoxicaps: Cardiac glycoside Ethosuximide: Zarontin: Anticonvulsant Ranitidine HCl: Zantac Geldose: Histamine H2 receptor inhibitor

Liquids that cannot be Encapsulated into a Soft Gelatin Capsule Easily migrate through capsule shell like materials with water above 5% Low molecular weight Water soluble and water volatile organic compounds (alcohols, ketones, acids, amine, and esters)

Preparation of Soft Gelatin Capsules Solids that may be Encapsulated into a Soft Gelatin Capsule Plate process Uses set of molds to form capsules Rotary die process Most commonly used Rotary die machine Liquid gelatin flowing from an overhead tank into two continuous ribbons brought together between rotating die More efficient and productive Results in bicolored capsules Very accurate filling (+/-1-3%) Reciprocating die process Norton capsule machine Similar to rotary die (gelatin ribbons are formed) Differs in encapsulating process Produced, filled and sealed in a continuous operation Accogel capsule machine Stern Machine Unlike the other fill dry powders into soft elastic capsules Also use liquids or liquids and powders as fill Used to cover tablets with a gelatin film (geltabs) Variety of shapes, sizes, color possible Solutions in a suitable liquid solvent, suspensions, dry powders, granules, pellets or small tablets

Compendial Requirements for Capsules Added substances may only be used: Harmless in the quantities used Do not exceed the minimum amount required to provide their intended effect Do not impair the products bioavailability therapeutic efficacy or safety Do not interfere with requisite compendial assays and tests

Utilization of Soft Gelatin Capsules To contain a variety of liquid, pastry and dry fills

Uses of Soft Gelatin Capsules

Comparison Between Hard and Soft Capsules Property Shell Hard Capsule Made of gelatin, sugar and powder Soft Capsule Gelatin, plasticizer (glycerin) or polyhydric alcohol (sorbitol) water and etc., colorants Shells and fill made and combined on one and the same process line By: plate process, rotary die process and reciprocating die process

Manufacturi ng processes

Content

Shells produced separately from the fill Continuous dipping, drying, removing and joining of capsules as peg containing plates rotate in and out of gelatin bath Dry powders or granules, pellet mixture, paste, small capsule and tablets

Formulation technology

13%-16% moisture content Moisture proof packaging needed Encapsulation using succinylated gelatin

Liquids and semi-liquids, suspensions, pasty materials, dry powders and preformed tablets More moisture Water content of fill not more than 5% Addition of titanium dioxides or iron oxides for light sensitive shells Packed in aluminum blisters Encapsulation uses succinylated, glycerol-free shell formulation, addition of PVP to the fill

Containers for dispensing capsules Tight Well-closed Light-resistant In glass or plastic containers Some with packets of desiccant (prevents absorption of excessive moisture) Unit dose and strip packaging of solid dosage forms provides: o Sanitary handling of the medications o Ease of identification o Security in accountability for medications Disintegration test fop capsules Uses basket rack assembly, immersed 30 times per minute into a thermostatically controlled fluid (37oC) and observed over the time described in the individual monograph To satisfy the test, the capsules disintegrate completely into a soft mass having no palpably firm core and only some fragments of the gelatin shell Dissolution test for capsules USP Apparatus I (stainless steel basket on a stirrer shaft) and USP apparatus II ( using paddle as the stirrer): same apparatus for immediate release tablet If the capsule shells interfere with the chemical analysis before proceeding with the sampling and chemical analysis: Contents of a specified number of capsules can be removed Empty capsule shells dissolved in the dissolution medium Weight variation Hard Capsules Individual weight of 10 capsules weight of empty shells = net weight of performed assay for content of active ingredient according to monograph Soft capsules Same as above, cut open the capsule and the content is removed by dissolving with suitable solvent Content uniformity Amount of active ingredient (determined by assay) must be: Within 85% to 115%of the label claim for 910 dosage units No unit outside the range of 70% to 125% of label claim Additional test are needed when 2-3 dosage units are outside of the desired range but within the stated extremes. Weight variation and content uniformity: uniformity of dosage units can be determined Content labeling requirement Express the quantity of each active ingredient in per dosage unit Stability testing Factors like temperature, humidity, light, formulative components and other container closure system using long term and accelerated stability tests Moisture permeation test For single unit and unit-dose containers to assure suitability for packaging

Uses color revealing desiccant pellet for color change and weight changes

Examples of some official capsules: Table 7.2: memorize Inspection Visual or electric inspection To detect any flaws in the integrity and appearance of the capsules Defective caps should be rejected. CGMP regulations if number of production flaws is excessive The cause must be investigated, documented and steps undertaken to correct the problem.

Counting Community pharmacy Counting small numbers of solid dosage units: specifically designed trays are used Spatula used to count and sweep the dosage units into the trough until the desired number is reached Tray must be wiped clean after every use to prevent batch-to-batch contamination Industrial scale Use of automated pieces of equipment dosage units into bulk containers

Packaging Caps are packaged in: Glass or in plastic containers Some containing packets of desiccant ( prevent absorption of excessive moisture) Unit dose and strip packaging of solid dosage forms Provides sanitary handling of the medications Ease of identification Security in accountability for medication

Storage Caps should be stored in tightly capped containers in a cool, dry place.

Вам также может понравиться

- Soft Cap-2Документ36 страницSoft Cap-2DrSambathkumar RamanathanОценок пока нет

- Tablet Technology EditedДокумент42 страницыTablet Technology EditedPramod Kc100% (1)

- Oral Controlled Release Formulation Design and Drug Delivery: Theory to PracticeОт EverandOral Controlled Release Formulation Design and Drug Delivery: Theory to PracticeHong WenОценок пока нет

- CapsuleskncopДокумент181 страницаCapsuleskncopboozokaranОценок пока нет

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- Phardose Lec Chapter 9Документ3 страницыPhardose Lec Chapter 9Diah MarianoОценок пока нет

- Art. Enteric CoatingДокумент13 страницArt. Enteric CoatingDiana Marcela Parra BaronaОценок пока нет

- Biocontamination Control for Pharmaceuticals and HealthcareОт EverandBiocontamination Control for Pharmaceuticals and HealthcareРейтинг: 5 из 5 звезд5/5 (1)

- Phardose Report (Solutions)Документ59 страницPhardose Report (Solutions)Anne Marion PerezОценок пока нет

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesОт EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumОценок пока нет

- Techniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Документ6 страницTechniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Stefany Luke0% (1)

- Pharmmanuf. Formulation of TabletsДокумент3 страницыPharmmanuf. Formulation of TabletsDenzyl Ann LaguitОценок пока нет

- IpqcДокумент37 страницIpqcAjitha AzhakesanОценок пока нет

- QC Tests For Tablet Dosage FormsДокумент8 страницQC Tests For Tablet Dosage FormsSai Krishna ManchikantiОценок пока нет

- Tablet FinalДокумент104 страницыTablet FinalAngela PagalilauanОценок пока нет

- CapsulesДокумент44 страницыCapsulesPrinceОценок пока нет

- Tablets Quality ControlДокумент18 страницTablets Quality ControlThangabalan Than100% (2)

- A Review of Progress and Challenges in Soft Gelatin Capsules Formulations For Oral AdministrationДокумент6 страницA Review of Progress and Challenges in Soft Gelatin Capsules Formulations For Oral Administrationlouish9175841Оценок пока нет

- AssignmentДокумент12 страницAssignmentAbdul Wahid OrakzaiОценок пока нет

- Preformulation MaterialДокумент10 страницPreformulation MaterialRajesh NayakОценок пока нет

- Dosage - Chapter 3 and Chapter 4Документ17 страницDosage - Chapter 3 and Chapter 4Aira AbellaОценок пока нет

- Dosage - Chapter 7Документ6 страницDosage - Chapter 7Kim ManlangitОценок пока нет

- An Overview On Tablet CoatingДокумент4 страницыAn Overview On Tablet Coatingronahaniifah11Оценок пока нет

- Pharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesДокумент7 страницPharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesBEST OF BESTОценок пока нет

- Dosage - Chapter 14Документ57 страницDosage - Chapter 14kaukau4ever100% (1)

- Chapter 7 Semi-SolidДокумент13 страницChapter 7 Semi-SolidAnaliza Kitongan Lantayan0% (1)

- Pilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsДокумент7 страницPilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsAsifОценок пока нет

- Preformulation Testing of Solid Dosage Forms (Latest)Документ74 страницыPreformulation Testing of Solid Dosage Forms (Latest)Muhd Khairul AmriОценок пока нет

- Development of Tablet Formulation of Amorphous Solid Dispersions PreparedДокумент19 страницDevelopment of Tablet Formulation of Amorphous Solid Dispersions PreparedBagoes As100% (1)

- Q C of Sterile ProductsДокумент103 страницыQ C of Sterile ProductsMuhammad TaimurОценок пока нет

- Expt - I - IpqcДокумент8 страницExpt - I - IpqcaltinakhotОценок пока нет

- Basic Concept of Process Validation in Solid Dosage Form (Tablet)Документ9 страницBasic Concept of Process Validation in Solid Dosage Form (Tablet)edgar palominoОценок пока нет

- QBD AnalyticalДокумент17 страницQBD Analyticalqbdresearch labОценок пока нет

- QC Lec FinalsДокумент31 страницаQC Lec FinalsPrecious MagpaliОценок пока нет

- Drug StabilityДокумент14 страницDrug StabilityBismah SaeedОценок пока нет

- Dosage Form: Pre-Formulation StudiesДокумент7 страницDosage Form: Pre-Formulation StudiesNimra AmeenОценок пока нет

- Opthalmic Preparations Unit III Part-BДокумент37 страницOpthalmic Preparations Unit III Part-BKrishna PrasadОценок пока нет

- Biopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)Документ22 страницыBiopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)vipinkv99Оценок пока нет

- Ipqc Various Dosage FormsДокумент8 страницIpqc Various Dosage FormsankitОценок пока нет

- A Review of On Preformulation Studies of DrugsДокумент11 страницA Review of On Preformulation Studies of DrugsPanji Wirawan0% (1)

- Hold Time StudyДокумент2 страницыHold Time StudyManivannan KathirvelОценок пока нет

- Evaluation of TabletsДокумент8 страницEvaluation of TabletsPraneeth Reddy100% (8)

- Assay and Dissolution EtoricoxibДокумент8 страницAssay and Dissolution Etoricoxibsesilia dyah novitrianiОценок пока нет

- Content UniformityДокумент9 страницContent UniformitySiri KalyanОценок пока нет

- Solid Dosage Forms - CapsulesДокумент14 страницSolid Dosage Forms - CapsulesHellcroZОценок пока нет

- Dosage - Chapter 15Документ67 страницDosage - Chapter 15Kim ManlangitОценок пока нет

- Aqueous PreparationsДокумент15 страницAqueous PreparationsAdiJoansyahОценок пока нет

- Flow Through Cell Dissolution ApparatusДокумент22 страницыFlow Through Cell Dissolution ApparatusKimberly MccoyОценок пока нет

- TabletsДокумент78 страницTabletsLoverboy ForuОценок пока нет

- Stability Studies Assessment ExperienceДокумент61 страницаStability Studies Assessment ExperienceDANIBATAОценок пока нет

- Super DisintegrantsДокумент19 страницSuper Disintegrantsvikaskiran60Оценок пока нет

- ICH Q1 Stability Training Program MY 2019 - Brochure - 07 2019 PDFДокумент4 страницыICH Q1 Stability Training Program MY 2019 - Brochure - 07 2019 PDFSih AtiiОценок пока нет

- Dealing With Post Approval Changes-Supac: Wasim Raja.S Sri Venkateswara College of PharmacyДокумент52 страницыDealing With Post Approval Changes-Supac: Wasim Raja.S Sri Venkateswara College of PharmacyProf_WasimОценок пока нет

- Stability in PreformulationДокумент48 страницStability in Preformulationmithaann2353Оценок пока нет

- Hard Gelatin CapsulesДокумент9 страницHard Gelatin CapsulesSai Keerthi100% (1)

- Applying QBD Principles For The Development of A Pharmaceutical Dosage FormДокумент31 страницаApplying QBD Principles For The Development of A Pharmaceutical Dosage FormSneha KaduОценок пока нет

- Design of Dosage FormsДокумент17 страницDesign of Dosage FormsMuhammad HilmiОценок пока нет

- Carbohydrates InfoДокумент5 страницCarbohydrates Infokaukau4everОценок пока нет

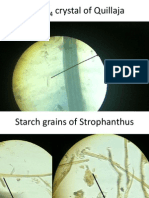

- Cac O Crystal of QuillajaДокумент22 страницыCac O Crystal of Quillajakaukau4everОценок пока нет

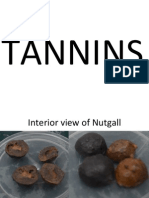

- Tannins & LipidsДокумент46 страницTannins & Lipidskaukau4ever100% (1)

- Boards GlycosidesДокумент11 страницBoards Glycosideskaukau4everОценок пока нет

- Glycosides For Practical PDFДокумент2 страницыGlycosides For Practical PDFkaukau4everОценок пока нет

- Practical Exam PicsДокумент3 страницыPractical Exam Picskaukau4everОценок пока нет

- Suha / Lukban: Citrus Grandis RutaceaeДокумент12 страницSuha / Lukban: Citrus Grandis Rutaceaekaukau4everОценок пока нет

- TANNINS CompleteДокумент61 страницаTANNINS Completekaukau4everОценок пока нет

- Volatile OilДокумент38 страницVolatile Oilkaukau4everОценок пока нет

- Resins (Practical Exam 8)Документ93 страницыResins (Practical Exam 8)kaukau4everОценок пока нет

- TanninsДокумент61 страницаTanninskaukau4everОценок пока нет

- Glycosides LecДокумент5 страницGlycosides Leckaukau4everОценок пока нет

- Volatile OilДокумент38 страницVolatile Oilkaukau4everОценок пока нет

- Alkaloids SummaryДокумент1 страницаAlkaloids Summarykaukau4everОценок пока нет

- Dosage Form Design Pharmaceutical and Formulation ConsiderationsДокумент103 страницыDosage Form Design Pharmaceutical and Formulation Considerationsprinceamit67% (3)

- AlkaloidsДокумент4 страницыAlkaloidskaukau4everОценок пока нет

- AATableДокумент2 страницыAATablekaukau4everОценок пока нет

- Module 1 - Topic 1 - The Chemistry of LifeДокумент142 страницыModule 1 - Topic 1 - The Chemistry of Lifekaukau4everОценок пока нет

- Dosage - Chapter 15Документ67 страницDosage - Chapter 15Kim ManlangitОценок пока нет

- Amino Acids TutorialДокумент9 страницAmino Acids Tutorialkaukau4everОценок пока нет

- Module 2 - Topic 1 - Protein Structure & Function Cont.Документ65 страницModule 2 - Topic 1 - Protein Structure & Function Cont.kaukau4everОценок пока нет

- Dosage - Chapter 2 and Chapter 5Документ13 страницDosage - Chapter 2 and Chapter 5Kim ManlangitОценок пока нет

- Amino AcidДокумент29 страницAmino Acidmjzapant09Оценок пока нет

- Suppositories and InsertsДокумент5 страницSuppositories and InsertsKim ManlangitОценок пока нет

- Special Application SolutionsДокумент41 страницаSpecial Application SolutionsKim Manlangit100% (1)

- Dosage - Chapter 6Документ6 страницDosage - Chapter 6kaukau4ever100% (3)

- Dosage - Chapter 13 (2d Half)Документ7 страницDosage - Chapter 13 (2d Half)kaukau4everОценок пока нет

- Dosage - Chapter 14Документ57 страницDosage - Chapter 14kaukau4ever100% (1)

- Dosage - Chapter 9Документ5 страницDosage - Chapter 9kaukau4everОценок пока нет

- 5 Coen3Документ3 страницы5 Coen3Yolby Milena Rodriguez ArizaОценок пока нет

- Chemical Bonding Review WorksheetДокумент2 страницыChemical Bonding Review WorksheetCatherine JeaneОценок пока нет

- Mechanical Seal Face MaterialsДокумент19 страницMechanical Seal Face MaterialsKamlesh Kamlesh Etwaro100% (1)

- The Most Expensive Materials in The World PDFДокумент10 страницThe Most Expensive Materials in The World PDFAnonymous gL38AGom29100% (2)

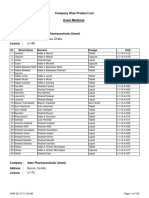

- Unani Product List PDFДокумент109 страницUnani Product List PDFAK50% (2)

- Castings, Steel and Alloy, Common Requirements, For General Industrial UseДокумент13 страницCastings, Steel and Alloy, Common Requirements, For General Industrial UseDarwin DarmawanОценок пока нет

- Distillation of Mixtures: Activity 2.3Документ4 страницыDistillation of Mixtures: Activity 2.3...Оценок пока нет

- Part I: Polymer Chemistry: Chapter 3: Molar Mass & Degree of PolymerizationДокумент34 страницыPart I: Polymer Chemistry: Chapter 3: Molar Mass & Degree of PolymerizationThanh Đình Lộc LêОценок пока нет

- Synthesis, Characterization and Evaluation of Antimicrobial Profile of 4-Thiazolidinone DerivativesДокумент7 страницSynthesis, Characterization and Evaluation of Antimicrobial Profile of 4-Thiazolidinone DerivativesPharma Research LibraryОценок пока нет

- Production Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)Документ8 страницProduction Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)yrdna nawaiteosОценок пока нет

- UnitTest - D11 Feb 2024Документ3 страницыUnitTest - D11 Feb 2024muniharshit16Оценок пока нет

- Fenotec e FinalДокумент2 страницыFenotec e FinalJohn ThinhОценок пока нет

- 2015chandra BasicConceptsofBiotechnology PDFДокумент518 страниц2015chandra BasicConceptsofBiotechnology PDFmayur borseОценок пока нет

- Aquatabs MPAДокумент2 страницыAquatabs MPADavid SalasОценок пока нет

- Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionДокумент7 страницHydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionAhmedОценок пока нет

- Chapter 20: Electrochemistry: Homework QuestionsДокумент2 страницыChapter 20: Electrochemistry: Homework Questionservaldi0% (1)

- TOPAS UserGuide V1 3 20151026a PDFДокумент126 страницTOPAS UserGuide V1 3 20151026a PDFRosa LourençoОценок пока нет

- Types of Fusion WeldingДокумент22 страницыTypes of Fusion WeldingvigneshОценок пока нет

- Chemistry1st ChapДокумент4 страницыChemistry1st ChapyumnaОценок пока нет

- Transmissions For Off-Road Equipment (Construction Machinery, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Документ15 страницTransmissions For Off-Road Equipment (Construction Machinery, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Mushhood SiddiquiОценок пока нет

- A Maritime Energy TransitionДокумент21 страницаA Maritime Energy TransitiondiansulaemanОценок пока нет

- Modeling of Ethane Thermal Cracking Kinetics in A PyrocrackerДокумент6 страницModeling of Ethane Thermal Cracking Kinetics in A PyrocrackerArash AbbasiОценок пока нет

- Newsletter ARBOCEL 0607Документ0 страницNewsletter ARBOCEL 0607saidvaretОценок пока нет

- CV of MAHESHWAR SHARON (42 PP)Документ42 страницыCV of MAHESHWAR SHARON (42 PP)anislinek15Оценок пока нет

- Astm A479 - A479m-18Документ8 страницAstm A479 - A479m-18Handa Bin Adi100% (1)

- 07 Dermatological Formulation and Transdermal SystemsДокумент81 страница07 Dermatological Formulation and Transdermal SystemsAlberto JacobusОценок пока нет

- Residue Fluid Catalystic Cracking Unit (Rfccu)Документ50 страницResidue Fluid Catalystic Cracking Unit (Rfccu)GauBeoMauNauОценок пока нет

- LME Special Contract Rules For Copper GRADE AДокумент4 страницыLME Special Contract Rules For Copper GRADE Aadelafuente2012Оценок пока нет

- Complete: ChemistryДокумент26 страницComplete: ChemistryDavid DarkoОценок пока нет

- Issue48 LimoncelloДокумент4 страницыIssue48 LimoncelloSalvador VaghiОценок пока нет