Академический Документы

Профессиональный Документы

Культура Документы

Wellheadcon Numenclature

Загружено:

Kehinde AdebayoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Wellheadcon Numenclature

Загружено:

Kehinde AdebayoАвторское право:

Доступные форматы

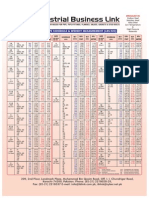

Down Hole Injection, Inc.

Page 1 of 2

Home

Sitemap

Contact DHI

About DHI

Technical Information

Investor Relations

Support

Contact DHI

April 5, 2012 Language Setting:

Home > Technical Information > DGWS > Wellhead Configuration

Typical DGWS Wellhead Configuration Overview Competitive Advantages Well Selection Criteria Installation Procedure Wellhead Configuration Horizontal Well Wellbore Schematic DGWS Capacities DGWS Advantages ADP BPV Photos & Videos

http://www.downholeinjection.com/technicalinfo/dgws/wellheadconfig.cfm

4/5/2012

Down Hole Injection, Inc.

Page 2 of 2

This is a typical DGWS wellhead configuration. This configuration prevents excessive tubing pressure build-up if a failure downhole occurs. Failures that could occur is hole(s) develops in the tubing, the downhole stuffing box (DSB) leaks, the insert pump becomes unseated and or etc. However, if the DSB tool leaks it could leak either way, up or down. If the DSB does develop a leak, it is a very small (drip) leak. See DHI's Manual of Practice (MOP) for more information. The surface backpressure valve (12) must be set so that the maximum pressure in the tubing at the surface cannot exceed 50psig. In addition, all of the valves except for the 2" and 1" valves that have the bull plugs screwed in must be fully open during operation. The bull plugs are present to prevent a spill if the valves develop a leak. Therefore, the bull plugs must always be securely tighten into the valves when personnel is not present at the wellsite. The inhibited/lubricated fluid in the tubing will evaporate if the tubing is vented at the surface. In addition, this fluid can expand after initial start up, resulting in increased pressure at the surface. After initial start up gas and or air that is entrained or dissolved in the inhibited/lubricated fluid will build up at the surface and this gas must be vented off and that volume replace with inhibited/lubricated fluid. See DHI's installation procedure for more information. The surface tubing pressure and fluid level in the tubing must be monitored to insure proper DGWS operation. For more information about DGWS monitoring and control see DHI's Manual of Practice. All valves, nipples, tees, elbows, plugs, connectors, plumbing and pipes must be sized and the appropriate grade/rating to withstand the operational pressures and flows. Insure that all surface connections are properly lubricated, sealed and fastened before operation. Well Head When selecting a well head the casing size, weight and thread must be known. The inner string is tubing and most of the time will be 2 3/8". The tubing string must be suspended by slips or hangers. The tubing is set in tension at the surface on all standard RFI systems. See DHI's installation procedure for more information. The casing head pressure rating (2000 to 3000psig) must be properly selected and the side outlets are most often 2" LP size. The packing material either nitrile or other seal/o-ring materials must be properly selected. For more information about wellheads see: http://www.rmenergy.com/pdf/hercwellhead.pdf

Copyright 2003 Down Hole Injection, Inc.

All Rights Reserved

Home

Sitemap

Support

Contact DHI

http://www.downholeinjection.com/technicalinfo/dgws/wellheadconfig.cfm

4/5/2012

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Fire Pump System ChecklistДокумент4 страницыFire Pump System ChecklistAhmed Sayed Abdel Tawab100% (1)

- Cosasco Access FittingsДокумент2 страницыCosasco Access FittingsE_Rodriguez20Оценок пока нет

- Access Fittings (Non Tee)Документ3 страницыAccess Fittings (Non Tee)anup_sahaniОценок пока нет

- Argus Automatic Pigging BrochureДокумент6 страницArgus Automatic Pigging BrochureKehinde AdebayoОценок пока нет

- Stress Analysis of Piping1Документ90 страницStress Analysis of Piping1sateesh chand100% (2)

- METRIC_ENGLISHДокумент14 страницMETRIC_ENGLISHKehinde AdebayoОценок пока нет

- Astm d1785Документ5 страницAstm d1785Kehinde AdebayoОценок пока нет

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Документ38 страницNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoОценок пока нет

- Overview of Piping Layout.Документ4 страницыOverview of Piping Layout.Kehinde AdebayoОценок пока нет

- SmartTrap Launcher ReceiverДокумент4 страницыSmartTrap Launcher ReceiverKehinde AdebayoОценок пока нет

- 1 - Pipe Schedule & Weight MeasurementДокумент1 страница1 - Pipe Schedule & Weight MeasurementSutrisno KlsОценок пока нет

- The Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringДокумент4 страницыThe Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringKehinde AdebayoОценок пока нет

- 2010 Pipe Materials GuideДокумент36 страниц2010 Pipe Materials GuideAlmeghalawyОценок пока нет

- FPSOДокумент143 страницыFPSORagunath KarthickОценок пока нет

- Sweco CatДокумент21 страницаSweco CatArmandoZacariasAcostaОценок пока нет

- Vista Complate Pressure Vessels CatalogeДокумент11 страницVista Complate Pressure Vessels CatalogeKehinde Adebayo100% (1)

- Table of Contents and Piperack Design GuidelinesДокумент20 страницTable of Contents and Piperack Design GuidelinesKehinde AdebayoОценок пока нет

- Stress Analysis Training - Caesar IIДокумент2 страницыStress Analysis Training - Caesar IIKehinde Adebayo100% (2)

- Process Plant Layout and Piping DesignДокумент460 страницProcess Plant Layout and Piping Design~E~97% (32)

- Cooling Water SystemДокумент14 страницCooling Water SystemKehinde AdebayoОценок пока нет

- Piping Design ProcedureДокумент42 страницыPiping Design ProcedureKehinde Adebayo75% (4)

- Pump document title under 40 charactersДокумент32 страницыPump document title under 40 charactersKehinde Adebayo100% (1)

- Table of Contents and Piperack Design GuidelinesДокумент20 страницTable of Contents and Piperack Design GuidelinesKehinde AdebayoОценок пока нет

- Table of Contents and Piperack Design GuidelinesДокумент20 страницTable of Contents and Piperack Design GuidelinesKehinde AdebayoОценок пока нет

- Class 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryДокумент3 страницыClass 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryKehinde AdebayoОценок пока нет

- Variable Spring Hangers - Installation & Maintenance GuideДокумент3 страницыVariable Spring Hangers - Installation & Maintenance GuideKehinde AdebayoОценок пока нет

- Preliminary Piping Design - 45Документ1 страницаPreliminary Piping Design - 45Kehinde AdebayoОценок пока нет

- PumpsДокумент22 страницыPumpsKehinde AdebayoОценок пока нет

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesДокумент4 страницыDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoОценок пока нет

- Flanged Pipe & Fittings: 2005 EditionДокумент38 страницFlanged Pipe & Fittings: 2005 Editionjpdavila205Оценок пока нет

- Downfeed SystemДокумент12 страницDownfeed SystemcharbelОценок пока нет

- Chennai Disaster Management Plan With Zonal Ready ReckonersДокумент725 страницChennai Disaster Management Plan With Zonal Ready ReckonersVaishnavi JayakumarОценок пока нет

- Lgu CaДокумент70 страницLgu CaMENRO GENERAL NATIVIDADОценок пока нет

- FIREMIKS Recommended Setup - Fixed - Automatic Flushing PDFДокумент1 страницаFIREMIKS Recommended Setup - Fixed - Automatic Flushing PDFAob AprilОценок пока нет

- Dce603ue SpecДокумент1 страницаDce603ue SpeccodefinderОценок пока нет

- TendersДокумент1 страницаTendersNaveen NagisettiОценок пока нет

- Plumbing NC II Tools ListДокумент3 страницыPlumbing NC II Tools ListIrvin Amor AndresОценок пока нет

- W16 AR 208 - WATER SUPPLY SANITATION Unit 1Документ50 страницW16 AR 208 - WATER SUPPLY SANITATION Unit 1Kabali VasudevasuОценок пока нет

- Alarm check valve trim chartДокумент3 страницыAlarm check valve trim chartNadjalle HordezОценок пока нет

- Orifice Catalogue EnglishДокумент11 страницOrifice Catalogue Englishrahman ariwibowoОценок пока нет

- AGRUAIR & AGRUSAN Piping Systems for Compressed Air & Sanitary ApplicationsДокумент4 страницыAGRUAIR & AGRUSAN Piping Systems for Compressed Air & Sanitary ApplicationsGianz Arvi MaglonzoОценок пока нет

- Sewer Sytems Professional PDFДокумент203 страницыSewer Sytems Professional PDFAmilaPezoОценок пока нет

- XU Agriculture Building Fire Sprinkler EvaluationДокумент16 страницXU Agriculture Building Fire Sprinkler EvaluationJohn Renzel RiveraОценок пока нет

- Flow Divider Catalog Permco FD SeriesДокумент13 страницFlow Divider Catalog Permco FD SeriesPiero Fabrizzio Mendoza FuenteОценок пока нет

- Wastewater Story Class 7 Science NotesДокумент3 страницыWastewater Story Class 7 Science NotesYash ArdeshnaОценок пока нет

- th103 HydrДокумент2 страницыth103 Hydrvic13rОценок пока нет

- Pumping HandbookДокумент80 страницPumping HandbookWalter Guttler100% (3)

- Catálogo Fisher - LP GasДокумент96 страницCatálogo Fisher - LP GaslopezmedgarОценок пока нет

- Hydraulic Fluid Power Parts CatalogДокумент14 страницHydraulic Fluid Power Parts CatalogEng-Mohammed SalemОценок пока нет

- Fundamentals of Crane HydraulicsДокумент7 страницFundamentals of Crane Hydraulicsritesh4009Оценок пока нет

- EC290B LC Hidrolik Service ManualДокумент96 страницEC290B LC Hidrolik Service ManualMilanОценок пока нет

- Pertamina EP Asset 4 Poleng BW-021 WO ProgramДокумент12 страницPertamina EP Asset 4 Poleng BW-021 WO ProgramDeddy BramОценок пока нет

- Carbon Steel Pipe Weight ChartДокумент27 страницCarbon Steel Pipe Weight ChartMaryam ArifОценок пока нет

- Membrane Water Treatment Technologies for Clean Water ProductionДокумент22 страницыMembrane Water Treatment Technologies for Clean Water ProductionSnehal Dawkhar patilОценок пока нет

- Aquifer Types and CatergoriesДокумент13 страницAquifer Types and CatergoriesTjale MofokengОценок пока нет

- Toyo Gate Valve PricelistДокумент1 страницаToyo Gate Valve PricelistLaurence Arcon BanalОценок пока нет

- 22 BASIC PRINCIPLES OF THE PHILIPPINE PLUMBING CODEДокумент59 страниц22 BASIC PRINCIPLES OF THE PHILIPPINE PLUMBING CODEnica tam50% (6)

- RWH School - Climate Change Control Team - Presentation PDFДокумент16 страницRWH School - Climate Change Control Team - Presentation PDFAsif AhmedОценок пока нет

- WaterQualityStandardsAndRegulationsInSaudiArabia PME PDFДокумент16 страницWaterQualityStandardsAndRegulationsInSaudiArabia PME PDFAdly Al-SaafinОценок пока нет