Академический Документы

Профессиональный Документы

Культура Документы

Use of Cargo As Fuel: 16.1 General

Загружено:

Putra AdamИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Use of Cargo As Fuel: 16.1 General

Загружено:

Putra AdamАвторское право:

Доступные форматы

IMO IGC Code Chapter 16 - Use of cargo as fuel

Chapter 16 Use of cargo as fuel

16.1

General

16.1.1 Methane (LNG) is the only cargo whose vapour or boil-off gas may be utilized in machinery spaces of category A and in such spaces may be utilized only in boilers, inert gas generators, combustion engines and gas turbines. 16.1.2 These provisions do not preclude the use of gas fuel for auxiliary services in other locations, provided that such other services and locations should be subject to special consideration by the Administration.

16.2

Arrangement of machinery spaces of category A

16.2.1 Spaces in which gas fuel is utilized should be fitted with a mechanical ventilation system and should be arranged in such a way as to prevent the formation of dead spaces. Such ventilation should be particularly effective in the vicinity of electrical equipment and machinery or of other equipment and machinery which may generate sparks. Such a ventilation system should be separated from those intended for other spaces. 16.2.2 Gas detectors should be fitted in these spaces, particularly in the zones where air circulation is reduced. The gas detection system should comply with the requirements of chapter 13. 16.2.3 Electrical equipment located in the double-wall pipe or duct specified in 16.3.1 should be of the intrinsically safe type.

16.3

Gas fuel supply

16.3.1 Gas fuel piping should not pass through accommodation spaces, services spaces, or control stations. Gas fuel piping may pass through or extend into other spaces provided they fulfil one of the following :

.1 the gas fuel piping should be a double-wall piping system with the gas fuel contained in the inner pipe. The space between the concentric pipes should be pressurized with inert gas at a pressure greater than the gas fuel pressure. Suitable alarms should be provided to indicate a loss of inert gas pressure between the pipes ; or the gas fuel piping should be installed within a ventilated pipe or duct. The air space between the gas fuel piping and inner wall of this pipe or duct should be equipped with mechanical exhaust ventilation having a capacity of at least 30 air changes per hour. The

.2

123

IMO IGC Code Chapter 16 - Use of cargo as fuel

ventilation system should be arranged to maintain a pressure less than the atmospheric pressure. The fan motors should be placed outside the ventilated pipe or duct. The ventilation outlet should be placed in a position where no flammable gas-air mixture may be ignited. The ventilation should always be in operation when there is gas fuel in the piping. Continuous gas detection should be provided to indicate leaks and to shut down the gas fuel supply to the machinery space in accordance with 16.3.10. The master gas fuel valve required by 16.3.7 should close automatically, if the required air flow is not established and maintained by the exhaust ventilation system.

16.3.2 If a gas leak occurs, the gas fuel supply should not be restored until the leak has been found

and repaired. Instructions to this effect should be placed in a prominent position in the machinery spaces.

16.3.3 The double-wall piping systems or the ventilated pipe or duct provided for the gas fuel piping

should terminate at the ventilation hood or casing required by 16.3.4.

16.3.4 A ventilation hood or casing should be provided for the areas occupied by flanges, valves, etc.,

and for the gas fuel piping, at the gas fuel utilization units, such as boilers, diesel engines or gas turbines. If this ventilation hood or casing is not served by the exhaust ventilation fan serving the ventilated pipe or duct as specified in 16.3.1.2, then it should be equipped with an exhaust ventilation system and continuous gas detection should be provided to indicate leaks and to shut down the gas fuel supply to the machinery space in accordance with 16.3.10. The master gas fuel valve required by 16.3.7 should close automatically if the required air flow is not established and maintained by the exhaust ventilation system. The ventilation hood or casing should be installed or mounted to permit the ventilating air to sweep across the gas utilization unit and be exhausted at the top of the ventilation hood or casing.

16.3.5 The ventilation inlet and discharge for the required ventilation systems should be respectively

from and to a safe location.

16.3.6 Each gas utilization unit should be provided with a set of three automatic valves. Two of these

valves should be in series in the gas fuel pipe to the consuming equipment. The third valve should be in a pipe that vents, to a safe location in the open air, that portion of the gas fuel piping that is between the two valves in series. These valves should be arranged so that failure of the necessary forced draught, loss of flame on boiler burners, abnormal pressure in the gas fuel supply line, or failure of the valve control actuating medium will cause the two gas fuel valves which are in series to close automatically and the vent valve to open automatically. Alternatively, the function of one of the valves in series and the vent valve can be incorporated into one valve body so arranged that, when one of the above conditions occurs, flow to the gas utilization unit will be blocked and the vent opened. The three shut-off valves should be arranged for manual reset.

16.3.7 A master gas fuel valve that can be closed from within the machinery space should be provided within the cargo area. The valve should be arranged so as to close automatically if leakage of gas is detected, or loss of ventilation for the duct or casing or loss of pressurization of the double-wall gas fuel piping occurs.

124

IMO IGC Code Chapter 16 - Use of cargo as fuel

16.3.8 Gas fuel piping in machinery spaces should comply with sections 5.2 to 5.5 as far as found applicable. The piping should, as far as practicable, have welded joints. Those parts of the gas fuel piping which are not enclosed in a ventilated pipe or duct according to 16.3.1 and are on the open deck outside the cargo area should have full penetration butt-welded joints and should be fully radiographed. 16.3.9 Provision should be made for inerting and gas-freeing that portion of the gas fuel piping system located in the machinery space. 16.3.10 Gas detection systems provided in accordance with the requirements of 16.3.1 and 16.3.4 should comply with 13.6.2 and 13.6.4 through 13.6.8 as applicable ; they should activate the alarm at 30% of the lower flammable limit and shut down the master gas fuel valve referred to in 16.3.7 before the gas concentration reaches 60% of the lower flammable limit.

16.4

Gas make-up plant and related storage tanks

16.4.1 All equipment (heaters, compressors, filters, etc.) for making up the gas for its use as fuel and the related storage tanks should be located in the cargo area in accordance with 3.1.5.4. If the equipment is in an enclosed space, the space should be ventilated according to section 12.1 of the Code and be equipped with a fixed fire-extinguishing system according to section 11.5 and with a gas detection system according to section 13.6, as applicable. 16.4.2 The compressors should be capable of being remotely stopped from a position which is always and easily accessible, and also from the engine-room. In addition, the compressors should be capable of automatically stopping when the suction pressure reaches a certain value depending on the set pressure of the vacuum relief valves of the cargo tanks. The automatic shutdown device of the compressors should have a manual resetting. Volumetric compressors should be fitted with pressure relief valves discharging into the suction line of the compressor. The size of the pressure relief valves should be determined in such a way that, with the delivery valve kept closed, the maximum pressure does not exceed by more than 10% the maximum working pressure. The requirements of 5.6.1.3 apply to these compressors. 16.4.3 If the heating medium for the gas fuel evaporator or heater is returned to spaces outside the

cargo area it should first go through a degassing tank. The degassing tank should be located in the cargo area. Provisions should be made to detect and alarm the presence of gas in the tank. The vent outlet should be in a safe position and fitted with a flame screen.

16.4.4 Piping and pressure vessels in the gas fuel conditioning system should comply with chapter 5.

16.5

Special requirements for main boilers

16.5.1 Each boiler should have a separate uptake.

125

IMO IGC Code Chapter 16 - Use of cargo as fuel

16.5.2 A system suitable to ensure the forced draught in the boilers should be provided. The particulars of such a system should be to the satisfaction of the Administration.

16.5.3 Combustion chambers of boilers should be of suitable form such as not to present pockets

where gas may accumulate.

16.5.4 The burner systems should be of dual type, suitable to burn either oil fuel or gas fuel alone or

oil and gas fuel simultaneously. Only oil fuel should be used during manuvring and port operations unless automatic transfer from gas to oil burning is provided, in which case the burning of a combination of oil and gas or gas alone may be permitted provided the system is demonstrated to the satisfaction of the Administration. It should be possible to change over easily and quickly from gas fuel operation to oil fuel operation. Gas nozzles should be fitted in such a way that gas fuel is ignited by the flame of the oil fuel burner. A flame scanner should be installed and arranged to ensure that gas flow to the burner is cut off unless satisfactory ignition has been established and maintained. On the pipe of each gas burner a manually operated shutoff valve should be fitted. An installation should be provided for purging the gas supply piping to the burners by means of inert gas or steam, after the extinguishing of these burners.

16.5.5 Alarm devices should be fitted in order to monitor a possible decrease in liquid fuel oil pressure or a possible failure of the related pumps.

16.5.6 Arrangements should be made that, in case of flame failure of all operating burners for gas or oil or for a combination thereof, the combustion chambers of the boilers are automatically purged before relighting. Arrangements should also be made to enable the boilers to be manually purged.

16.6 Special requirements for gas-fired internal combustion engines and gas-fired turbines

Special provisions for gas-fuelled internal combustion engines and for gas turbines will be considered by the Administration in each case.

126

Вам также может понравиться

- Abschn 16Документ4 страницыAbschn 16tuanОценок пока нет

- Cargo-Tank Venting and Gas-Freeing ArranegmentsДокумент4 страницыCargo-Tank Venting and Gas-Freeing ArranegmentsJan KubišОценок пока нет

- E.5 Engine Room Ventilation SystemДокумент5 страницE.5 Engine Room Ventilation Systemednsmn100% (1)

- E.5Engine Room Ventilation System PDFДокумент6 страницE.5Engine Room Ventilation System PDFSimon LaurentОценок пока нет

- IG System Solas ch2 Regulation 62Документ3 страницыIG System Solas ch2 Regulation 62Ravi chinnaduraiОценок пока нет

- LPG Carrier Cargo Motor and Compressor Room SafetyДокумент8 страницLPG Carrier Cargo Motor and Compressor Room SafetyÁřvíňď PřášáďОценок пока нет

- GodrejdДокумент49 страницGodrejdsandeshlikesОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- 3-Fuel Gas PipingДокумент38 страниц3-Fuel Gas PipingLi ReОценок пока нет

- Air Brake RDSO Report 0159 Rev - 0 Jan - 2013Документ149 страницAir Brake RDSO Report 0159 Rev - 0 Jan - 2013Niking Thomsan0% (1)

- Solas Regulation IIДокумент3 страницыSolas Regulation IIhackey720Оценок пока нет

- General Instructions For Safe Operation of High Pressure CompressorsДокумент6 страницGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıОценок пока нет

- Oxysystems 2v3x 172 4.1 ManualДокумент21 страницаOxysystems 2v3x 172 4.1 ManualDavid GarciaОценок пока нет

- PreparationForOpeningATankAndTankEntry Tank DrillingДокумент4 страницыPreparationForOpeningATankAndTankEntry Tank DrillingargaegargvagrОценок пока нет

- Erc .507-515 ManualДокумент33 страницыErc .507-515 ManualJoseph Geraci50% (6)

- DUEL Fuel EnginesДокумент11 страницDUEL Fuel EnginesMohamed Al NazooqueОценок пока нет

- IGGДокумент12 страницIGGGanesh MohiteОценок пока нет

- Megafire ManualДокумент6 страницMegafire ManualBehnam NoorizadehОценок пока нет

- PCVДокумент20 страницPCVyared abebeОценок пока нет

- Executive Order G-70-150-Ad Exhibit 2 Specifications For The Vaporvac Bootless Nozzle SystemДокумент5 страницExecutive Order G-70-150-Ad Exhibit 2 Specifications For The Vaporvac Bootless Nozzle SystemEnrique ArmandoОценок пока нет

- Inert Gas SystemДокумент10 страницInert Gas Systemjinsana100% (1)

- Webasto AIRTOP 3500/5000 Installation InstructionsДокумент32 страницыWebasto AIRTOP 3500/5000 Installation InstructionsDavid ButlerОценок пока нет

- Quadrajet Dodge cm337.1.0 PDFДокумент27 страницQuadrajet Dodge cm337.1.0 PDFAndy WilsonОценок пока нет

- F20 F20 Inert Gas Systems F20Документ5 страницF20 F20 Inert Gas Systems F20Rick MsaОценок пока нет

- Steam Blowing BHELДокумент9 страницSteam Blowing BHELdnageshm4n244100% (1)

- Solutions: TankersДокумент7 страницSolutions: TankersKirtishbose ChowdhuryОценок пока нет

- Aerofoil FansДокумент8 страницAerofoil FansCarlos PintoОценок пока нет

- The Boiler HouseДокумент9 страницThe Boiler Housemeijon pelayerОценок пока нет

- CFPP 01-01 Part C Steam SterilizationДокумент31 страницаCFPP 01-01 Part C Steam Sterilizationsbalu12674Оценок пока нет

- Start Mesin Utama DNVДокумент6 страницStart Mesin Utama DNVJack HoleОценок пока нет

- 3-Way Valve Preparation FinalДокумент20 страниц3-Way Valve Preparation FinalOmar KhaledОценок пока нет

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- Airport Fuel Installation FireДокумент10 страницAirport Fuel Installation Firermaffireschool100% (1)

- EGE16B22Документ21 страницаEGE16B22Jhonny Rafael Blanco CauraОценок пока нет

- 22 0 100 - NCДокумент7 страниц22 0 100 - NCjussmeeeОценок пока нет

- Unconventional Flare Gas Recovery Systems (FGRS)Документ4 страницыUnconventional Flare Gas Recovery Systems (FGRS)Alvaro Andres Blanco Gomez100% (1)

- Inert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS ConventionДокумент5 страницInert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS Conventionvihaan100% (1)

- Gas Booster 5 0.75 Series Models AG AGD AGT S PDFДокумент16 страницGas Booster 5 0.75 Series Models AG AGD AGT S PDFu2006262918100% (1)

- English General VRUДокумент23 страницыEnglish General VRUzubair1951Оценок пока нет

- NFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsДокумент5 страницNFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsprokjongОценок пока нет

- General Procedures For Raising SteamДокумент3 страницыGeneral Procedures For Raising SteamAlma Dela PeñaОценок пока нет

- 5 107 Vaporizers and DemisterДокумент7 страниц5 107 Vaporizers and DemisterLeonidas PetrouОценок пока нет

- Air SystemДокумент22 страницыAir Systemabhi_mohit2005100% (1)

- Sporlan Adlse-2Документ12 страницSporlan Adlse-2Serrefriair Garcia RefriОценок пока нет

- Inert Gas OverviewДокумент6 страницInert Gas OverviewRahulChoudharyОценок пока нет

- Dry Gas Seal DesignДокумент26 страницDry Gas Seal DesignCALLESJ100% (1)

- Propac: Flushing Procedure For Hydraulic Piping, Tubing & HoseДокумент4 страницыPropac: Flushing Procedure For Hydraulic Piping, Tubing & HoseClaudio Hernández PobleteОценок пока нет

- Centrala Termica RMG 20MKДокумент18 страницCentrala Termica RMG 20MKLiviu GrigОценок пока нет

- Selection Guidelines For Dry Gas SealsДокумент26 страницSelection Guidelines For Dry Gas SealsVivek RathodОценок пока нет

- 0519 - R304P - Westinghouse Technology 15.3 Gaseous Radioactive Waste Processing SystemsДокумент22 страницы0519 - R304P - Westinghouse Technology 15.3 Gaseous Radioactive Waste Processing SystemsRAMI HAMADОценок пока нет

- SafetyДокумент2 страницыSafetyPankaj PatilОценок пока нет

- Vol3 Section12Документ40 страницVol3 Section12M Sabri SapangalloОценок пока нет

- Functional Specification Export Gas Compressor PDFДокумент7 страницFunctional Specification Export Gas Compressor PDFdndudcОценок пока нет

- Chapter 10 - Fuel SystemsДокумент87 страницChapter 10 - Fuel SystemsKHAWAJA ZOHAIR NADEEM100% (1)

- MA-4 Carb ManualДокумент34 страницыMA-4 Carb Manualayazkhan797100% (1)

- Part 09 Chapter06Документ18 страницPart 09 Chapter06SrewaBenshebilОценок пока нет

- Appendix 12 Fire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder InstallationsДокумент25 страницAppendix 12 Fire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder InstallationsAadil KhoodoruthОценок пока нет

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentОт EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentОценок пока нет

- Print - Lesson TopicДокумент12 страницPrint - Lesson TopicPutra AdamОценок пока нет

- Presentasi Industri - BURSA KARIR ITS - 25Документ2 страницыPresentasi Industri - BURSA KARIR ITS - 25Putra AdamОценок пока нет

- 6CH3 6che Hte3 R2011 1Документ1 страница6CH3 6che Hte3 R2011 1Putra AdamОценок пока нет

- EstimasiДокумент2 страницыEstimasiPutra AdamОценок пока нет

- Module 1 Basics of Shipboard LifeДокумент15 страницModule 1 Basics of Shipboard LifePutra AdamОценок пока нет

- Presented by MR Teguh HandokoДокумент5 страницPresented by MR Teguh HandokoPutra AdamОценок пока нет

- Nimbuzz11 - 6 - 2012 1 - 7 - 23 - 837Документ38 страницNimbuzz11 - 6 - 2012 1 - 7 - 23 - 837Putra AdamОценок пока нет

- Resistance PDFДокумент96 страницResistance PDFPutra AdamОценок пока нет

- C Users ME AppData Local Temp HhDBECДокумент32 страницыC Users ME AppData Local Temp HhDBECPutra AdamОценок пока нет

- Nimbuzz22 - 6 - 2012 7 - 41 - 31 - 523Документ2 страницыNimbuzz22 - 6 - 2012 7 - 41 - 31 - 523Putra AdamОценок пока нет

- ReadmeДокумент3 страницыReadmeMarcel PoianaОценок пока нет

- S26 ContsДокумент1 страницаS26 ContsPutra AdamОценок пока нет

- 7.5 02 02 03Документ5 страниц7.5 02 02 03Putra AdamОценок пока нет

- Nimbuzz14 - 6 - 2012 20 - 5 - 19 - 777Документ4 страницыNimbuzz14 - 6 - 2012 20 - 5 - 19 - 777Putra AdamОценок пока нет

- MAN B&W Diesel A/S S26MC Project Guide: 6.05 Stuffing Box Drain Oil SystemДокумент1 страницаMAN B&W Diesel A/S S26MC Project Guide: 6.05 Stuffing Box Drain Oil SystemPutra AdamОценок пока нет

- S 260611Документ12 страницS 260611Putra AdamОценок пока нет

- Nim BuzzДокумент7 страницNim BuzzPutra AdamОценок пока нет

- S 260609Документ9 страницS 260609Putra AdamОценок пока нет

- S2608Документ23 страницыS2608Putra AdamОценок пока нет

- S 260607Документ3 страницыS 260607Putra AdamОценок пока нет

- MAN B&W Diesel A/S S26MC Project Guide: Main Menu QuitДокумент3 страницыMAN B&W Diesel A/S S26MC Project Guide: Main Menu QuitPutra AdamОценок пока нет

- 6.06 Cooling Water Systems: MAN B&W Diesel A/S S26MC Project GuideДокумент8 страниц6.06 Cooling Water Systems: MAN B&W Diesel A/S S26MC Project GuidePutra AdamОценок пока нет

- S 260610Документ10 страницS 260610Putra AdamОценок пока нет

- S2607Документ7 страницS2607Putra AdamОценок пока нет

- Full Page Fax PrintДокумент1 страницаFull Page Fax PrintPutra AdamОценок пока нет

- C Users ME AppData Local Temp HhDBECДокумент32 страницыC Users ME AppData Local Temp HhDBECPutra AdamОценок пока нет

- Chap 12Документ2 страницыChap 12Putra AdamОценок пока нет

- Operating Requirements: 18.1 Cargo InformationДокумент4 страницыOperating Requirements: 18.1 Cargo InformationPutra AdamОценок пока нет

- QSC8.3-M SpecsheetДокумент2 страницыQSC8.3-M SpecsheetnarisОценок пока нет

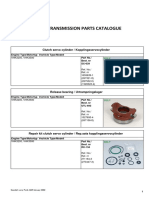

- Power Transm - Parts CatalogueДокумент76 страницPower Transm - Parts CatalogueAldi Yasi0% (1)

- Mexican Beetle 1600i Engine Bay 28 Pin Connector Information:-Connector LocationДокумент3 страницыMexican Beetle 1600i Engine Bay 28 Pin Connector Information:-Connector LocationDaniel Muñoz Sotomayor100% (1)

- Deutz Aditivos para Combustible Clean DieselДокумент2 страницыDeutz Aditivos para Combustible Clean Dieselley-ponОценок пока нет

- Power HP Ecu PDFДокумент82 страницыPower HP Ecu PDFhugo del rio100% (2)

- Valv CAT 3116Документ8 страницValv CAT 3116Tatiano Brollo100% (1)

- China KDE7000E Generator Set Manufacturers, Suppliers, Factory - KAMAДокумент3 страницыChina KDE7000E Generator Set Manufacturers, Suppliers, Factory - KAMAAliОценок пока нет

- Engine Characteristics (DE12TI/DE12TIS) - Technical Tips For MaintenanceДокумент23 страницыEngine Characteristics (DE12TI/DE12TIS) - Technical Tips For MaintenanceBùi Xuân Đức100% (1)

- E-021 Auxiliary Engine Performance.04Документ2 страницыE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- 2 Engine GeneralДокумент23 страницы2 Engine GeneralChabou Rafik100% (1)

- Volvo TWD1031Документ422 страницыVolvo TWD1031hoi100% (1)

- Adjustment and Overhaul of The K301 and K302 Carburetors CurtДокумент34 страницыAdjustment and Overhaul of The K301 and K302 Carburetors CurtWouter Vastmaar67% (3)

- Build A 500HP N54 BMW 135i, 335i, 535i For Under $1,500Документ1 страницаBuild A 500HP N54 BMW 135i, 335i, 535i For Under $1,500Arik Yeganyan100% (1)

- Cylinder Head - Install: Desarmado y ArmadoДокумент4 страницыCylinder Head - Install: Desarmado y ArmadoDavid Apaza HurtadoОценок пока нет

- CB350 Parts ManualДокумент110 страницCB350 Parts ManualTomSerna100% (1)

- 1988-1989 Yamaha Enticer 340 400 Snowmobile Service Manual RepairДокумент199 страниц1988-1989 Yamaha Enticer 340 400 Snowmobile Service Manual Repairtimmckenna100% (1)

- Wankel EngineДокумент9 страницWankel EngineAnand GorkarОценок пока нет

- Perkins 3.152 WorkshopДокумент102 страницыPerkins 3.152 WorkshopJeanderson MirandaОценок пока нет

- qst30 System SpecificationsДокумент24 страницыqst30 System SpecificationsMuhammad IshfaqОценок пока нет

- Bosch EV6 3868 - 7626Документ5 страницBosch EV6 3868 - 7626hacvuaОценок пока нет

- 1106C-E66TAG2 ElectropaK (PN1861 Oct08)Документ2 страницы1106C-E66TAG2 ElectropaK (PN1861 Oct08)Eko SulistyoОценок пока нет

- Air Start SystemДокумент5 страницAir Start SystemPaolo FerjančićОценок пока нет

- of SuperchargerДокумент18 страницof SuperchargerNEERAJОценок пока нет

- Diagnostic List Dongfeng Heavy TruckДокумент1 страницаDiagnostic List Dongfeng Heavy TruckQuốc Phú ĐinhОценок пока нет

- The New Marine Power Reference: Customer Benefi TsДокумент2 страницыThe New Marine Power Reference: Customer Benefi TsCarlos PariОценок пока нет

- Engine Complete 3Документ40 страницEngine Complete 3Garcia CruzОценок пока нет

- Cummins PT Pump Adjust PDFДокумент3 страницыCummins PT Pump Adjust PDFHugh O'Brien GwazeОценок пока нет

- Internal Combustion Engine Quiz 1Документ2 страницыInternal Combustion Engine Quiz 1Snunkhaem EcharojОценок пока нет

- Perkins Engines Guide VK - od.UAДокумент5 страницPerkins Engines Guide VK - od.UANoui BouzidОценок пока нет

- Tecumseh OV195EA - OV195XA Engine ManualДокумент32 страницыTecumseh OV195EA - OV195XA Engine Manual"Rufus"0% (1)